Method for separating narrow cut fraction industrial grade n-hexane from C5 to C7 light hydrocarbon mixture, as well as packed towel and float valve tower thereof

A mixture, n-hexane technology, applied in fractional distillation, hydrocarbon distillation, petroleum industry and other directions, can solve problems such as complex process, and achieve the effects of increasing economic benefits, reducing width and reducing benzene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

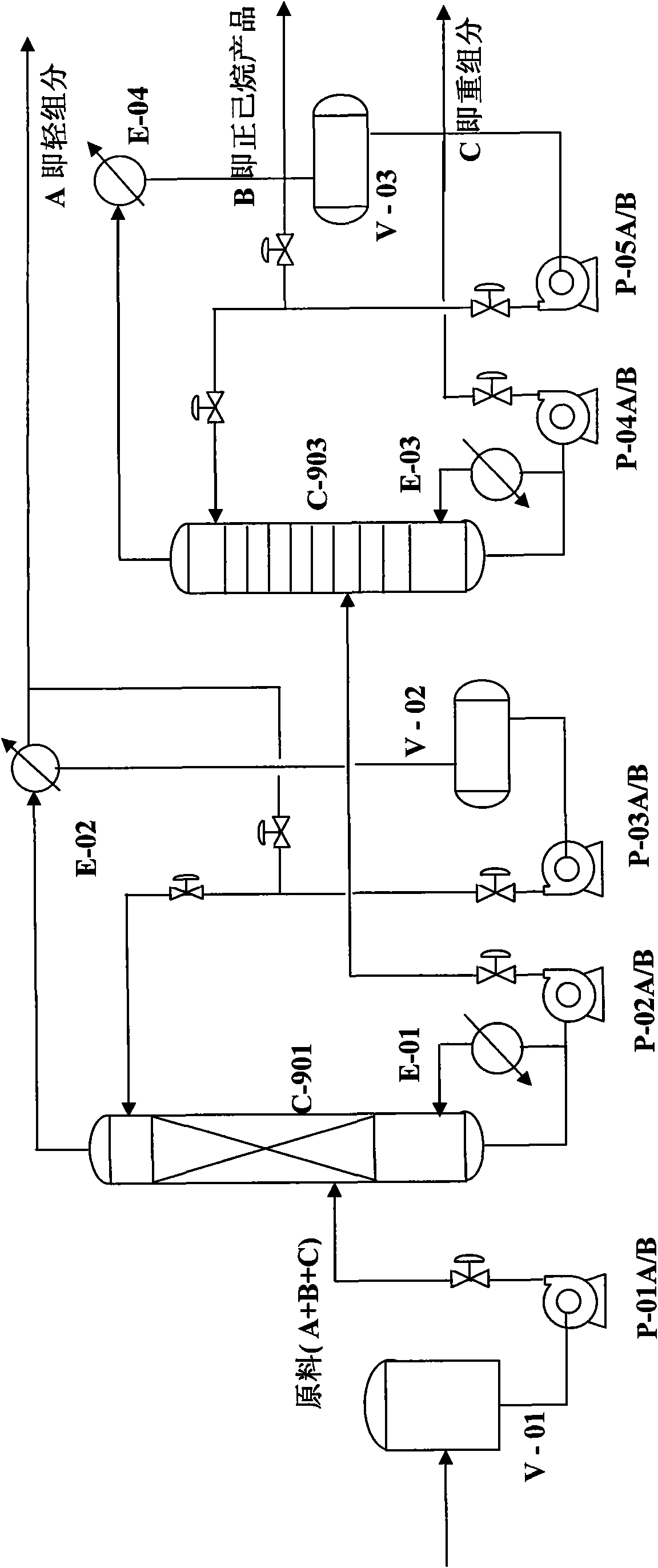

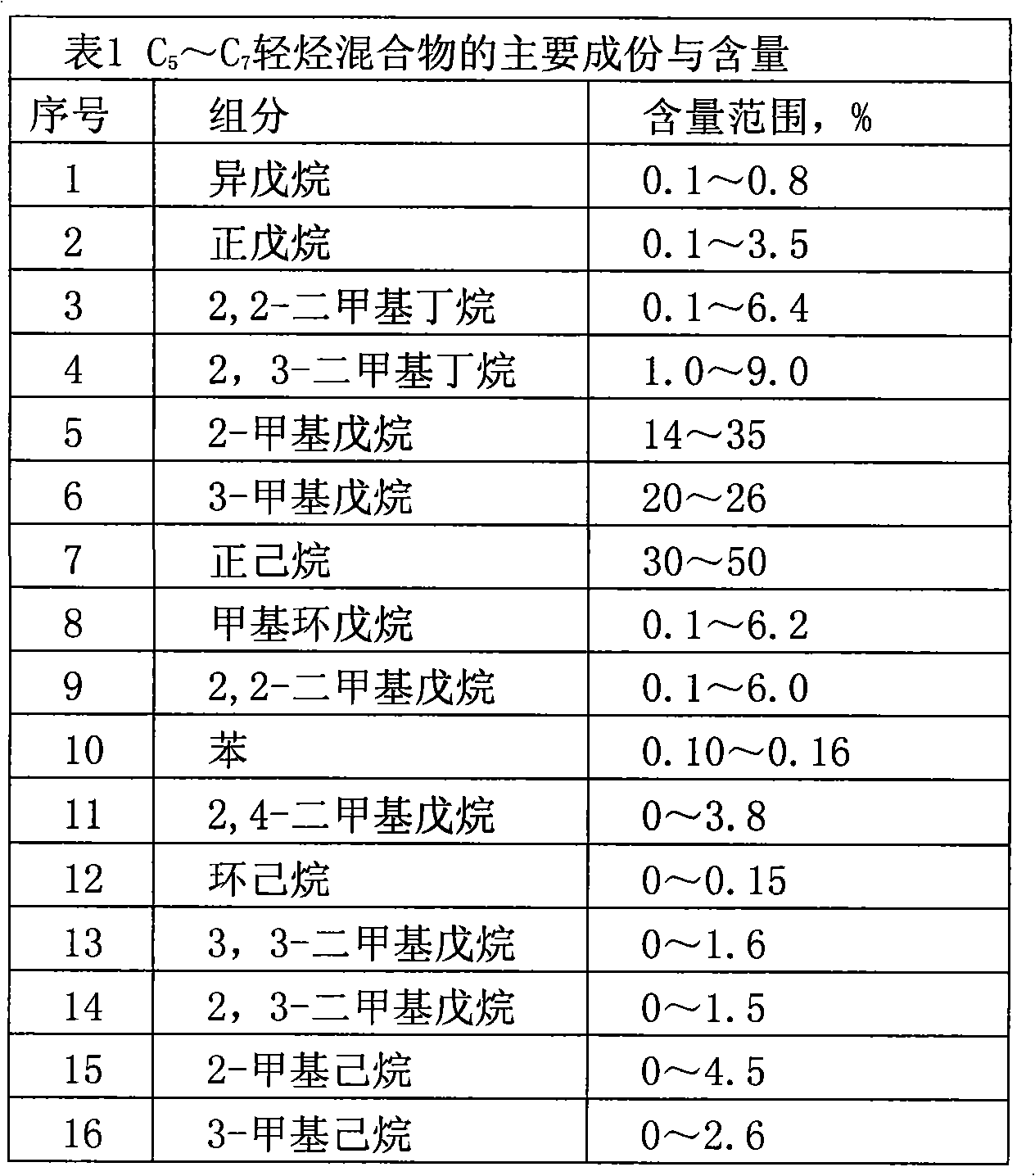

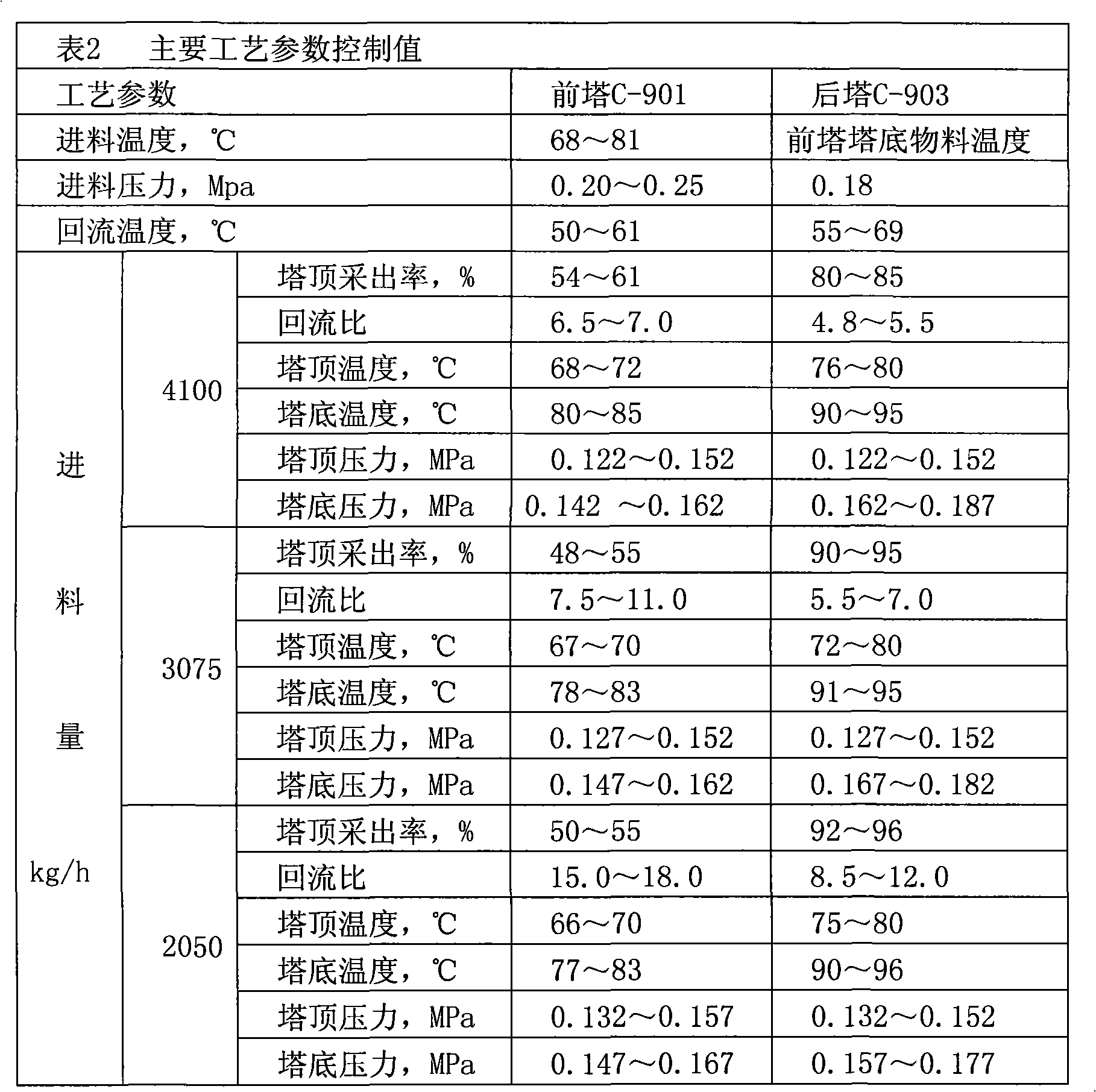

[0024] as attached figure 1 shown, the slave C 5 to C 7 The method for separating narrow cut technical grade n-hexane in light hydrocarbon mixture is characterized in that it is carried out according to the following steps: raw material C 5 to C 7 The light hydrocarbon mixture enters the corrugated structured packing tower from the middle for rectification, the light components are separated from the top of the corrugated structured packing tower, and the middle and heavy components are separated from the bottom of the corrugated structured packing tower; separated from the bottom of the corrugated structured packing tower The intermediate components and heavy components enter the valve tower from the middle for rectification. The intermediate components, namely n-hexane components, are separated from the top of the valve tower, and the heavy components are separated from the top of the valve tower. The n-hexane separated from the top of the float valve tower is first cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com