LED lamp with lens injected with fluorescent glue and packaging method thereof

A fluorescent glue and lens technology, applied to optical elements, light sources, electric light sources, etc. used to change the spectral characteristics of emitted light, can solve the problem of uncontrollable thickness consistency of fluorescent glue layers, large differences in color uniformity of LED lights, The problem of uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples, so that the realization process of how to use technical means to solve technical problems and achieve technical effects in the present invention can be fully understood and implemented accordingly.

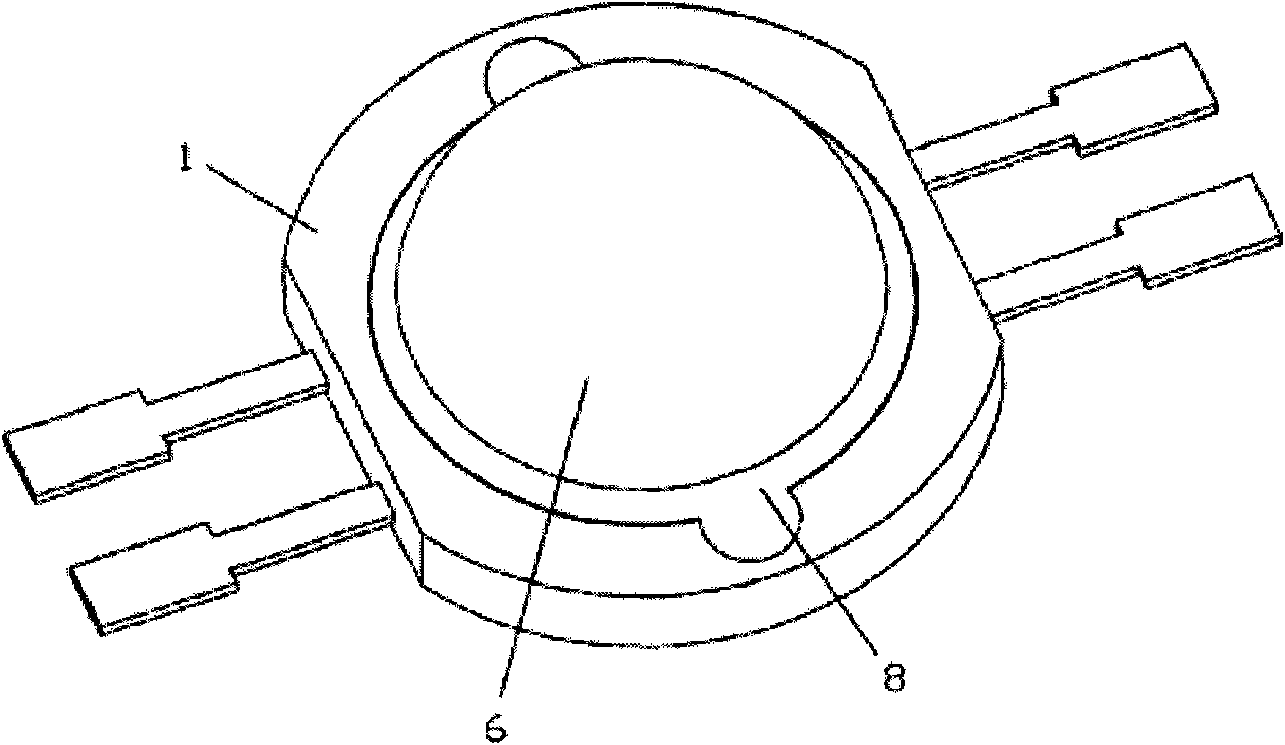

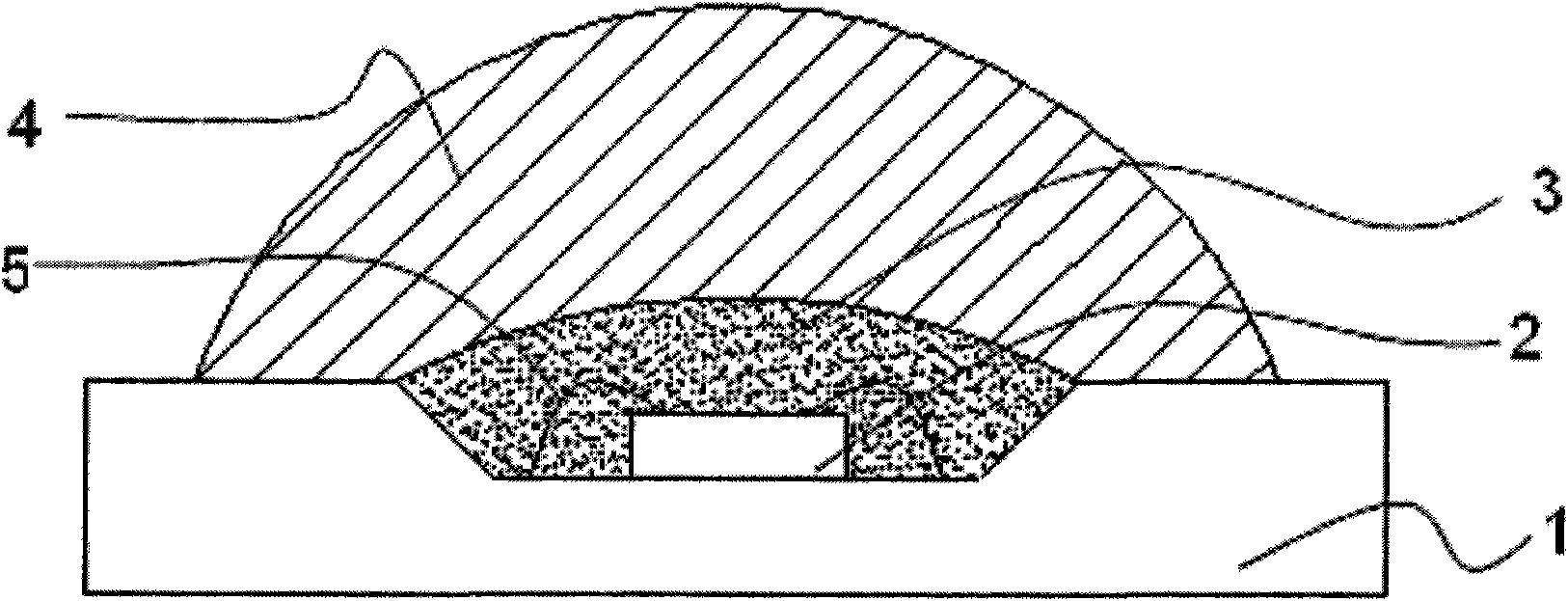

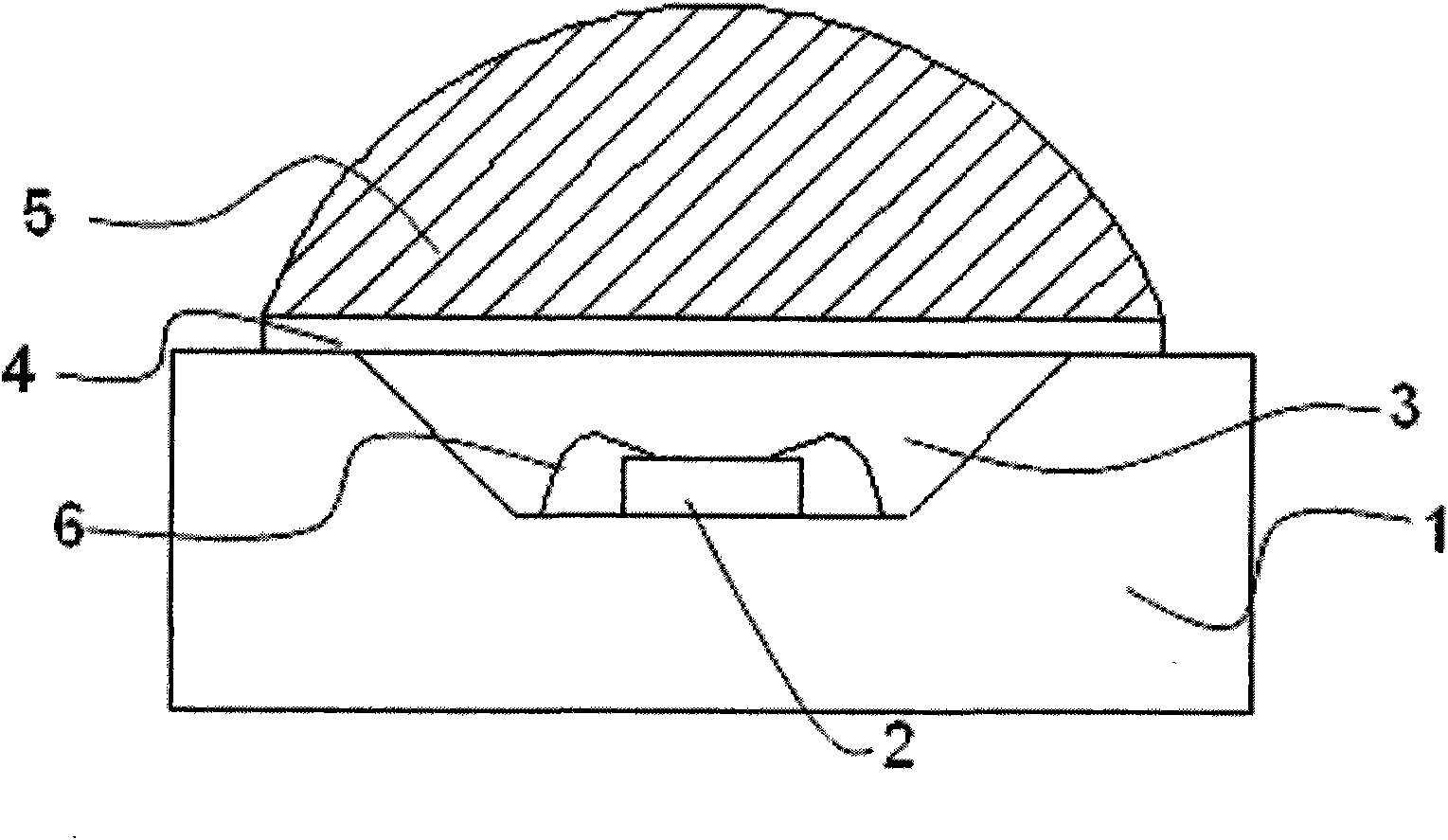

[0031] The core of the present invention: the lens covers the LED crystal grain to form a cavity containing encapsulation glue, the lens has a cavity layer for filling fluorescent glue inside, and the lens also has a glue injection hole; the LED The crystal grain is covered with cured and molded encapsulation glue injected into the cavity through the glue injection hole, and there is cured and molded fluorescent glue injected through the glue injection hole in the cavity layer.

[0032] The thickness of the entire cavity layer can be adjusted to a consistent uniform thickness.

[0033] The lens is provided with two glue injection holes and two exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com