Industrial frequency resonance transformer

A resonant transformer and transformer technology, applied in the direction of transformers, inductors, electrical components, etc., can solve the problems of high-power variable frequency power supply resonant transformer total cost increase, test frequency deviation from power frequency, test equivalence deterioration, etc., to achieve weight Lightweight, compact and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

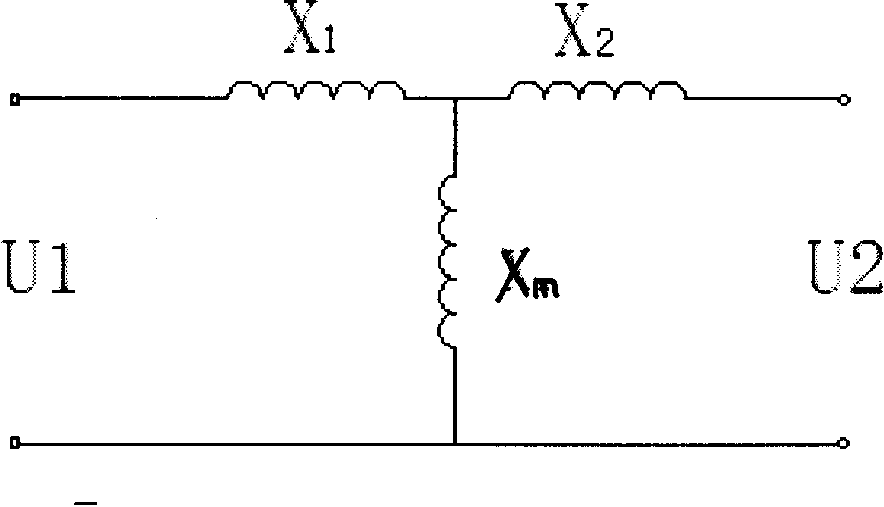

[0048] Embodiment 1, in order to realize the mixed AC and DC magnetization of the iron core, the resonant transformer of the present invention includes two identical excitable transformers T1, a rectifier Z connected thereto, an isolation transformer T2 and a controller, and the isolation transformer T2 enables excitation The transformer T1 and the controller realize high-potential isolation, and the controller adjusts the AC excitation impedance of the excitable transformer and the test object through DC bias after detecting the collection current on the primary and secondary sides of the isolation transformer T2 and the output current of the rectifier. The impedance forms a resonance. In this embodiment, current collection is realized through a current transformer CT.

[0049] Figure 4 It is the implementation schematic diagram of a resonant transformer with independent excitation windings. The input and output AC windings of the two transformers T1 are connected in parall...

Embodiment 2

[0050] Embodiment two, Figure 5 It is an implementation scheme of a resonant transformer that superimposes a DC excitation current on an AC winding. This scheme is also composed of an excitable transformer T1, the AC power supply windings are connected in parallel (or in series), and the AC output winding is composed of four coils crossed in series and then connected in parallel (the cross-series and parallel windings can also be set on the power supply side). The AC voltage difference between the two points is zero, and the saturation of the two transformer cores can be controlled by injecting DC excitation current from these two points, so as to achieve the purpose of adjusting the AC excitation current. Figure 5 form of a resonant transformer with Figure 4 The control methods of the resonant transformers in different forms are the same, so I won’t go into details here.

Embodiment 3

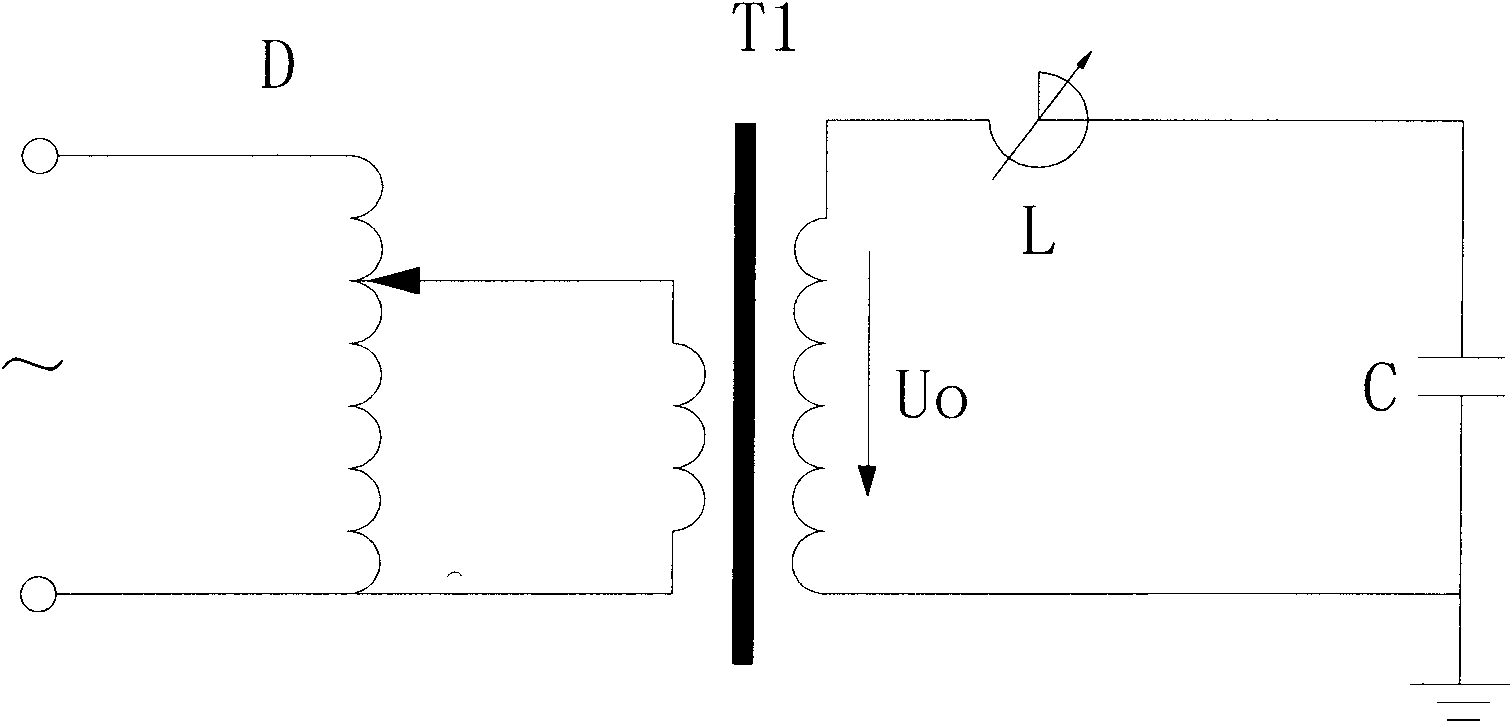

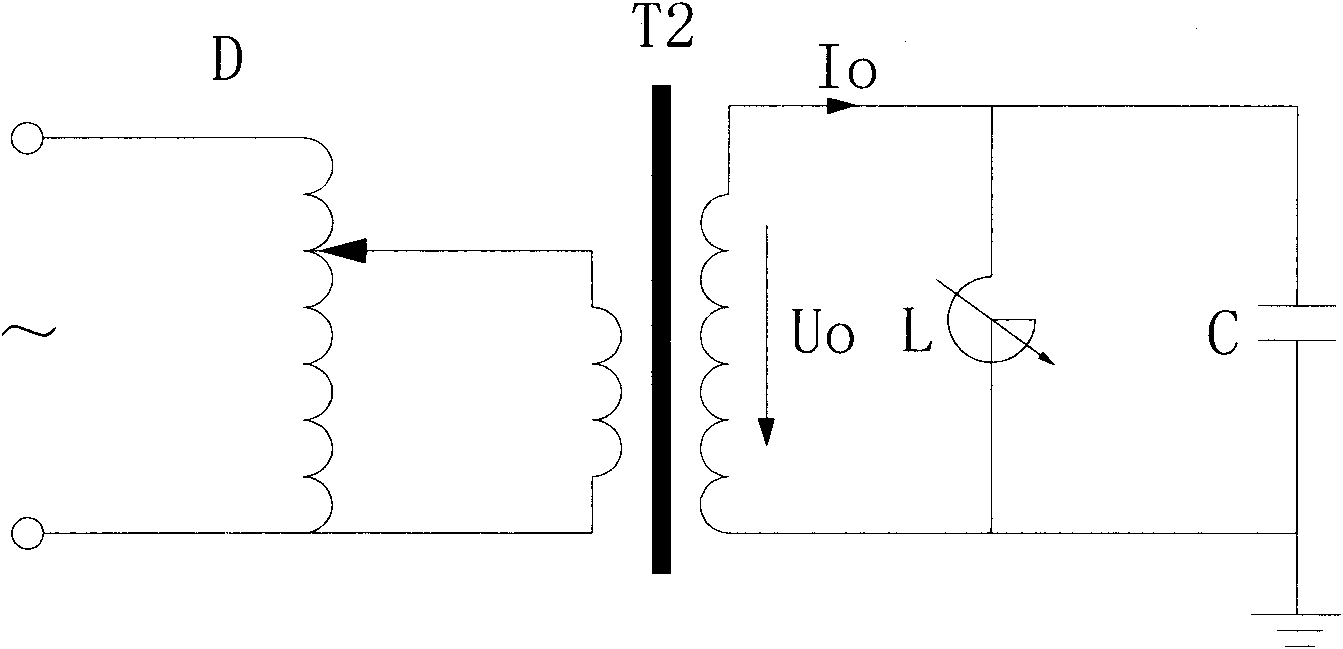

[0051] Embodiment 3, the power frequency resonant transformer of this embodiment, one end is connected to the power supply, and the other end is connected to the tested product, refer to Figure 6 and Figure 7 , which includes a voltage regulator D, an isolation transformer T1, an inductance element L, a rectifier Z, a transformer T2, a controller and a current transformer 1, wherein the primary side and the secondary side of the isolation transformer T1 are respectively connected in series with a current transformer 1, and the regulator The transformer D is connected to the inductance element L through the isolation transformer T1, and the controller adjusts the inductance value of the inductance element L through the transformer T2 and the rectifier Z after detecting the collected current on the primary side and the secondary side of the isolation transformer T1, The inductance element L is connected to the tested product C, and the DC excitation winding and the AC reactanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com