Fault diagnosis device for spindle bearing of roadheader cutting head and use method thereof

A fault diagnosis device and spindle bearing technology, which is applied in the direction of mechanical bearing testing, etc., can solve problems such as the fault diagnosis device for the spindle bearing of the cutting head of the roadheader that has not yet been seen, so as to improve the execution speed and system reliability, and the results are accurate and reliable. The effect of avoiding unexpected accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

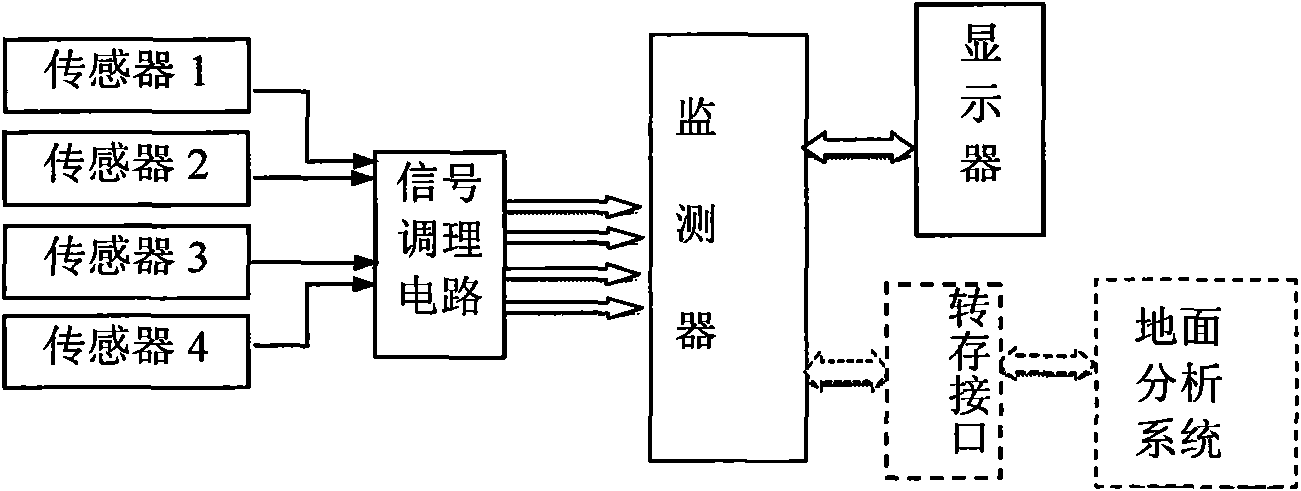

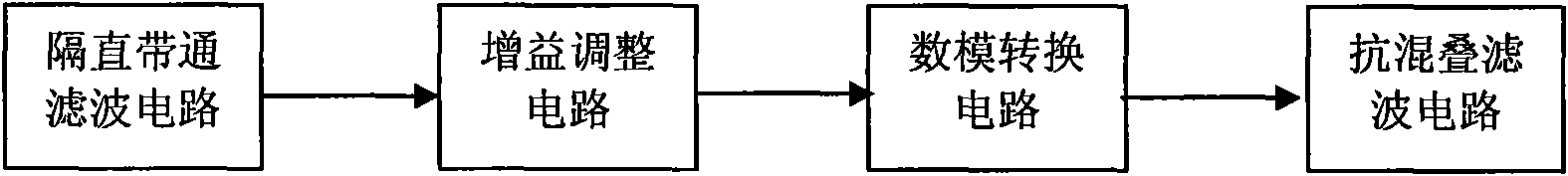

[0027] The overall structure of the embodiment of the fault diagnosis device for the main shaft bearing of the cutting head of the roadheader is as follows: figure 1 As shown, including the monitor and the acceleration sensor, two acceleration sensors are respectively installed on the front bearing shell and the rear bearing shell of the cutting head spindle of the roadheader; the acceleration sensor is connected to the monitor through the signal conditioning circuit.

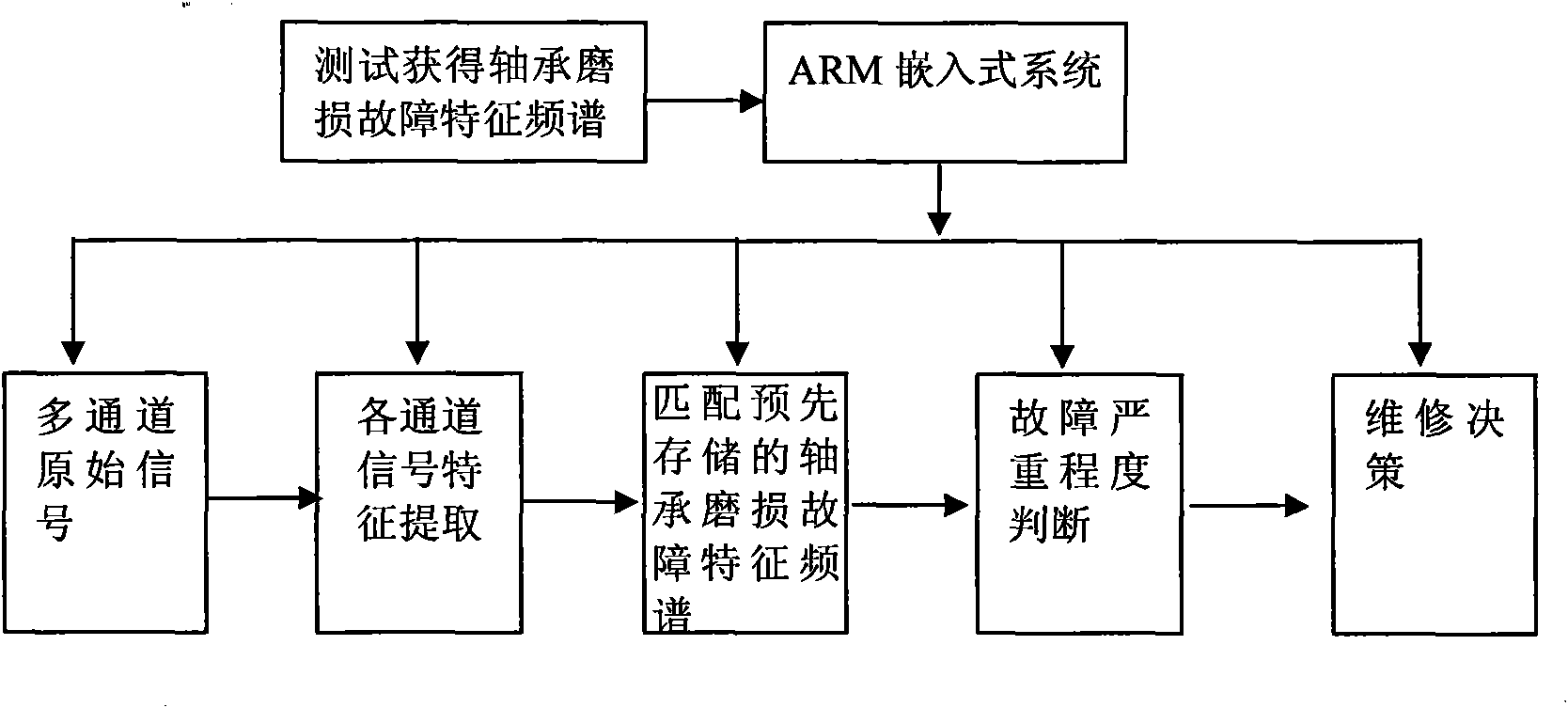

[0028] monitors for ARM embedded systems such as figure 2 The shown includes raw signal module, feature extraction module and maintenance guidance module. The original signal module includes the real-time signal receiving unit of the acceleration sensor, the peak-peak value storage unit and the vibration value comparison unit of the main shaft vibration of each monitoring part of the roadheader; the feature extraction module includes the time domain index analysis unit, fast Fourier transform (FFT) analysis un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com