Full-automatic microphone testing machine

A testing machine, fully automatic technology, applied in electrical components, sorting and other directions, can solve problems such as overall product quality, competitiveness impact, misjudgment, and inability to detect leaking products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

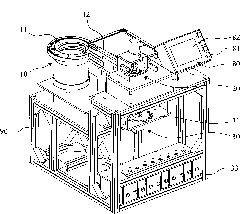

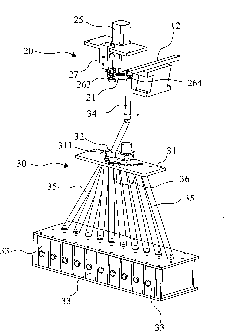

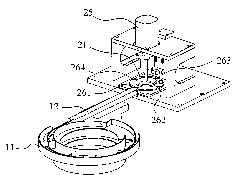

[0041] First, please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention. The automatic microphone testing machine includes two parts, namely: the mechanical part and the electrical part. The mechanical part includes a frame 90 and a mechanical feeding system 10 arranged on the frame 90, a mechanical testing system 20 mechanical sorting system 30 and a man-machine interface operating system 80; the electrical part includes a polarity discrimination module 40, a conversion An amplification module 50 , an AD acquisition module 60 and a PLC operation control module 70 .

[0042] Wherein, the mechanical feeding system 10 is used for flipping and queuing up the microphones one by one into the subsequent mechanical testing system 20 . The mechanical feeding system 10 includes a vibration plate 11 and a linear vibration device 12, the output end of the vibration plate 11 is connected to the input end of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com