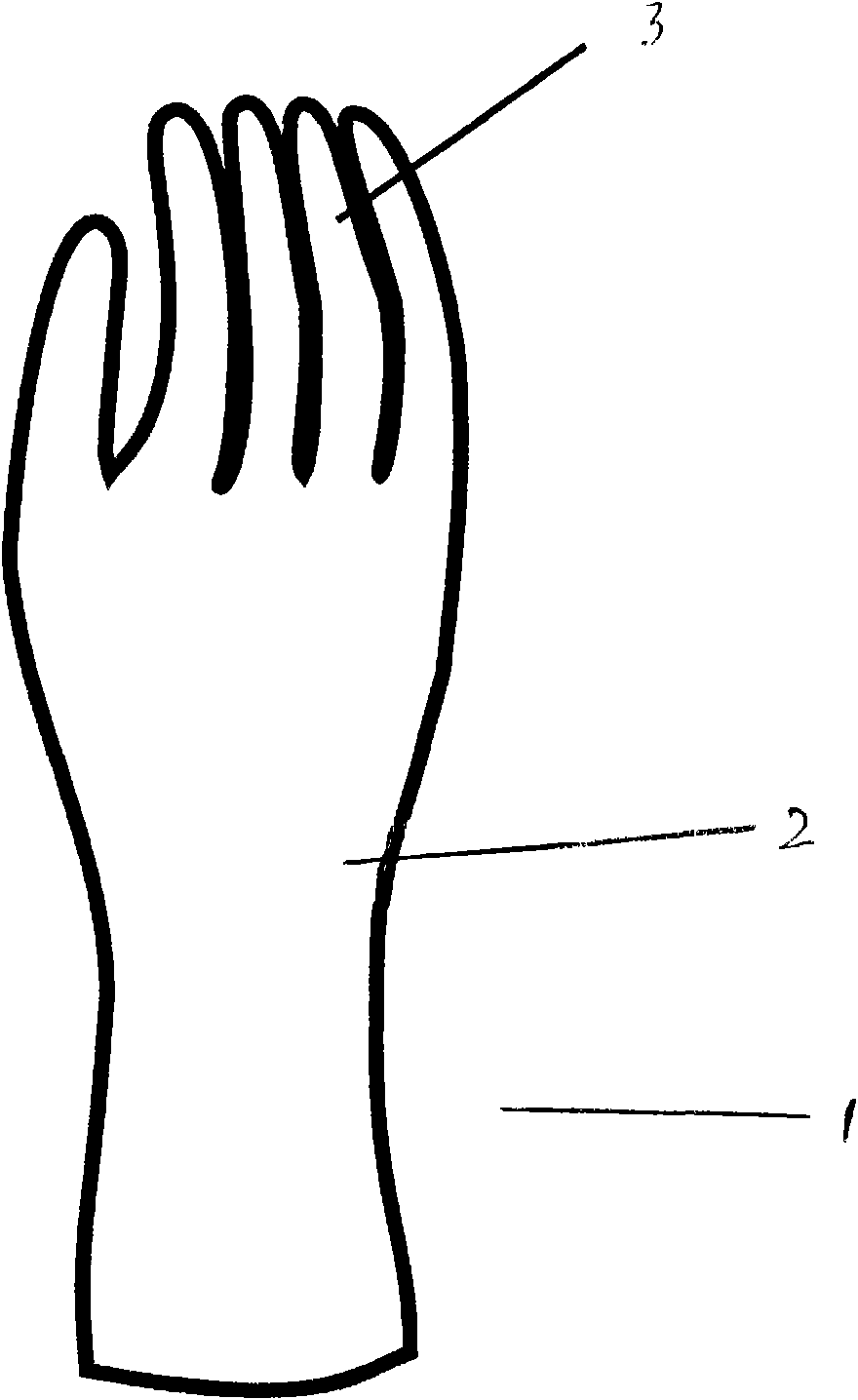

Rubber latex insulating glove and manufacturing method thereof

A technology of insulating gloves and a manufacturing method, which is applied to protective clothing and other directions, can solve the problems of poor wearing comfort of insulating gloves, operator's hand fatigue, and reduced work efficiency, so as to achieve excellent performance of gloves, improve work efficiency and work quality, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Preparation of Rubber Latex Insulated Gloves

[0055] 1) Prepare 2000 grams of rubber

[0056] Weigh respectively 1860 grams of natural rubber latex, 18.6 grams of sulfur, 13 grams of accelerator PX, 7.4 grams of accelerator ZDC, 30 grams of plasticizer Y, 9.2 grams of zinc oxide, 22.56 grams of antioxidant DNP, and 18.6 grams of antioxidant DOP , Potassium Hydroxide 10.76 grams, pure water 10.2 grams, then stir and mix to make rubber compound;

[0057] 2) Prepare 200 grams of coagulant

[0058] Take by weighing 56 grams of calcium chloride, 2.8 grams of cyclohexanone, 7.2 grams of TM-1 type gel hole forming agent, and 134 grams of pure water, and stir and mix the above components for later use;

[0059] 3) Vulcanized molding gloves

[0060] The prepared rubber is vulcanized by a vulcanized bed, the vulcanization condition is 60 ° C / 1 minute, and the aging treatment is 5 days; the mature latex is immersed in the aqueous solution of the coagulant for 6 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com