Deposition method of multi-section camium sulfide thin film

A technology of thin film deposition and cadmium sulfide, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as high resistance, lower solar cell efficiency, and large difference in coverage of each layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

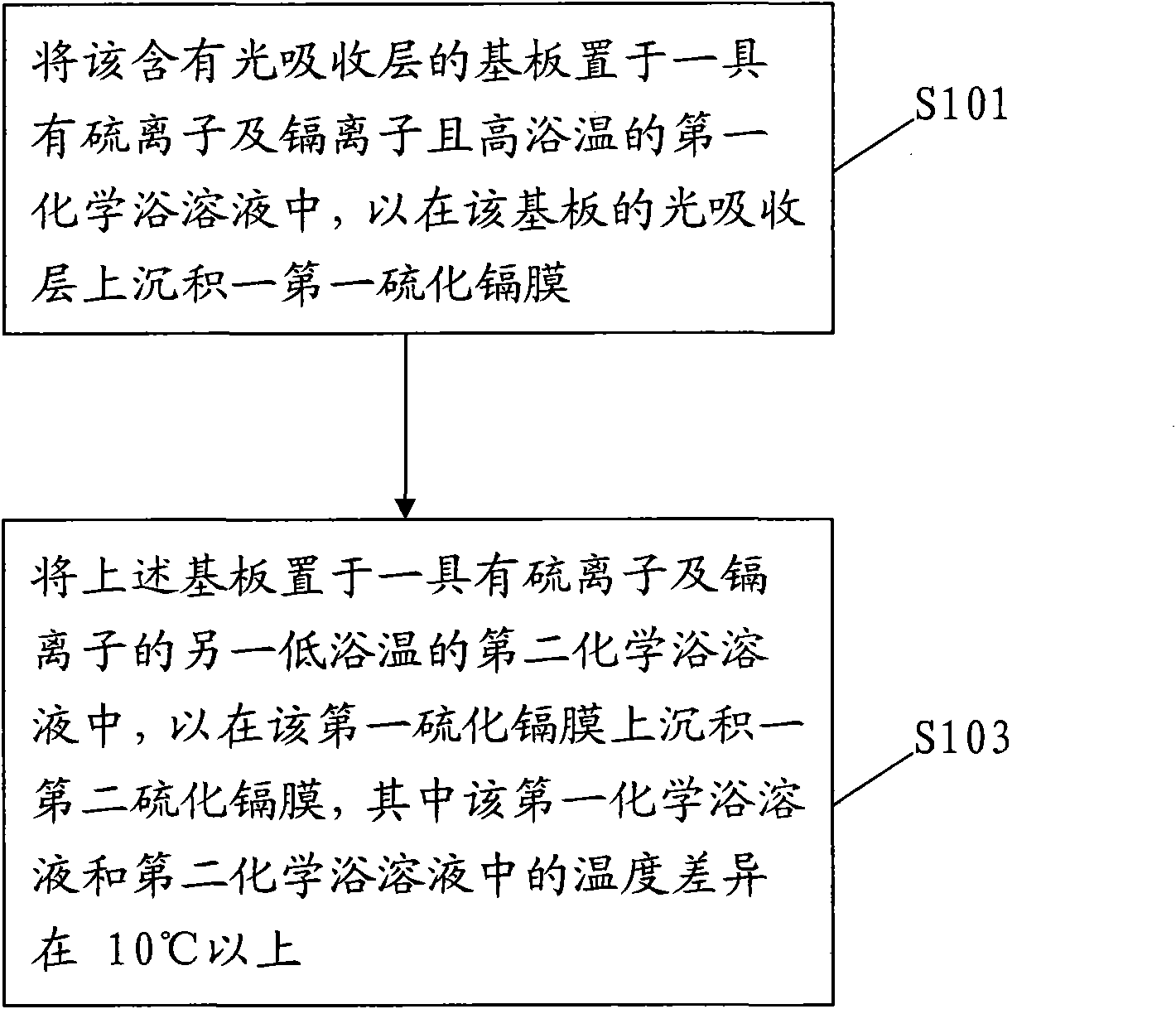

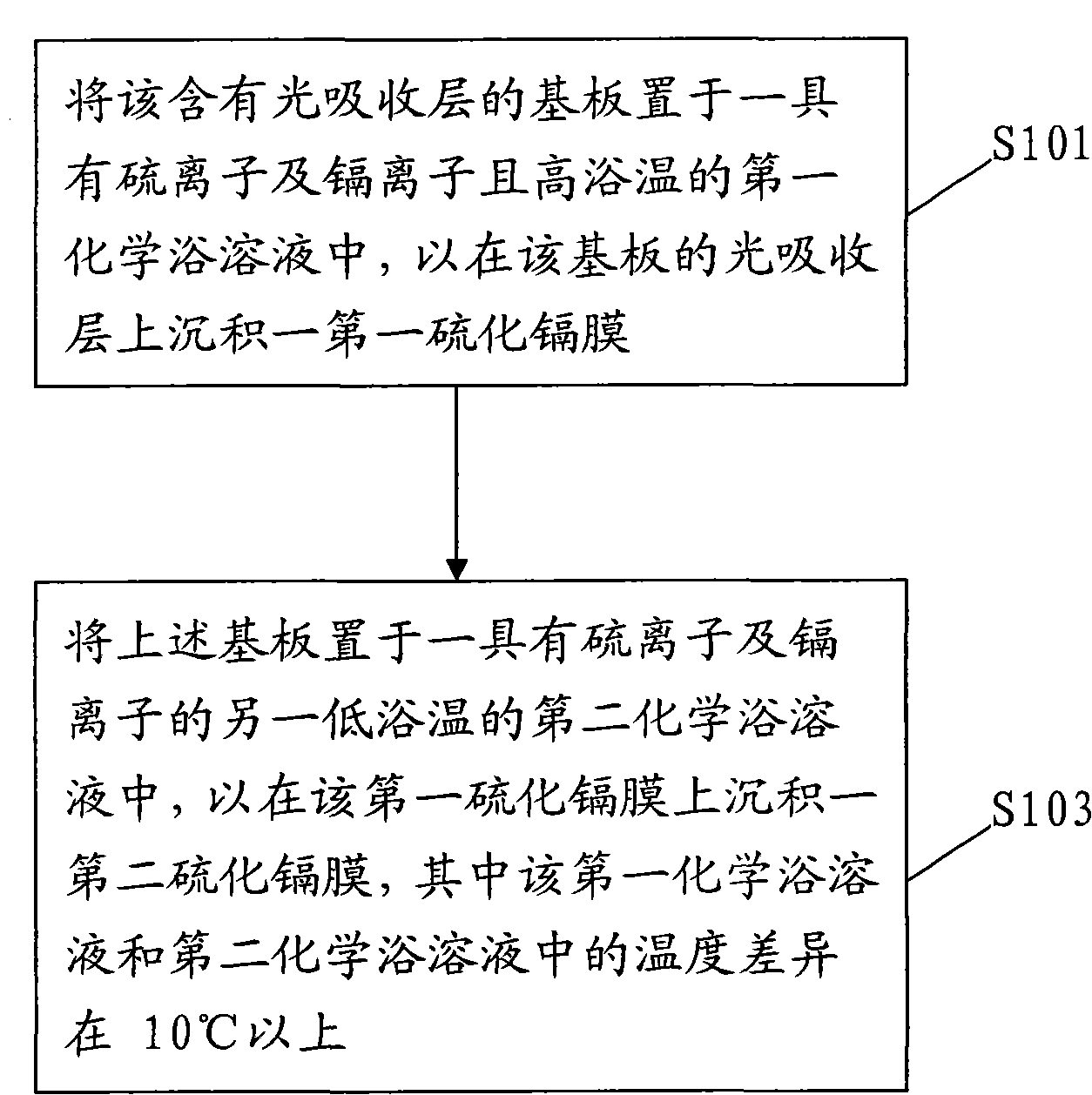

[0028] In order to further illustrate the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, method and steps of the multi-stage cadmium sulfide thin film deposition method proposed according to the present invention will be described below. , features and their effects are described in detail below.

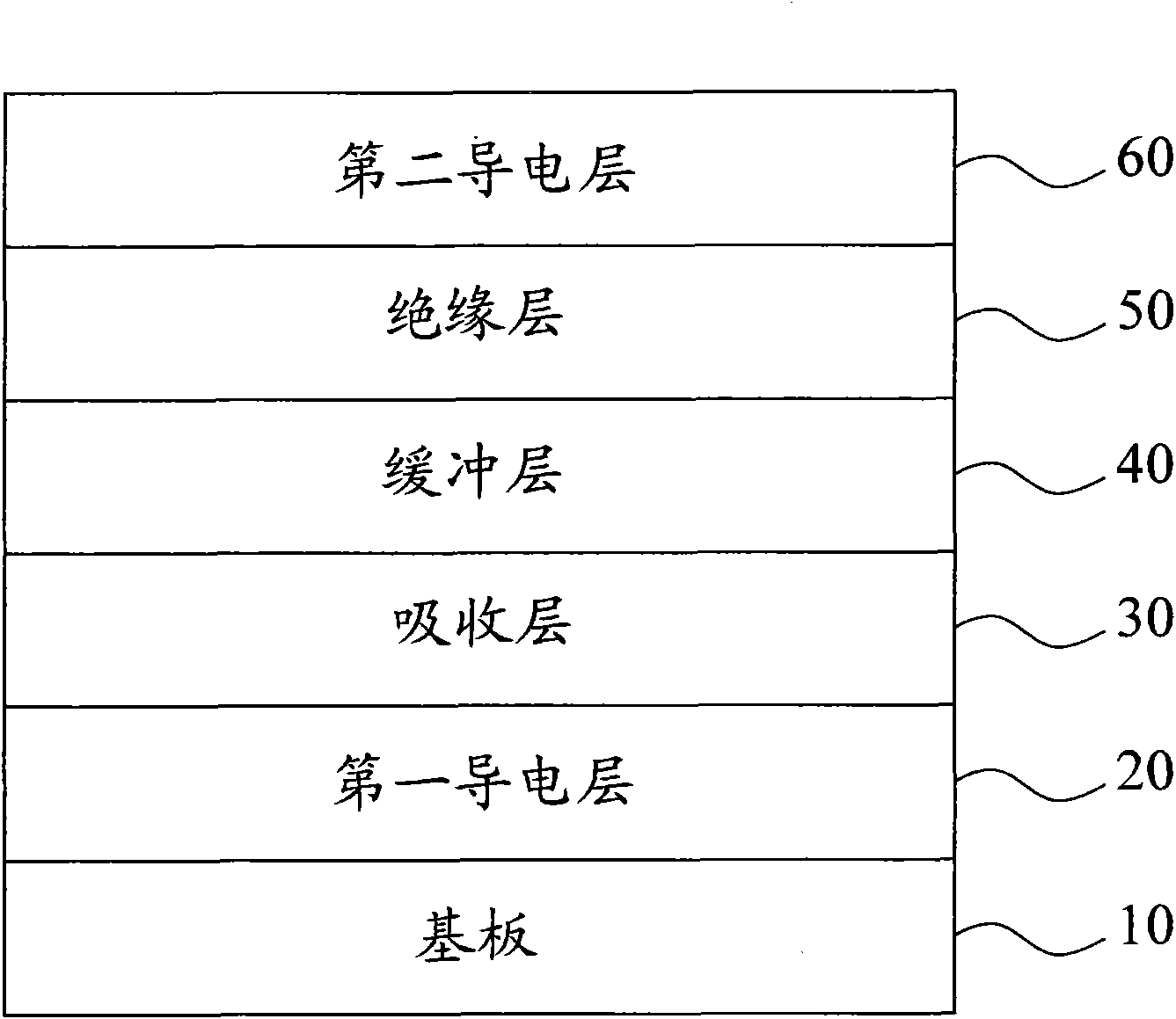

[0029] The present invention proposes a multi-stage cadmium sulfide film deposition method, which provides a chemical bath utilizing different temperatures to form two or more multilayer cadmium sulfide films with different cadmium sulfide particles, and because of the above-mentioned differences The chemical bath at high temperature can deposit cadmium sulfide particles of different sizes, so the deposition method of the present invention can produce a cadmium sulfide film with better coverage, so the efficiency o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com