Reinforced structure for foundation with wide defect and construction method thereof

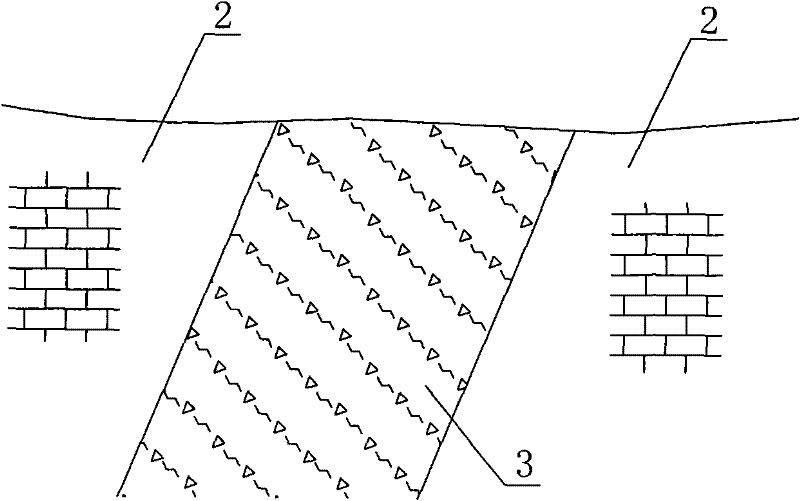

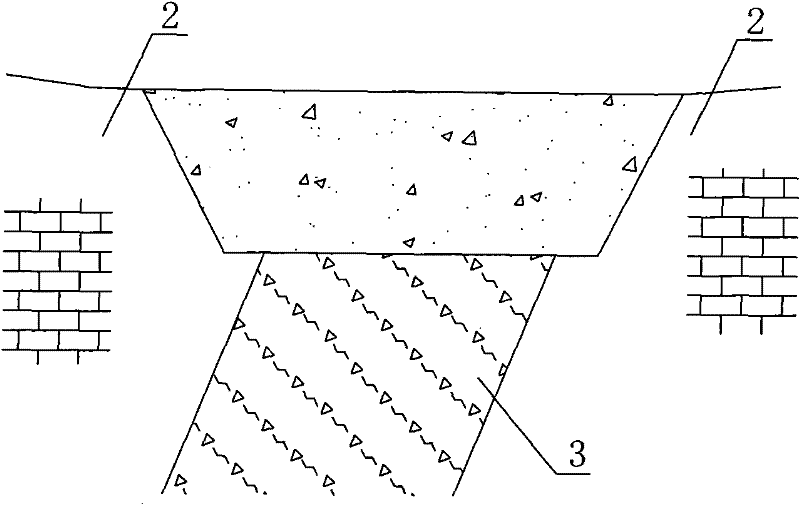

A construction method and foundation reinforcement technology, which is applied to the reinforcement structure and construction field of wide defect foundations, can solve the problems of increasing engineering excavation processing volume, construction complexity and construction period, increased volume of foundation cast-in-place, and poor scheme economy, etc. problems, to achieve the effect of reducing the difficulty of foundation treatment, reducing the difficulty of construction, and reliable structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

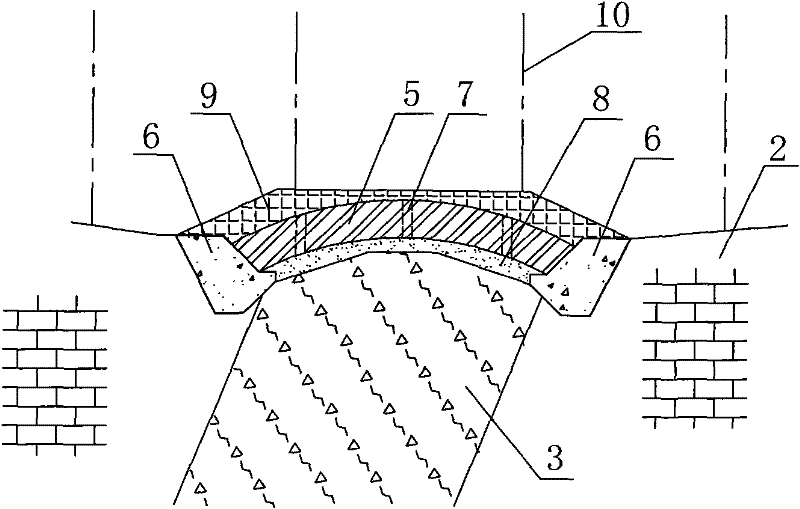

[0023] Such as image 3 As shown, in this embodiment, a vertical arch bearing body 5 is arranged above the wider crushing zone 3, and the two ends of the bearing body respectively pass through two abutments 6 (the two abutments are arranged in parallel lines or in sections along their longitudinal direction). are parallel lines) are set on the stable bedrock 2, and the load from the upper part is transmitted to the stable bedrock 2 at both ends, without using geological defects to bear the load. Small, the spanable width is larger, and the basic structure is smaller. The plate beam structure is the main structure, which simplifies the temperature control requirements and is not easy to crack.

[0024] A set of grouting holes 7 is reserved on the carrier 5 . If the anti-seepage curtain line needs to pass through, the curtain grouting can be carried out through the grouting hole 7, and the reinforcement grouting treatment of the geological defect body can also be carried out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com