Control module, control method, brake vacuum servo device and electric automobile

A control module and electric vehicle technology, applied in the direction of brake transmission, brake, brake safety system, etc., can solve the problems of vacuum pump loss, high energy consumption, and safety hazards of the brake system, so as to reduce energy consumption and work time, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

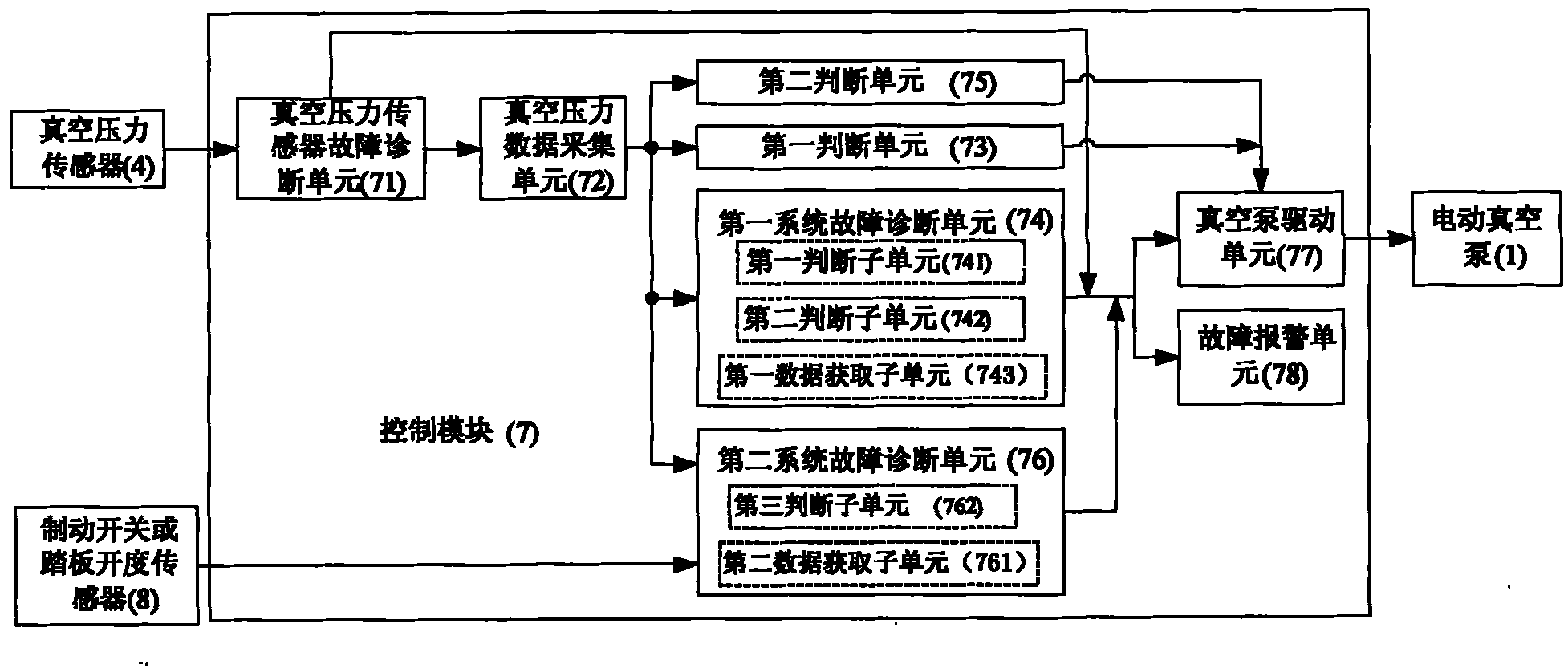

[0022] see Figure 1 ~ Figure 3 , a control module 7 of an electric vehicle brake vacuum booster, the control module 7 includes a vacuum pressure sensor fault diagnosis unit 71 and a vacuum pressure data acquisition unit 72, and the vacuum pressure data acquisition unit 72 is based on the collected vacuum pressure sensor 4 The output voltage value calculates the vacuum pressure value, and the vacuum pressure sensor fault diagnosis unit 71 is used to judge whether the vacuum pressure sensor 4 is faulty, if yes, control the vacuum pump 1 to work and give a fault alarm; if not, the control module 7 also Including a first judging unit 73, the first judging subunit 73 is used to judge whether the vacuum pressure value exceeds the first set value when the vacuum pressure sensor fault diagnosis unit 71 judges that the vacuum pressure sensor 4 is not faulty, and if so , to control the vacuum pump 1 to work, if not, the control module 7 also includes a first system fault diagnosis unit...

Embodiment 2

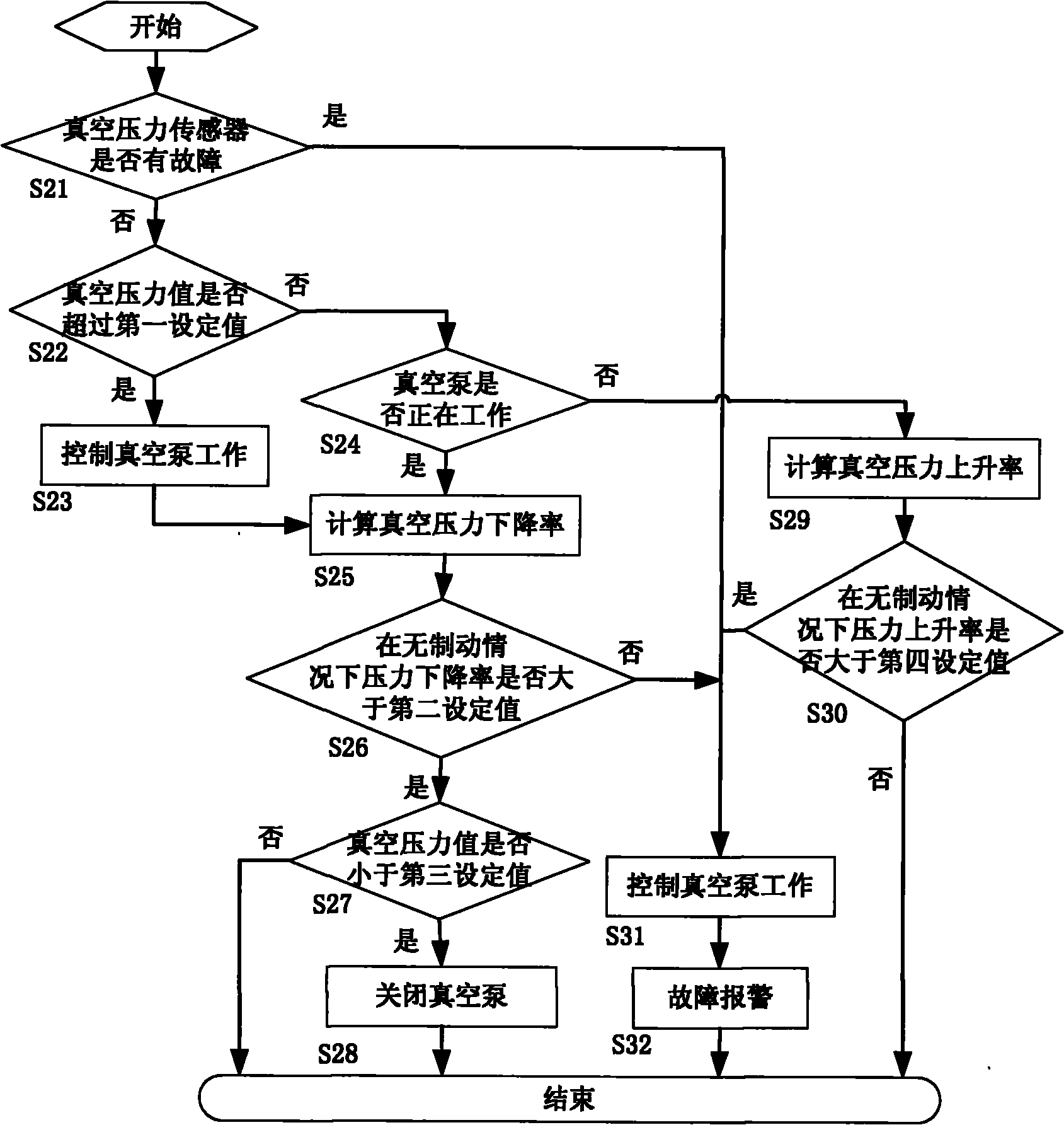

[0038] see Figure 1 ~ Figure 3 , an embodiment of the present invention provides a control method of a brake vacuum booster device for an electric vehicle, the control method comprising the following steps:

[0039] Step S21: Determine whether the vacuum pressure sensor 4 is faulty, if yes, execute step S31 and step S32: control the vacuum pump to work all the time and give a fault alarm; if not, execute step S22;

[0040] Step S22: Determine whether the vacuum pressure value exceeds the first set value, if yes, it indicates that the vacuum degree is insufficient at this time, and execute step S23; if not, execute step S24;

[0041] Step S23: Control the vacuum pump 1 to work;

[0042] Step S24: Determine whether the vacuum pump 1 is working, if yes (when the vacuum pump 1 is working), execute step S25, if not, execute step S29;

[0043] Step S25: Obtain the vacuum pressure drop rate;

[0044] Step S26: In the case of no braking, judge whether the vacuum pressure drop rate...

Embodiment 3

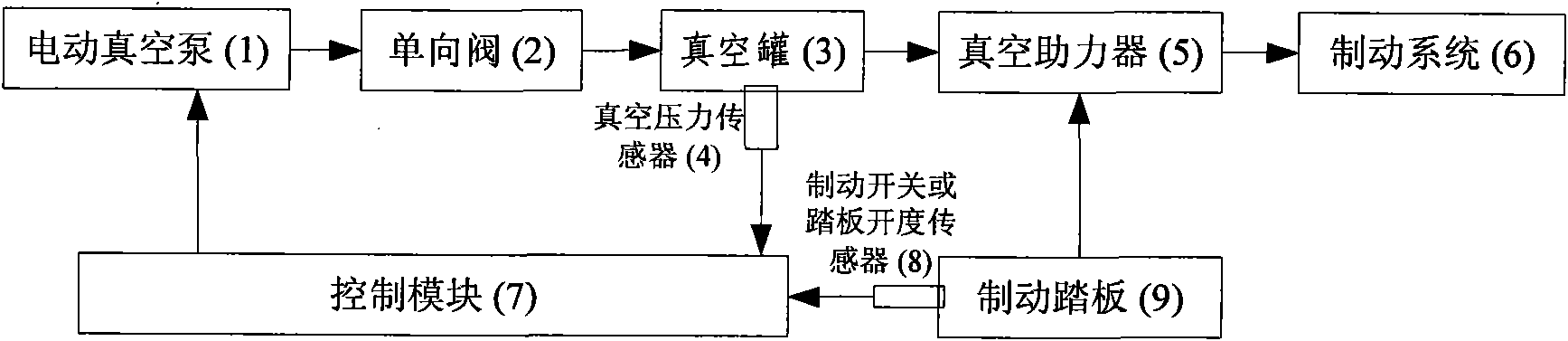

[0056] see Figure 1 ~ Figure 3 , a brake vacuum booster for an electric vehicle, comprising a vacuum booster 5, an electric vacuum pump 1, a vacuum tank 3, a vacuum pressure sensor 4 and a control module 7; the vacuum booster 5 is connected to a brake pedal 9 to provide boost for braking; the vacuum pump 1 communicate with the vacuum servo air chamber of the vacuum booster 5 through the vacuum tank 3, and are used to extract gas from the vacuum servo air chamber; the vacuum pressure sensor 4 is used to measure the air pressure in the vacuum tank 3, and the vacuum pressure sensor 4 and the control module 7 Electrical connection; the structure of the control module 7 is the same as that of Embodiment 1, and its control method is the same as that of Embodiment 2, and will not be repeated here. A brake switch or a pedal opening sensor 8 is provided on the brake pedal 9 for providing braking information to the control module 7 , and the vacuum booster 5 is connected to the brake s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com