Silica gel fixed phase of mixed model as well as preparation method and application thereof

A mixed mode, stationary phase technology, applied in chemical instruments and methods, other chemical processes, ion exchange, etc., can solve the problems of difficult wide application, difficult development of chromatographic stationary phase, and few available types, and achieve simple and heavy-duty preparation methods. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

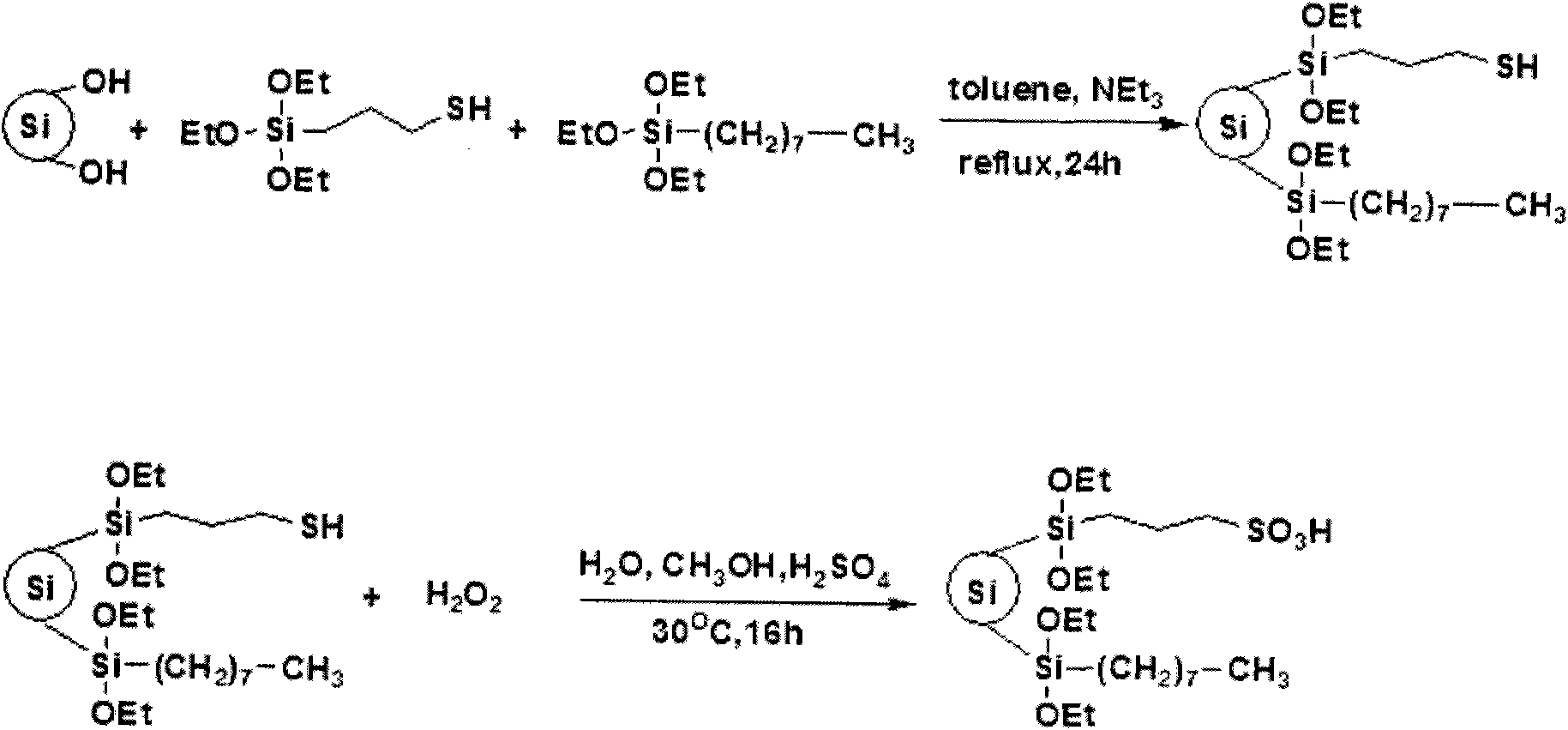

[0036] Example 1 Preparation of Mixed Mode Silica Gel Stationary Phase

[0037] In this example, 3-mercaptopropyltriethoxysilane and octyltriethoxysilane were used as silane coupling agents to prepare a mixed-mode silica gel stationary phase. The preparation process is as follows figure 1 shown.

[0038] Preparation steps:

[0039] 1. Preparation of octyl-mercapto bonded silica gel: Take 3.00g of vacuum-dried silica gel in a 250ml three-necked flask, add 120ml of treated anhydrous toluene, 1.28g of 3-mercaptopropyltriethoxysilane and 0.75g of octyltriethoxysilane, stirring mechanically, was added dropwise with 3 drops of triethylamine. N 2 After heating under reflux for 24 hours under protection, it was cooled, filtered, and washed twice with toluene, methanol and acetone. Vacuum dried at 70°C for 5 h before use.

[0040] 2. Preparation of octyl-sulfonate bonded silica gel: Take 3.00 g of octyl-mercapto bonded silica gel in a 100 mL three-necked flask, add 50 ml of 30% hy...

Embodiment 2

[0041] Example 2 Preparation of Mixed Mode Silica Gel Stationary Phase

[0042]1. Preparation of octyl-mercapto bonded silica gel: Take 3.00g of vacuum-dried silica gel in a 250ml three-necked flask, add 120ml of treated anhydrous toluene, 1.28g of 3-mercaptopropyltriethoxysilane and 1.50g of octyltriethoxysilane, stirring mechanically, was added dropwise with 3 drops of triethylamine. N 2 After heated under reflux for 30 hours under protection, it was cooled, filtered, and washed with toluene, methanol and acetone in turn. Vacuum dried at 70°C for 5 h before use.

[0043] 2. Preparation of octyl-sulfonate bonded silica gel: Take 3.00 g of octyl-mercapto bonded silica gel in a 100 mL three-necked flask, add 50 ml of 25% hydrogen peroxide solution and 12 mL of methanol, stir mechanically, add two drops of concentrated sulfuric acid, After reacting at 28°C for 20 h, it was filtered and washed with distilled water and methanol successively. Vacuum dried at 70°C for 5 h before...

Embodiment 3

[0044] Example 3 Preparation of Mixed Mode Silica Gel Stationary Phase

[0045] 1. Preparation of octyl-mercapto bonded silica gel: Take 3.00g of vacuum-dried silica gel in a 250ml three-necked flask, add 120ml of treated anhydrous toluene, 0.64g of 3-mercaptopropyltriethoxysilane and 1.50g of octyltriethoxysilane, stirring mechanically, was added dropwise with 3 drops of triethylamine. N 2 After heated under reflux for 30 hours under protection, it was cooled, filtered, and washed with toluene, methanol and acetone in turn. Vacuum dried at 70°C for 5 h before use.

[0046] 2. Preparation of octyl-sulfonate bonded silica gel: Take 3.00 g of octyl-mercapto bonded silica gel in a 100 mL three-necked flask, add 50 ml of 35% hydrogen peroxide solution and 20 mL of methanol, stir mechanically, add two drops of concentrated sulfuric acid, After reacting at 30° C. for 10 h, filter and wash with distilled water and methanol successively. Vacuum dried at 70°C for 5 h before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com