Processing method of instant millet congee

A processing method and technology for instant porridge, applied in application, food preparation, food science and other directions, can solve the problems of poor sensory quality and rice grain regeneration, and achieve the effects of long shelf life, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of embodiment 1α-millet instant porridge

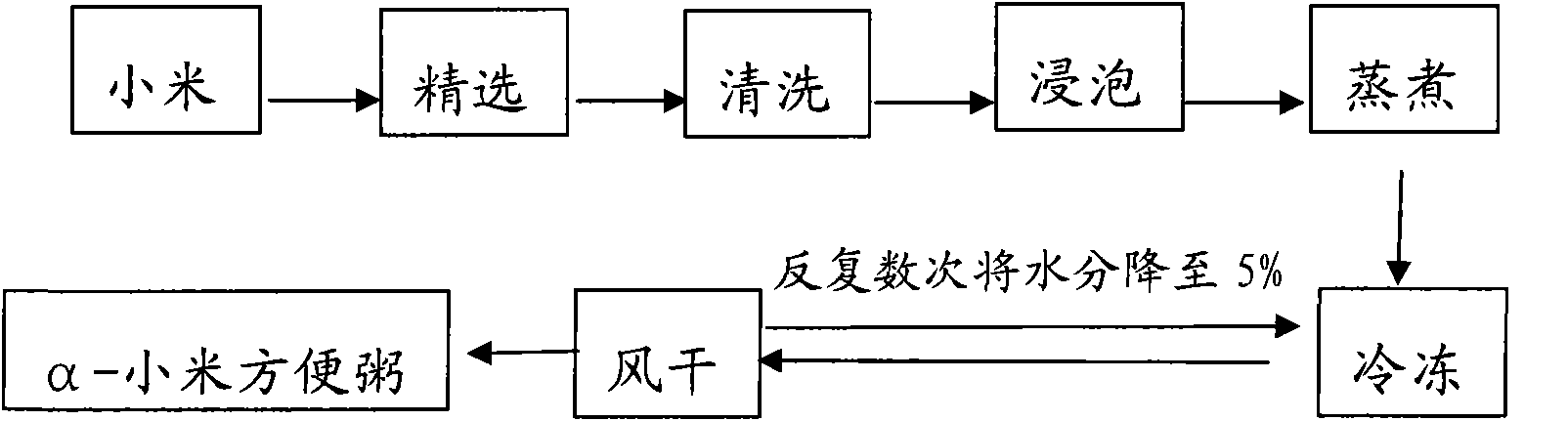

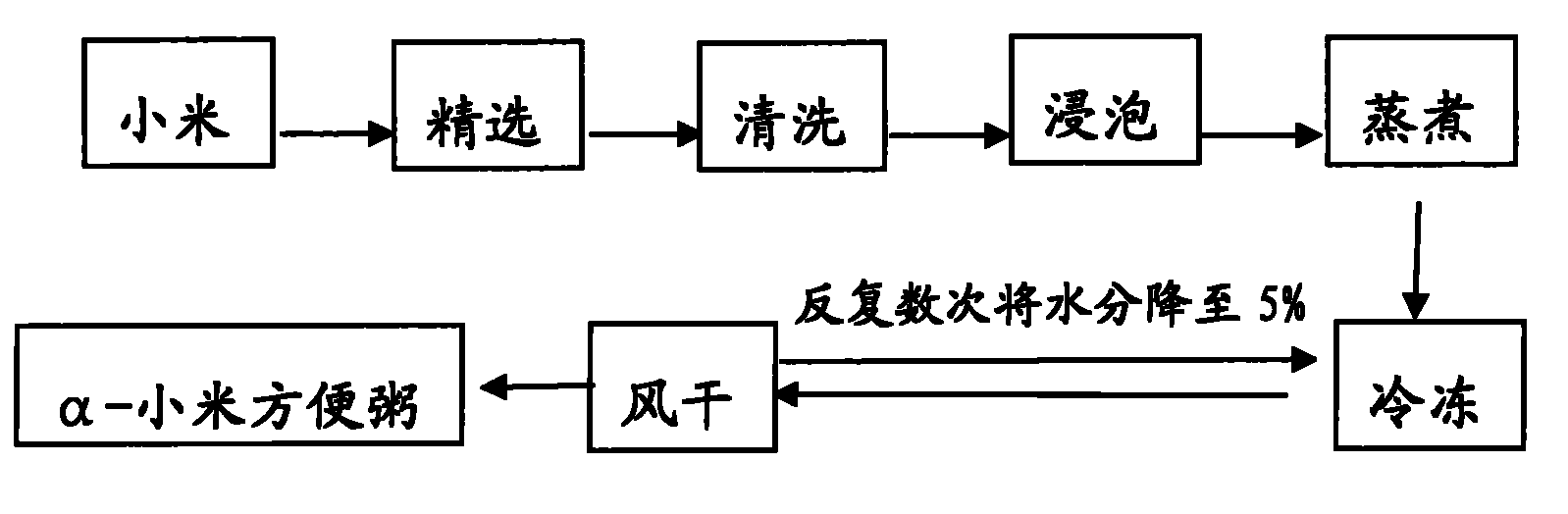

[0022] The preparation process of α-millet instant porridge is as follows: figure 1 As shown, the details are as follows:

[0023] 1. Selection: Using Jingu No. 29 as raw material, select 0.5kg of high-quality millet through stone removal, shelling, 18-mesh sieve and manual removal of impurities;

[0024] 2. Cleaning: use a stainless steel sieve to wash repeatedly in clean water for 10 times;

[0025] 3. Soaking: Add 800g of water at 50°C to the cleaned millet and soak for 2 hours;

[0026] 4. Steaming: Put the soaked millet into a steamer and steam for 35 minutes;

[0027] 5. Discrete: spread the steamed millet on a 25cm*35cm aluminum alloy sieve frame, the thinner the better;

[0028] 6. Freezing: Put the millet together with the sieve into the freezer for 2 hours;

[0029] 7. Air-drying: Take out the millet together with the sieve rack and put it into a blast drying oven with a temperature adjusted to 10...

Embodiment 2

[0031] The preparation of embodiment 2α-millet instant porridge

[0032] 1. Selection: Using Jingu No. 40 as raw material, 0.5kg of high-quality millet is selected through stone removal, shelling, 18-mesh sieve and manual removal of impurities;

[0033] 2. Cleaning: use a stainless steel sieve to wash repeatedly in clean water for 5 times;

[0034] 3. Soaking: Add 1000g of water at 30°C to the cleaned millet and soak for 3 hours;

[0035] 4. Cooking: Put the soaked millet into a steamer and steam for 60 minutes;

[0036] 5. Discrete: spread the steamed millet on a 25cm*35cm aluminum alloy sieve frame, the thinner the better, and there should be no adhesion between the rice grains;

[0037] 6. Freezing: Put the millet together with the sieve into the freezer for 2.5 hours;

[0038] 7. Air-drying: Take out the millet together with the sieve rack and put it into a blast drying oven with a temperature adjusted to 100°C, and dry it by blasting for 5 minutes;

[0039] 8. Freezin...

Embodiment 3

[0040] The preparation of embodiment 3α-millet instant porridge

[0041] 1. Selection: use Fenxuan No. 3 millet as raw material, select 0.3kg of high-quality millet through stone removal, shelling, 18-mesh sieve and manual removal of impurities;

[0042] 2. Cleaning: use a stainless steel sieve to wash repeatedly in clean water for 6 times;

[0043] 3. Soaking: Add 500g of 40°C water to the cleaned millet and soak for 2.5 hours;

[0044] 4. Steaming: Put the soaked millet into a steamer and steam for 45 minutes;

[0045] 5. Discrete: spread the steamed millet on a 25cm*35cm aluminum alloy sieve frame, the thinner the better;

[0046] 6. Freezing: Put the millet together with the sieve into the freezer for 2.5 hours;

[0047] 7. Air-drying: Take out the millet together with the sieve rack and put it into a blast drying oven with a temperature adjusted to 100°C, and dry it by blast for 3.5 minutes;

[0048] 8. Freezing and air-drying are repeated 11 times, and the freezing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com