Polymer solar battery with high open-circuit voltage

A solar cell and open-circuit voltage technology, applied in the field of solar cells, can solve the problems of degradation of photoelectric properties of polymers, widening of the band gap, and decline in the overall energy conversion efficiency of solar cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

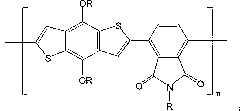

[0016] Using 2,6-bis(trimethyltin)-4,8-bis(2-ethylhexyloxy)benzo[1,2-b:4,5-b']bisthiophene (abbreviation: BDT) and The Stille coupling reaction of N-(2-ethylhexyl)-3,6-dibromobenzimide (abbreviation: PhI) is used to synthesize P(BDT-PhI), and the reaction equation is:

[0017]

[0018] In the formula, R represents 2-ethylhexyl. Among them, BDT was synthesized by the method reported in Journal of the American Chemical Society, 2009, 131, 15586, and PhI was synthesized by the method reported in Journal of the American Chemical Society, 2009, 131, 7206. The synthesis steps of P(BDT-PhI) are:

[0019] Add 20ml of toluene, 0.772g of BDT (1.0mmol) and 0.417g of PhI (1.0mmol) into a 50ml round bottom three-neck flask, stir to dissolve BDT and PhI in toluene, and bubble the solution with nitrogen for 10 minutes, then add 30mg of Pd (PPh 3 ) 4 As a catalyst, nitrogen was sparged for another 20 minutes. The temperature of the reaction system was raised to 110° C., and the reacti...

Embodiment 2

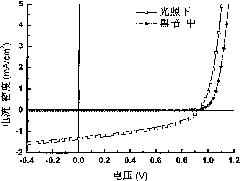

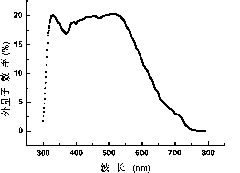

[0022] The transparent conductive glass with strip-shaped ITO (anode) etched on the surface was cleaned with detergent solution, deionized water, acetone and isopropanol by ultrasonic oscillation, dried, and then treated with oxygen plasma for 10 minutes; The aqueous solution of the mixture of PEDOT and PSS is spin-coated on the surface of the conductive glass at a speed of 2000r / min, and dried at 150°C for 15 minutes to obtain a 30nm-thick composite film (anode modification layer) of PEDOT and PSS; then, spin-coat on it The mixed solution of P(BDT-PhI) and PCBM, the rotating speed is 1500r / min, the total concentration of the solution is 20mg / ml, the solvent is chlorobenzene, the weight ratio of P(BDT-PhI) and PCBM is 1:1, spin coating The time is 60 seconds, after the end of spin coating, when the pressure is lower than 1×10 -4 Dry at room temperature under the vacuum of Pa for 2 hours to obtain a composite film (active layer) of P(BDT-PhI) and PCBM with a thickness of 87nm; ...

Embodiment 3

[0026] The transparent conductive glass with strip-shaped ITO (anode) etched on the surface was cleaned with detergent solution, deionized water, acetone and isopropanol by ultrasonic oscillation, dried, and then treated with oxygen plasma for 10 minutes; The aqueous solution of the mixture of PEDOT and PSS is spin-coated on the surface of the conductive glass at a speed of 2000r / min, and dried at 150°C for 15 minutes to obtain a 30nm-thick composite film (anode modification layer) of PEDOT and PSS; then, spin-coat on it The mixed solution of P(BDT-PhI) and PCBM, the rotating speed is 1000r / min, the total concentration of the solution is 20mg / ml, the solvent is chlorobenzene, the weight ratio of P(BDT-PhI) and PCBM is 1:1, spin coating The time is 60 seconds, after the end of spin coating, when the pressure is lower than 1×10 -4 Dry at room temperature under the vacuum of Pa for 2 hours to obtain a composite film (active layer) of P(BDT-PhI) and PCBM with a thickness of 100nm;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com