Preparation method of aged asphalt for on-site heat regeneration tests

A technology of aging asphalt and thermal regeneration, applied in the preparation of test samples, etc., can solve problems affecting the quality and effectiveness of thermal regeneration asphalt, the effect of thermal regeneration experiments, and the effect of asphalt rejuvenation agents, etc., to save time and manual operation cost, short preparation cycle and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A kind of preparation method of aged asphalt used for on-site thermal regeneration experiment of the present invention, comprises the following steps:

[0032] (1) Sampling: From the asphalt road section where on-site thermal regeneration construction is planned to be carried out, the pavement surface mixture of three different damaged parts of the road surface before construction heating and after construction heating is collected. Moderate and severe damage, and extract and recover the pavement surface mixture in various states to obtain the corresponding asphalt binder;

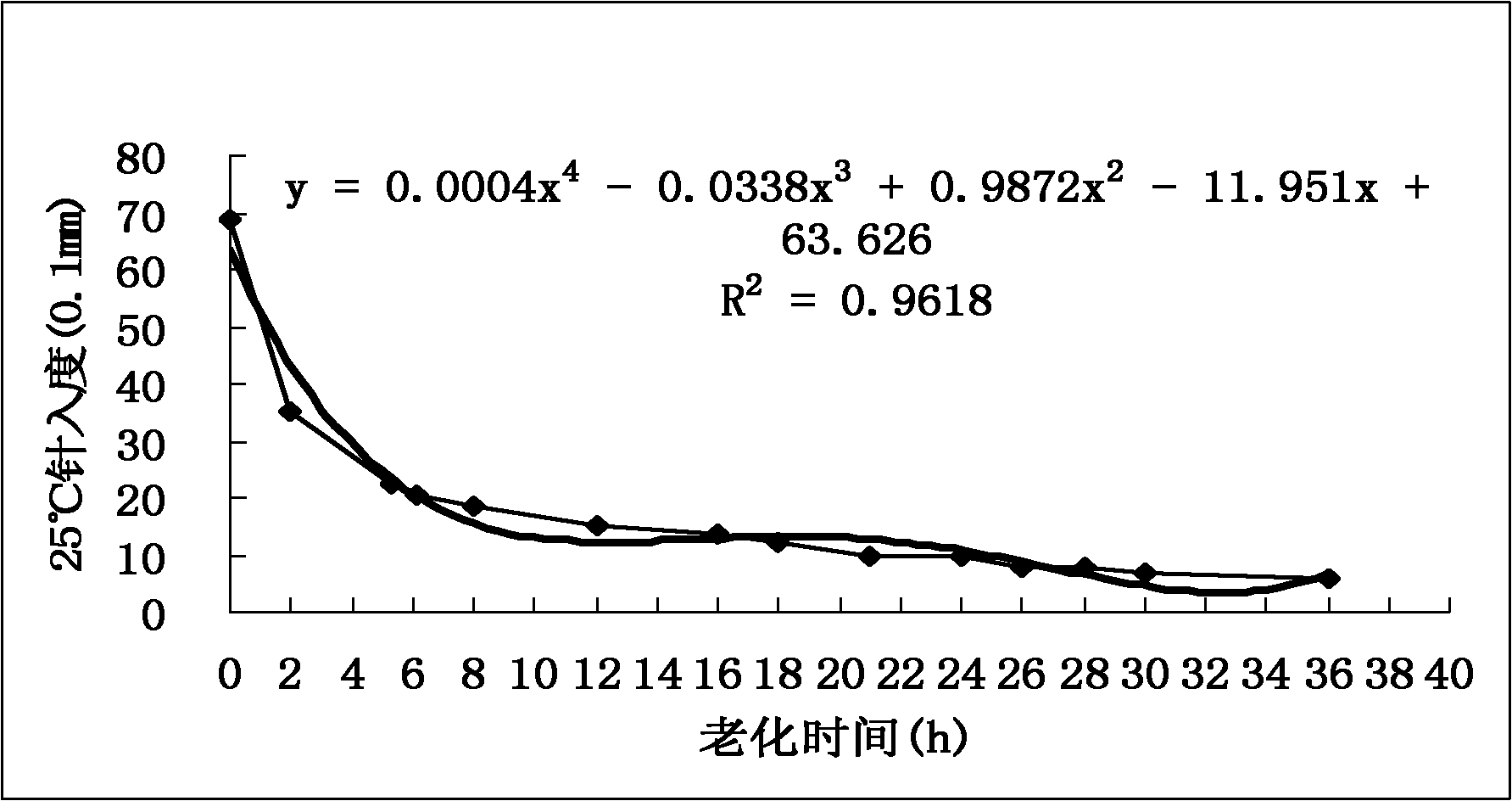

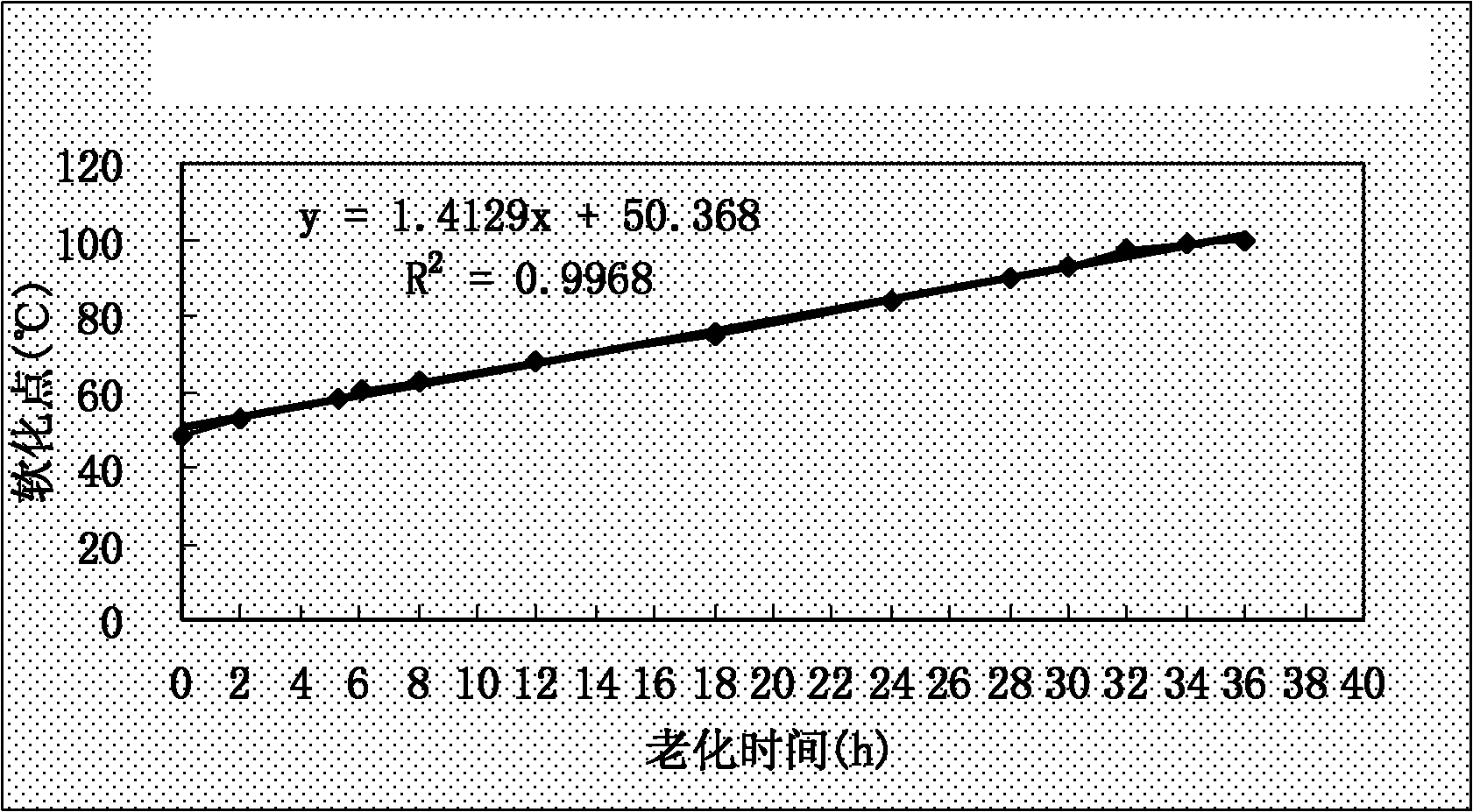

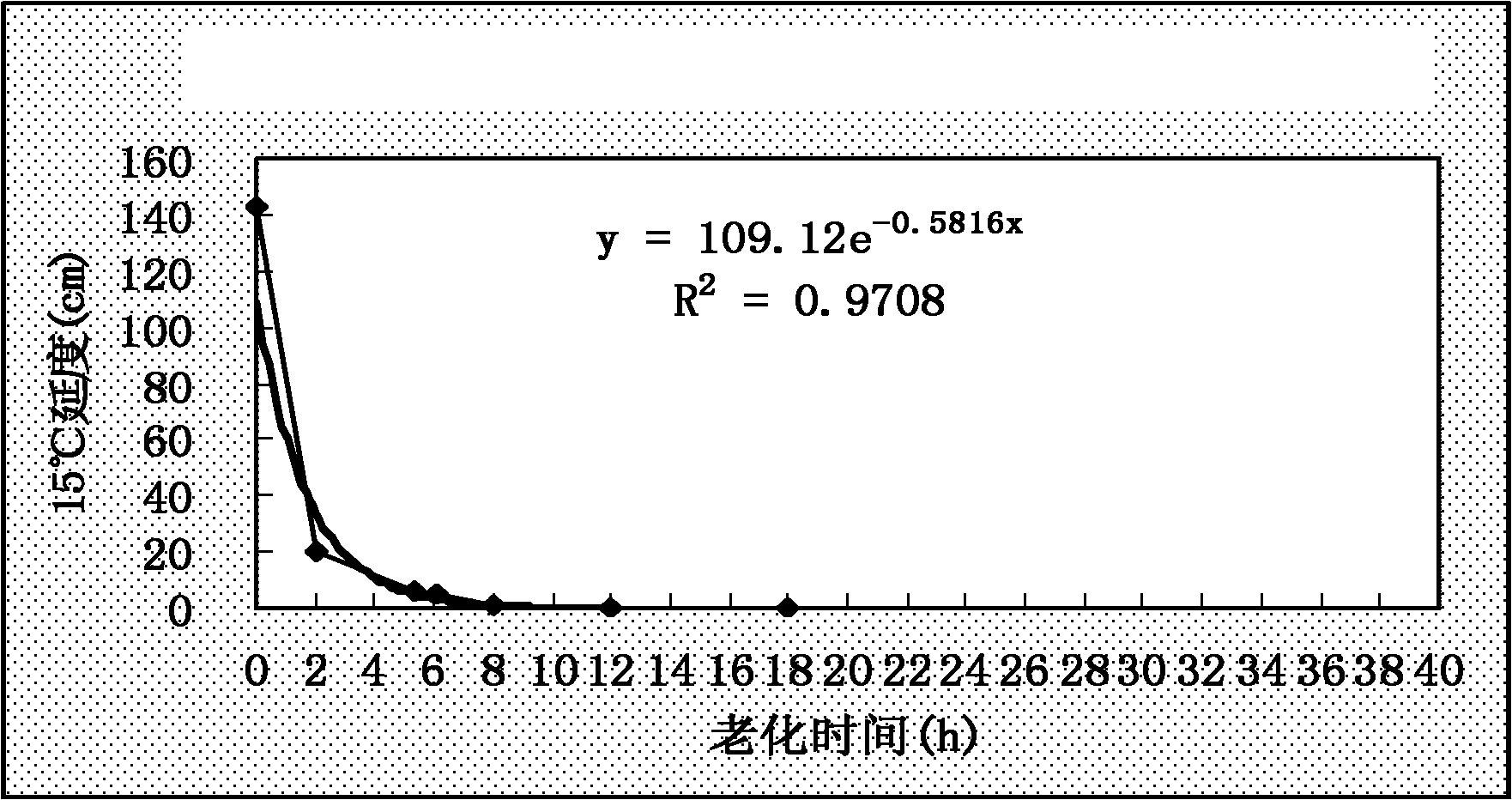

[0033] (2) Test: Carry out two index tests of penetration and softening point respectively to each asphalt binder that step (1) obtains, record the index value of each asphalt binder as shown in table 1 below;

[0034] Table 1: Index values measured for each asphalt binder in the examples

[0035]

[0036] (3) Film oven aging: Carry out the rotating film oven aging test on the original base as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com