Gluing device, use method and products thereof

A glue coating device and product technology, which is applied to the surface coating liquid device, coating, semiconductor/solid device manufacturing, etc., can solve the problem of uneven thickness of the glue, air in the glue, and large resistance of the glue flowing through the scraper, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

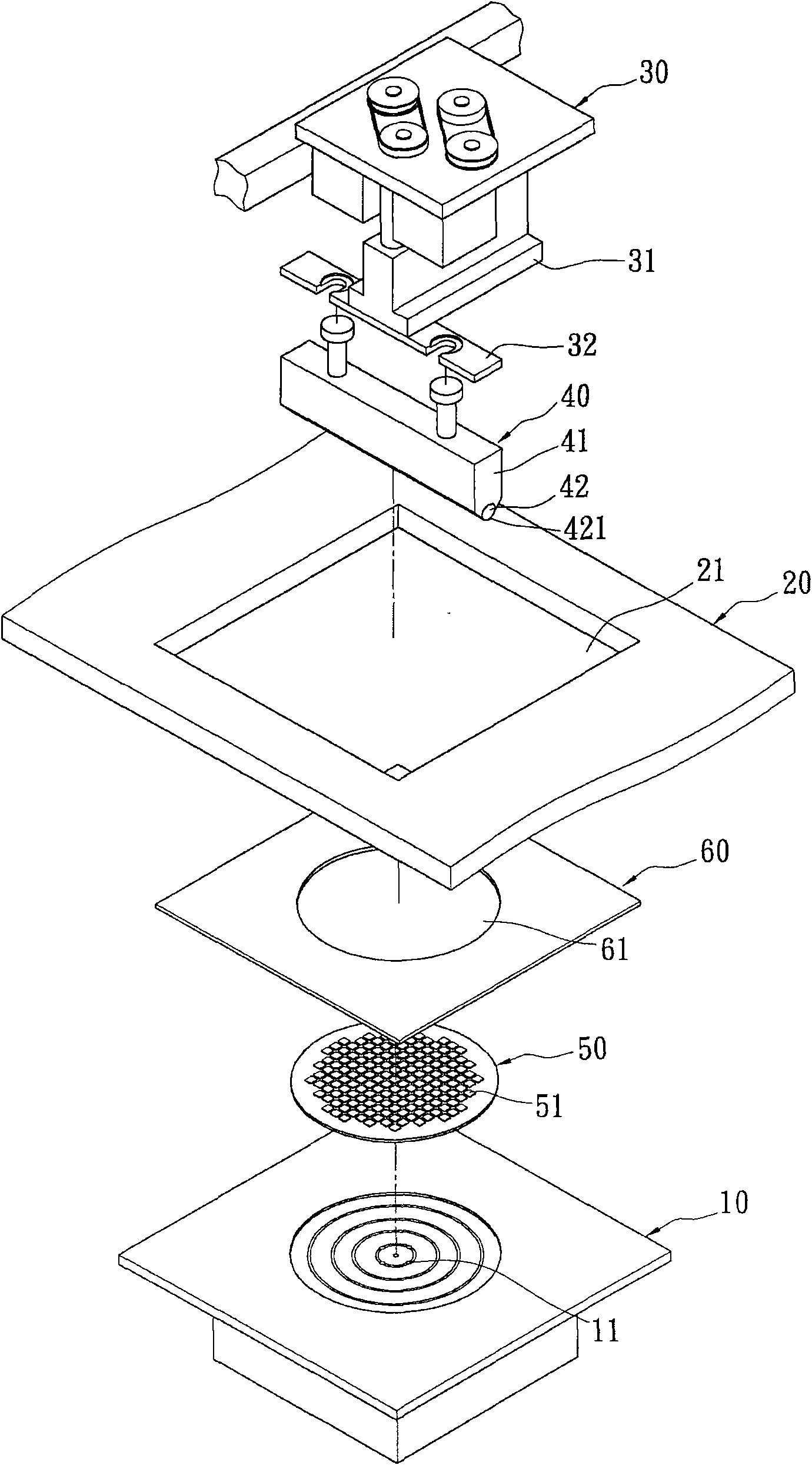

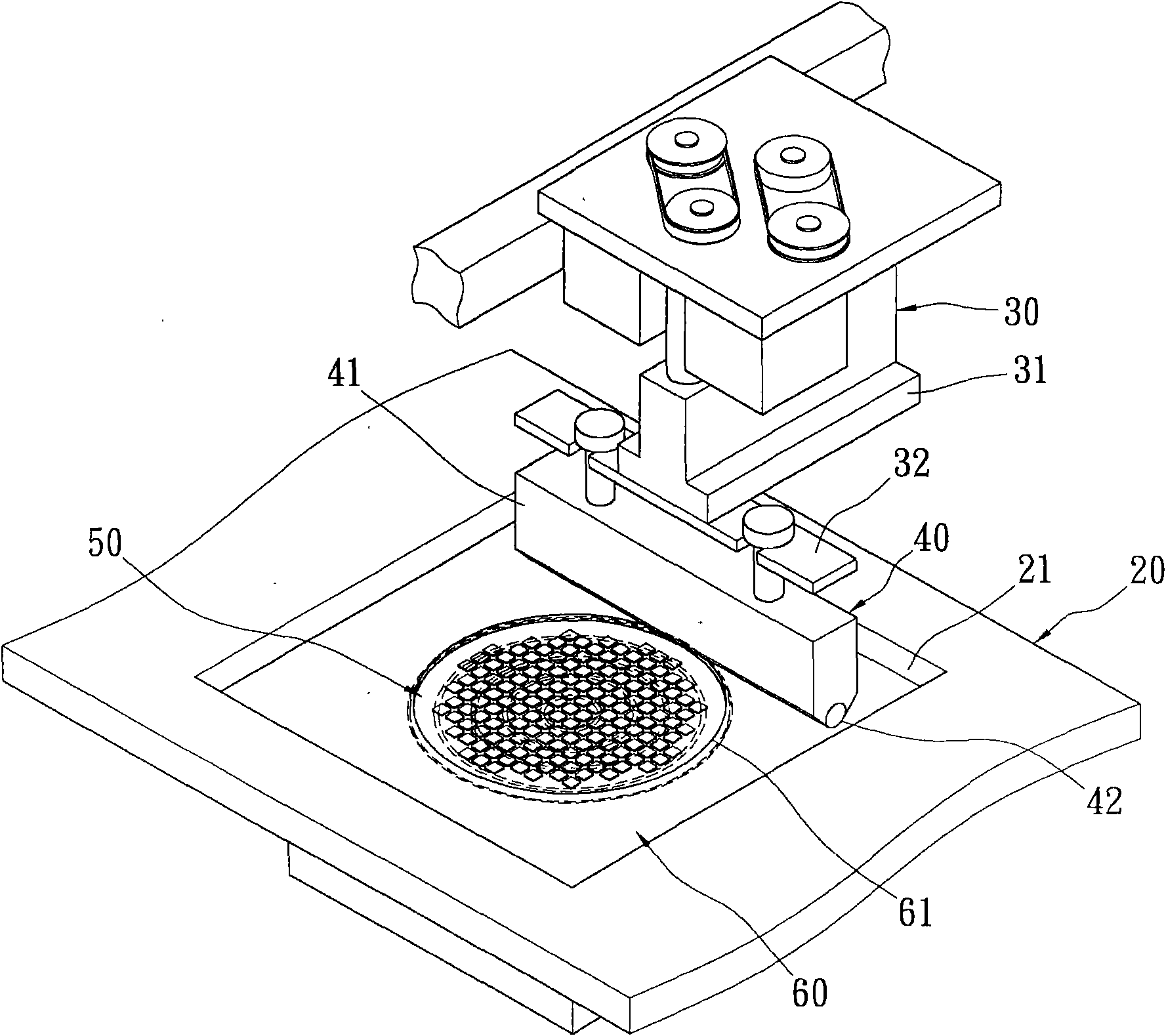

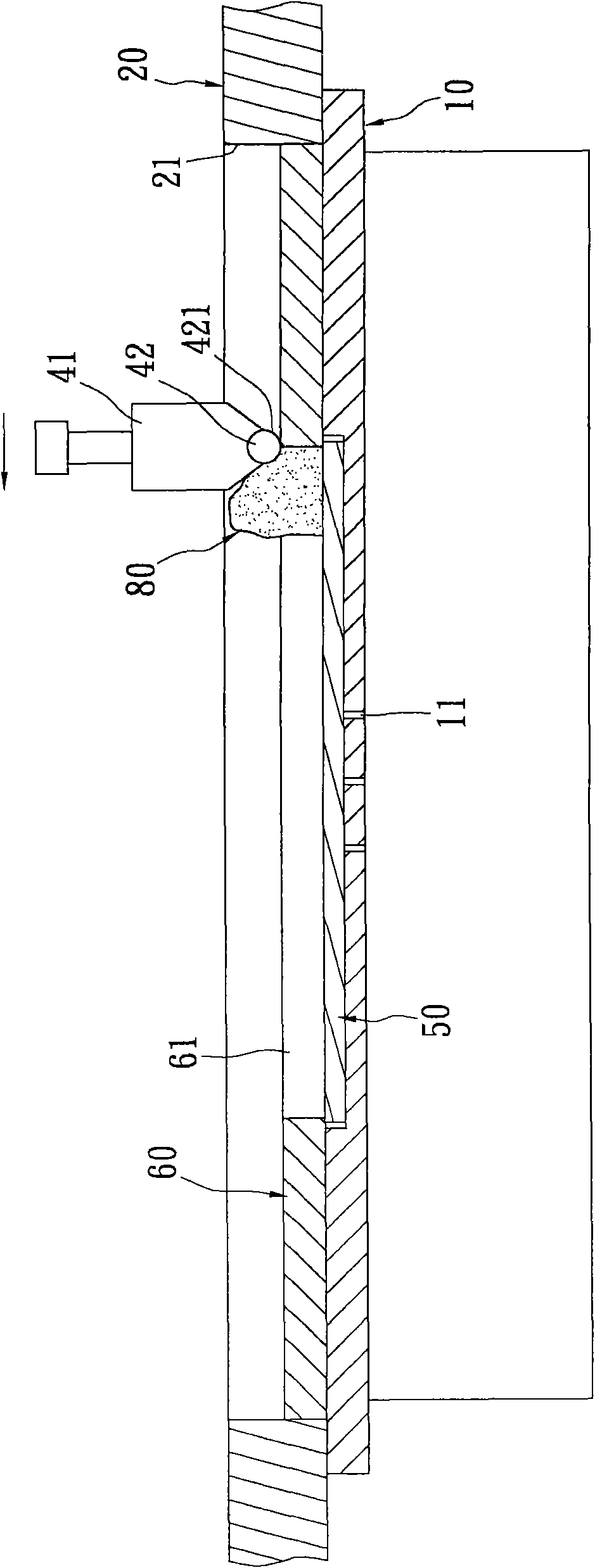

[0043] see Figure 1 to Figure 3 , the present invention proposes a gluing device, which includes: a vacuum chuck 10 , a placement platform 20 , a scraper moving module 30 and a scraper structure 40 .

[0044] The vacuum chuck 10 is a board, which can move up and down to change the use height of the vacuum chuck 10 . The center of the vacuum chuck 10 has a plurality of suction holes 11 . The suction holes 11 are recessed on the top surface of the vacuum chuck 10 and penetrate to the bottom surface of the vacuum chuck 10 . The vacuum chuck 10 also has a vacuum pump (not shown), and the lower end of the suction hole 11 is connected with the vacuum pump. Thus, when the vacuum pump generates suction, the suction hole 11 will also generate suction to absorb an object to be glued 50 (such as a wafer) placed on the top surface of the vacuum chuck 10 .

[0045] The placing platform 20 is arranged on the top of the vacuum chuck 10, and has a rectangular placing groove 21 in its cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com