Method for manufacturing black silicon material by scanning and irradiation of light source of broad-pulse laser

A laser and wide-pulse technology, which is applied in the field of scanning and irradiating black silicon materials with wide-pulse laser light sources. The effect of shortening the time of the same area, cheap price, and wide working pulse width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

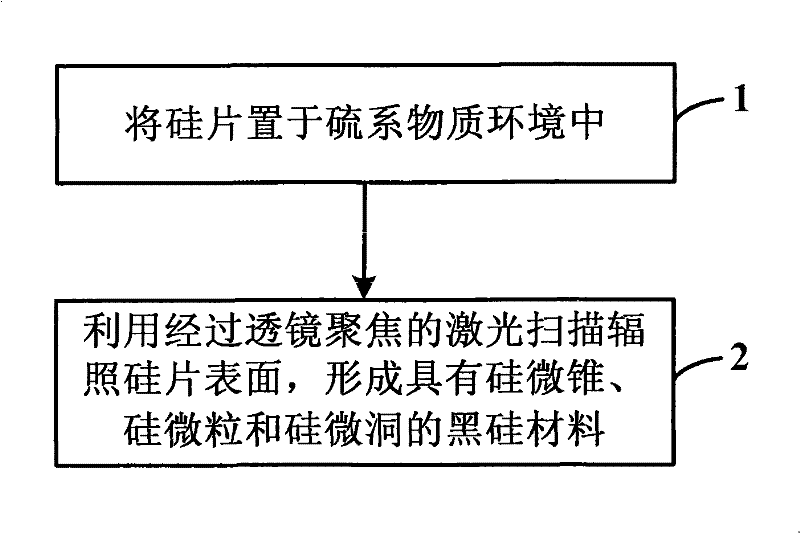

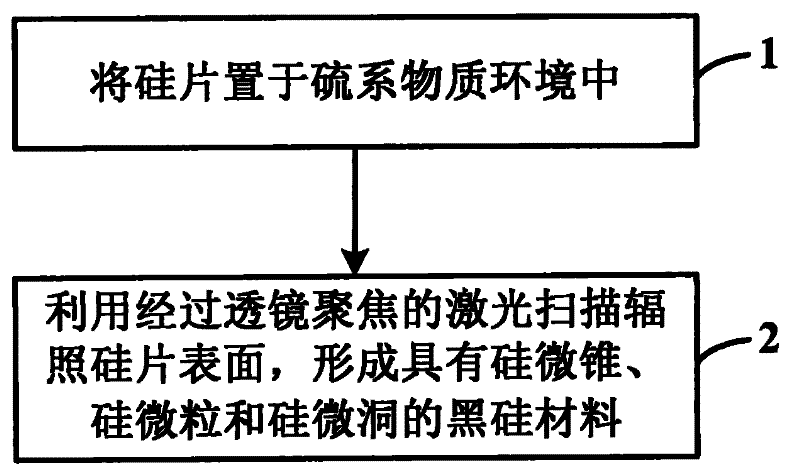

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0025] The method provided by the present invention adopts wide pulse laser light source scanning irradiation to produce black silicon material, the pulse width is from nanoseconds or microseconds or milliseconds to continuous DC mode, and the wavelength is 1064nm. Using this kind of wide pulse 1064nm laser light source to scan a silicon wafer placed in a chalcogenide environment can produce silicon microcones, particles, and microcavity microstructures on the surface of the wafer to form a so-called black silicon material, which is harmful to the sun. The spectrum has a strong absorption coefficient and is not limited by the low-energy absorption band of silicon, even in the near-infrared band of the solar spectrum, it st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap