Method for well drilling and cementing of radial horizontal well with ultra-short radius and equipment thereof

A technology for ultra-short radius and horizontal wells, applied in drilling equipment, directional drilling, drilling equipment and methods, etc., can solve the problem that flexible drill pipes cannot go down well smoothly, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

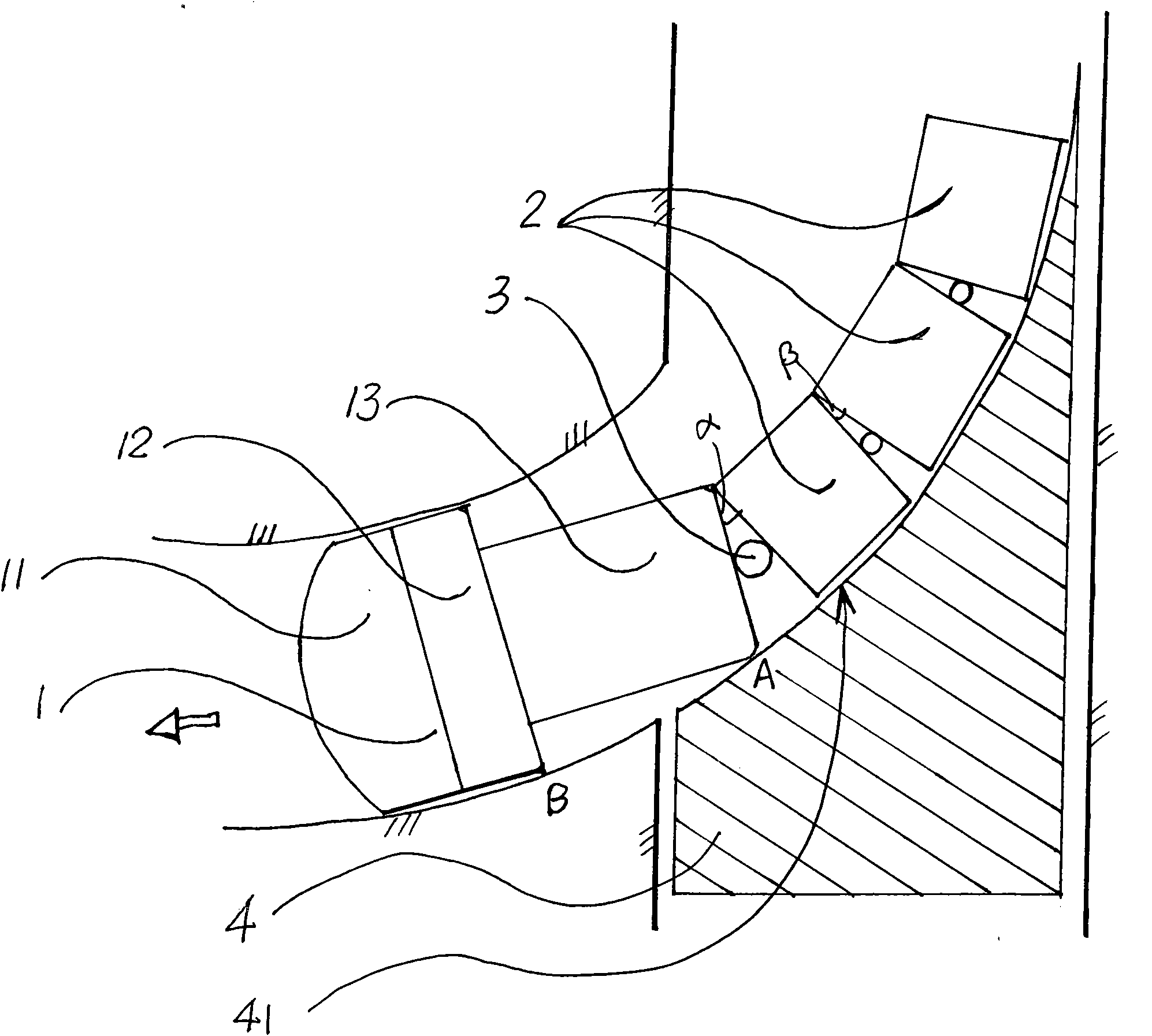

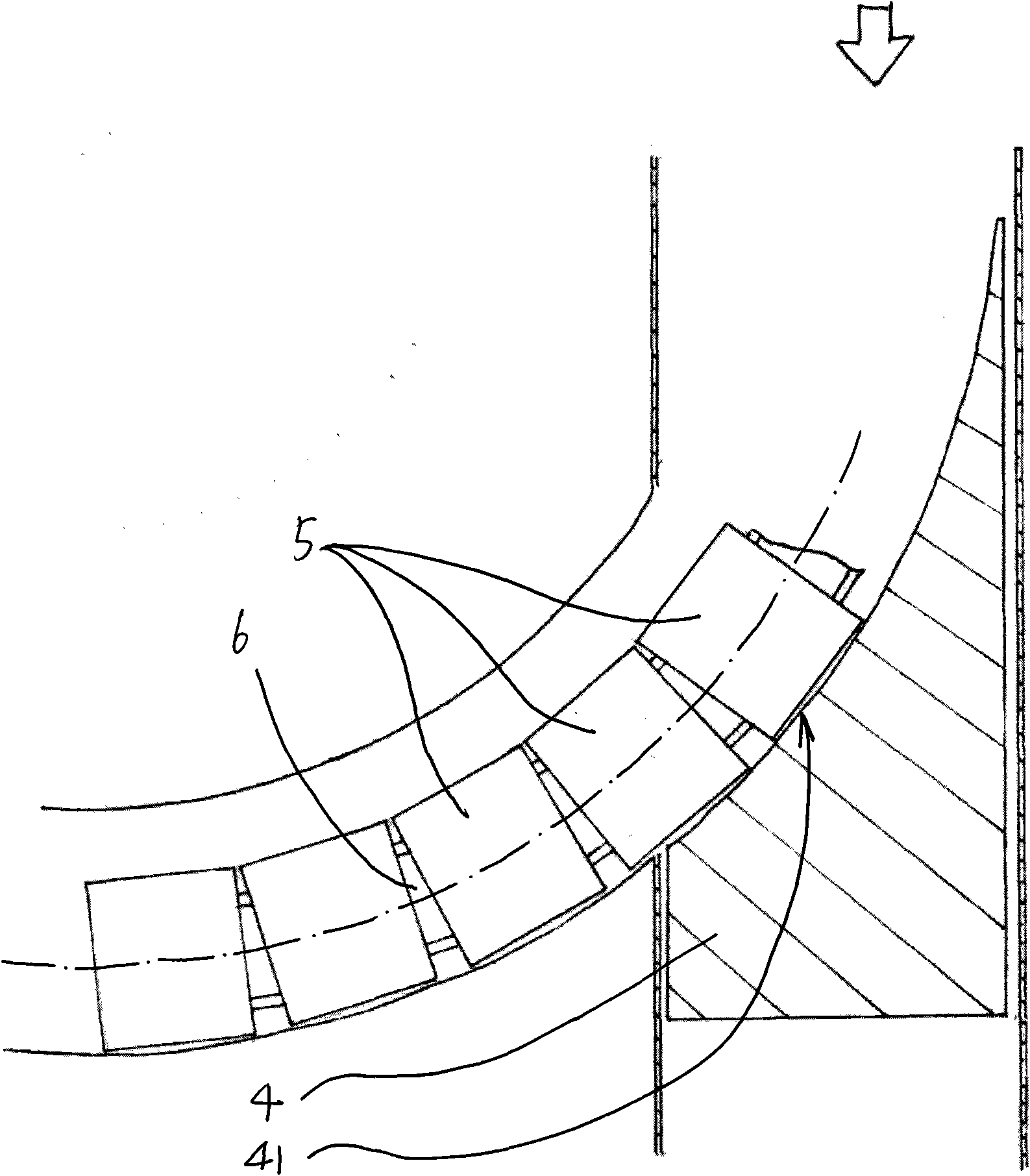

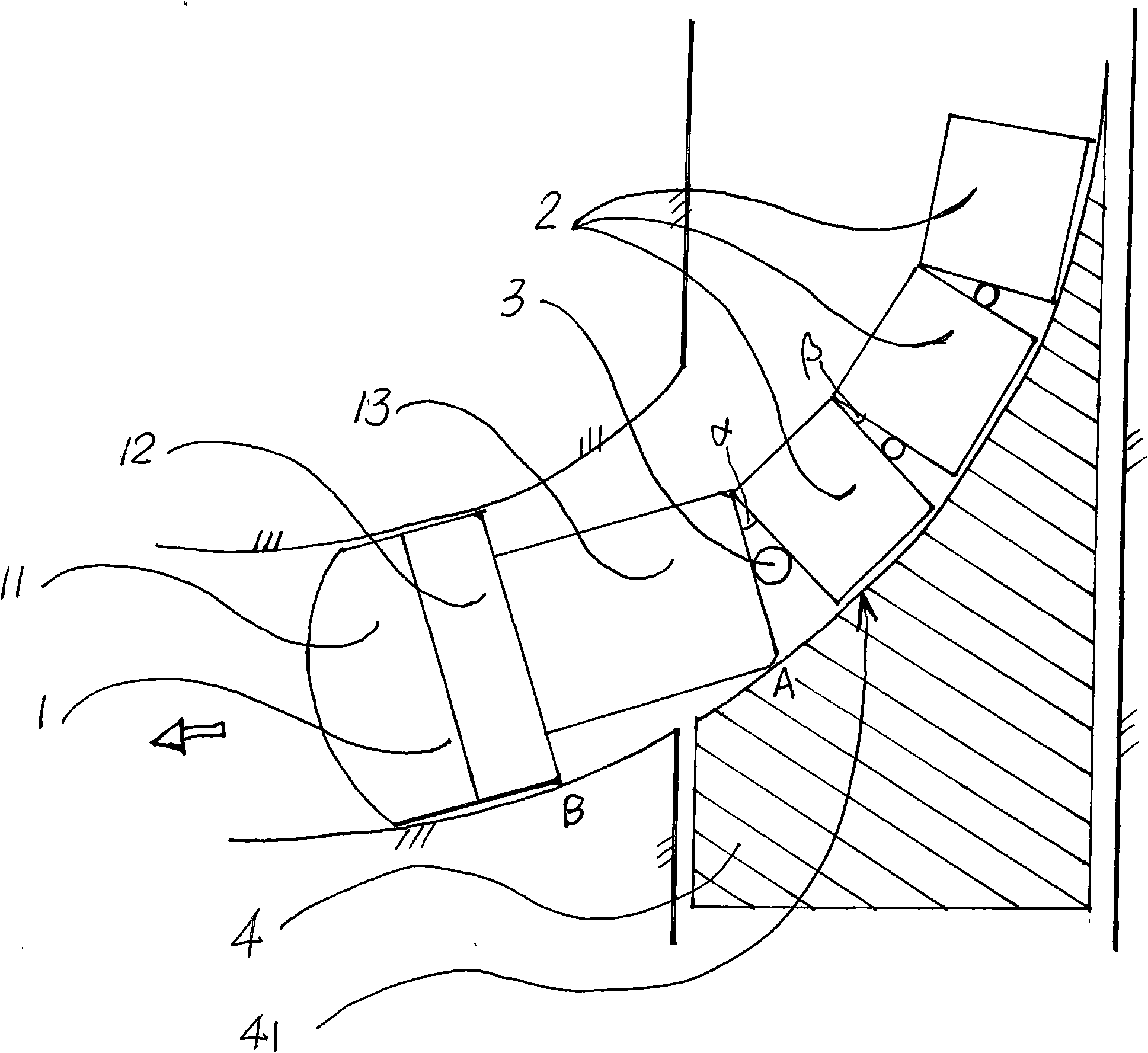

[0051] see figure 1 It is the structure schematic diagram and the figure 2 As shown in the schematic diagram of the structure of the cementing equipment of the present invention in the well, it is a drilling and cementing equipment for ultra-short radius radial horizontal wells. Device 4, the cementing equipment is several sections of flexible casing 5, wherein:

[0052] In the drilling equipment, two adjacent sections of flexible drill pipes 2 are movably connected through universal joints 3, and the deflection-increasing drill bit 1 and the first section of flexible drill pipes 2 are movably connected through universal joints; The device 4 is arranged in the vertical shaft, and the upper surface is a guiding arc 41 obliquely downward.

[0053] The inclination-increasing drill bit 1 is divided into a drill bit crown 11, a gauge body 12 and a drill bit body 13, the front end surface of the drill bit crown 11 has a taper, the gauge body 12 and the drill bit body 13 are cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com