Manufacturing method of SU-8 nano fluid system

A SU-8, nanofluid technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of increasing process complexity and manufacturing cost, and nanoimprinting technology cannot process micro-nano composite structures at the same time. The method is simple and controllable, and the effect of low cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation is carried out according to the following process:

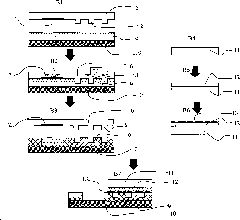

[0029] 1. Clean the quartz substrate, and spin-coat the photoresist used to make the grating mask on the quartz substrate, such as figure 1 Shown in middle A1; Utilize the holographic method to make the grating pattern of photoresist on the quartz substrate, as figure 1 Shown in A2; then transfer the grating pattern of the photoresist to the quartz substrate by reactive ion etching to form a quartz substrate with a grating pattern structure, which is spin-coated on the quartz substrate with the grating structure to make a sample cell mask photoresist, such as figure 1 Shown in A3 in the middle; Utilize the sample cell template to expose and develop the photoresist to form a photoresist pattern with a sample cell structure, such as figure 1 Shown in A4 among middle; Utilize reactive ion etching to transfer the photoresist pattern with the sample cell structure to the quartz substrate, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com