Low-carbon equivalent weight high-strength thick steel plate with excellent low-temperature toughness and manufacture method

A technology of low temperature toughness and manufacturing method, applied in the field of metallurgy, can solve the problems of increasing alloy resource consumption and production cost, increasing energy consumption and production cost, low temperature impact toughness and welding performance deterioration, etc. Low carbon equivalent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

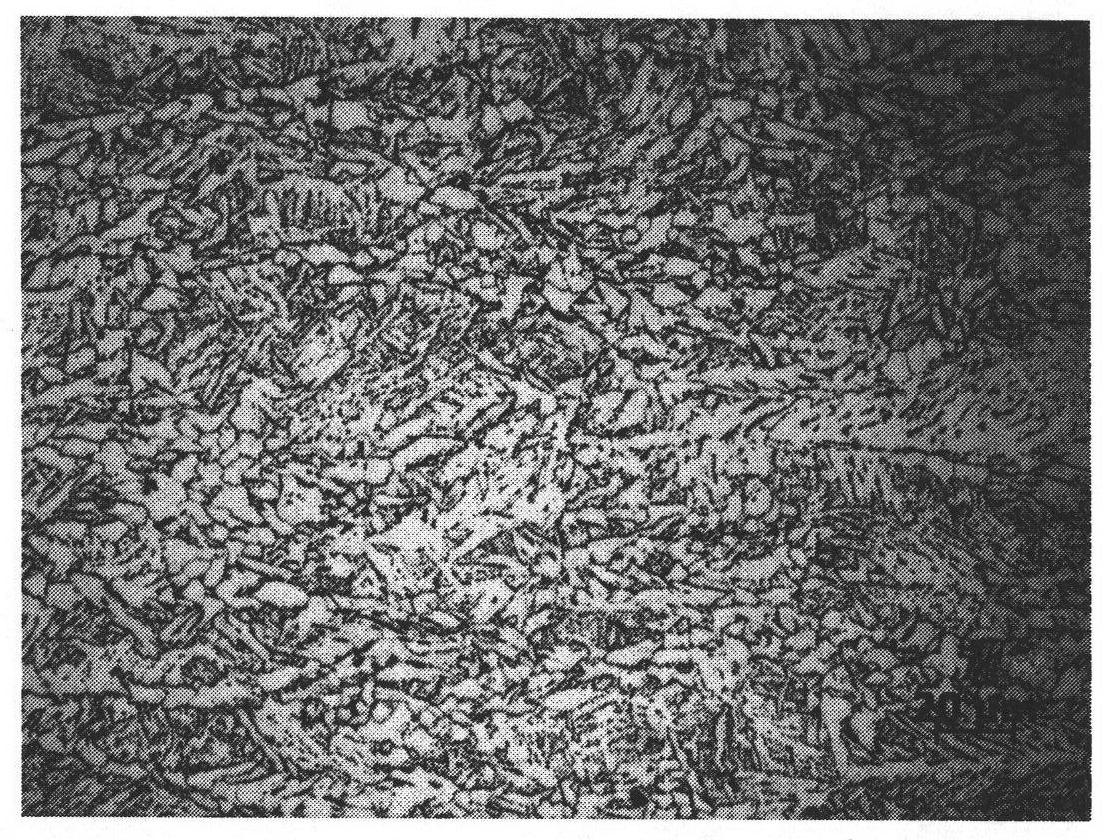

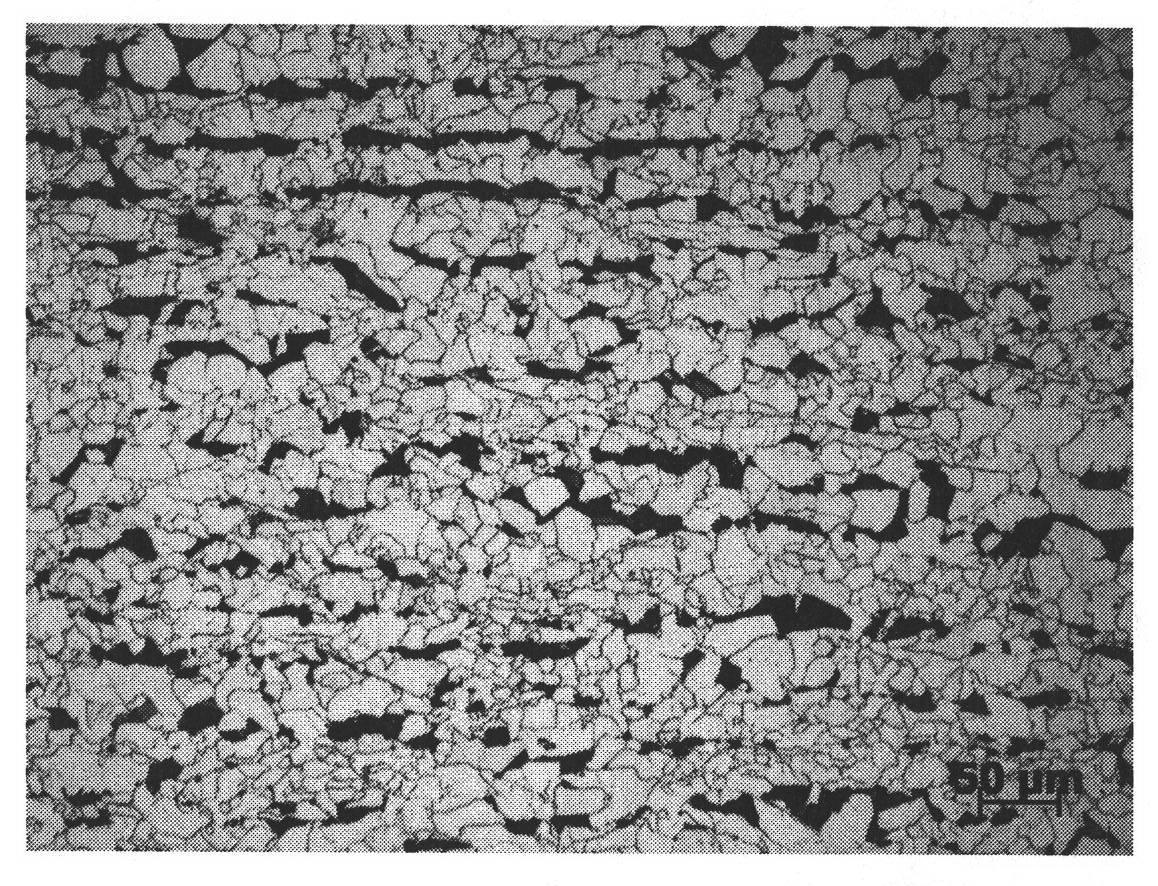

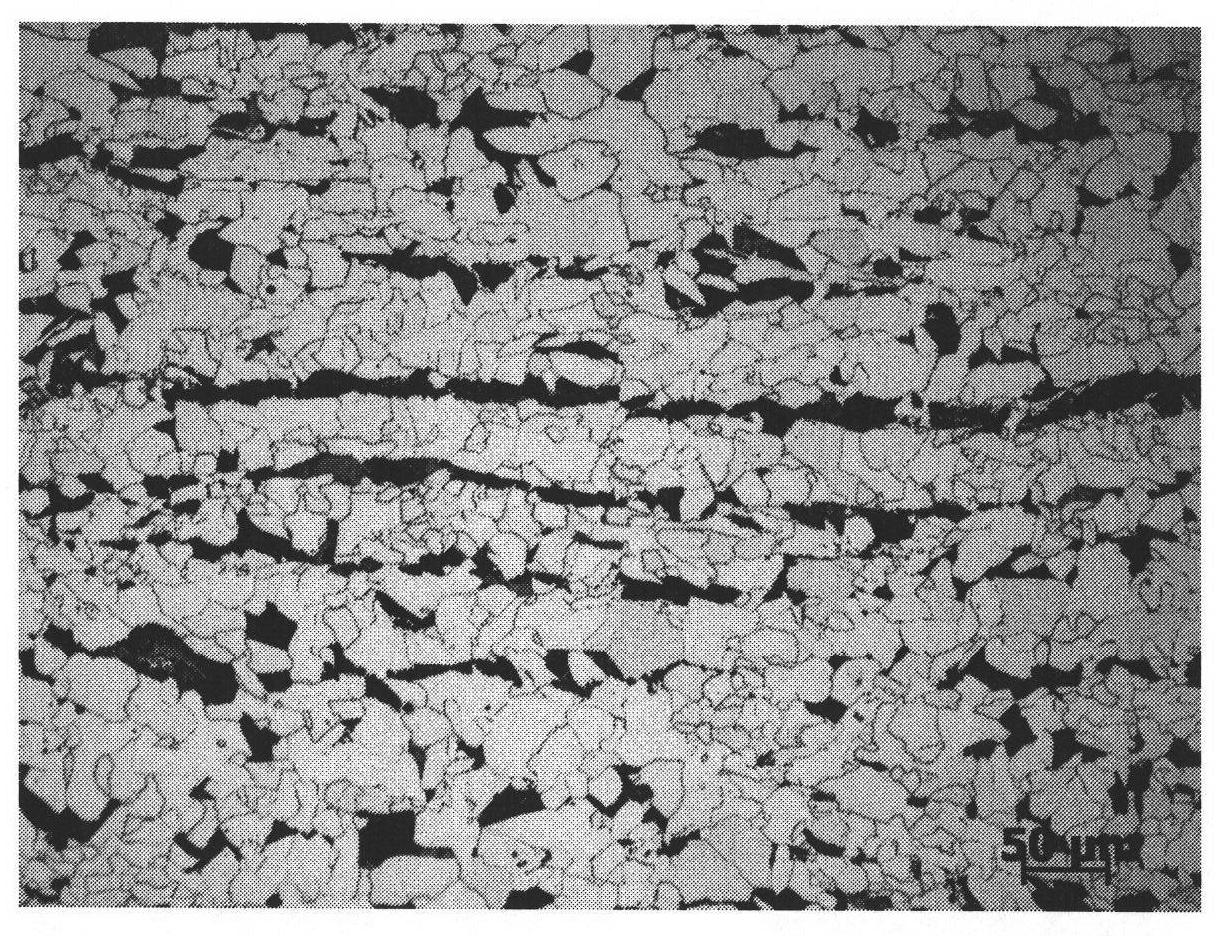

Image

Examples

Embodiment Construction

[0029] A low-carbon-equivalent high-strength thick steel plate with excellent low-temperature toughness and a manufacturing method thereof according to the present invention will be further described in detail below in conjunction with specific examples.

[0030] According to the method of the present invention, 6 heats of test steels were trial-manufactured, as an embodiment. The process flow is: converter smelting→LF refining→RH vacuum treatment→billet continuous casting→slab acceptance→surface cleaning→slab heating→high pressure water descaling→rough mill rolling→intermediate billet waiting for temperature→finish rolling mill→ACC→straightening Straightening→off-line at high temperature and slow cooling→flaw detection→inspection→storage.

[0031] The thickness of the continuous casting billet is 260 mm, and the chemical composition of the billet is shown in Table 1.

[0032] The chemical composition (wt %) of the embodiment of the present invention of table 1

[0033] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Charpy impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com