Double-wall thermal-insulation steel silo

A heat preservation tube and heat preservation layer technology, which is applied to fruit hanging devices, rot-preventing containers, gardening, etc., can solve problems such as thin warehouse walls, difficulties in safe grain storage, and condensation, so as to improve mechanical performance and increase The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

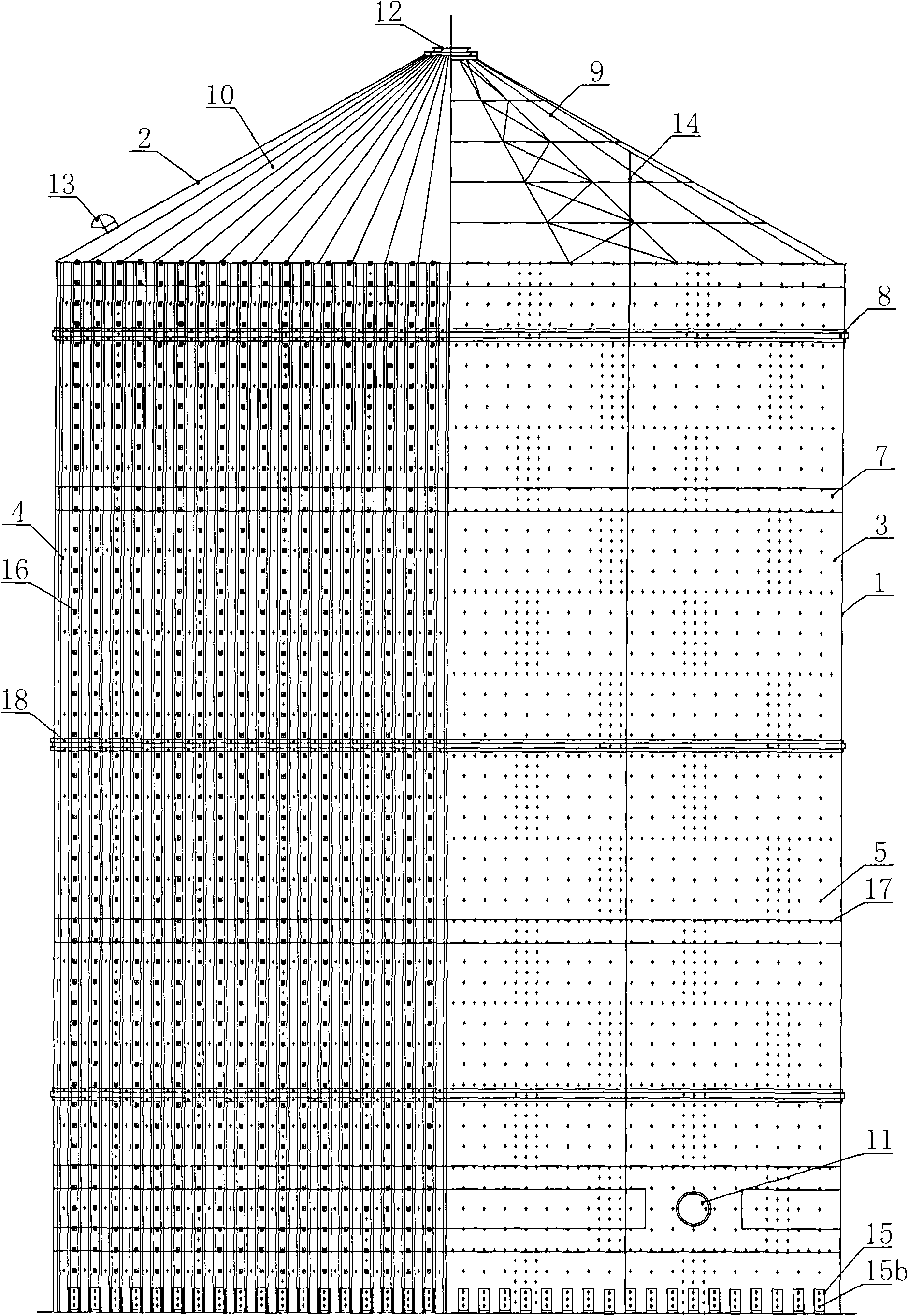

[0039] Such as figure 1 As shown, the double-walled steel thermal insulation silo of the present invention comprises a silo roof 2, a silo body 1 and a support 15, the silo body 1 is provided with a door 11, the lower part of the silo body 1 is fixed on the support 15, and the silo body 1 includes The inner plate 3 and the outer plate 4, the inner and outer circumferences of the warehouse body at the same height are respectively formed by lapping the ends of several inner plates and outer plates, and the overlapping parts of the upper and lower adjacent circles are staggered with each other, and the inner and outer sides correspond to each other. The laps of the circumference are staggered. In this way, each component can be prefabricated in the factory through standardized production, and then the entire silo can be assembled and installed on site through the "flip chip method".

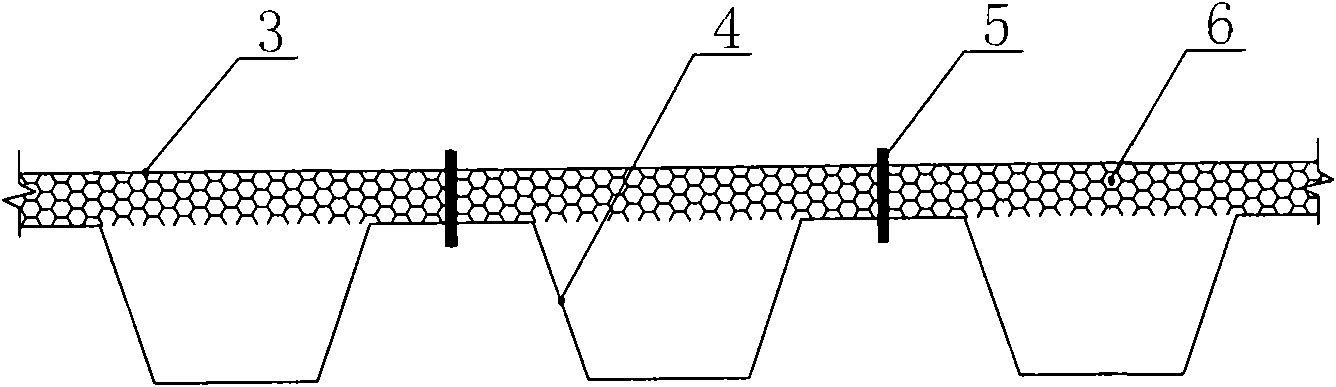

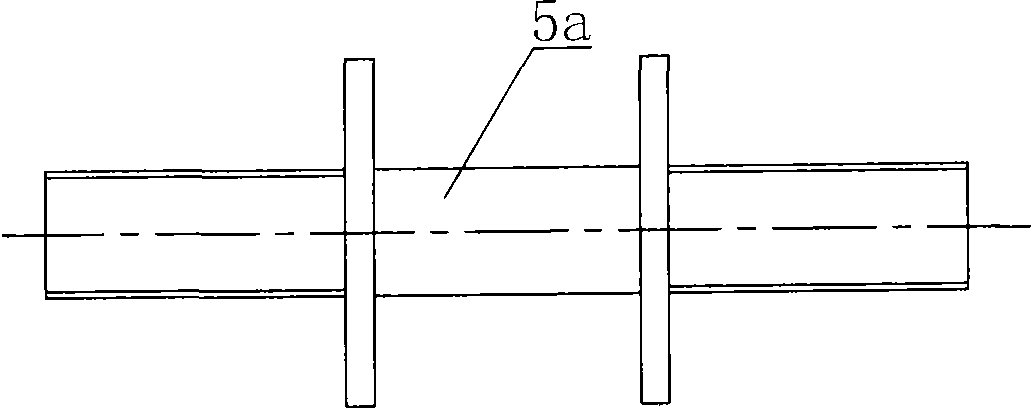

[0040]The inner plate 3 and the outer plate 4 are connected to each other through the bolt conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com