Silicon controlled rectifier electrostatic discharge protection circuit structure triggered by grid controlled diode

A gate-controlled diode and electrostatic discharge technology, applied in the electronic field, can solve problems such as unfavorable internal circuit device protection, and achieve the effect of low trigger voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

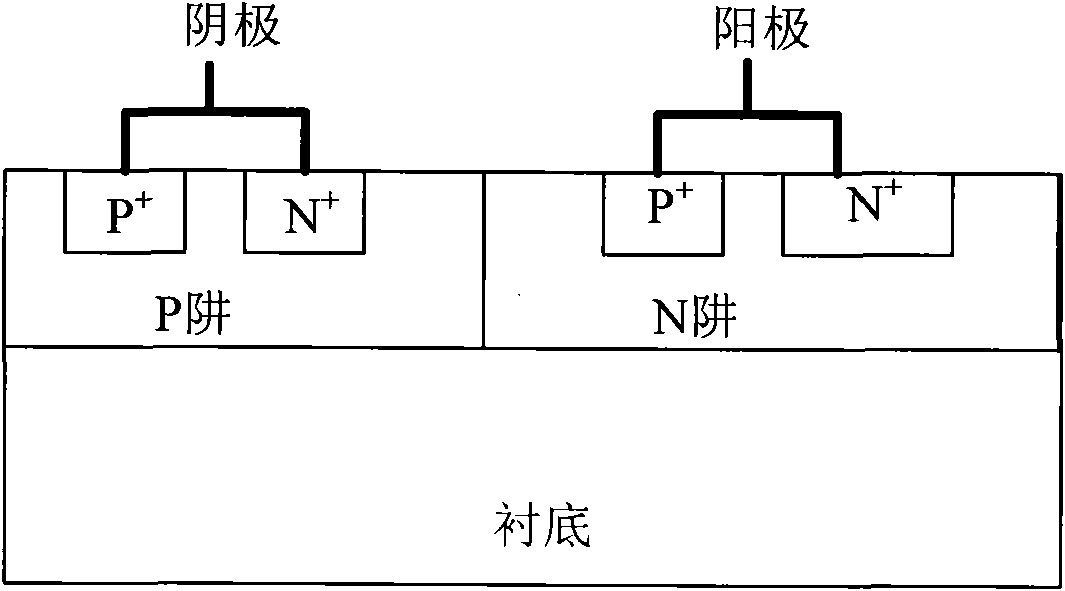

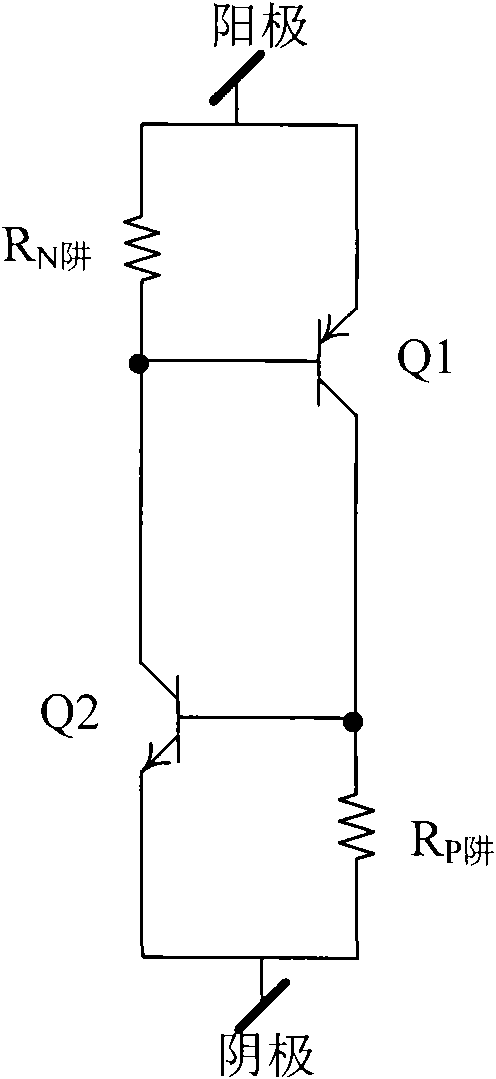

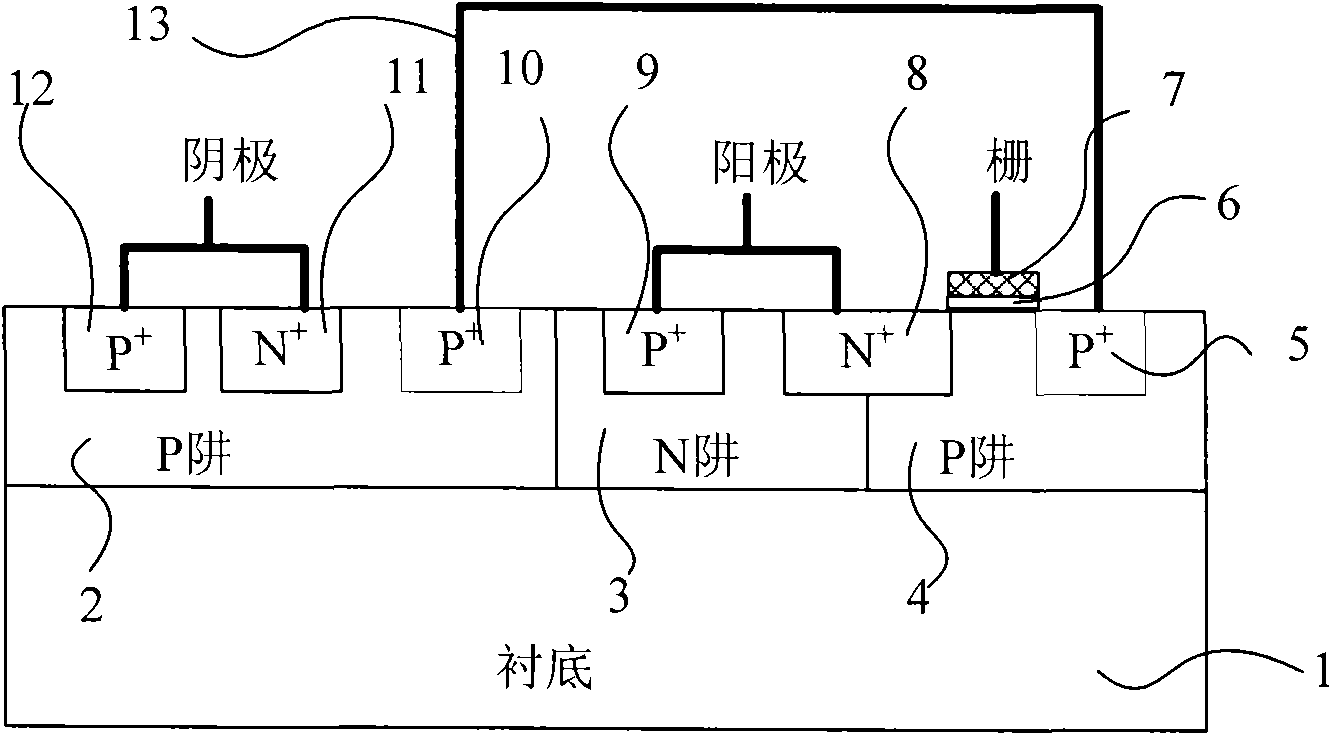

[0021] A thyristor rectifier type electrostatic discharge protection circuit structure triggered by a gate control diode, such as image 3 As shown, it includes: two conductive types of well regions located on a semiconductor substrate substrate 1: a P-type well region 2 and an N-type well region 3; two heavily doped regions located in the first P-type well region 2 District: P + Heavily doped region 12 and N + Heavily doped region 11; two heavily doped regions located in the N-type well region 3: P + Heavily doped region 9 and N + Heavily doped region 8; a first electrode that contacts the surface of the two heavily doped regions in the first P-type well region 2; a second electrode that contacts the surface of the two heavily doped regions in the N-type well region 3 . The protection circuit structure also includes a second P-type well region 4, which is connected to the first P-type well region 2 and surrounds the N-type well region 3 in the middle, and the N-type well region...

specific Embodiment approach 2

[0028] A gate-controlled diode-triggered silicon controlled rectifier type electrostatic discharge protection circuit structure, comprising: two conductive types of well regions on a semiconductor substrate substrate 1: N-type well region 2 and P-type well region 3; Two heavily doped regions in the first N-type well region 2: N + Heavily doped region 12 and P + Heavily doped region 11; two heavily doped regions located in the P-type well region 3: N + Heavily doped region 9 and P + Heavily doped region 8; a first electrode in surface contact with the two heavily doped regions in the first N-type well region 2; a second electrode in surface contact with the two heavily doped regions in the P-type well region 3 . The protection circuit structure further includes a second N-type well region 4, the second N-type well region 4 is connected to the first N-type well region 2 and surrounds the P-type well region 3 in the middle, and the P-type well region P in zone 3 + A part of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com