Uniform middling distributor of large-size rotational flow microbubble flotation column

A micro-bubble flotation column and uniform distributor technology, which is applied in flotation, solid separation, etc., can solve the problems that it is not convenient to observe the operation of the foam trap of the bubble generator at the same time, and reduce the convenience and effectiveness of equipment operation. , to achieve the effect of enhancing convenience and effectiveness, improving sorting effect and separation precision, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

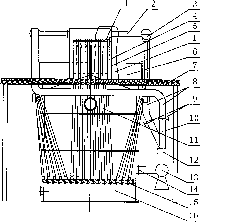

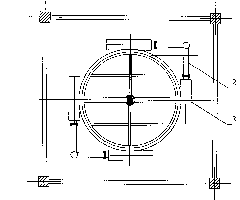

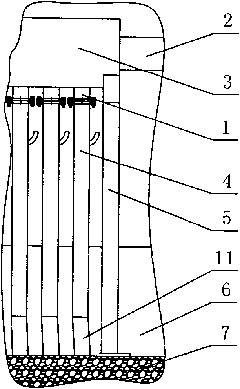

[0011] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0012] figure 1 As shown, the large-scale cyclone micro-bubble flotation column medium ore uniform distributor of the present invention is mainly composed of a circulation pump 13, a flow splitter 12, a distributor 3, a Venturi tube bubble generator 4, a rubber hose 11, a medium ore cutter Composition to feed port 15. The circulation pump 13 is connected with the middling ore circulation port 14 of the flotation column 16 through pipelines, and a plurality of middling ore tangential feeding ports 15 are evenly arranged at the lower part of the flotation column 16, and a plurality of middling ore tangential feeding ports 15 are evenly arranged. The layout of the mouth 15 is divided into 24, 32 or 40 according to the size of the cylinder. Four distributors 3 are arranged on the outer side of the upper part of the flotation column 16. The distributors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com