Fireproof building material for steel structure buildings

A technology for steel structures and building materials, applied in fire protection, construction, building components, etc., can solve the problems of difficult effective control of coating thickness, poor decoration of steel structure surface, easy damage of fireproof coating, etc., and achieve simple, fast and flexible construction , good decoration, easy repair and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

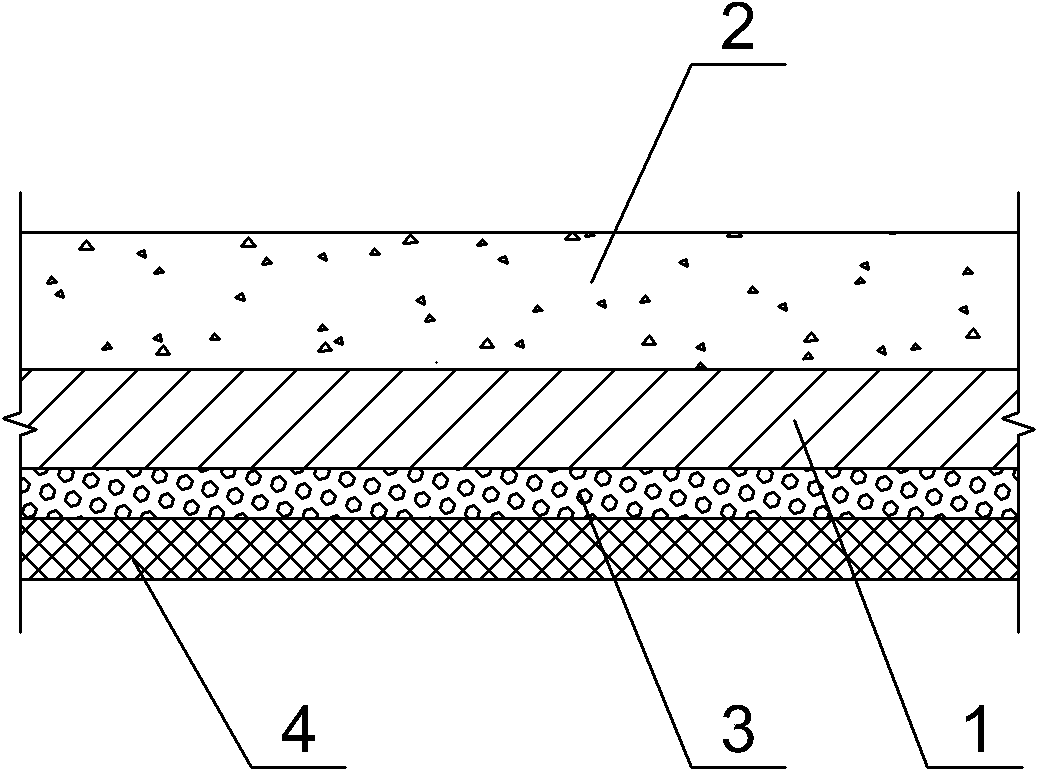

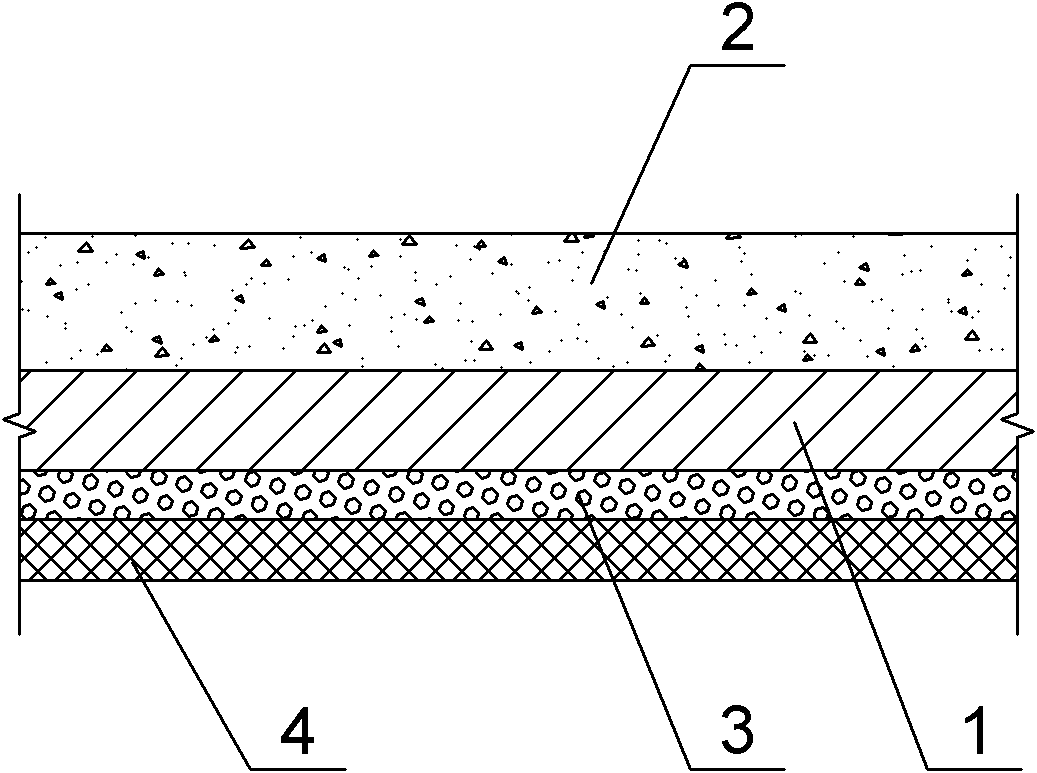

[0014] like figure 1 As shown, the fireproof building material used for steel structure buildings in this embodiment is a fireproof coiled material, and the fireproof building material is made into a coiled material, which is conducive to transportation and storage, saves space, and is convenient to use. The use of this embodiment The cross-sectional structure of the fireproof building material for steel structure buildings includes a fireproof base material 1, the upper surface of the fireproof base material 1 is coated with a fireproof paint layer 2, and the lower surface of the fireproof base material 1 is provided with an adhesive layer 3, so The bottom surface of the adhesive layer 3 is covered with a protective layer 4, the fire-resistant base material 1 adopts flame-retardant paper or flame-retardant felt, the fire-resistant coating layer 2 adopts nano-scale fire-resistant coating, and a colorant is added in the fire-resistant coating layer 2 , is conducive to improving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com