Method for measuring volatile substance release in interior wall coating

A technology for interior wall coatings and a measurement method, which is applied to the measurement of the release of volatile harmful substances in interior wall coatings, and the measurement of the release concentration of volatile organic compounds and formaldehyde in interior wall coatings, can solve problems such as damage to indoor air quality, etc. Achieving the effect of convenient indoor air pollution situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

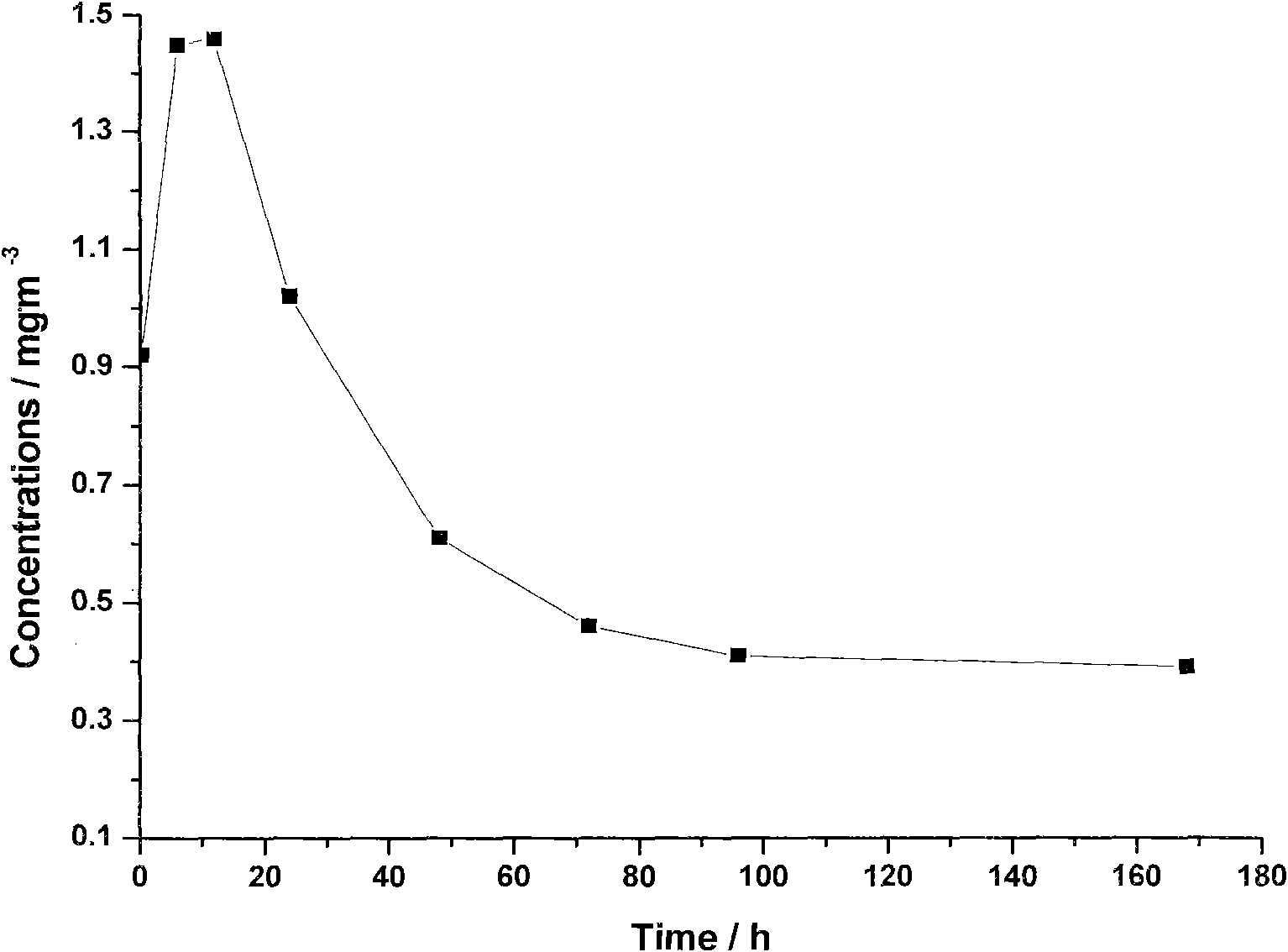

[0017] The interior of the environmental test chamber is cleaned with an alkaline cleaner, and room air is fed into the chamber for 24 hours. The background concentration of VOCs in the cabin is 0.032~0.038mg / m 3 , Inside the cabin in the paint test: (23±1)°C, relative humidity RH is (45±5)%, air exchange frequency is 1 time / h, and the area painted by the paint in each cubic meter of space is 1m 2 / m 3 .

[0018] Select inert flat glass as the substrate material for paint painting, and measure interior wall paint sample 1 according to the instructions on the amount of paint used in the interior wall paint (wherein the total amount of volatile organic compounds VOC is 183.72g L -1 ), evenly coated on both sides in two times, and immediately placed in the environmental test chamber, using thermal desorption gas chromatography to track and monitor the VOCs release characteristics of interior wall coatings. The determination method is to load an appropriate amount of adsorbent ...

Embodiment 2

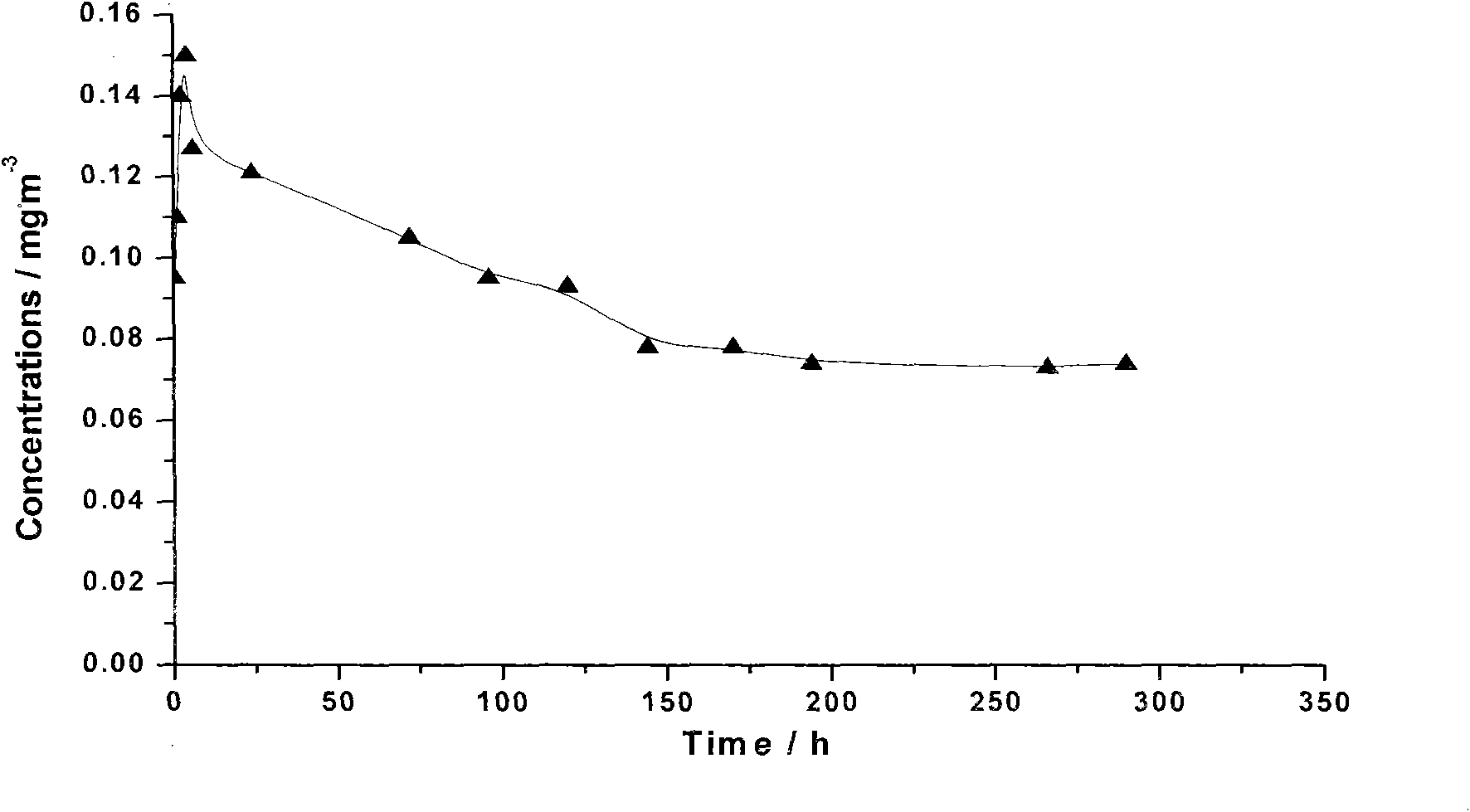

[0020] The interior of the environmental test chamber is cleaned with an alkaline cleaner, and room air is fed into the chamber for 24 hours. The background concentration of formaldehyde in the cabin is 0.029~0.033mg / m 3 , Inside the cabin in the paint test: (23±1)°C, relative humidity RH is (45±5)%, air exchange frequency is 1 time / h, and the area painted by the paint in each cubic meter of space is 1m 2 / m 3 .

[0021] Select inert flat glass as the substrate material for paint painting, and measure interior wall paint sample 2 according to the instructions on the amount of paint used in the interior wall paint (the total content of free formaldehyde is 0.021g kg -1 ), spread it evenly on both sides in two times, and immediately put it in the environmental test chamber, and use the phenol reagent method to measure the formaldehyde release concentration in the sample air. It is oxidized by ferric ions in acidic solution to form a blue-green compound. According to the depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com