Steel-concrete joint section structure of beams

A concrete bonding and concrete technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of poor fatigue resistance, difficult construction operation, complex processing and manufacturing, etc., to achieve high torsional and bending stiffness, clear and reasonable force , the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

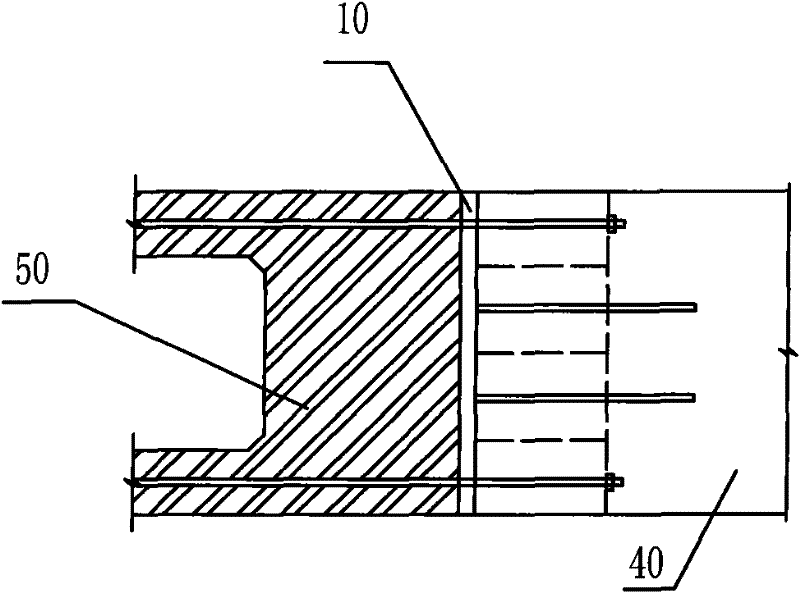

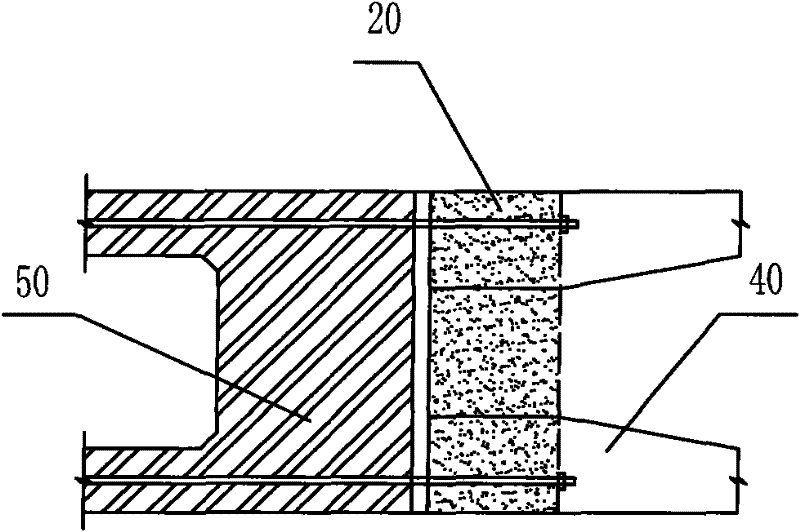

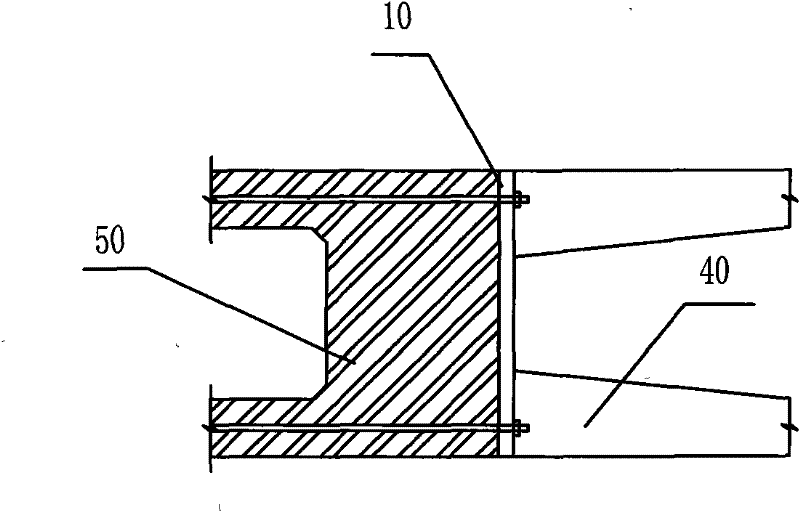

[0036] Such as figure 2 As shown, the structure of the steel-concrete bonded section of the beam of the present invention includes a steel beam 1 and a concrete beam 2, and a pressure bearing plate 3 is arranged at the junction of the steel beam 1 and the concrete beam 2, and the steel beam 1 It includes a steel beam top plate 11, a steel beam bottom plate 12 and a steel beam web 13; the concrete beam 2 includes a concrete web 21; the section profile of the steel beam 1 is consistent with the section profile of the concrete beam 2, The steel beam 1 is overlaid on the concrete beam 2, thereby forming a transition section 4 from the concrete beam to the steel beam, and the steel beam web 13 in the transition section 4 is inserted into the concrete beam web 21 to form a steel-concrete The combined section of , such as image 3 As shown; between the steel beam top plate 11 and the steel beam bottom plate 12 in the transition section 4, there are upper and lower closed compartmen...

Embodiment 2

[0039] In the second embodiment, on the basis of the first embodiment above, the position of the transverse partition of the compartment is improved, that is, as Figure 6 As shown, in the second embodiment, the slope of the transverse partition 14 of the compartment 15 between the steel beam top plate 11 and the steel beam bottom plate 12 in the transition section 4 is 1:8˜1:15. Such as image 3 , Figure 4 and Figure 5 As shown, the structures of other parts in the second embodiment are the same as those in the first embodiment, and will not be repeated here.

[0040] In summary, the structure of the steel-concrete joint section of the beam of the present invention is compared with the prior art. The end bearing plate 3 adopts a 60mm thick integral steel plate that completely matches the cross section of the steel beam, which has high rigidity and small deformation. It can effectively ensure the uniform transmission of axial force and the anchoring requirements of prestr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com