Heating container

A technology for heating containers and containers, which is applied to utensils with enlarged heating surfaces, heating devices, etc., can solve problems such as inability to perform self-heating, and achieve the effects of being less prone to failure, increasing the heating area, and avoiding pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

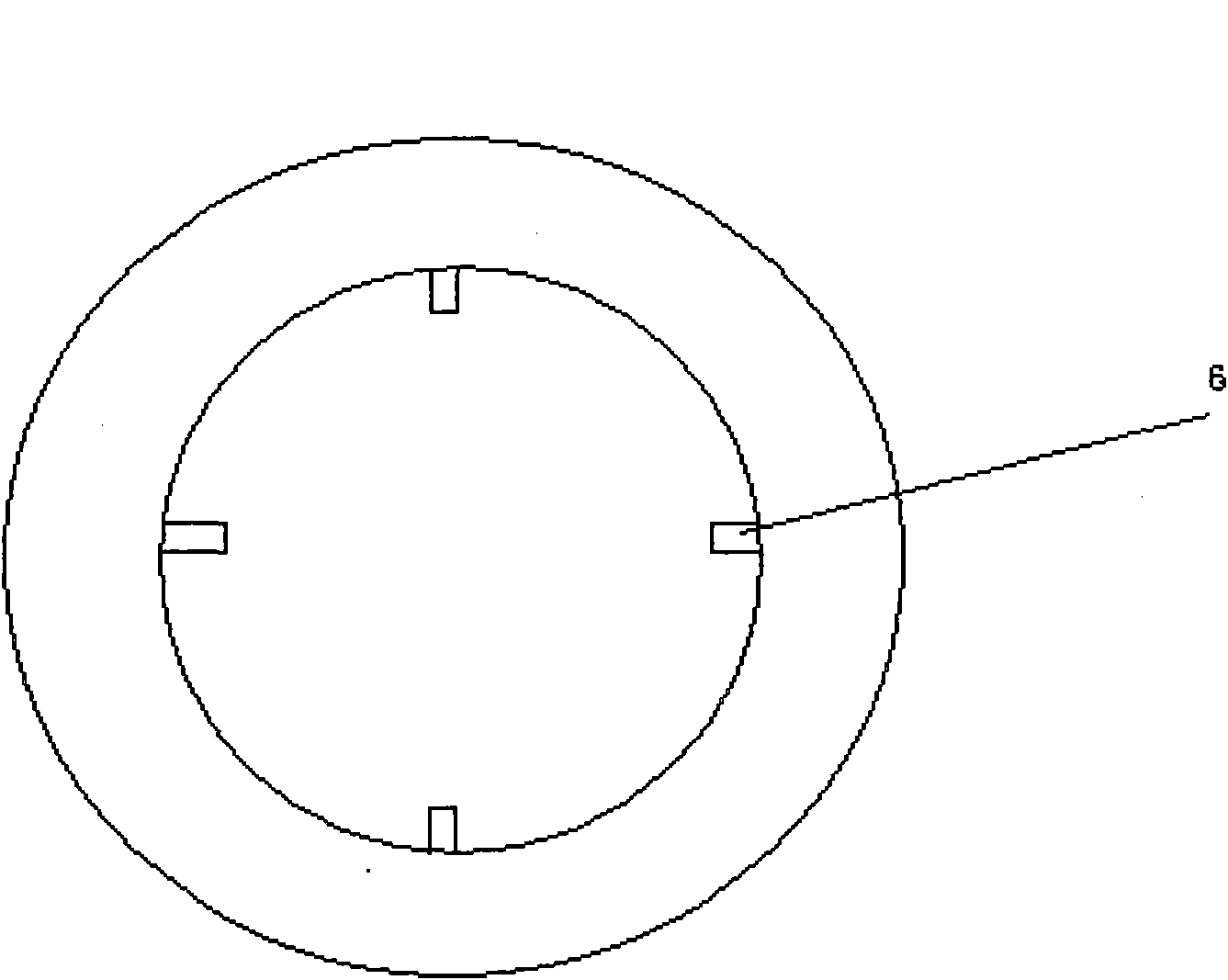

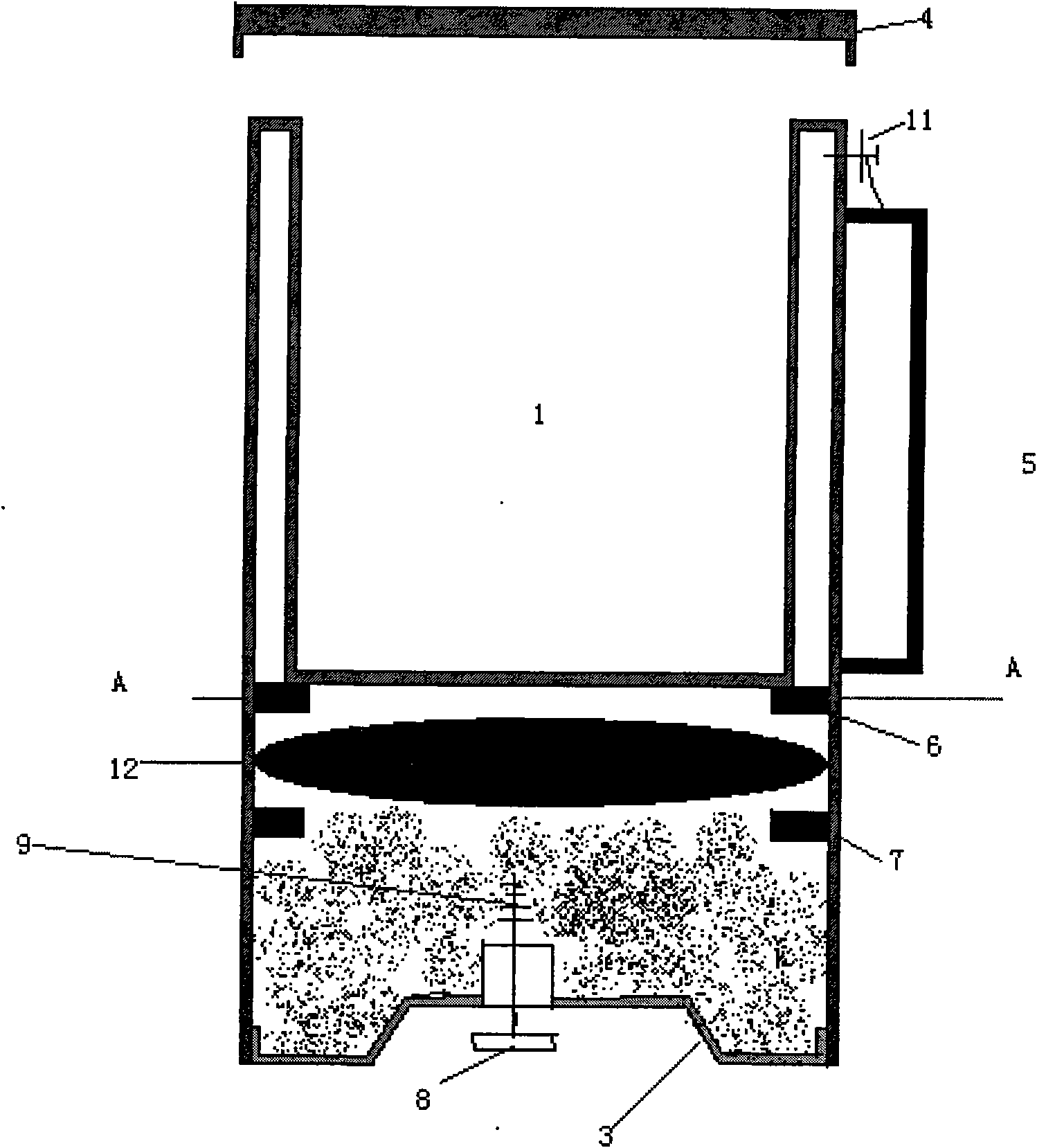

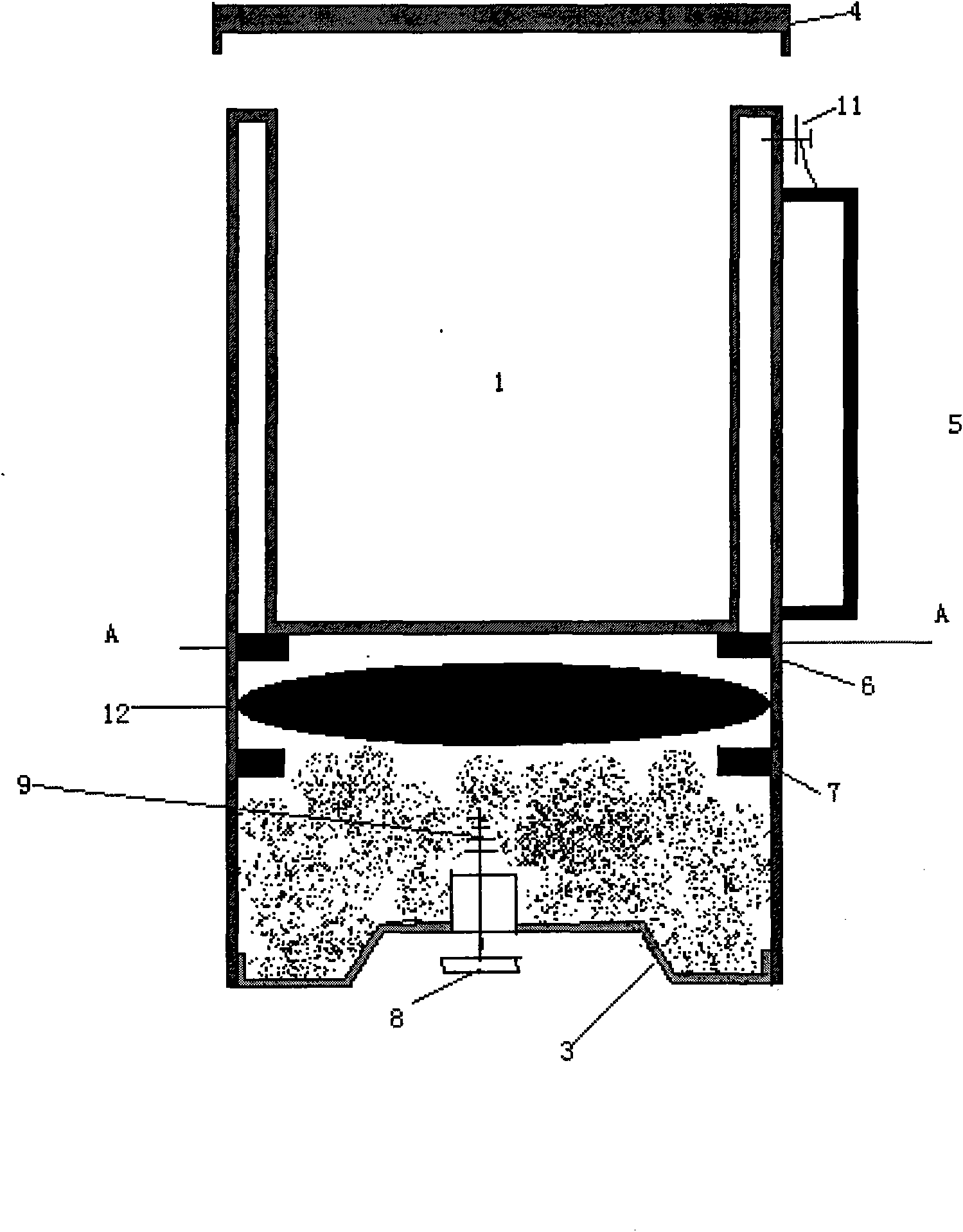

[0013] attached figure 1 It is a structural schematic diagram of the container of the present invention, including a first cavity 1 and a second cavity 2, the first cavity is used to hold the contents of the container, and the second cavity is used to hold a heating body. The base 3 is used to close the second cavity 2, and the container cover 4 is used to close the first cavity. The first cavity is made of heat-conducting material, and has a helical groove on its peripheral wall, and the groove increases the contact area of the first cavity, so that heat is received more rapidly and the heat exchange speed is accelerated. The inner wall of the second cavity is coated with a flame-retardant and heat-insulating layer to prevent heat loss through the wall of the second cavity. In addition, a handle 5 is also provided on the outer wall of the second cavity, so that the user can hold it more easily. The base 3 is threaded on the lower end of the second cavity and is recessed u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com