Combined cable trench

A cable groove and combined technology, which is applied in cable installation, ground cable installation, and underground pipeline cable installation, can solve the problems of low construction efficiency, difficult management of raw materials, long construction period, etc. The effects of work, fast assembly speed and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

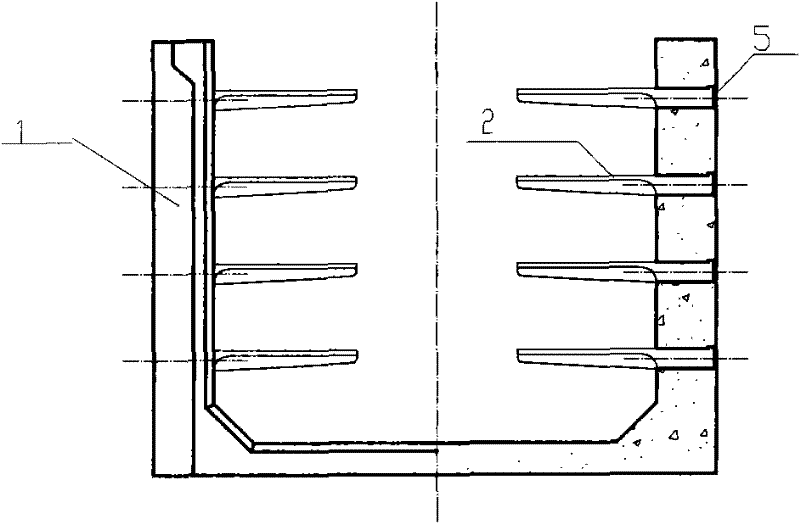

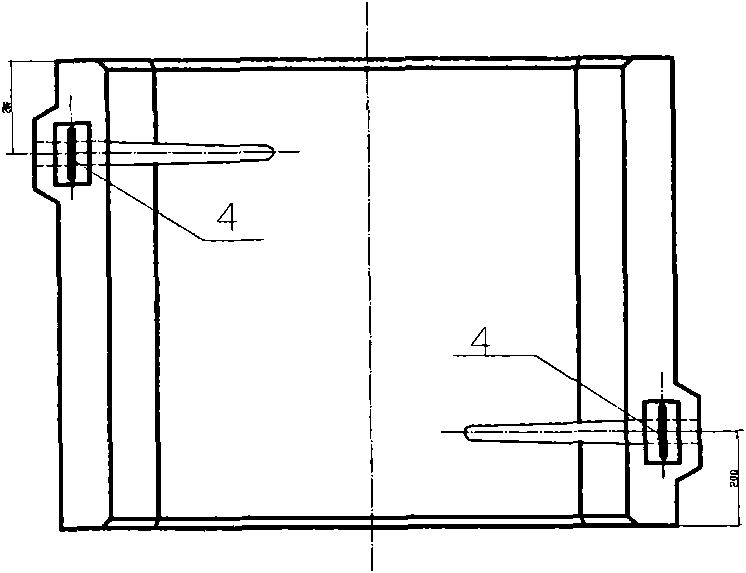

[0041] Such as Figure 1 to Figure 3 The combined cable groove shown is one of the embodiments of the present invention, which includes a plurality of cable supports 2 and a trough body 1 connected head to tail. The cross section of the trough body is U-shaped, and the cable supports are arranged up and down on the On the side wall of the tank body, the heights of the two rows of cable brackets on the two side walls of the tank body correspond to each other.

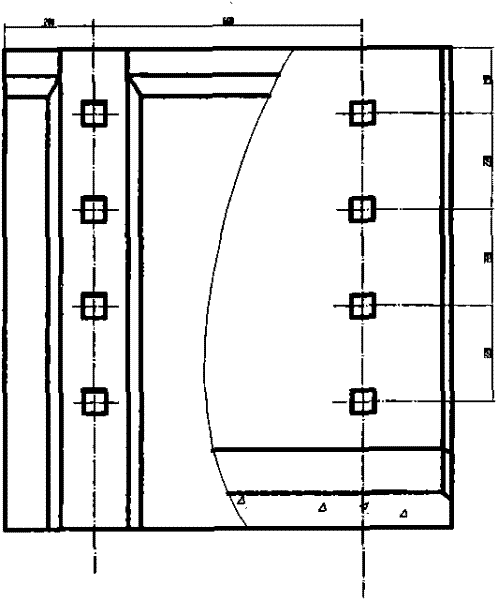

[0042] see Figure 4 to Figure 6 , the unit length of the tank body 1 is 1000mm, the thick wall reference of the two side walls is 50mm, and the upper part of the two side walls of the tank body 1 is designed as a trapezoidal cross section with a thickness of 100mm and a height of 60mm.

[0043] The groove body 1 of the combined cable groove is composed of the following raw material components mixed in parts by weight:

[0044] R42.5 or R52.5 ordinary Portland cement: 320-400 parts;

[0045] Medium coarse sand: 670-72...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com