Crane safety mechanism control system

A technology of safety mechanism and control system, applied in safety devices, load hanging components, transportation and packaging, etc., can solve the problems of unmoving the operating lever, high cost and high failure rate, and achieve sensitive action, easy operation and low cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

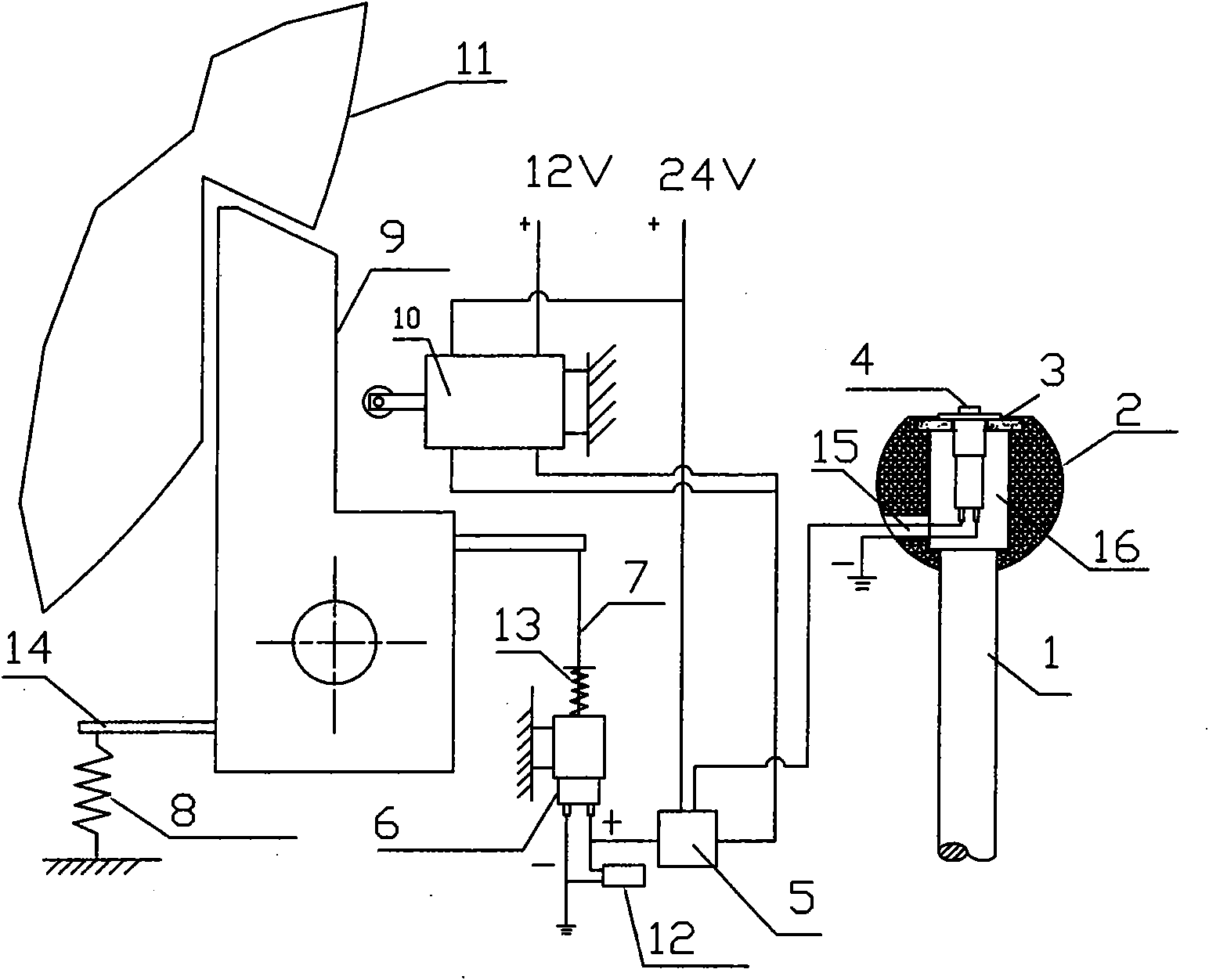

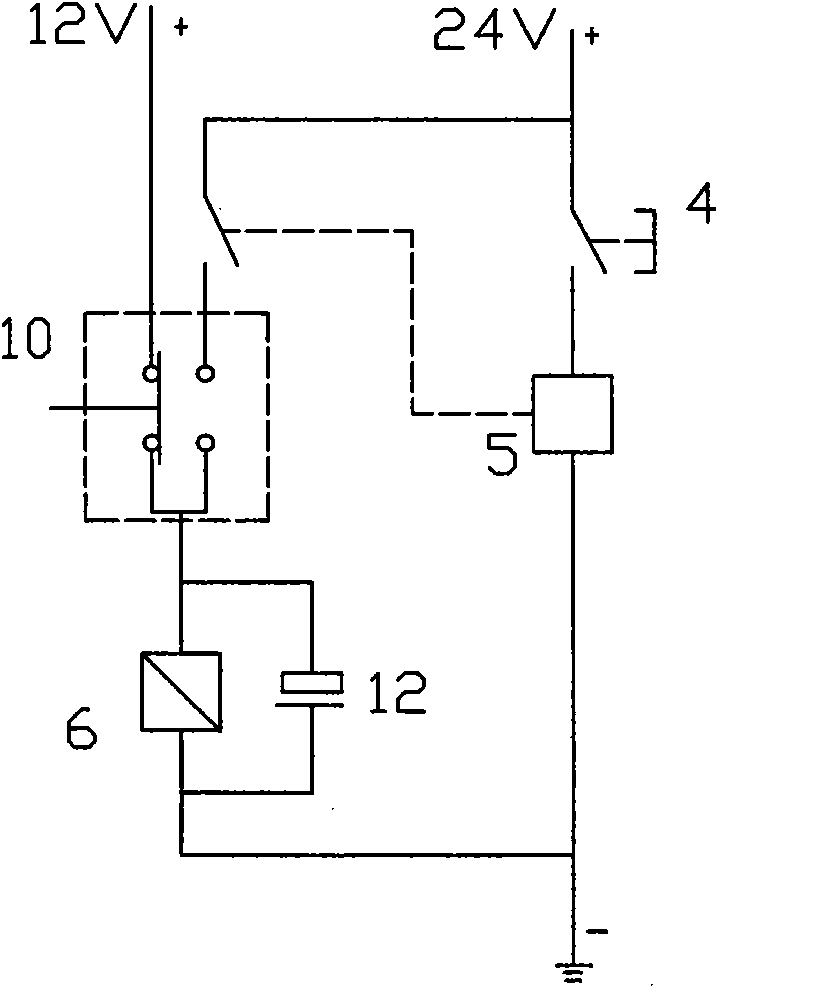

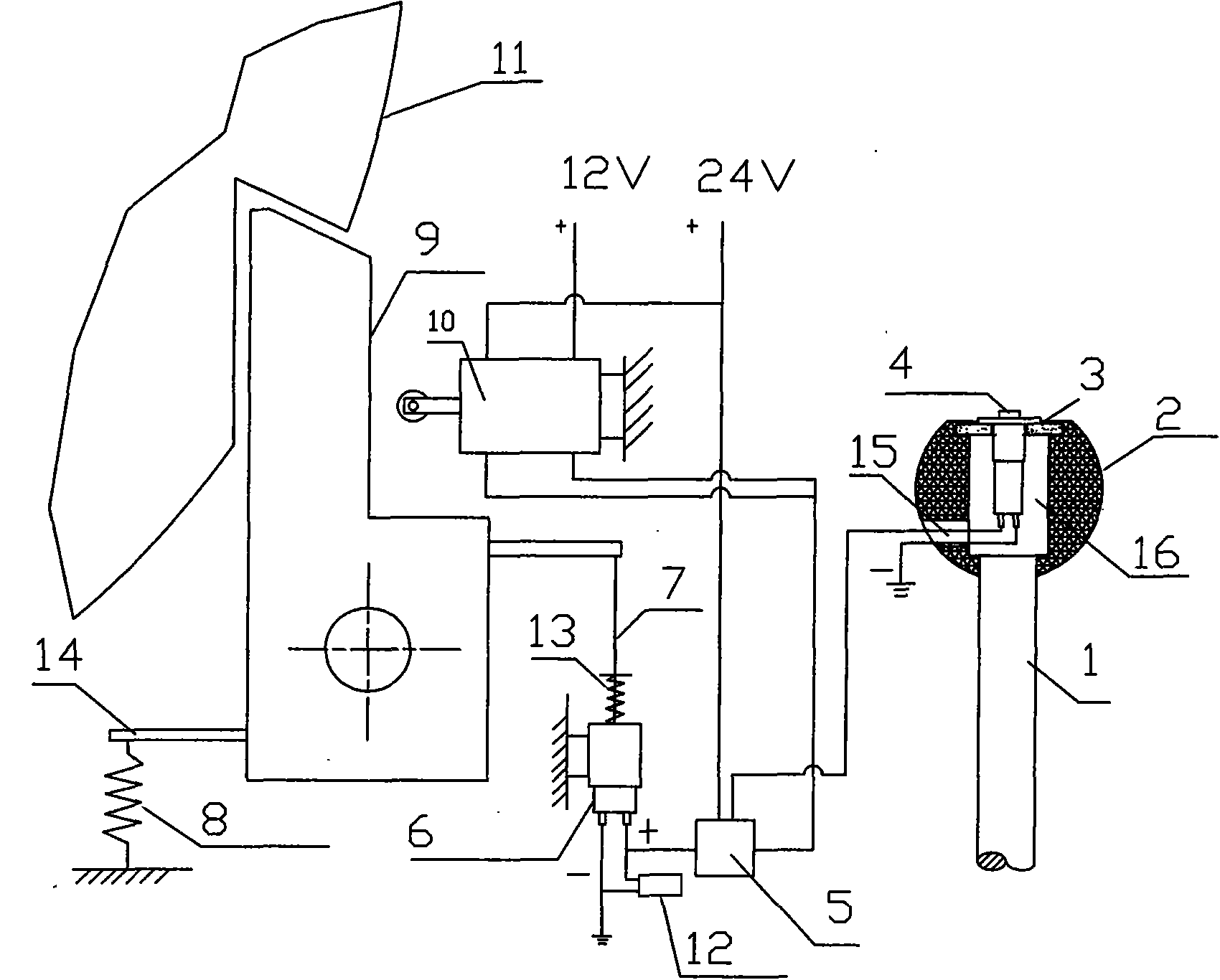

[0021] figure 1 It is a physical wiring diagram of an embodiment of the present invention, and this embodiment is a crawler crane. Unscrew the plastic ball head 2 on the top of the operating rod 1. The plastic ball head 2 includes a hollow abdominal cavity 16, which can accommodate a small button switch 4. Uncover the sealed aluminum plate 3 on the top of the ball head, and drill a small hole on the sealed aluminum plate 3. , Fix the button switch 4 on the aluminum plate. Then the button switch 4 lower half is contained in the hollow abdominal cavity 16, drills an aperture at the plastic ball head 2 side and communicates with the ball head abdominal cavity as the lead-out line passage 15. One contact of the push button switch 4 is connected with the lead wire of the push button switch, and the other contact is grounded. Re-fix the sealing aluminum plate 3 on the plastic ball head 2 with glue.

[0022] A fixed point is welded on the crane structure below the pawl 9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com