Fiber web handling and/or production line and method in connection with fiber web handling and/or production line

A fiber web and processing line technology, applied in thin material processing, strip winding, transportation and packaging, etc., can solve problems such as inflexibility, and achieve the effect of flexible design, improved operation safety, saving and capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

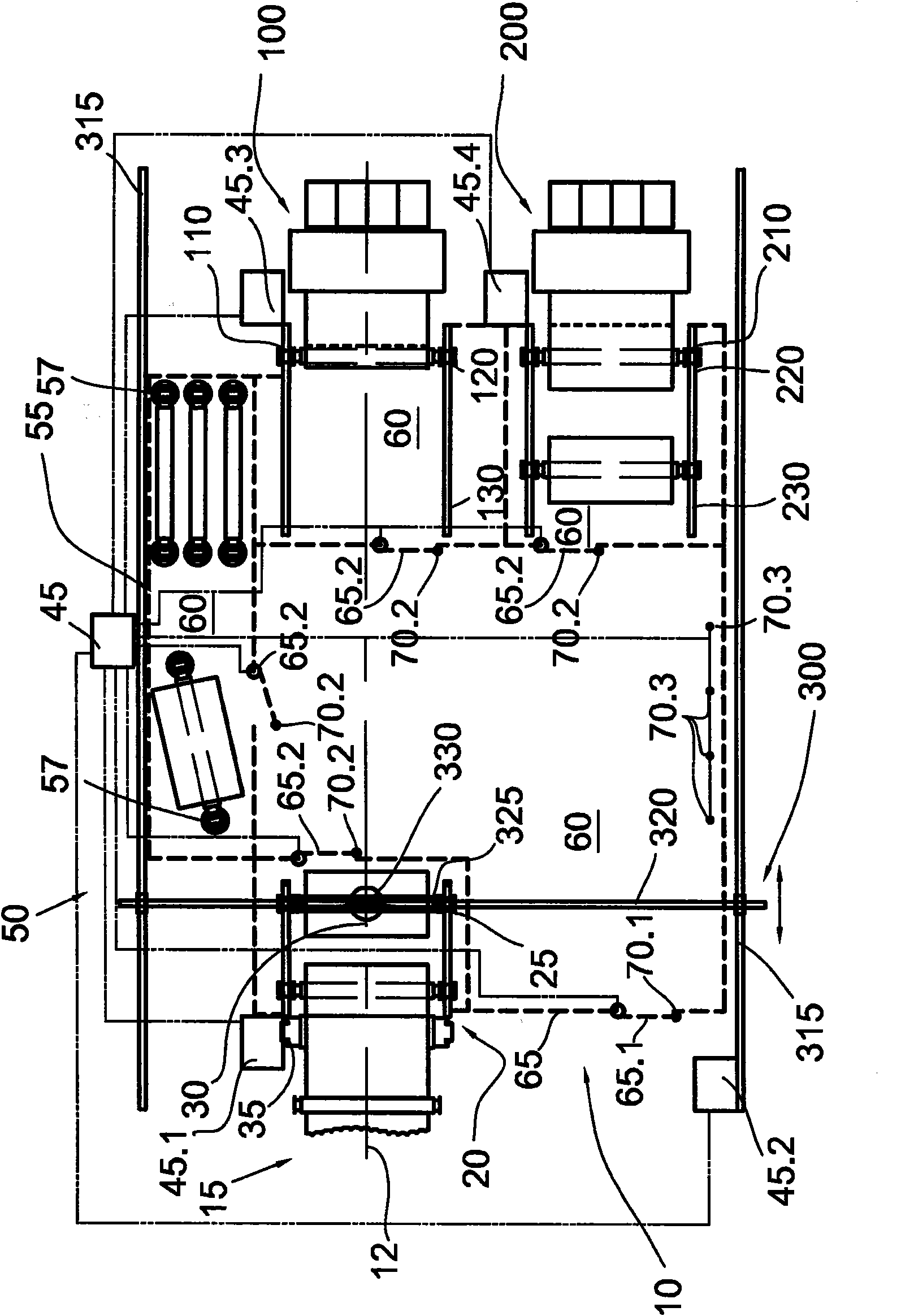

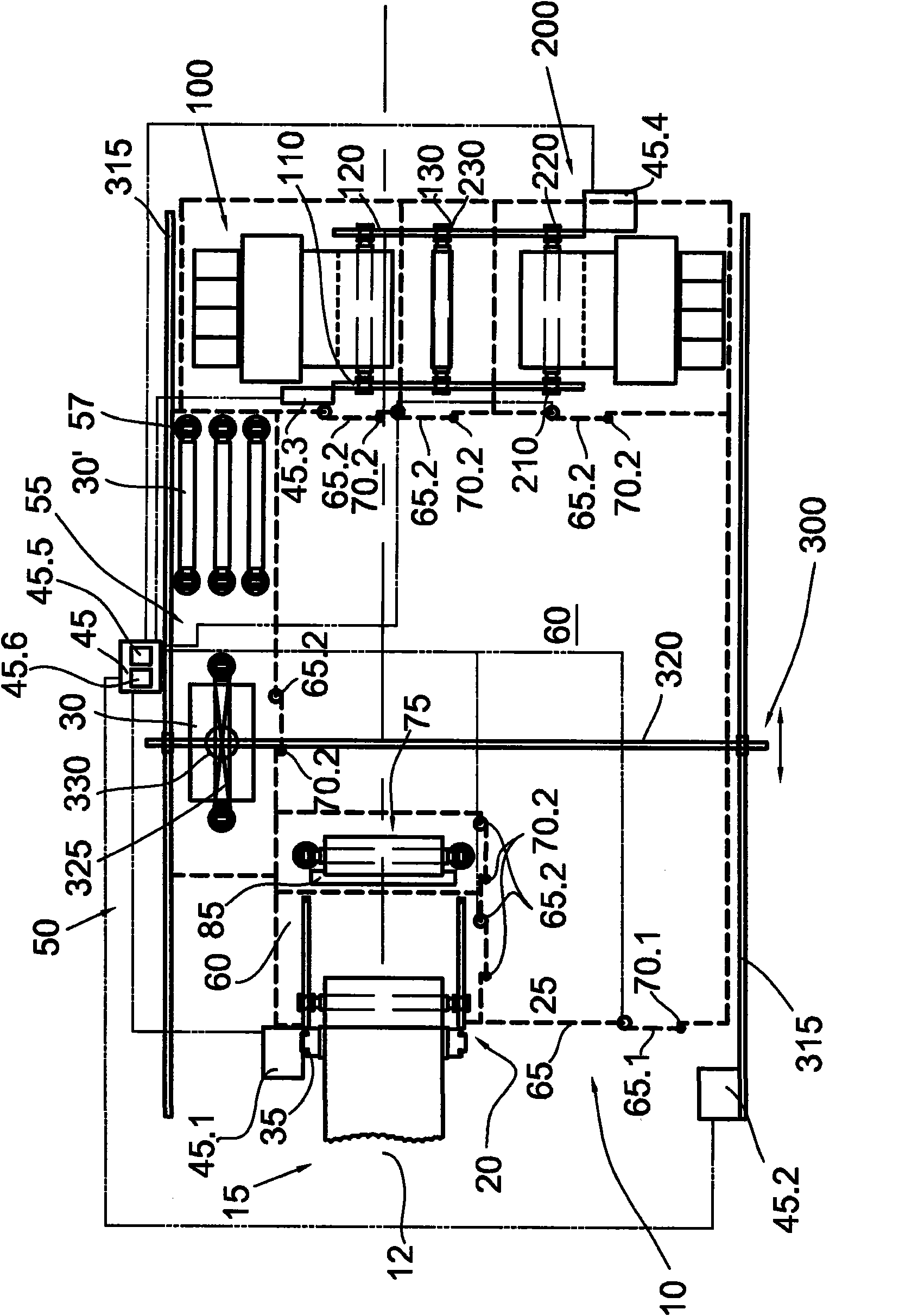

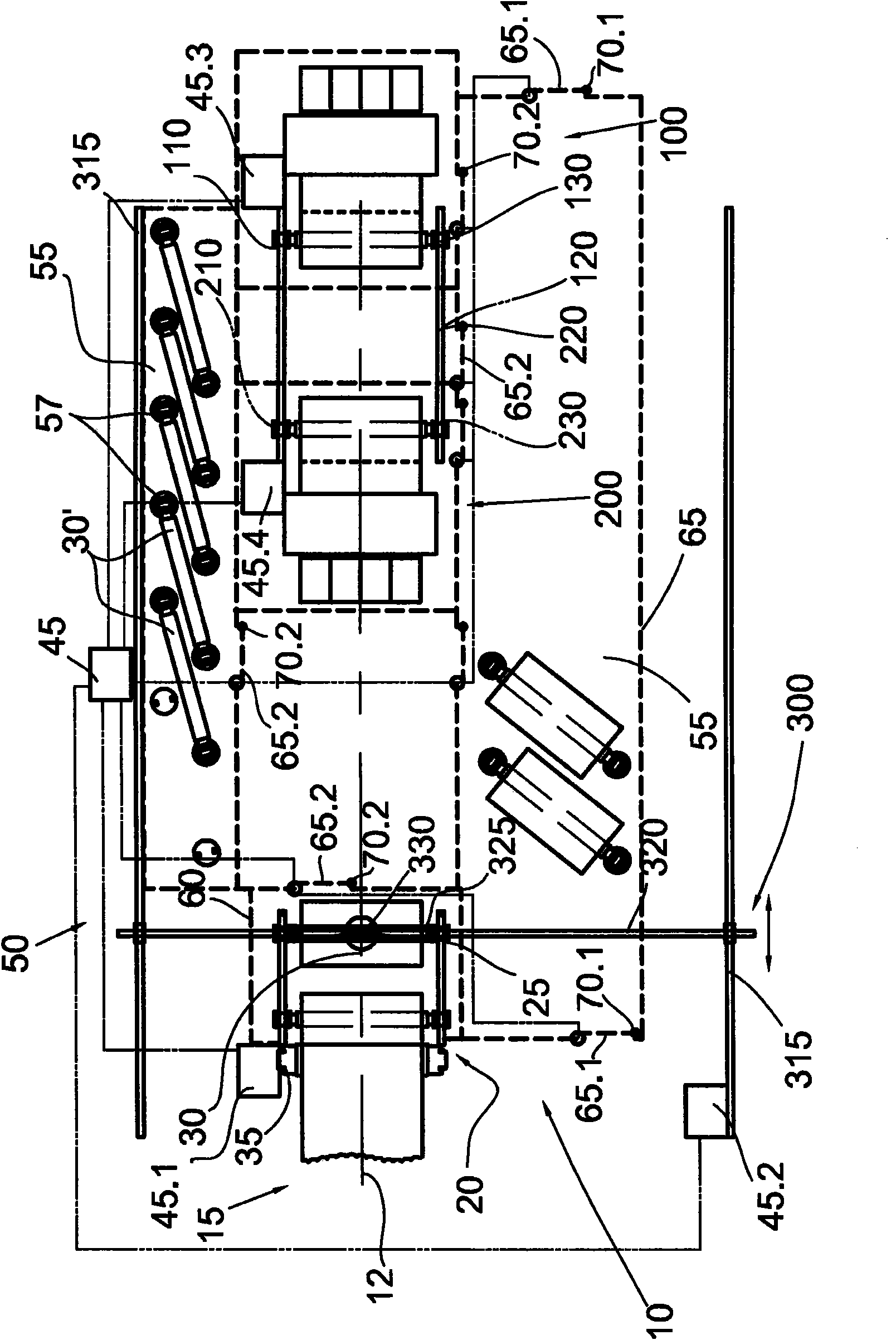

[0037] figure 1 A production and treatment line 10 of a fiber web according to one embodiment is schematically shown, ie a treatment device 50 for machine rolls of the production and treatment line. In this embodiment the production and handling line comprises a fiber web machine 15 (not shown in the figure for the sake of clarity) and a first processing unit associated therewith, ie a coiler 20 . The basic operation and construction of such a coiler 20 is known per se. Coiler 20 includes a pick-up station 25 for fully loaded machine reels, to which it delivers finished machine reels 30 . The reel also comprises a receiving station 35 for the empty reel 30', which is preferably a support device for the reel on the reel, for example a so-called main reel. In this embodiment, the pick-up station 25 for the machine roll on the reel may consist of a relatively short track or secondary carriage which is moved far enough away from the reel cylinder immediately after the roll is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com