Diaphragm type heat-flow density sensor and manufacturing method thereof

A technology of heat flux density and manufacturing method, which is applied to calorimeters, thermometers and instruments using directly heat-sensitive electric/magnetic elements, etc., can solve the problems of high cost, low reliability and low precision of heat flux density sensors, and achieve Great practical application value, low cost and high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below by means of specific embodiments:

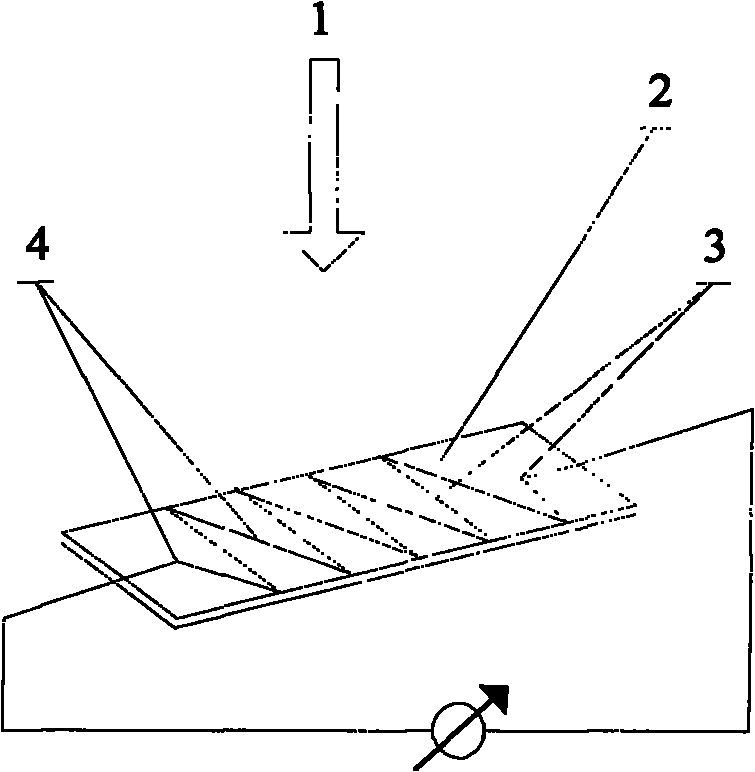

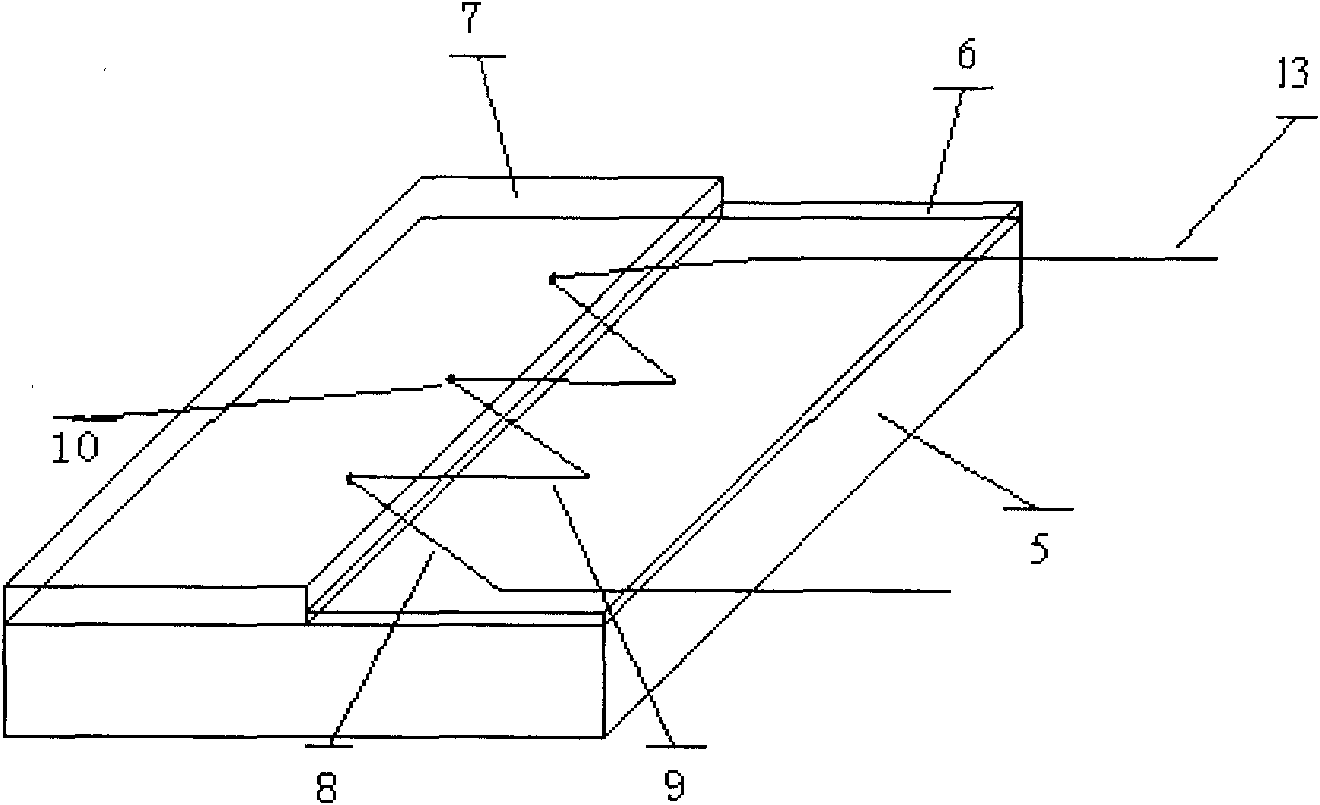

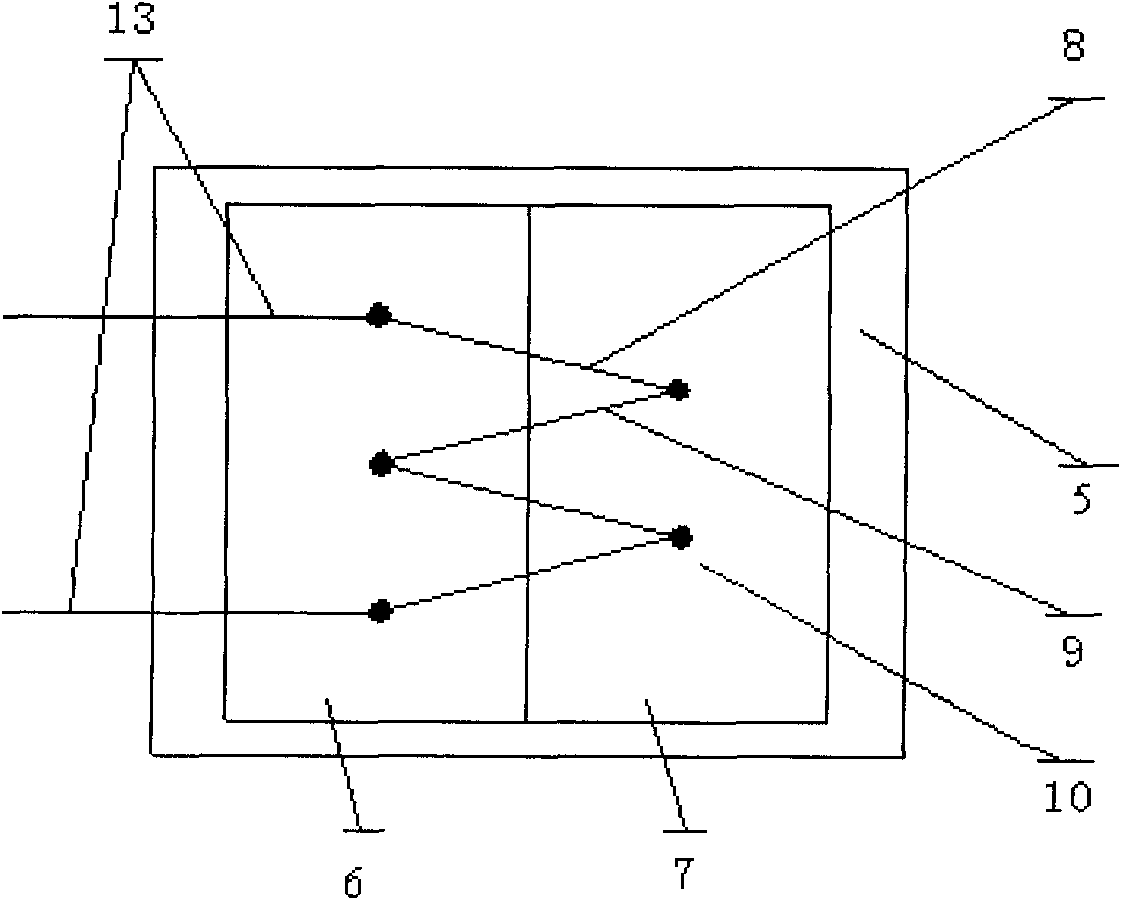

[0041] Please also see figure 2 and image 3 ,in figure 2 It is a schematic diagram of the appearance of a preferred embodiment of the thin-film heat flux sensor of the present invention, image 3 Yes figure 2 top view diagram. Wherein, the thin-film heat flux sensor of the present invention includes a substrate 5 , a first thermal resistance material 6 , a second thermal resistance material 7 , thermal electrodes A8 , thermal electrodes B9 , and lead wires 13 . The base 1 is a heat-resistant material with a certain thickness. In this embodiment, the water-cooled plate is made of metal material. Of course, it can also be other common heat-resistant materials, as long as it can prevent heat flow transmission.

[0042] see again Figure 4 ,actually image 3 side view. The thermode A and thermode B are two kinds of standard thermode materials, the two are sputtere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com