Barium titanate dielectric powder, method for manufacturing the same, method for manufacturing ceramic green sheet, and method for manufacturing laminated ceramic capacitor

A manufacturing method and dielectric technology, applied in the direction of laminated capacitors, fixed capacitor dielectrics, fixed capacitor parts, etc., can solve the problems of inability to improve the reliability of the dielectric constant temperature characteristics, and achieve the suppression of grain growth and temperature characteristics Flat, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

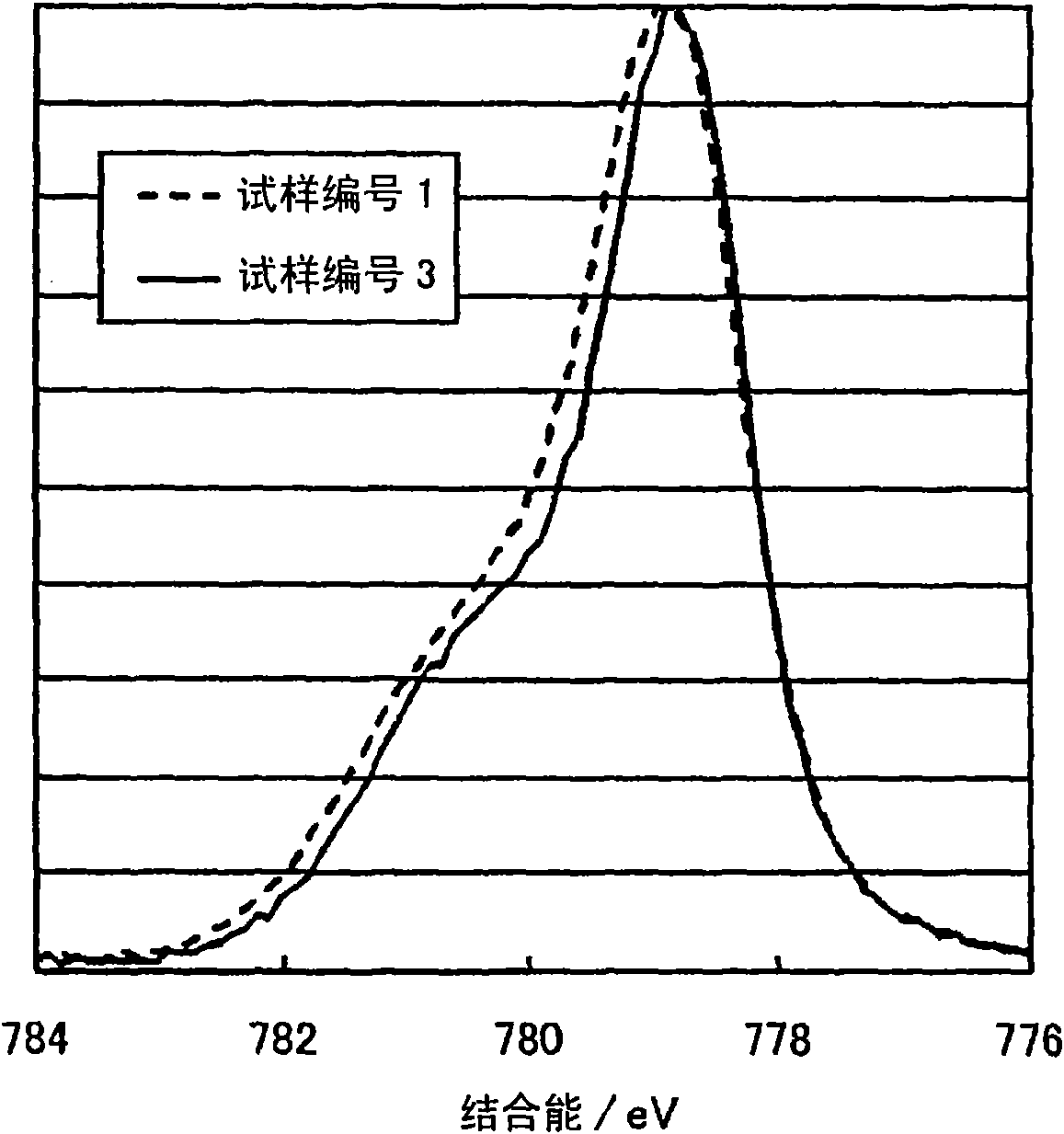

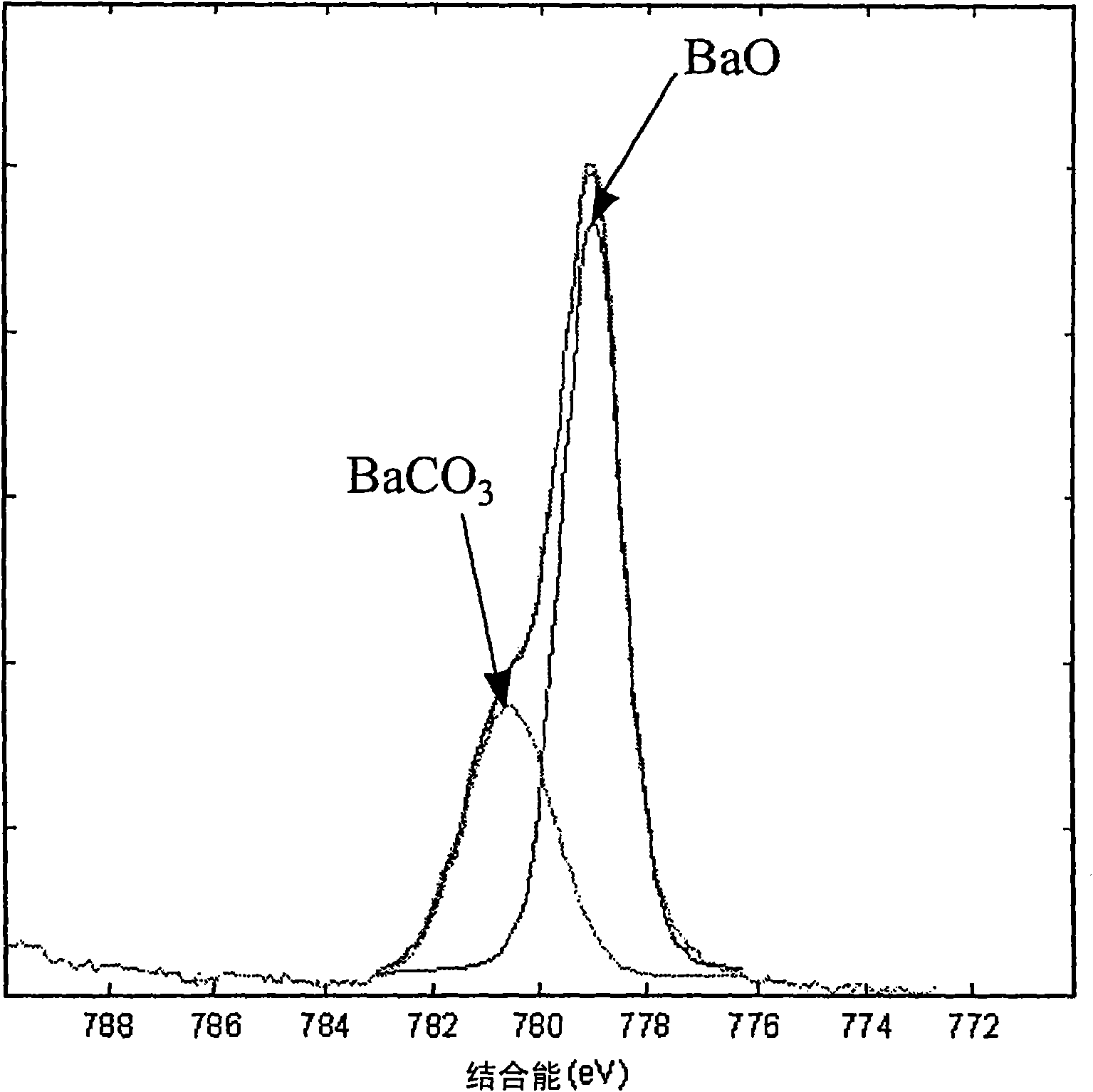

[0053] Prepare BaCO 3 、TiO 2 As a starting material, it weighed and mixed so that the ratio of Ba and Ti may become Ba / Ti=1.01 (atomic ratio). Then, use a ball mill (using PSZ abrasives with a diameter of 2mm) to mix the raw materials, and heat-treat at 900-1050°C in the atmosphere to synthesize the general formula Ba 1.01 TiO 3 Represented barium titanate compound.

[0054] Next, by pulverizing the barium titanate-based compound, barium titanate-based compound powders (Ba 1.01 TiO 3 powder).

[0055] Next, the above Ba 1.01 TiO 3 100 g of the powder was put into a container together with 100 g of water, and immersed in water while stirring for the time (1 to 120 hours) shown in Table 1. Specifically, stirring is achieved by adding Ba 1.01 TiO 3 Powder and water are then swirled. In addition, this process is not accompanied by pulverization (only stirring), and the barium titanate compound powder (Ba 1.01 TiO 3 powder) in the process of immersing in water.

[005...

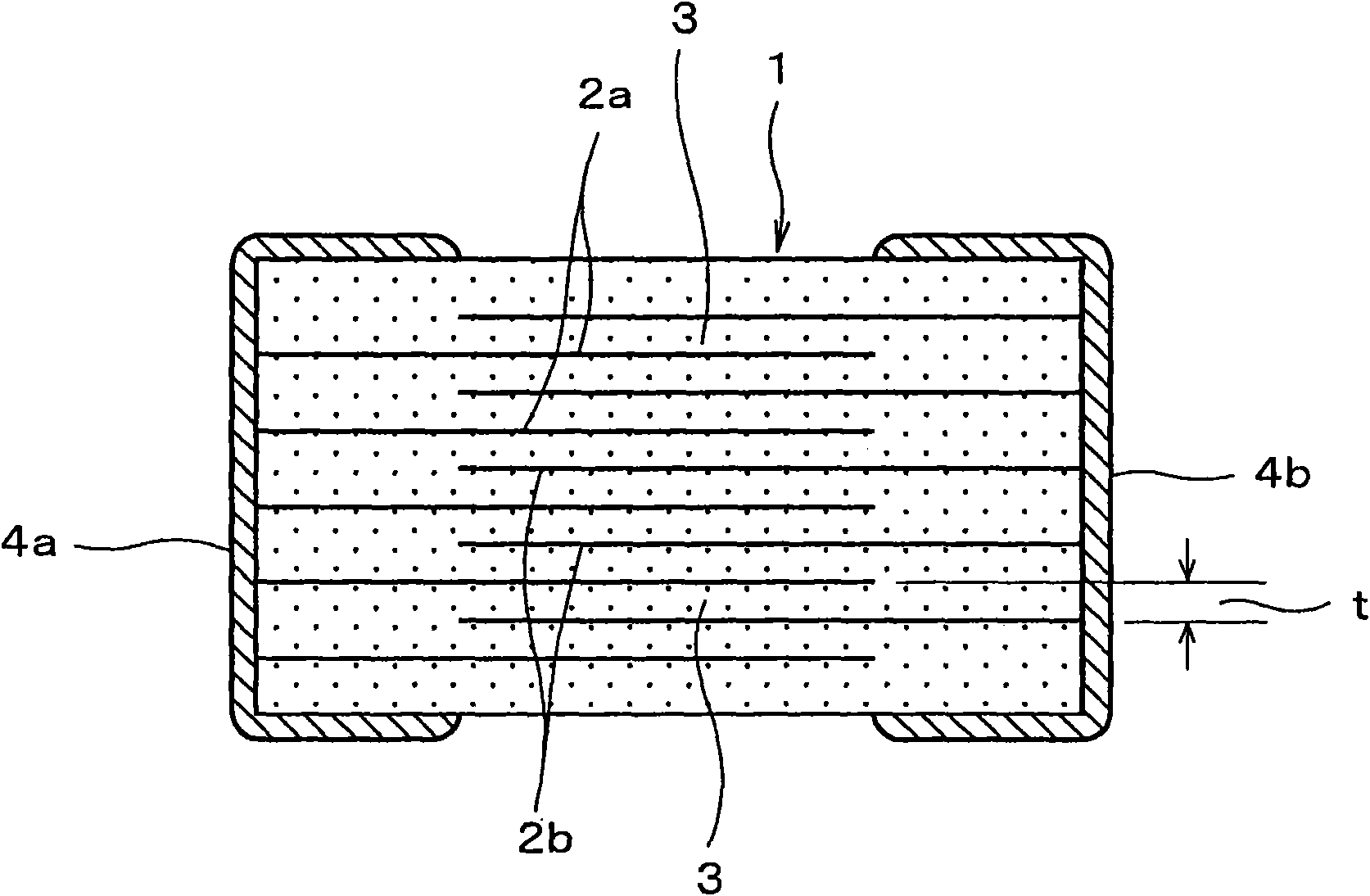

Embodiment 2

[0101] Prepare BaCO 3 、TiO 2 As a starting material, it weighed and mixed so that the ratio of Ba and Ti may become Ba / Ti=1.000 (atomic ratio). Then, use a ball mill (using PSZ abrasives with a diameter of 2mm) to mix the raw materials, and heat-treat at 1000°C in the atmosphere to synthesize the general formula BaTiO 3 Represented barium titanate.

[0102] Next, by pulverizing the barium titanate, barium titanate powder (BaTiO 3 powder).

[0103] Alternatively, prepare BaZrO 3 、BaCO 3 、Gd 2 o 3 、Dy 2 o 3 , MnCO 3 , MgCO 3 , SiO 2 as an added ingredient.

[0104] Next, the barium titanate powder (BaTiO 3 Powder) 100g, according to the following proportions, mix selected from the above-mentioned additive group, that is, selected from BaZrO 3 、BaCO 3 、Gd 2 o 3 、Dy 2 o 3 , MnCO 3 , MgCO 3 , SiO 2 Each sample (raw material powder of barium titanate-based dielectric material) of sample numbers 10 to 13 in Table 2 was prepared for the additive components in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com