Concrete-structured conjoined cylindrical shell construction device and method therefor

A technology for concrete structures and construction devices, which is applied in building construction, formwork/formwork/work frame, large-capacity bulk material storage, etc. High problems, to achieve the effect of reducing construction cost, convenient installation and dismantling, and reasonable and reliable use structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

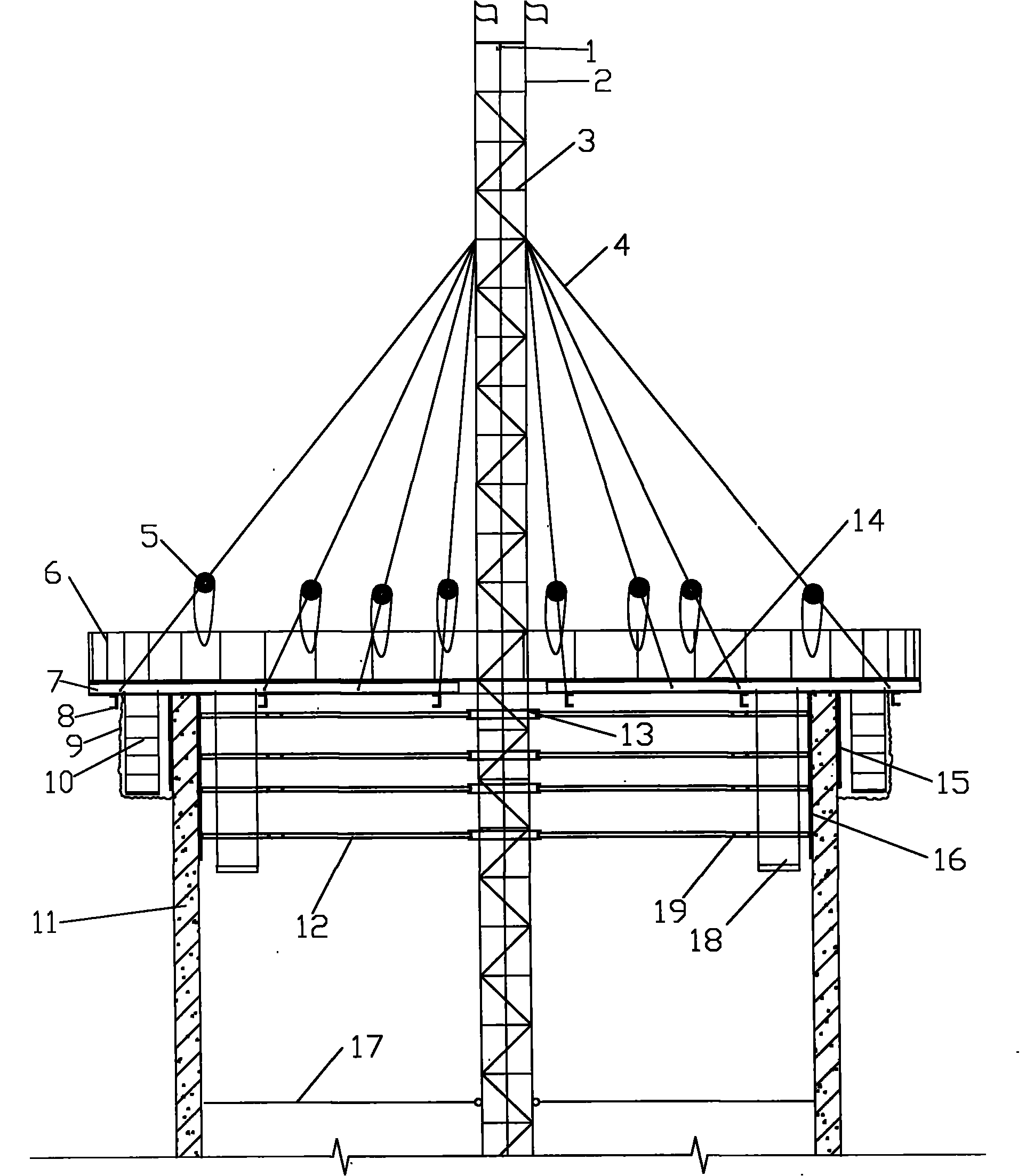

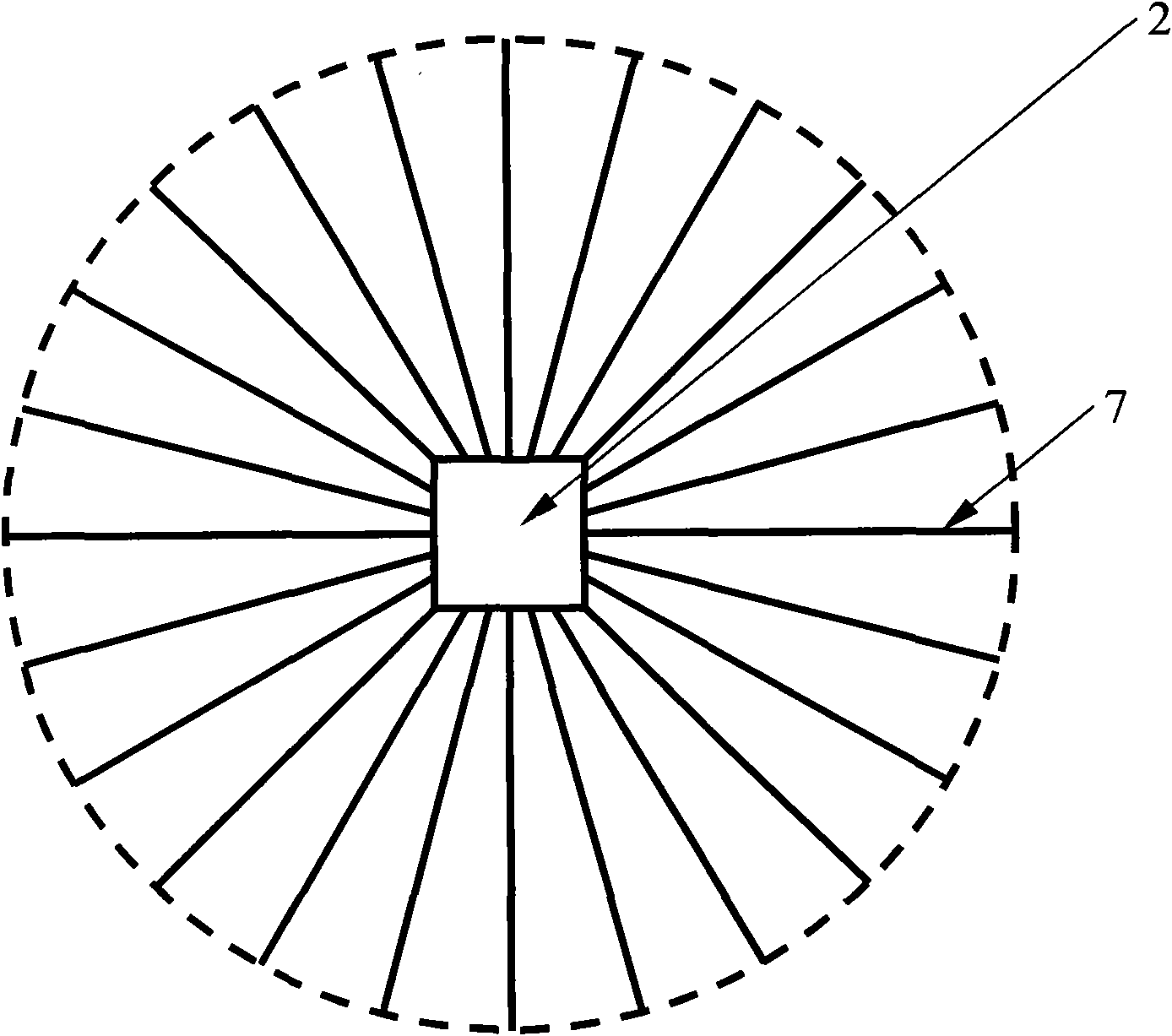

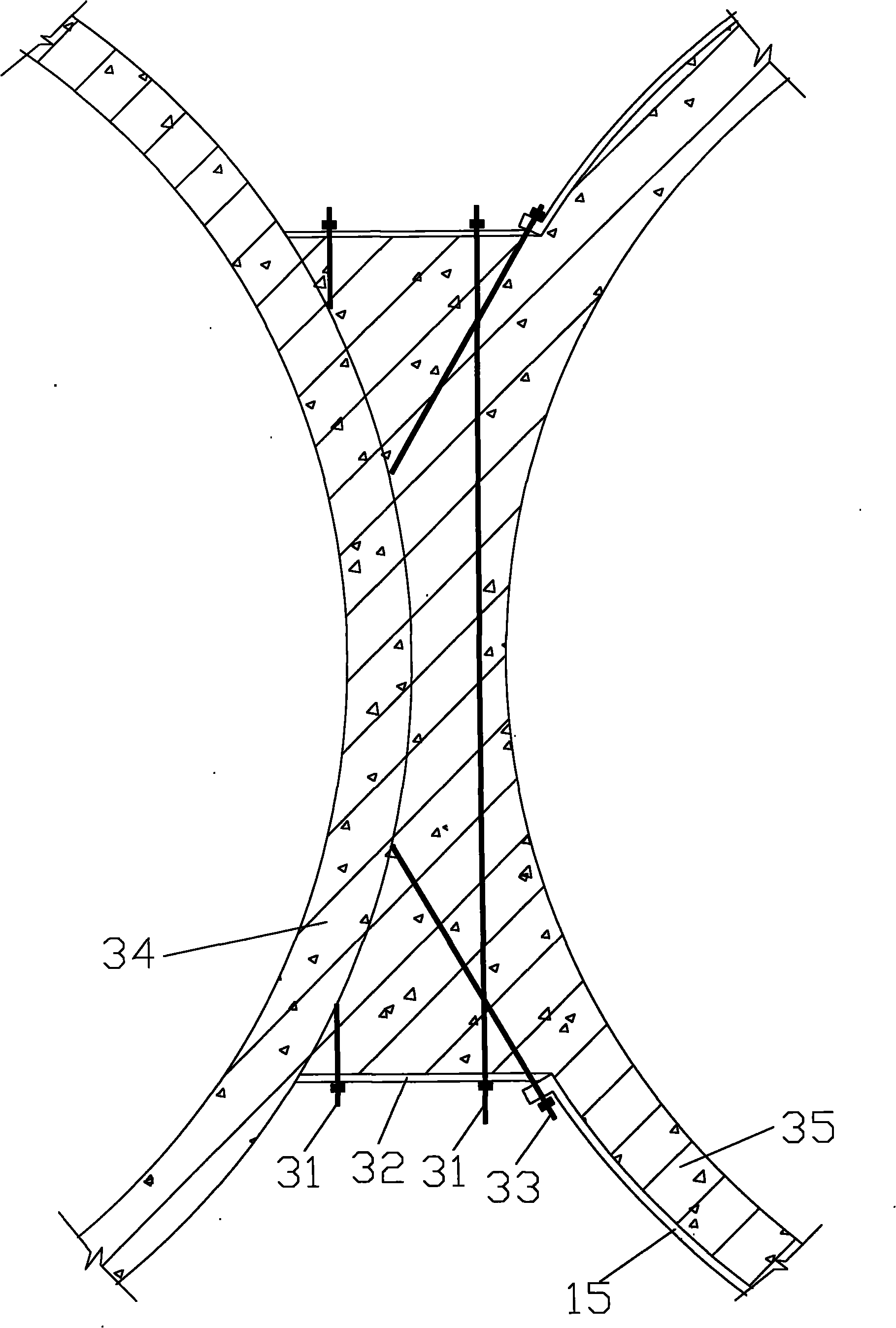

[0035] A concrete structure conjoined barrel construction device, including pulley 1, shaft frame 2, reinforcement hoop 3, steel wire rope 4, chain hoist 5, railing 6, radiation beam 7, platform ring beam 8, safety net 9, and outer hanger 10. Inner formwork strut 12, strut fulcrum ring center line frame 13, operating platform 14, outer formwork 15, inner formwork 16, rigid coupling axis 17, inner hanger 18 and adjusting screw 19, such as figure 1As shown, the specific structure is: the vertical derrick 2 is a 1200×1200 single-hole derrick, the vertical derrick 2 is constructed by vertical rods, horizontal rods and inclined rods, the vertical rods are perpendicular to the ground, the horizontal rods are perpendicular to the vertical rods and are connected with the vertical rods The phase is fixedly connected, the oblique rod is connected to the intersection of the vertical rod and the horizontal rod in turn, the vertical rod, horizontal rod and oblique rod are made of ∠75×8 angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com