Patents

Literature

920results about "Pulse generation by opto-electronic devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

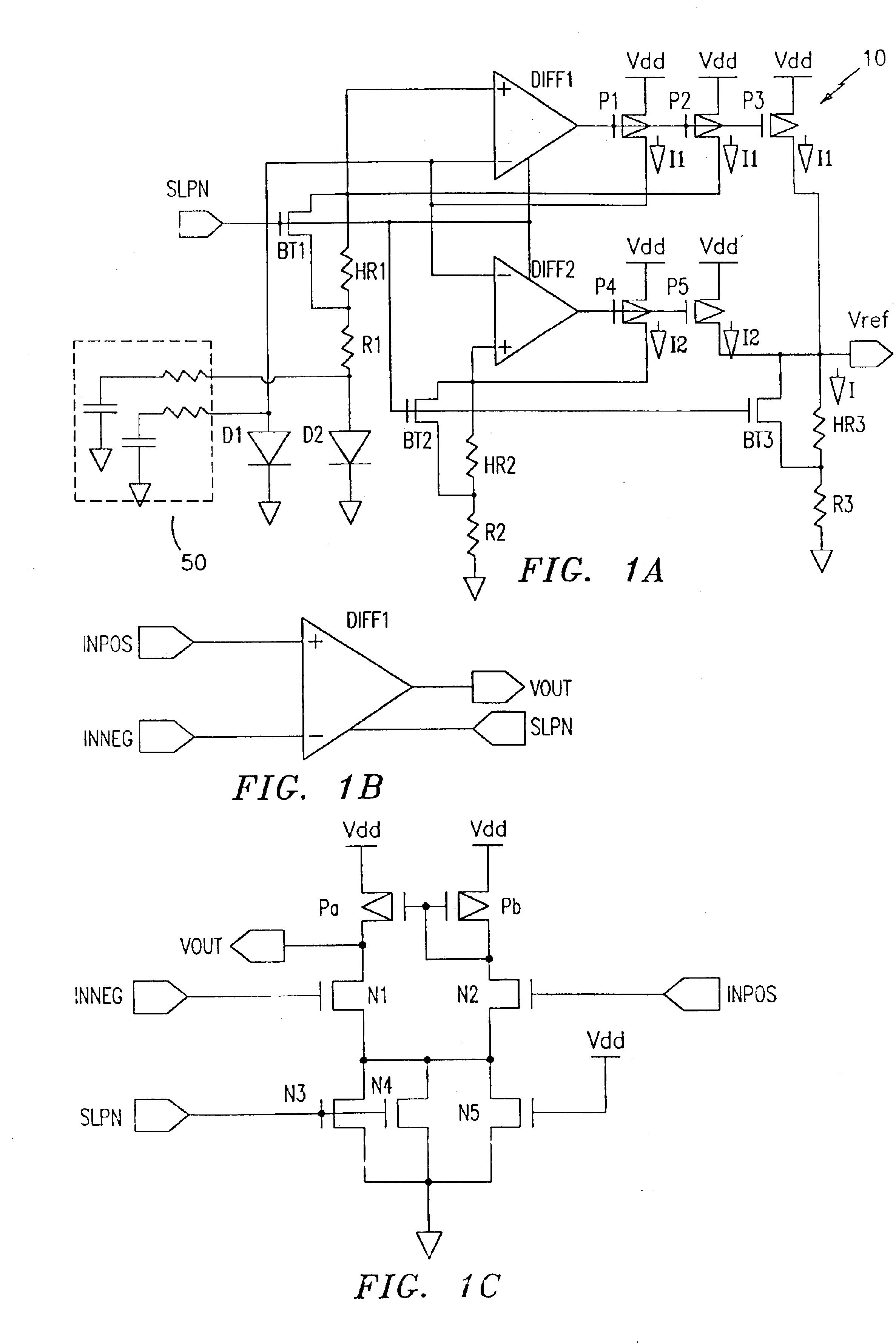

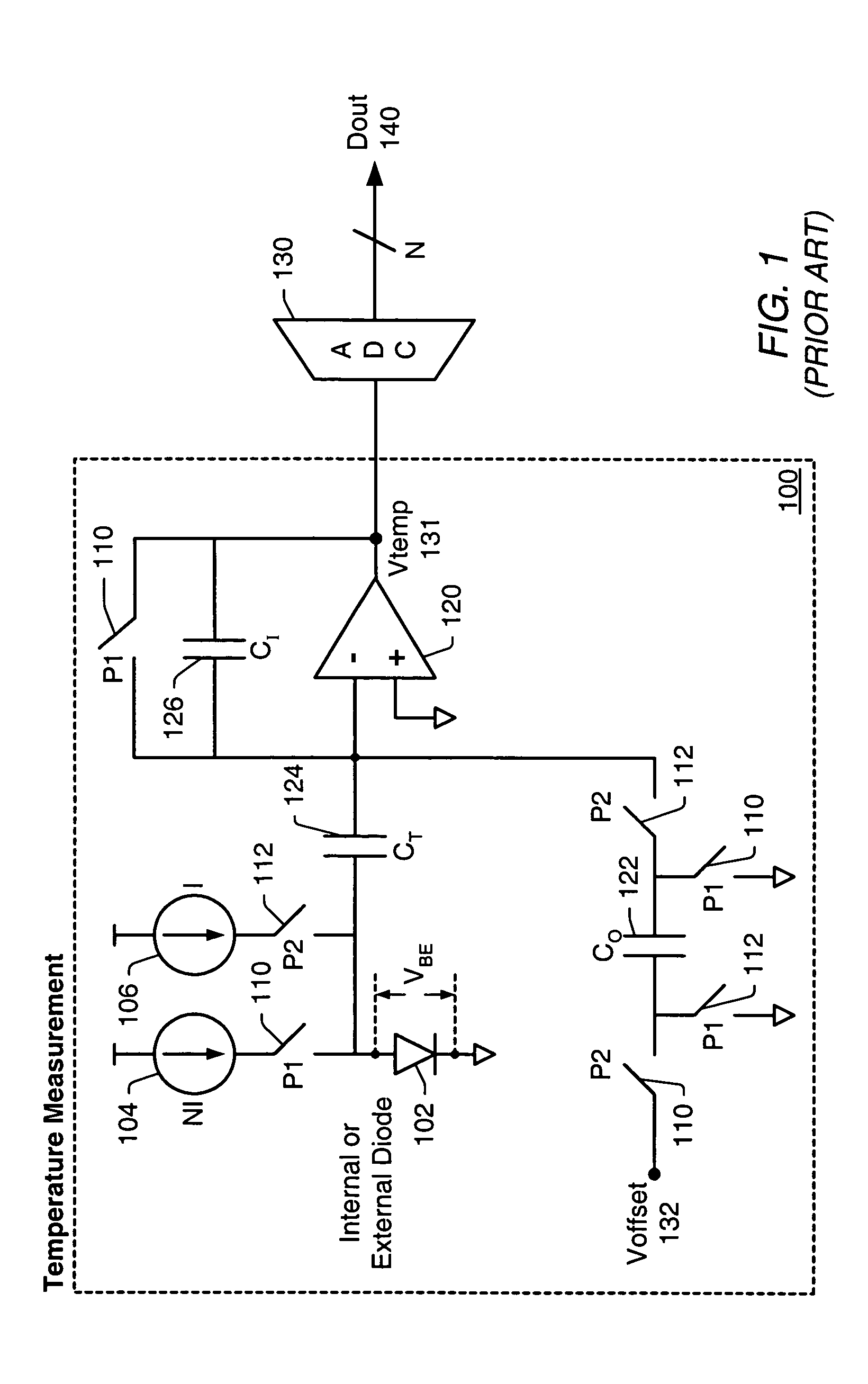

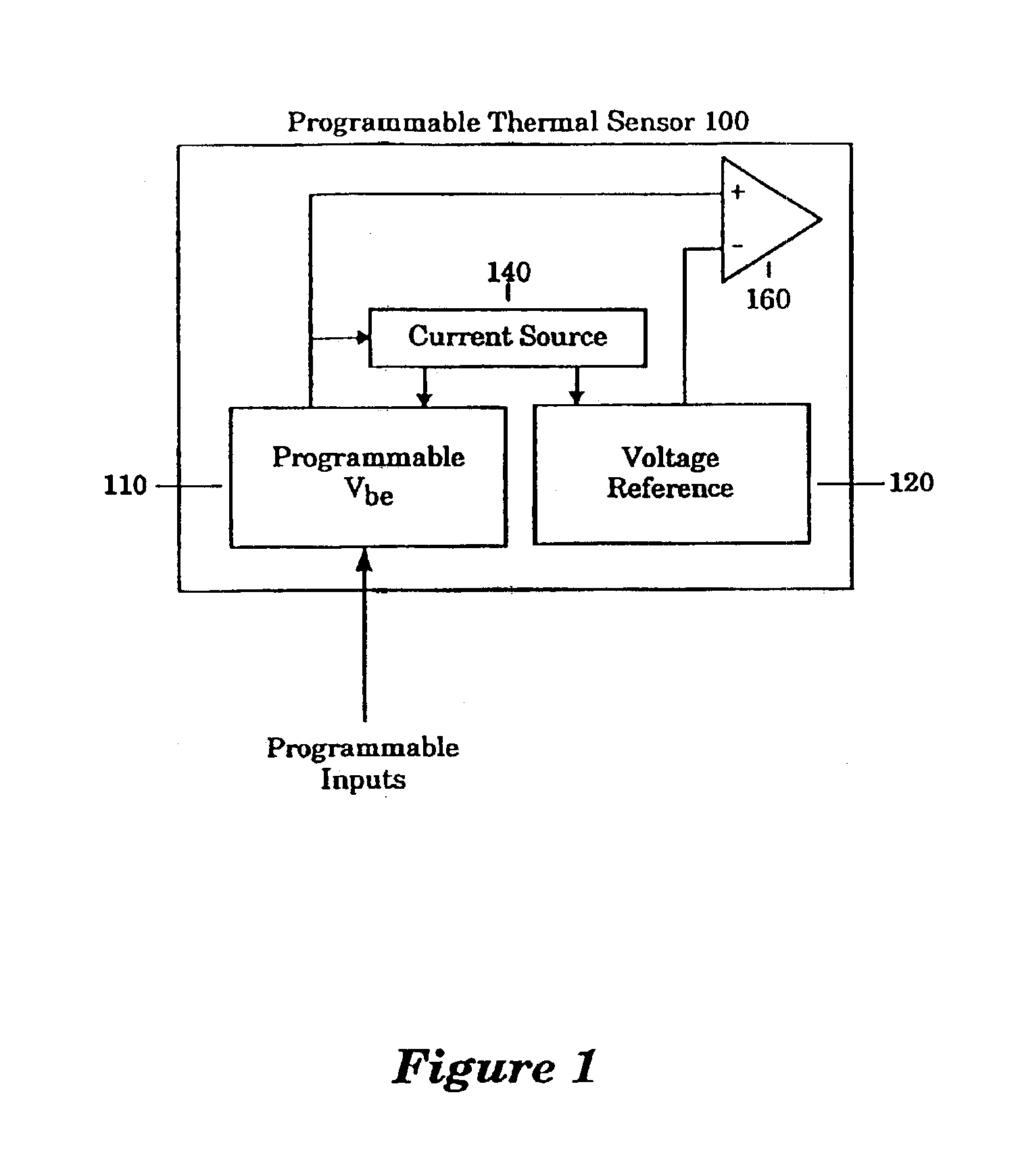

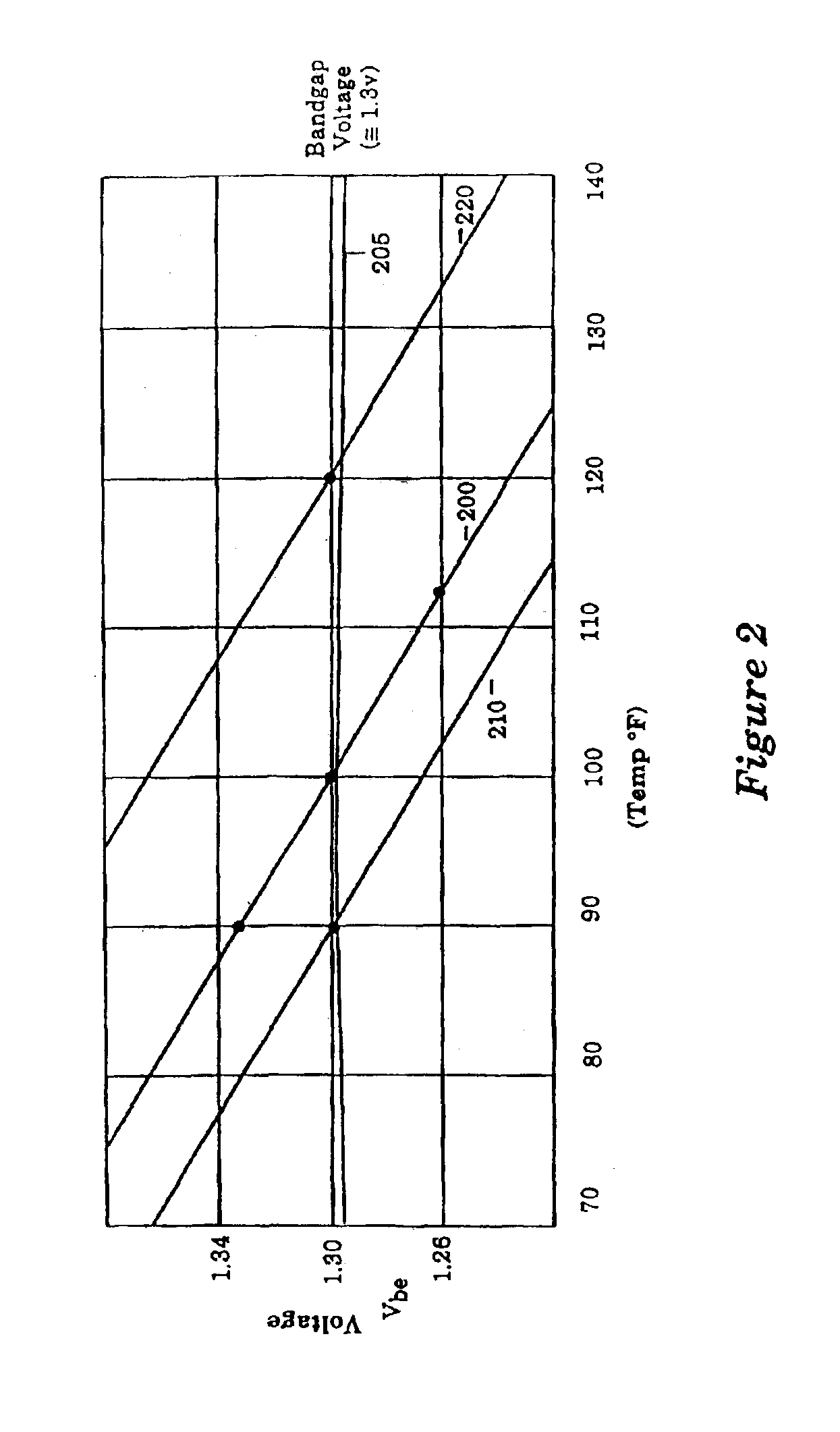

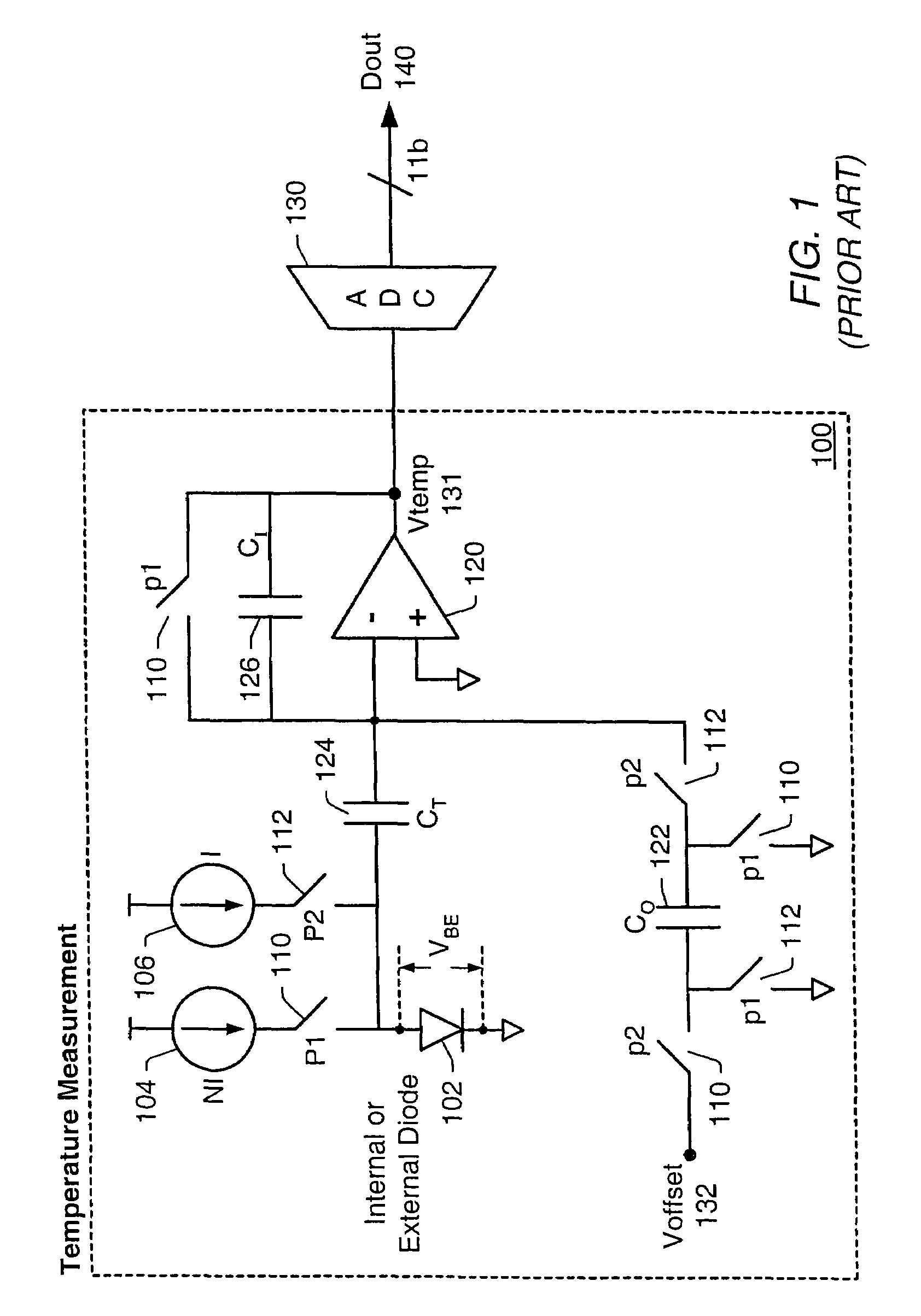

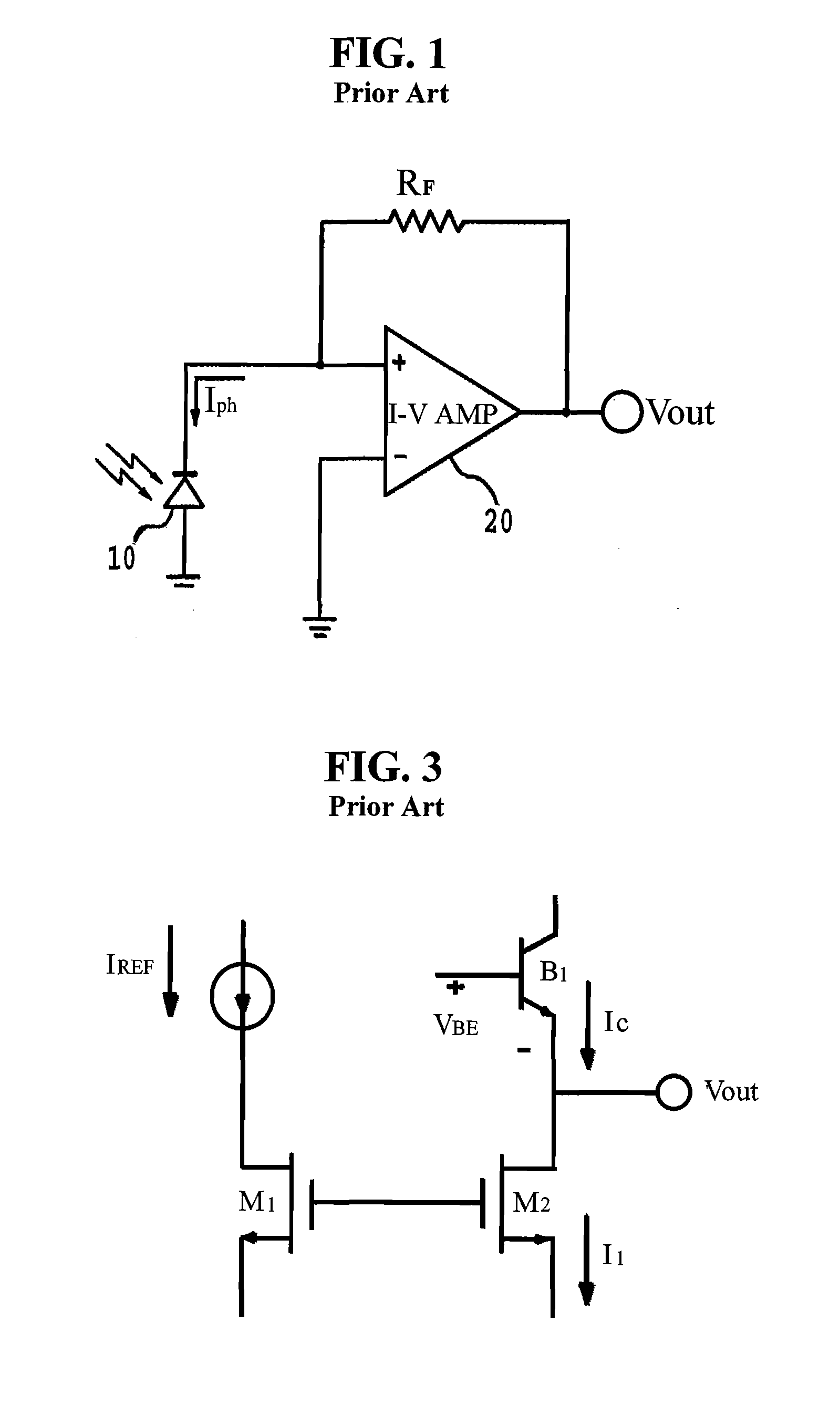

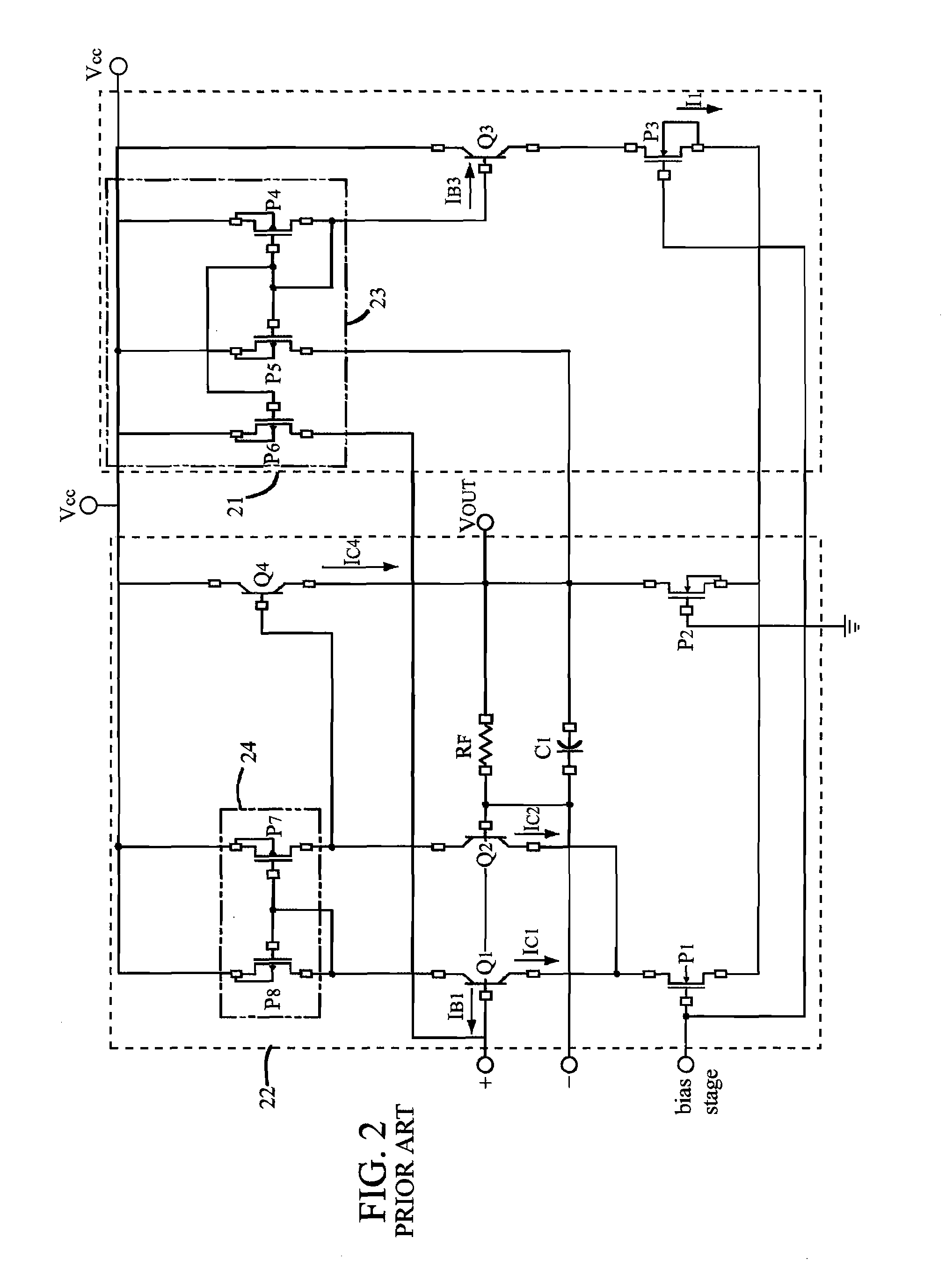

Power supply independent temperature sensor

InactiveUS6157244AMultiple input and output pulse circuitsInstant pulse delivery arrangementsAudio power amplifierEngineering

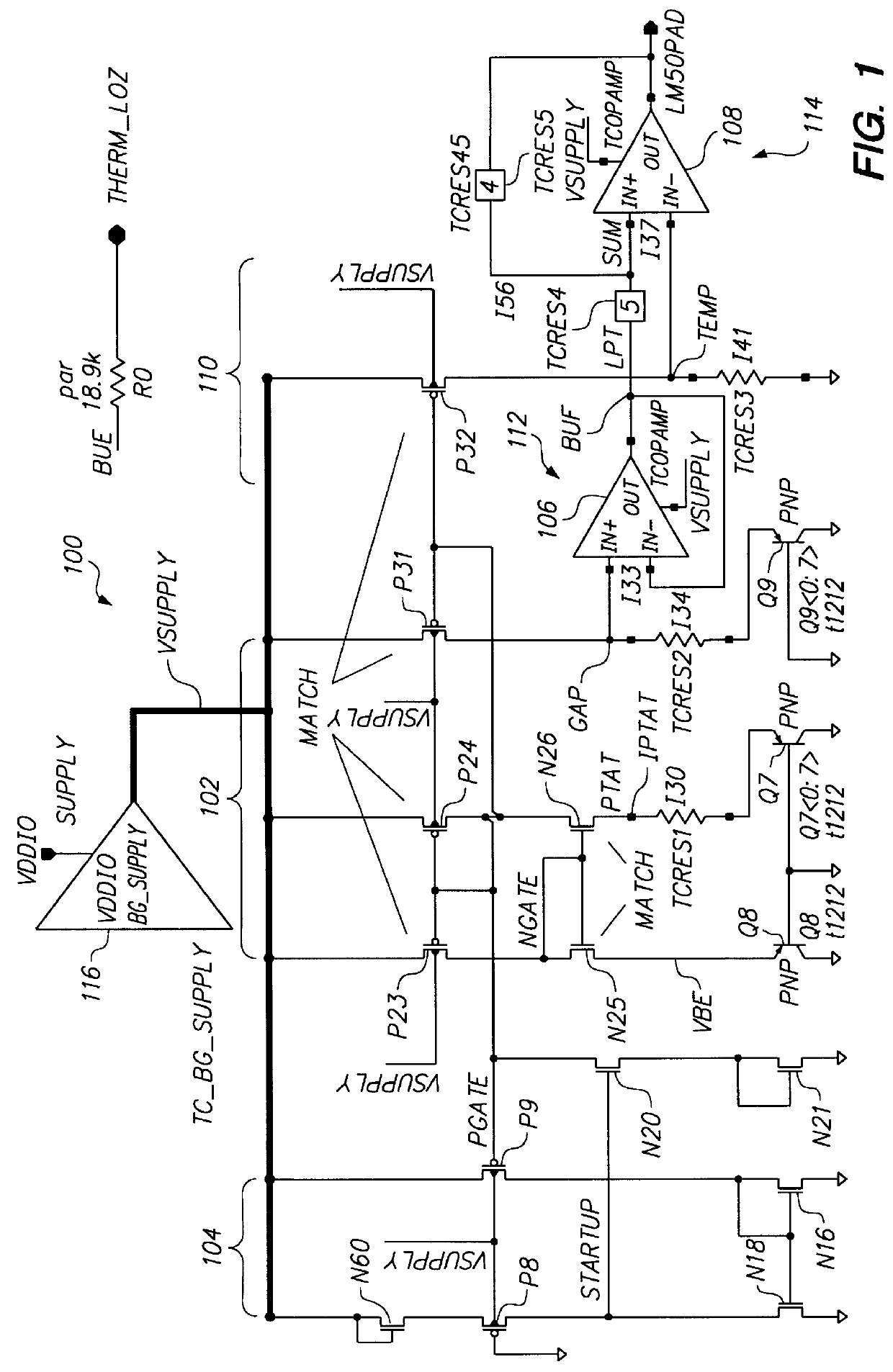

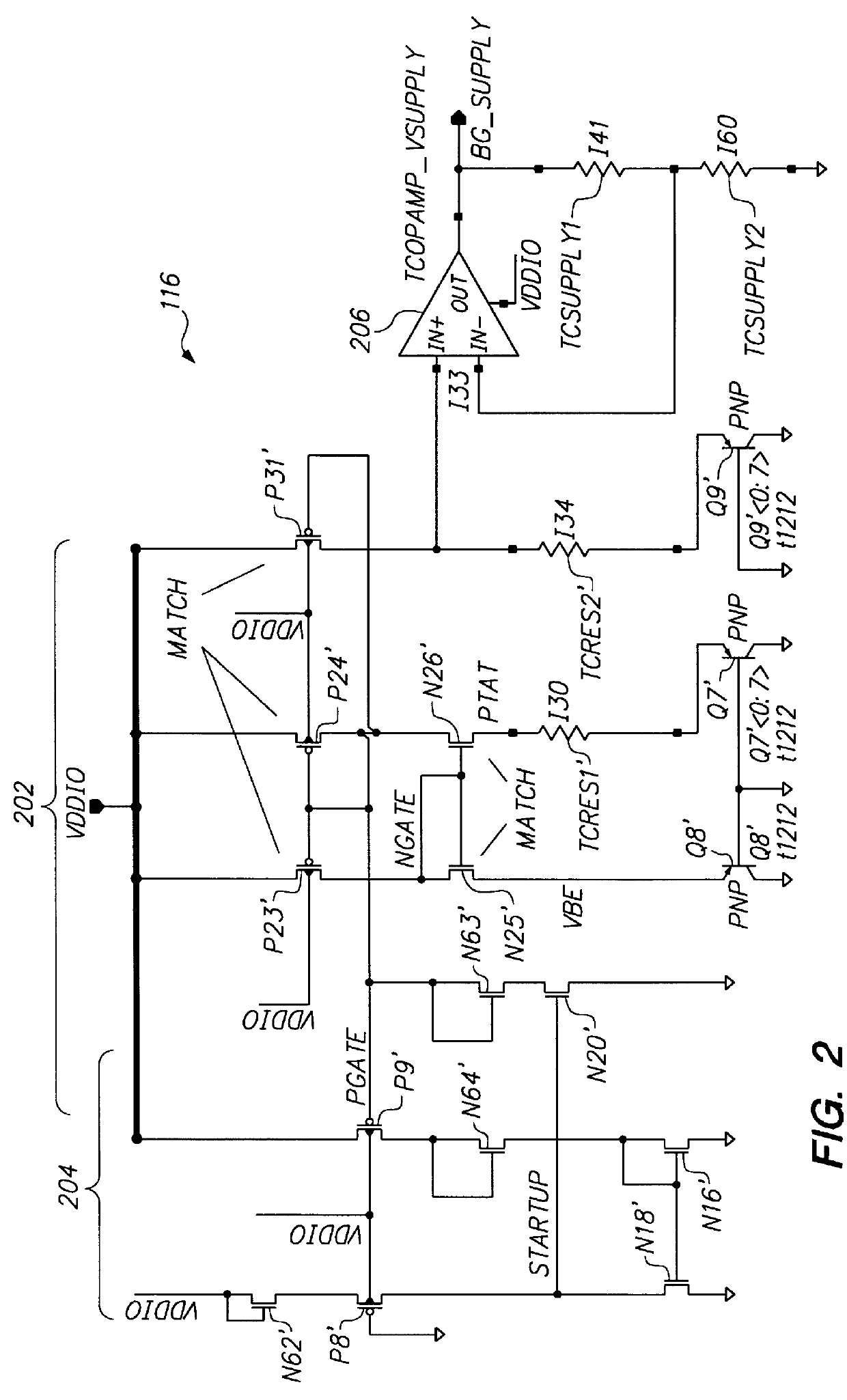

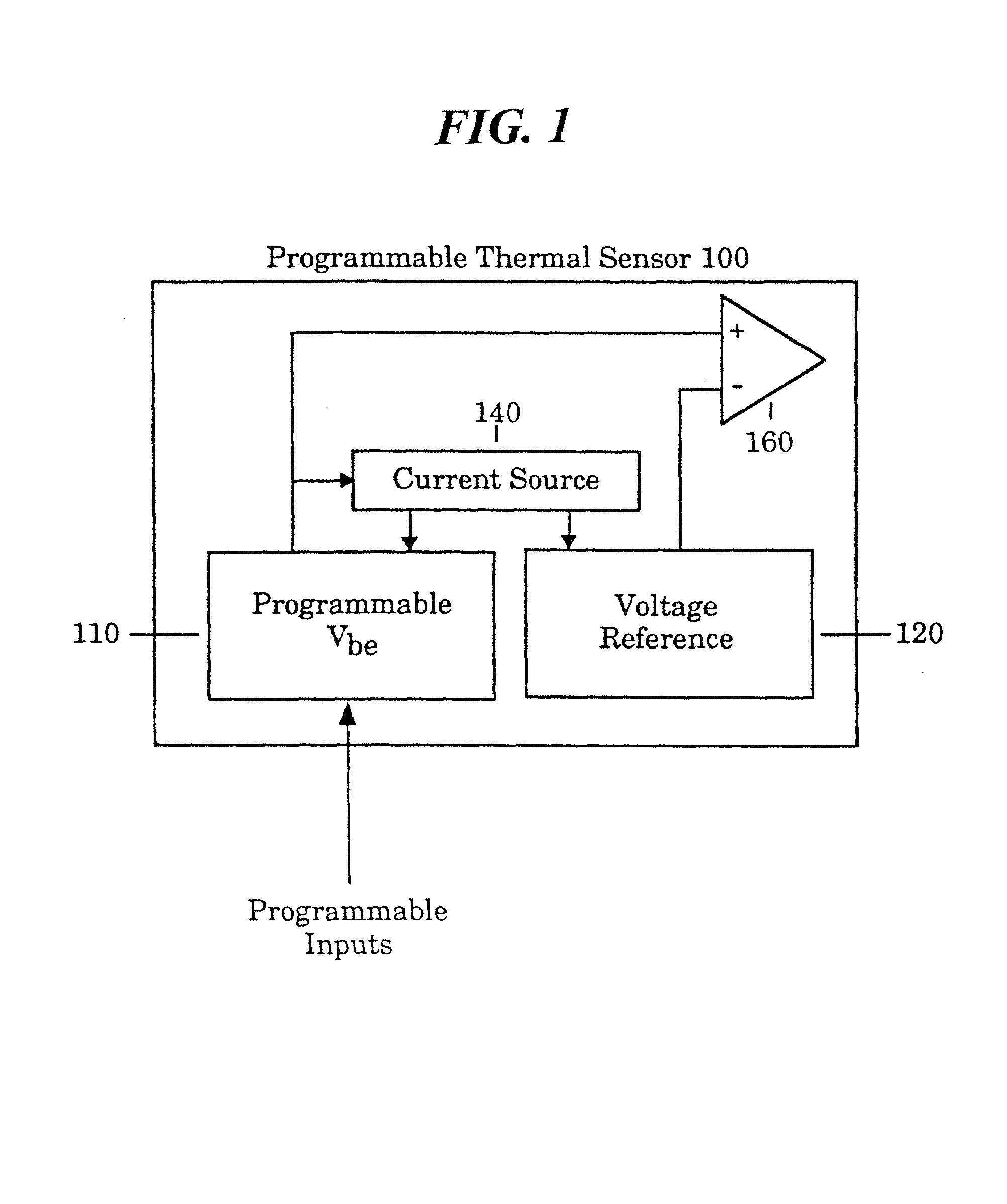

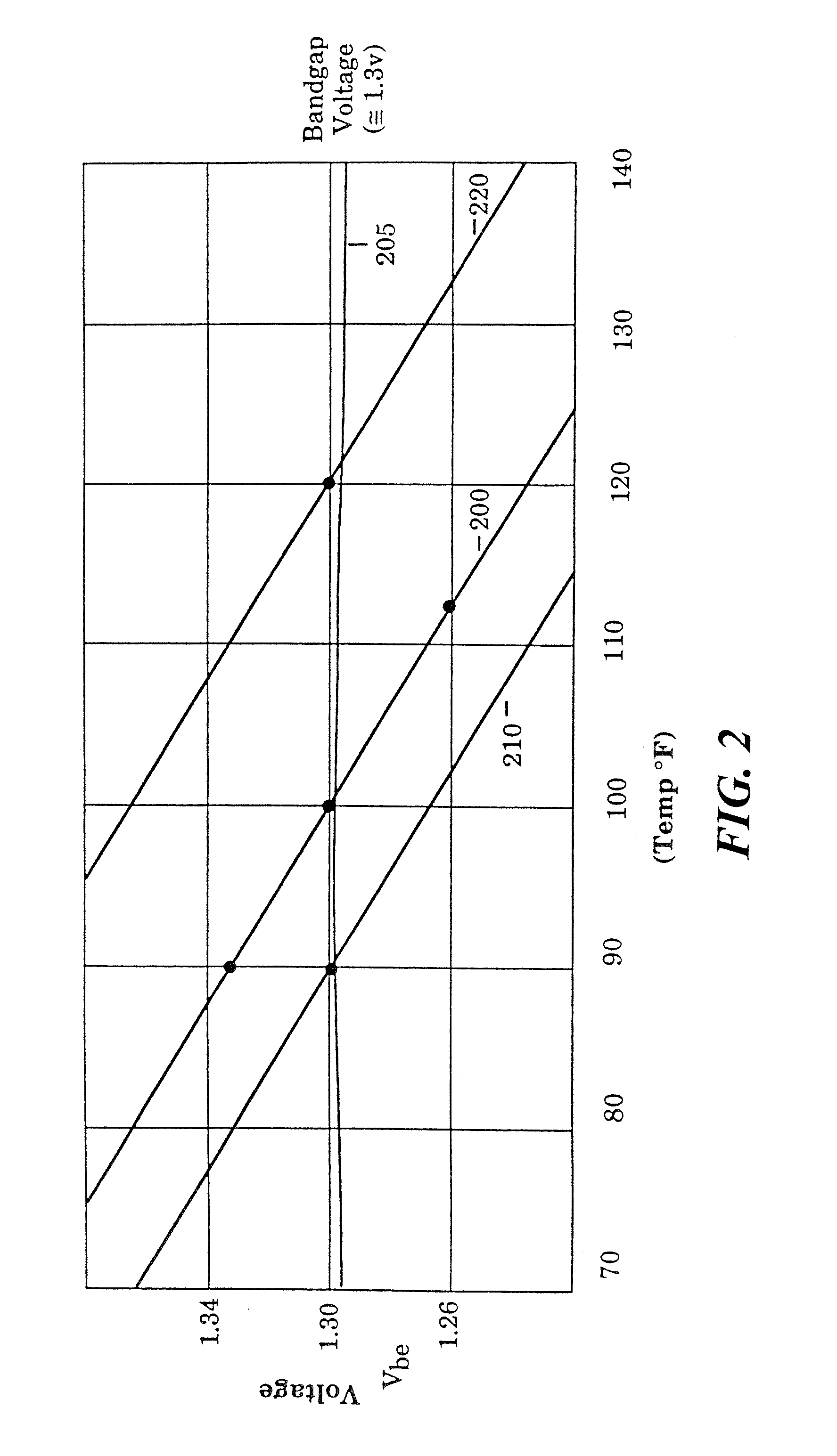

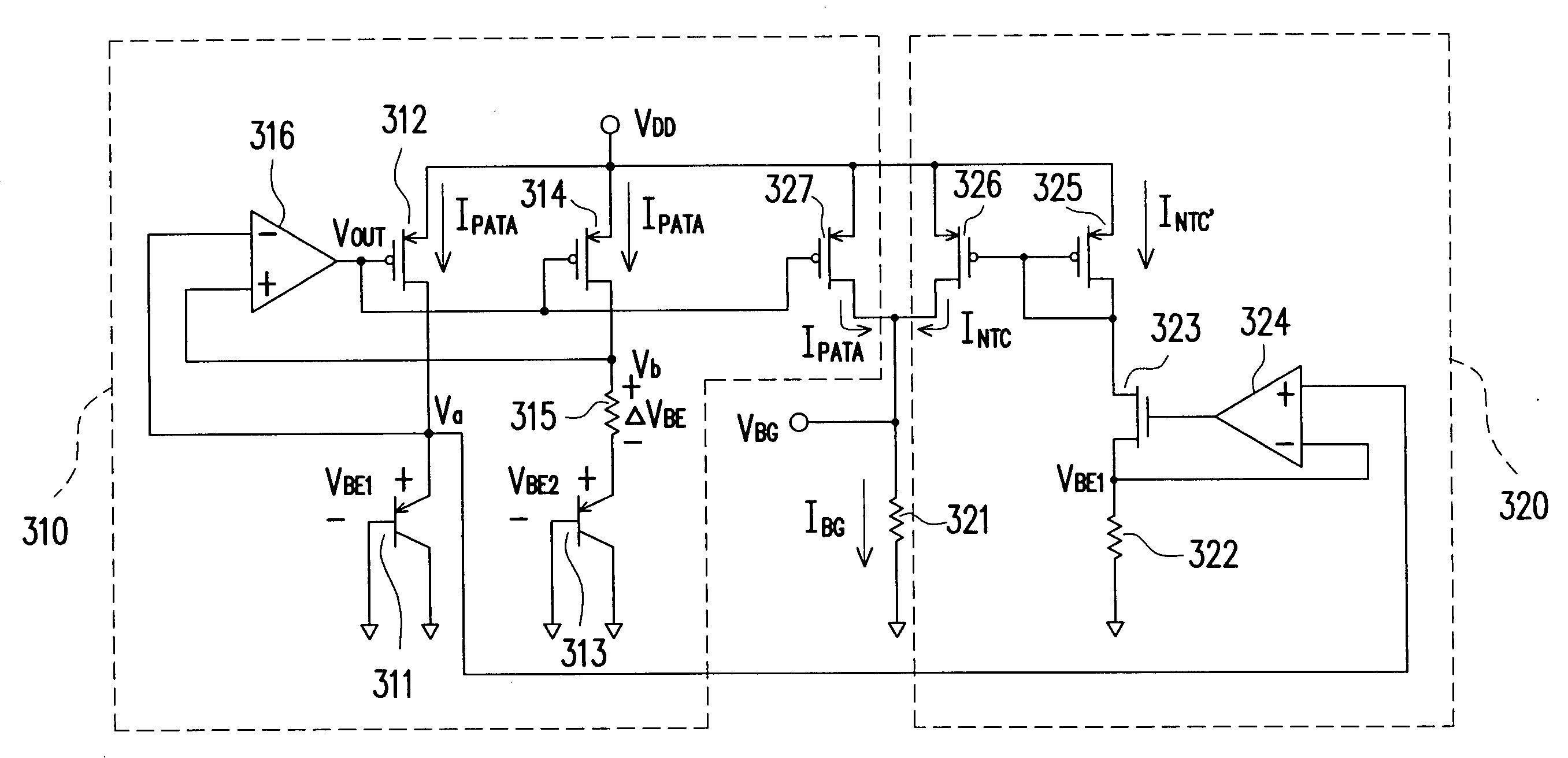

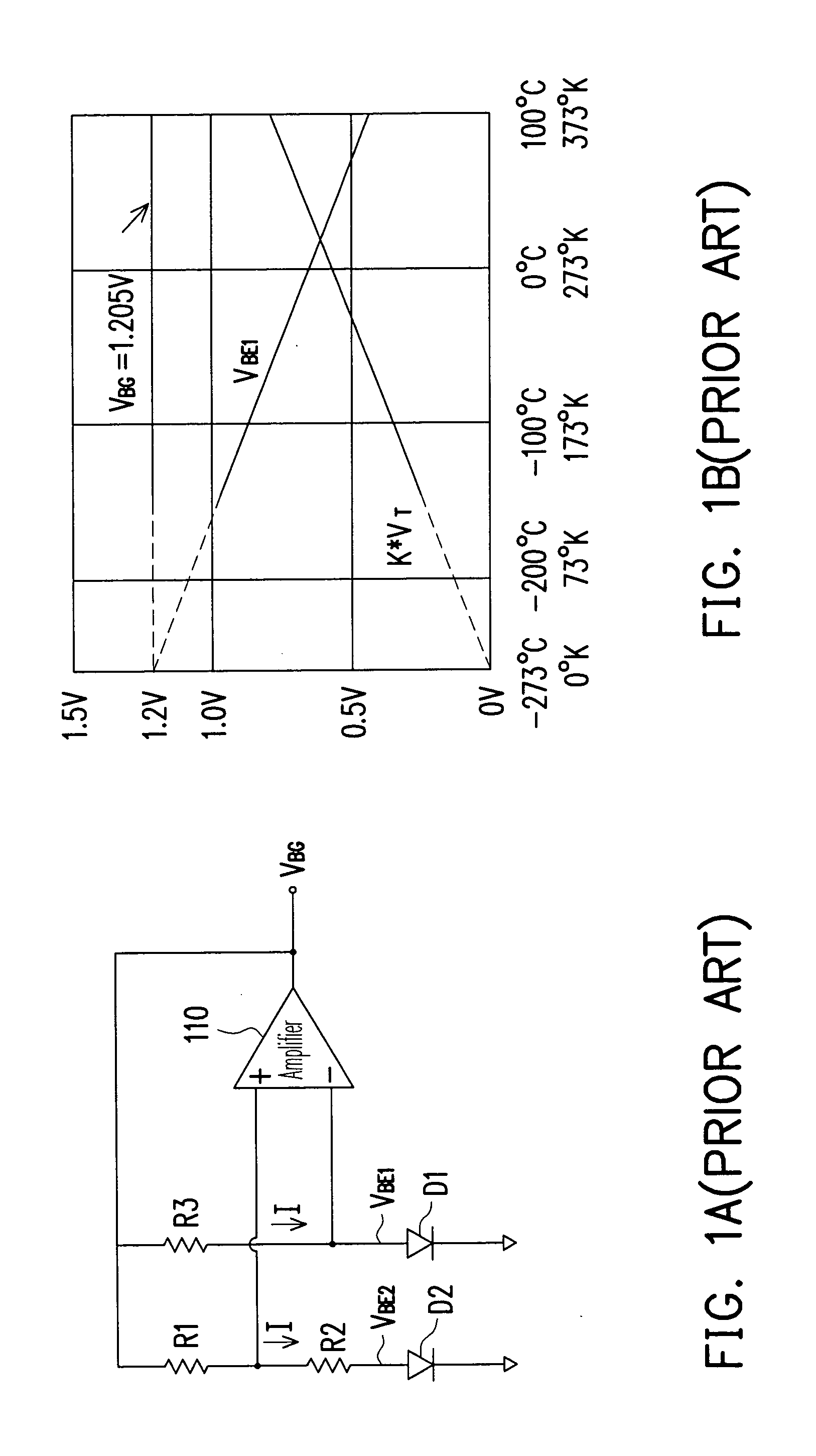

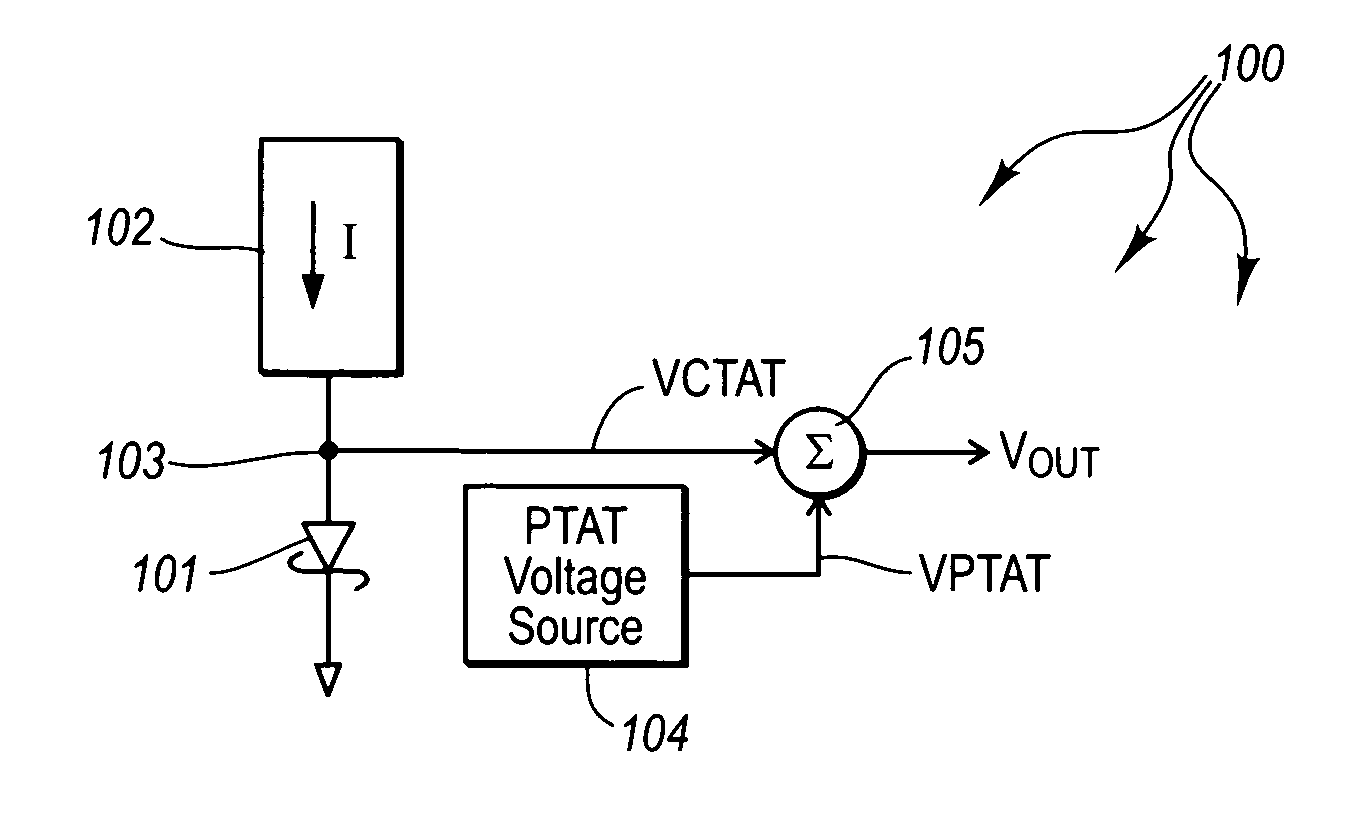

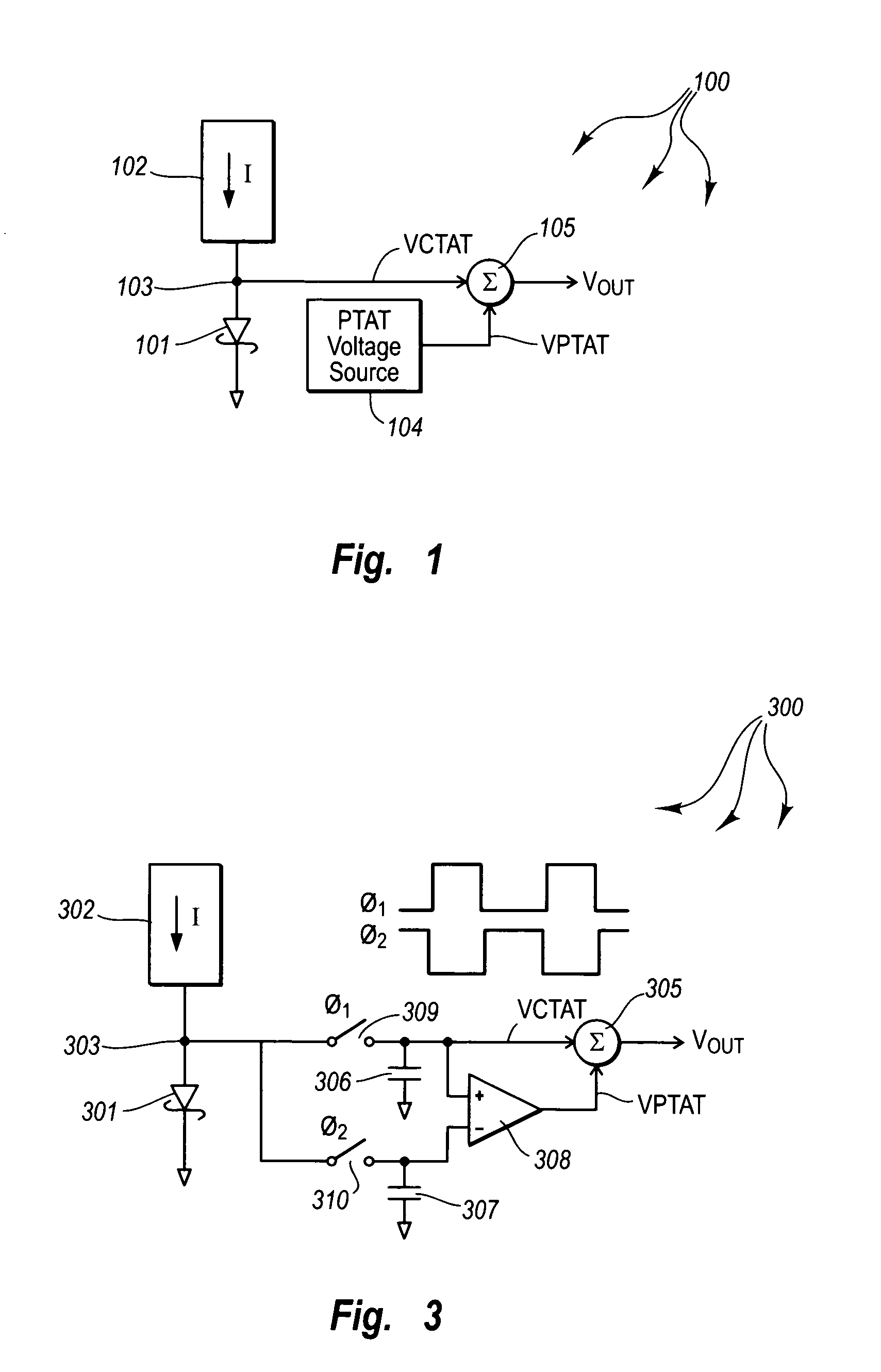

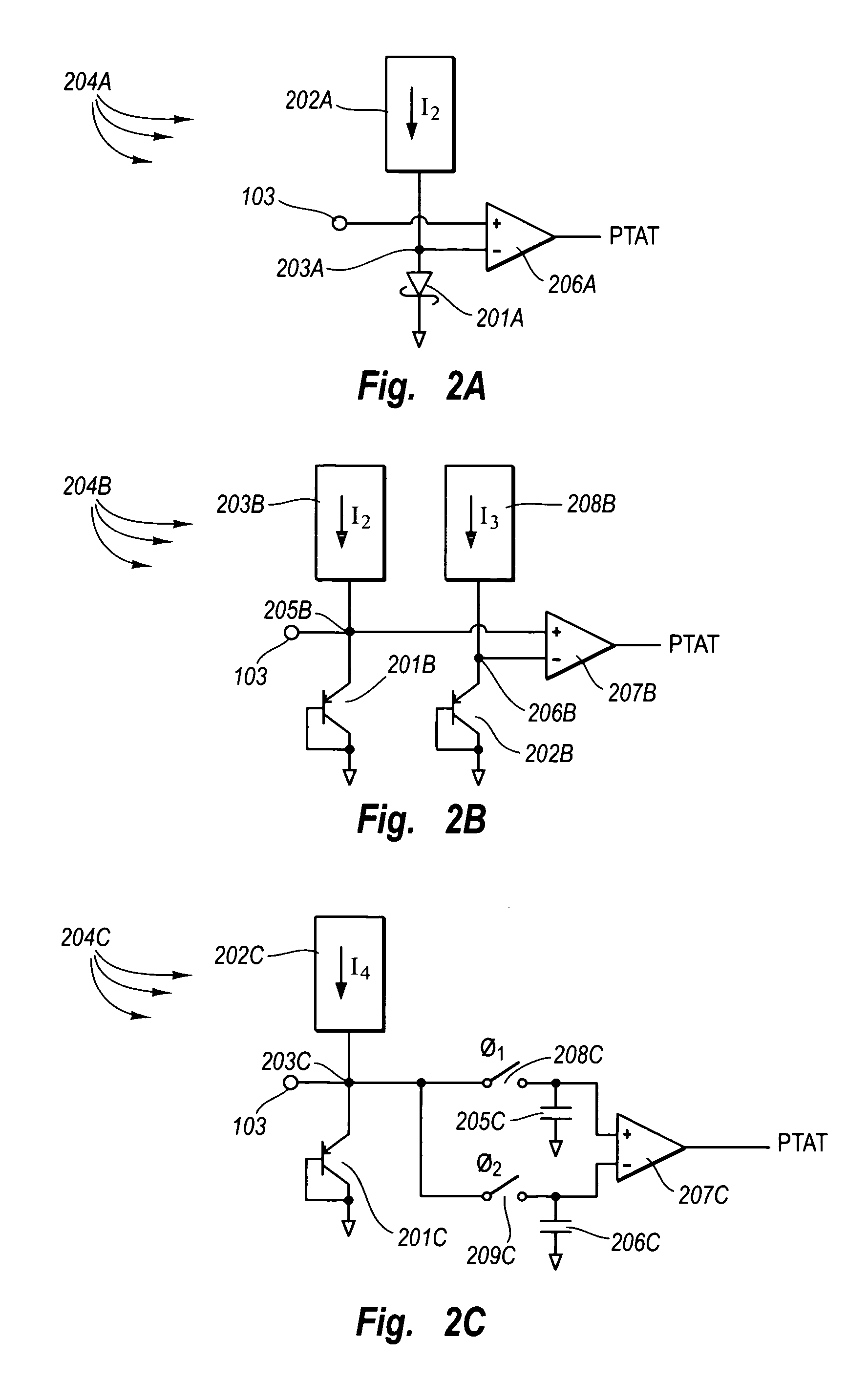

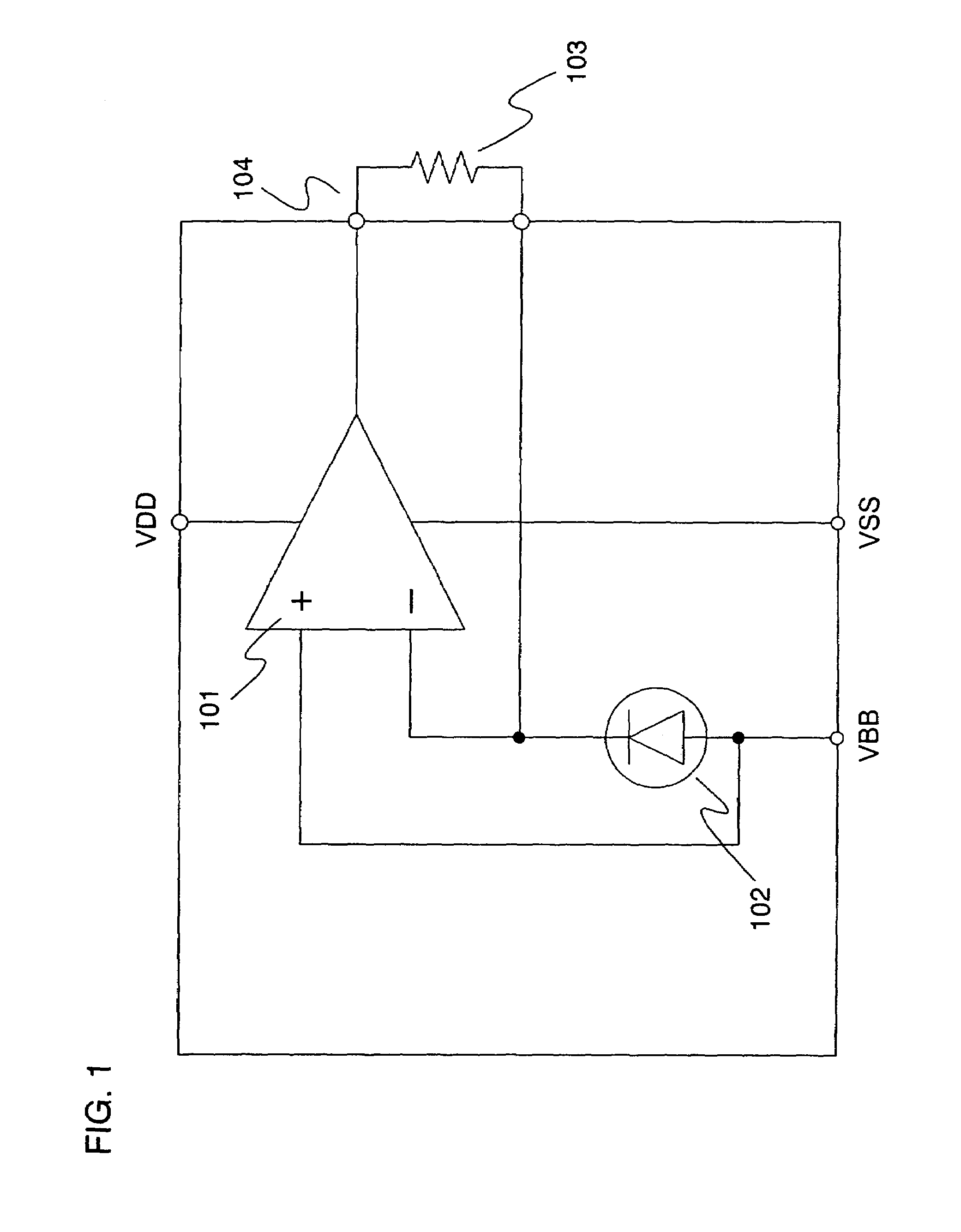

A temperature sensor is fabricated in an integrated circuit in combination with another device such as a microprocessor using a fabrication technology that is suitable for fabricating the device. Operation of the temperature sensor is based on the bandgap physics of semiconductors using a bandgap reference circuit and an amplifier that generate two measurement voltages, a voltage that is temperature-dependent and a voltage that is temperature-independent. The temperature sensor includes a bandgap power supply circuit that supplies a power supply voltage that is very stable to drive the temperature sensor so that the temperature sensor generates an output signal that is essentially independent of the power supply voltage.

Owner:GLOBALFOUNDRIES INC

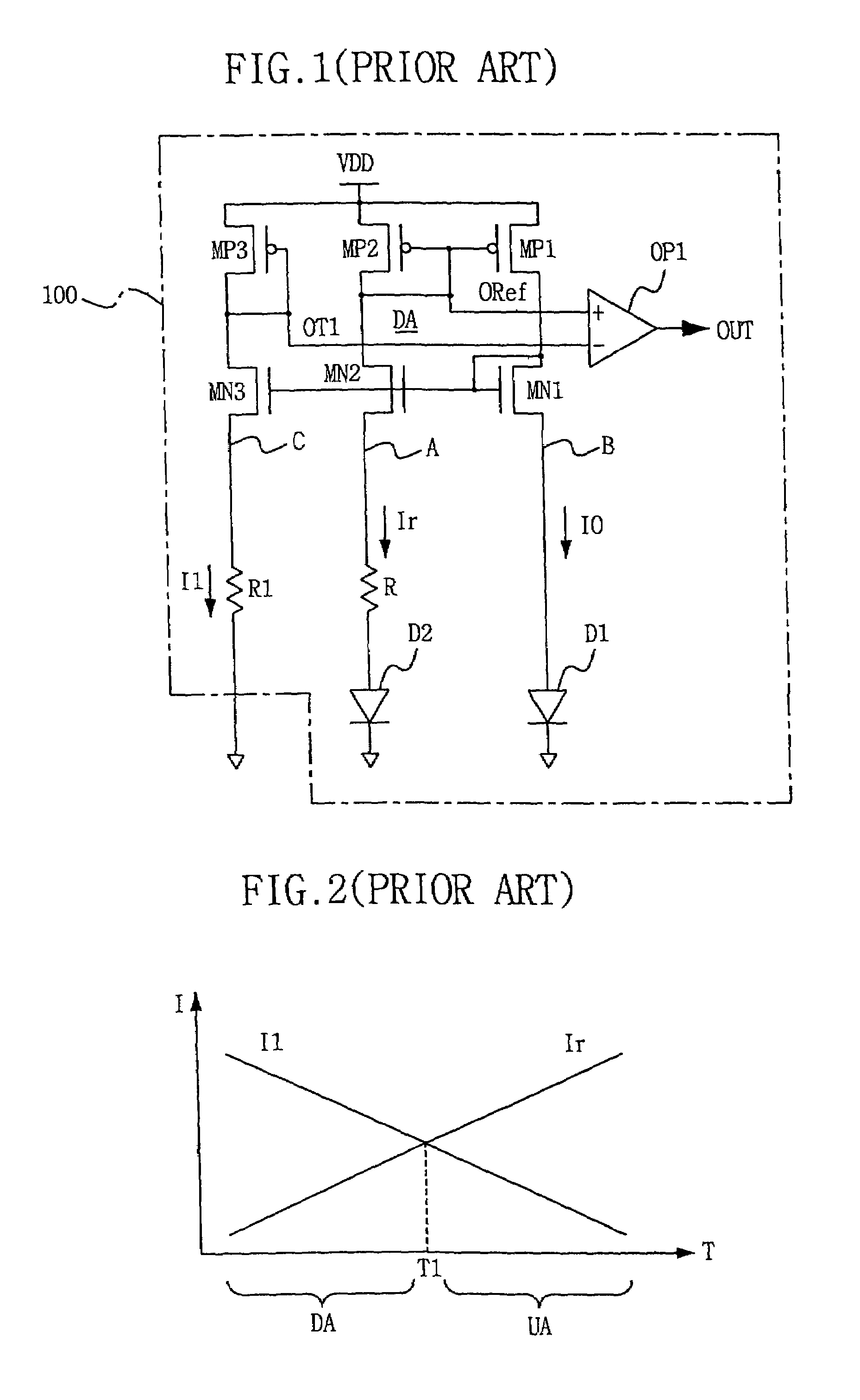

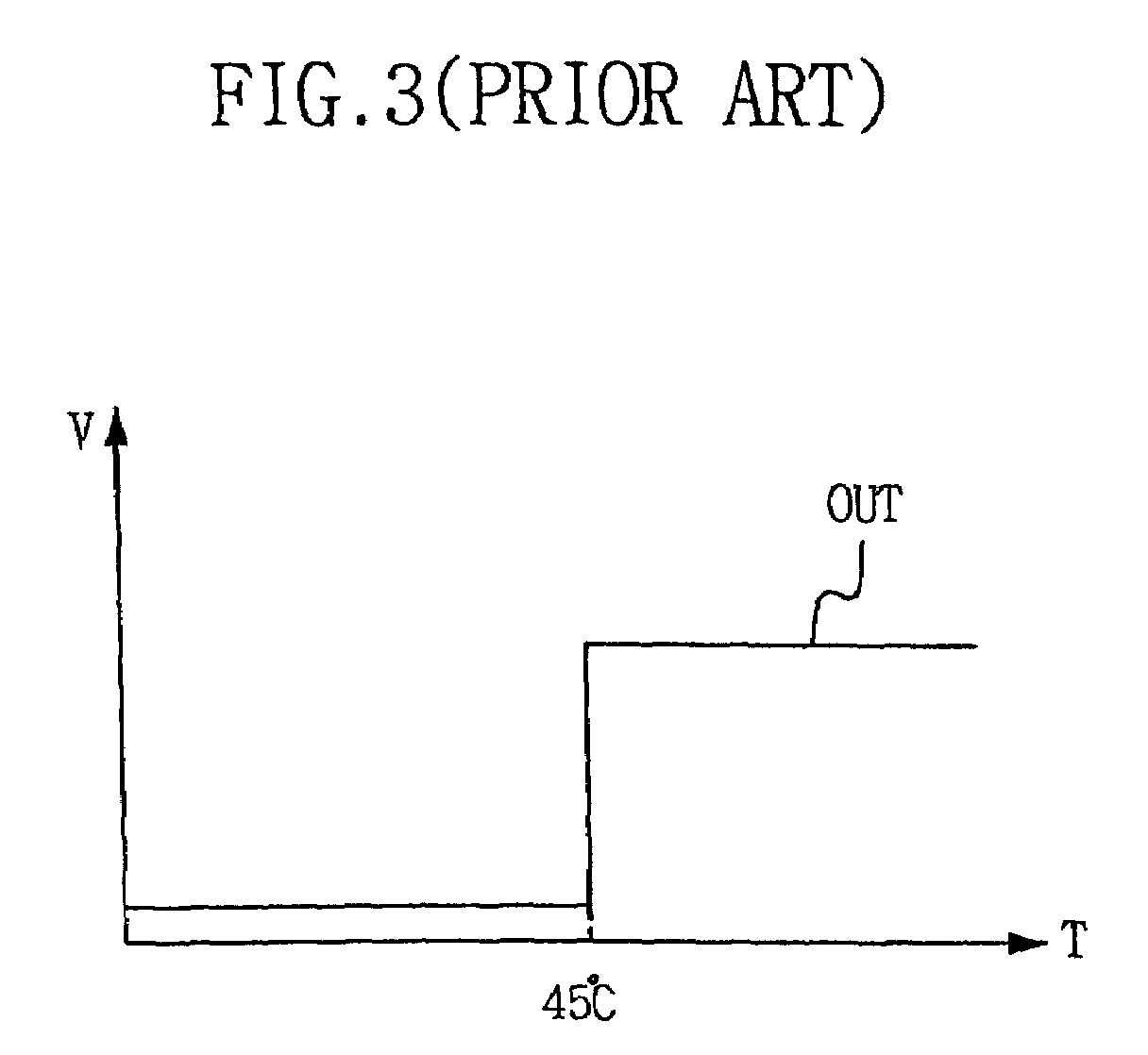

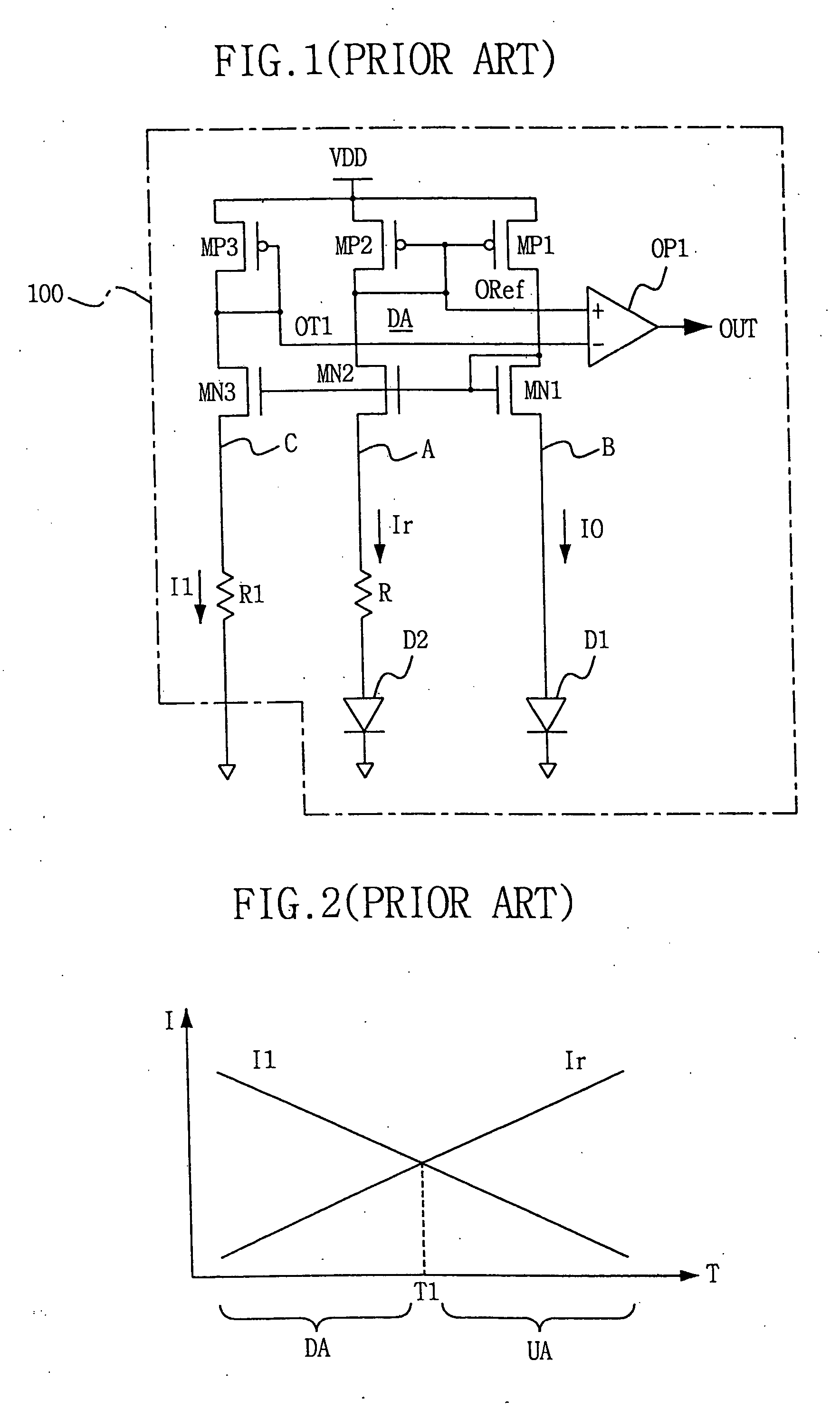

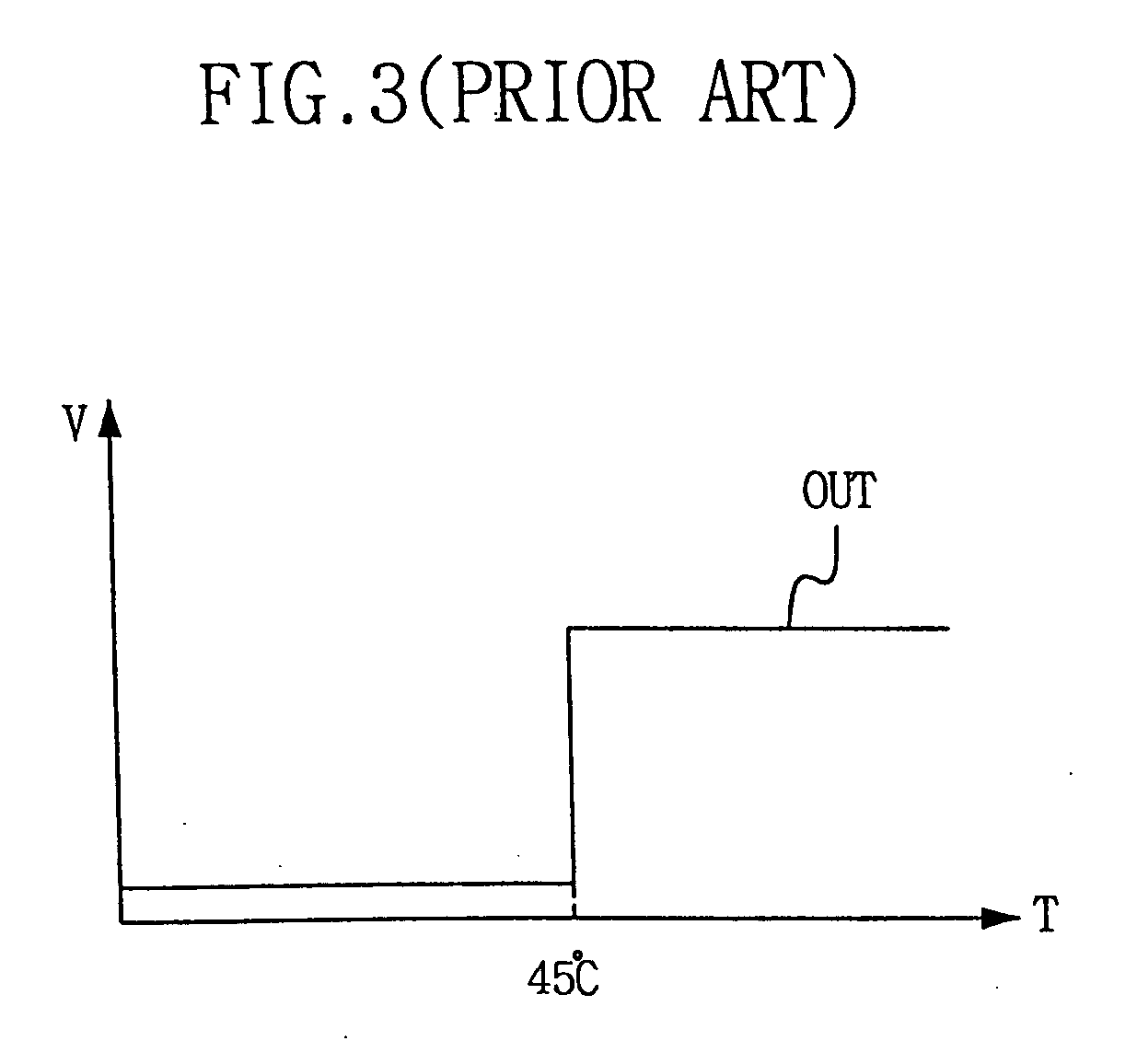

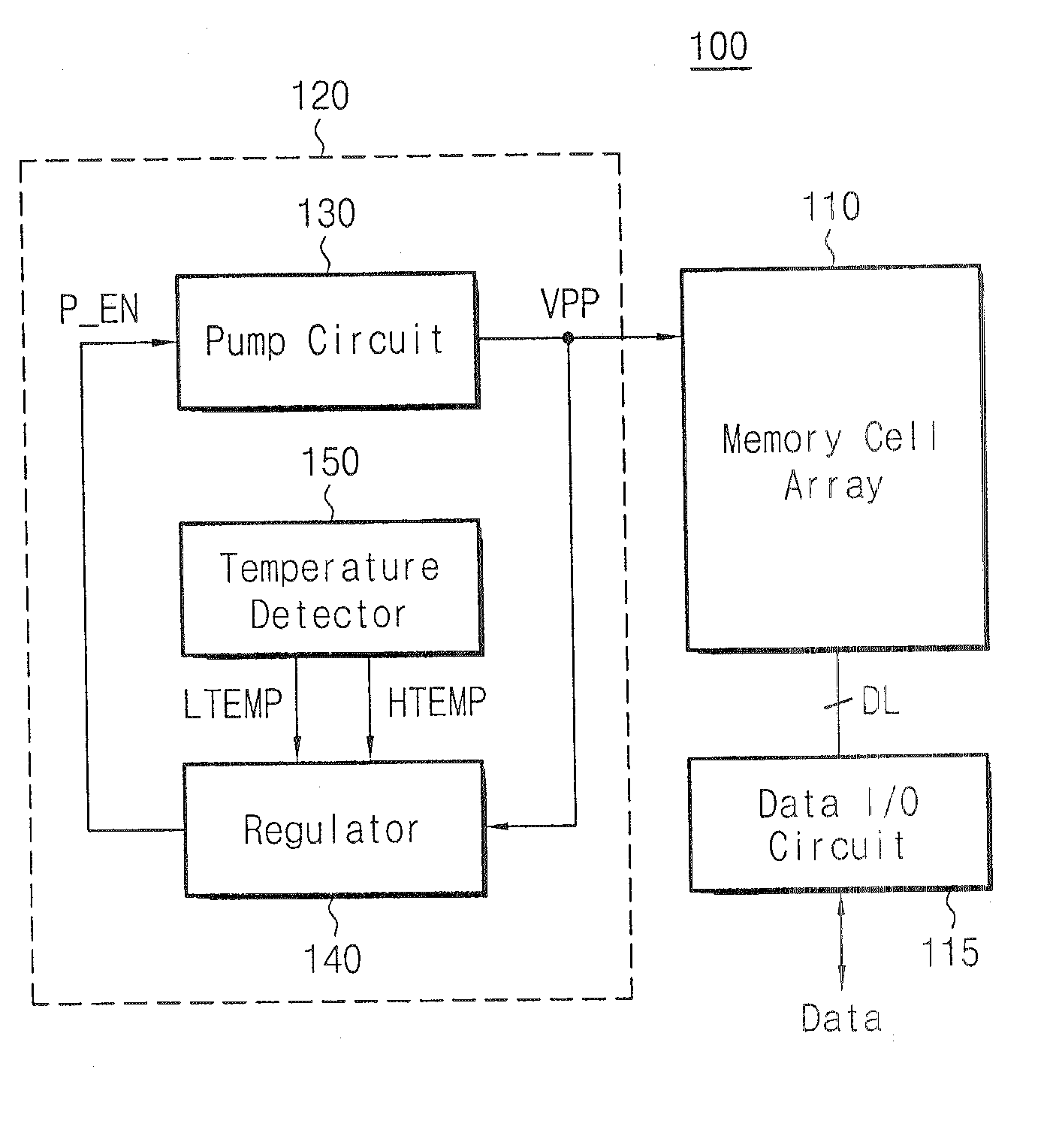

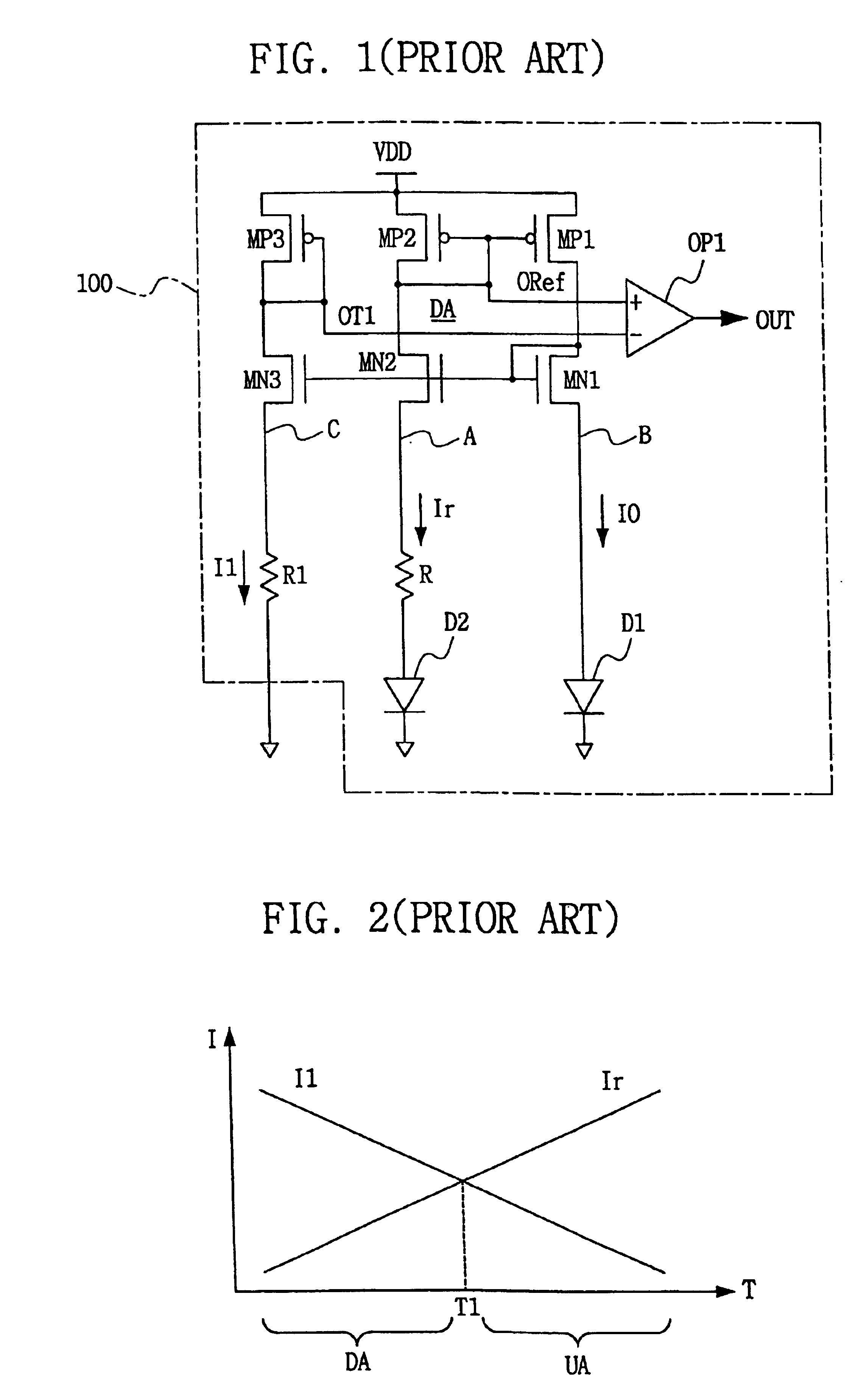

Temperature sensing circuit for use in semiconductor integrated circuit

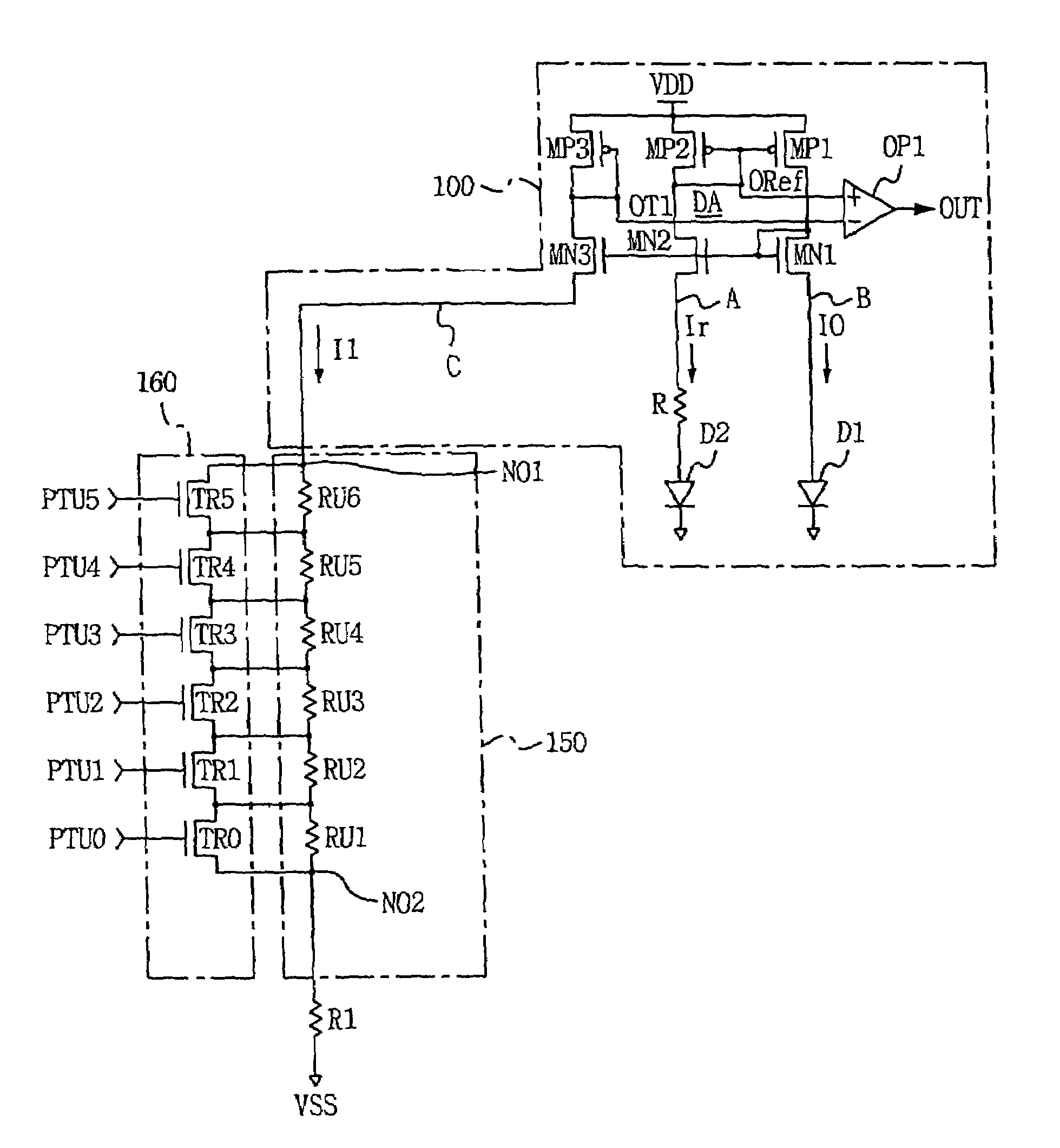

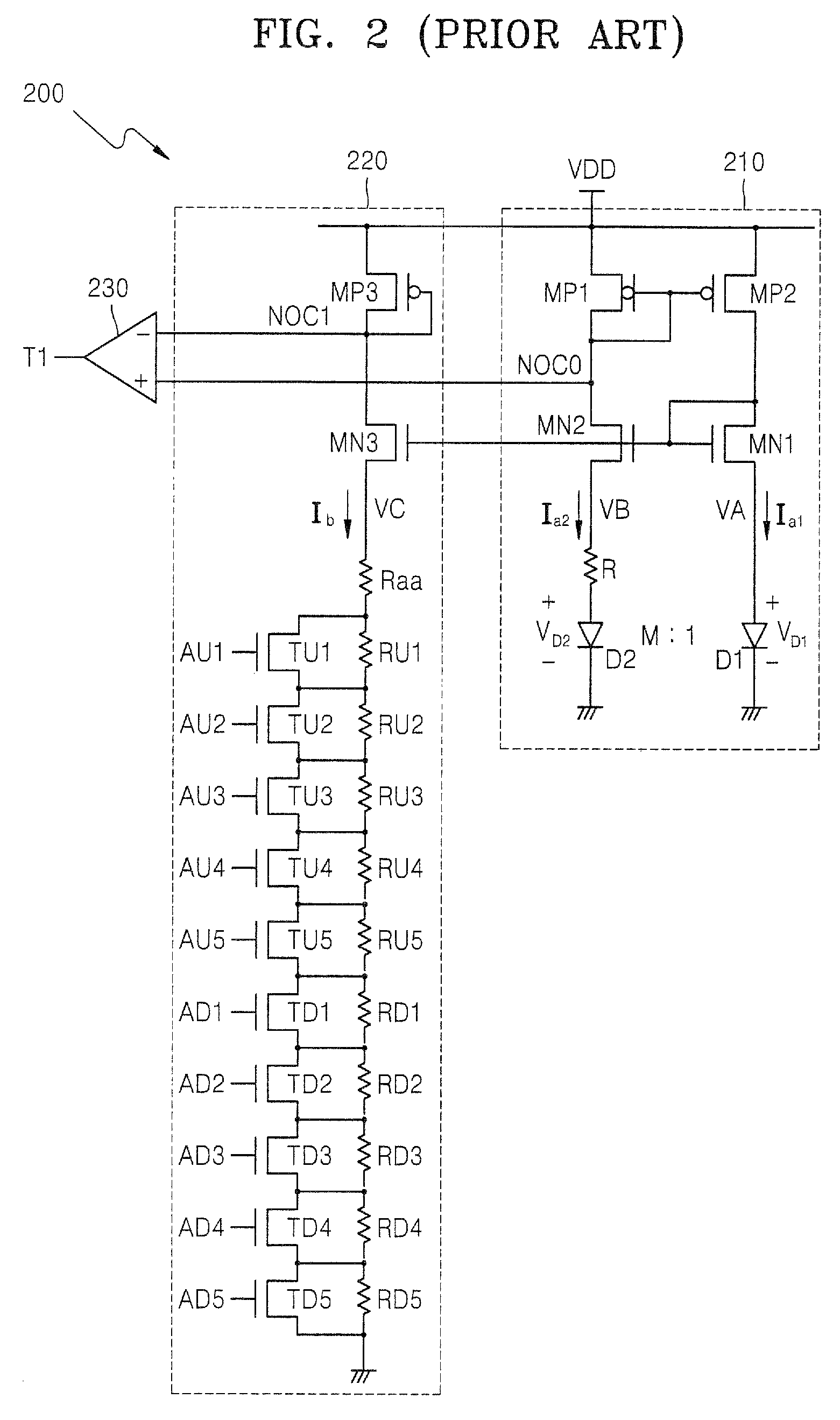

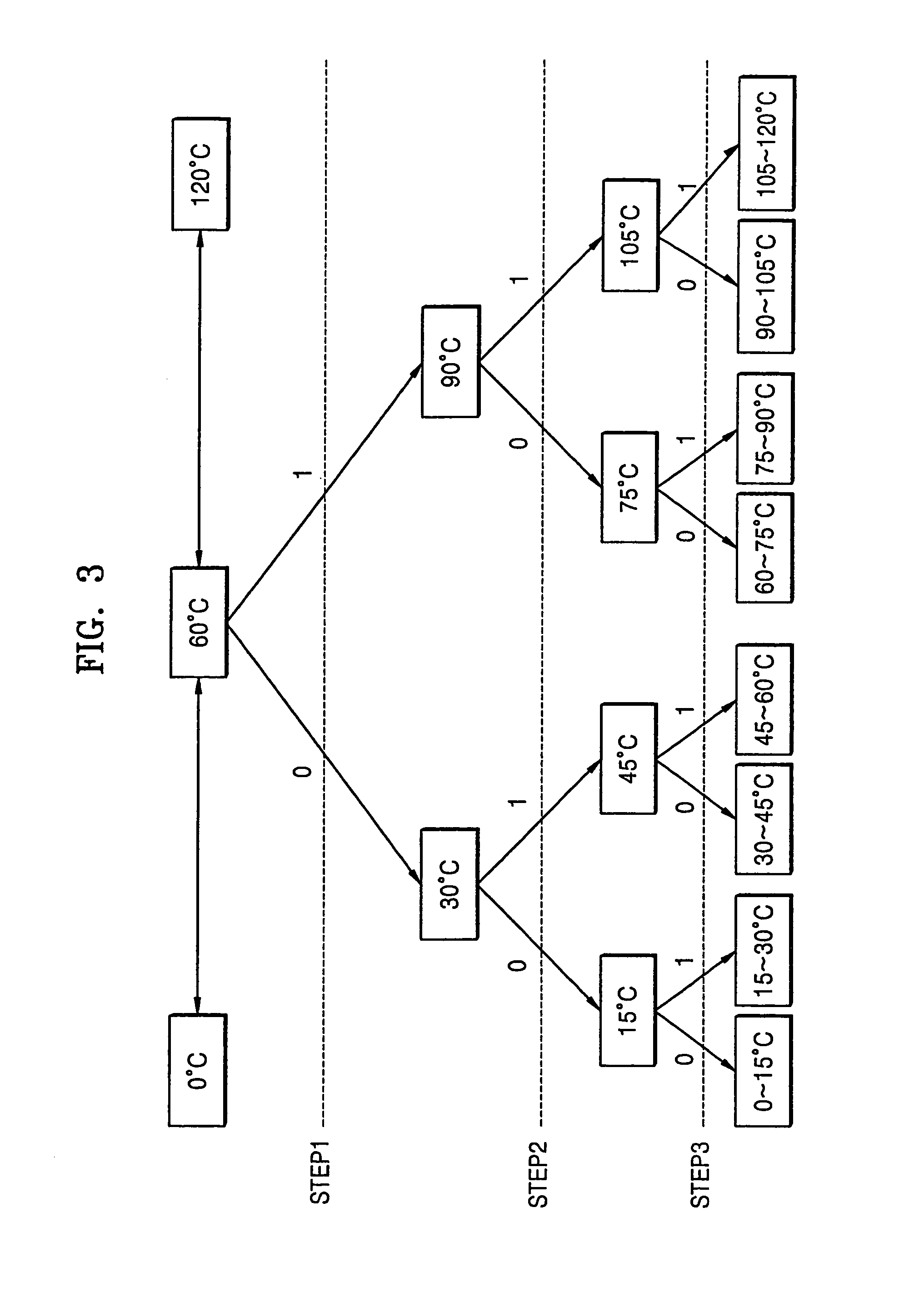

A temperature sensing circuit has numerous trip points in conformity with a temperature change without adding decrease resistance branches, so as to obtain a fine control based on the temperature change. Accordingly, when employed in a semiconductor memory device, the temperature sensing circuit substantially reduces the consumption of refresh electrical power in a stand-by state without decreasing the reliability of the semiconductor memory device.

Owner:SAMSUNG ELECTRONICS CO LTD

Low-power band-gap reference and temperature sensor circuit

InactiveUS6876250B2Short refresh cycle timeIncrease temperatureSemiconductor/solid-state device detailsThermometers using electric/magnetic elementsLow voltageMicroprocessor

A combined low-voltage, low-power band-gap reference and temperature sensor circuit is provided for providing a band-gap reference parameter and for sensing the temperature of a chip, such as an eDRAM memory unit or CPU chip, using the band-gap reference parameter. The combined sensor circuit is insensitive to supply voltage and a variation in the chip temperature. The power consumption of both circuits, i.e., the band-gap reference and the temperature sensor circuits, encompassing the combined sensor circuit is less than one μW. The combined sensor circuit can be used to monitor local or global chip temperature. The result can be used to (1) regulate DRAM array refresh cycle time, e.g., the higher the temperature, the shorter the refresh cycle time, (2) to activate an on-chip or off-chip cooling or heating device to regulate the chip temperature, (3) to adjust internally generated voltage level, and (4) to adjust the CPU (or microprocessor) clock rate, i.e., frequency, so that the chip will not overheat. The combined band-gap reference and temperature sensor circuit of the present invention can be implemented within battery-operated devices having at least one memory unit. The low-power circuits of the sensor circuit extend battery lifetime and data retention time of the cells of the at least one memory unit.

Owner:GLOBALFOUNDRIES INC

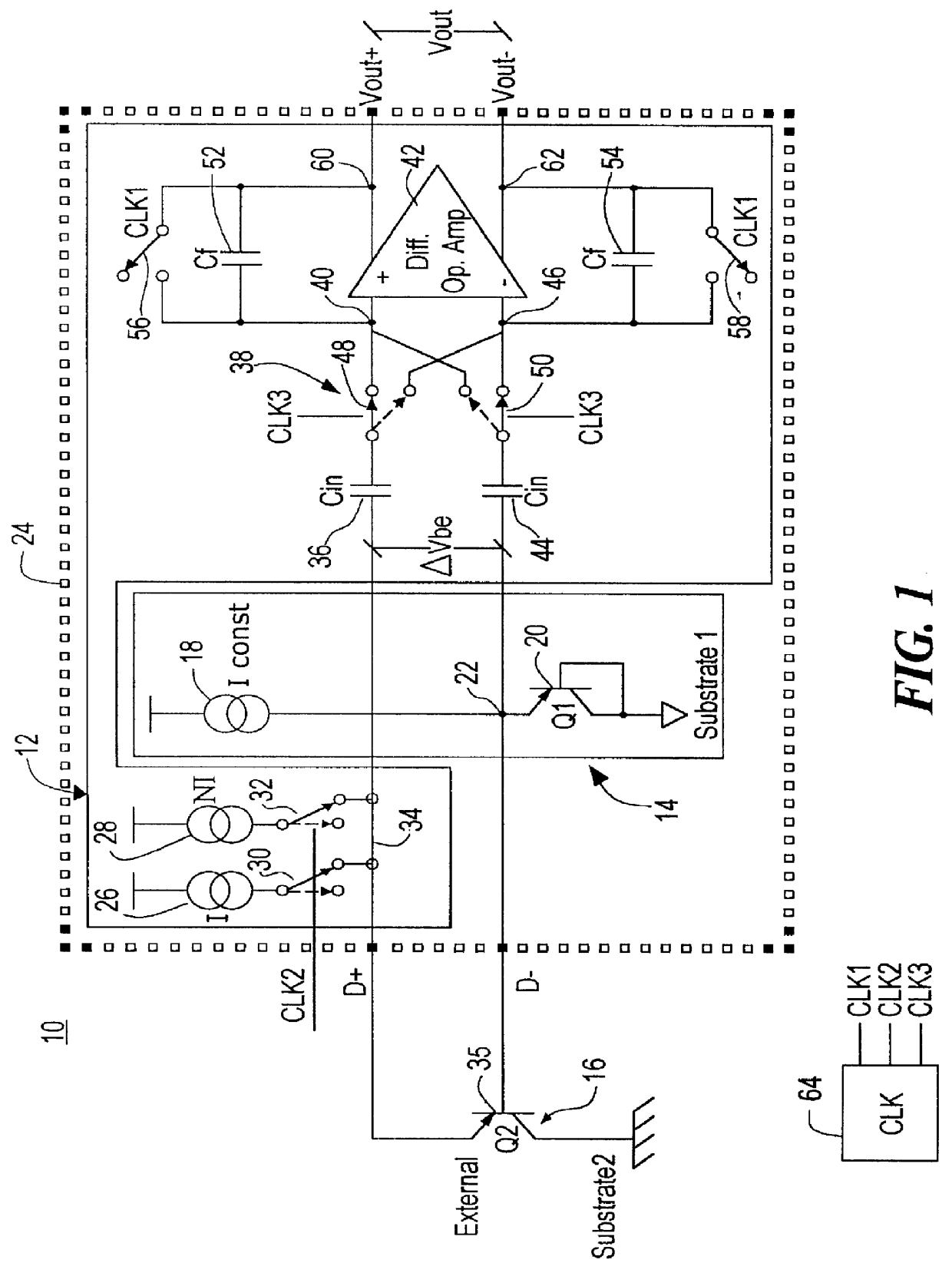

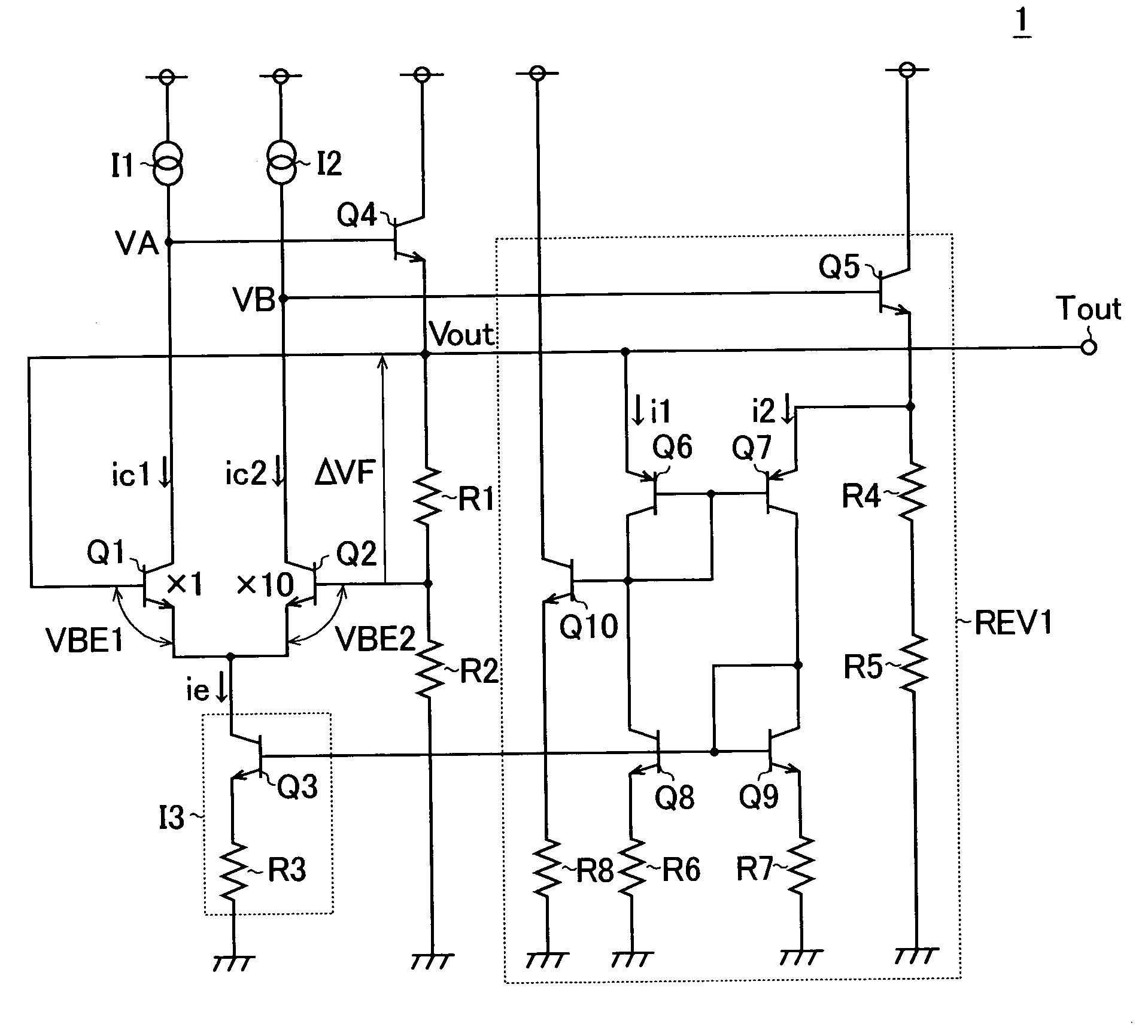

Method and a measuring circuit for determining temperature from a PN junction temperature sensor, and a temperature sensing circuit comprising the measuring circuit and a PN junction

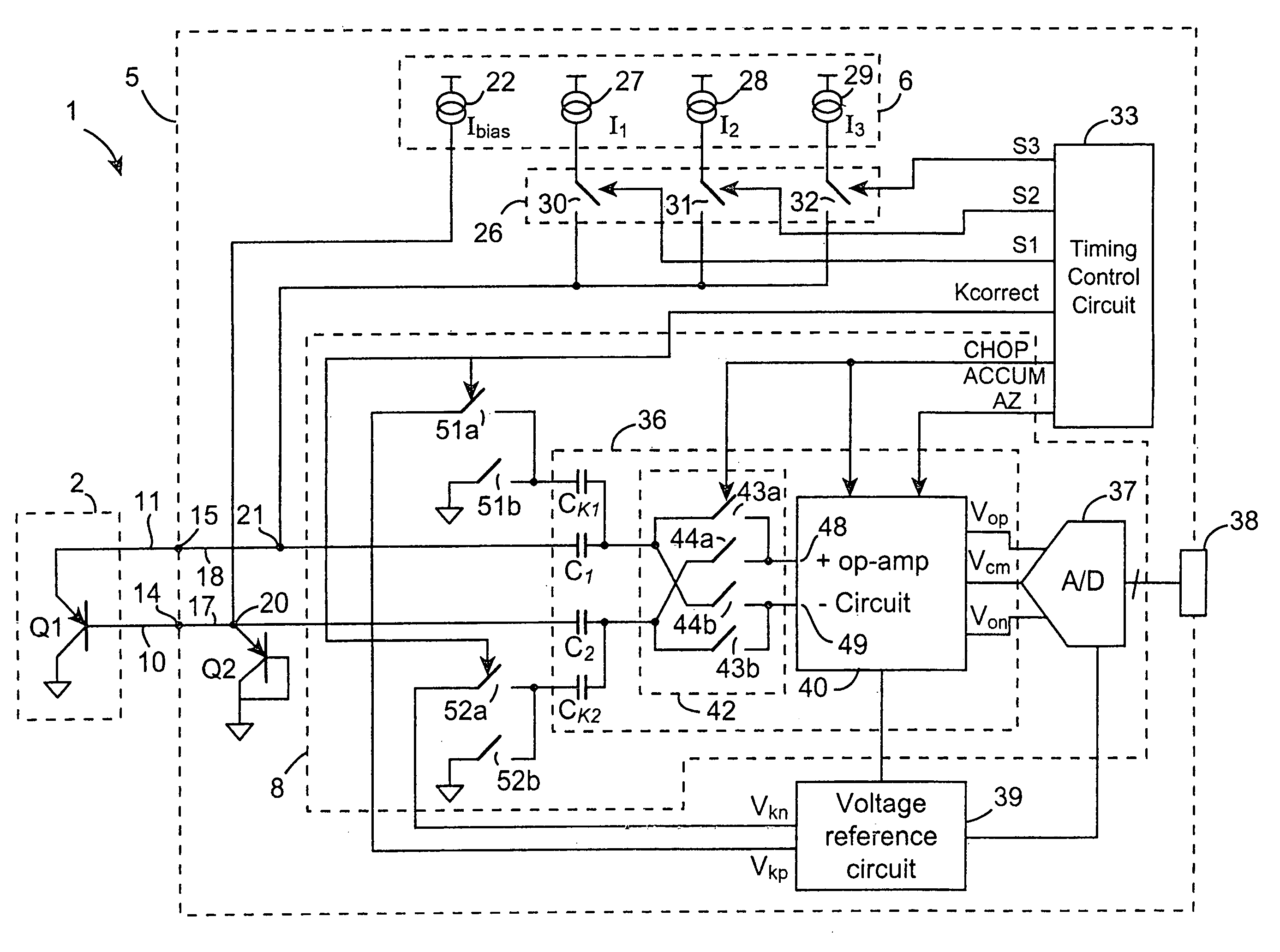

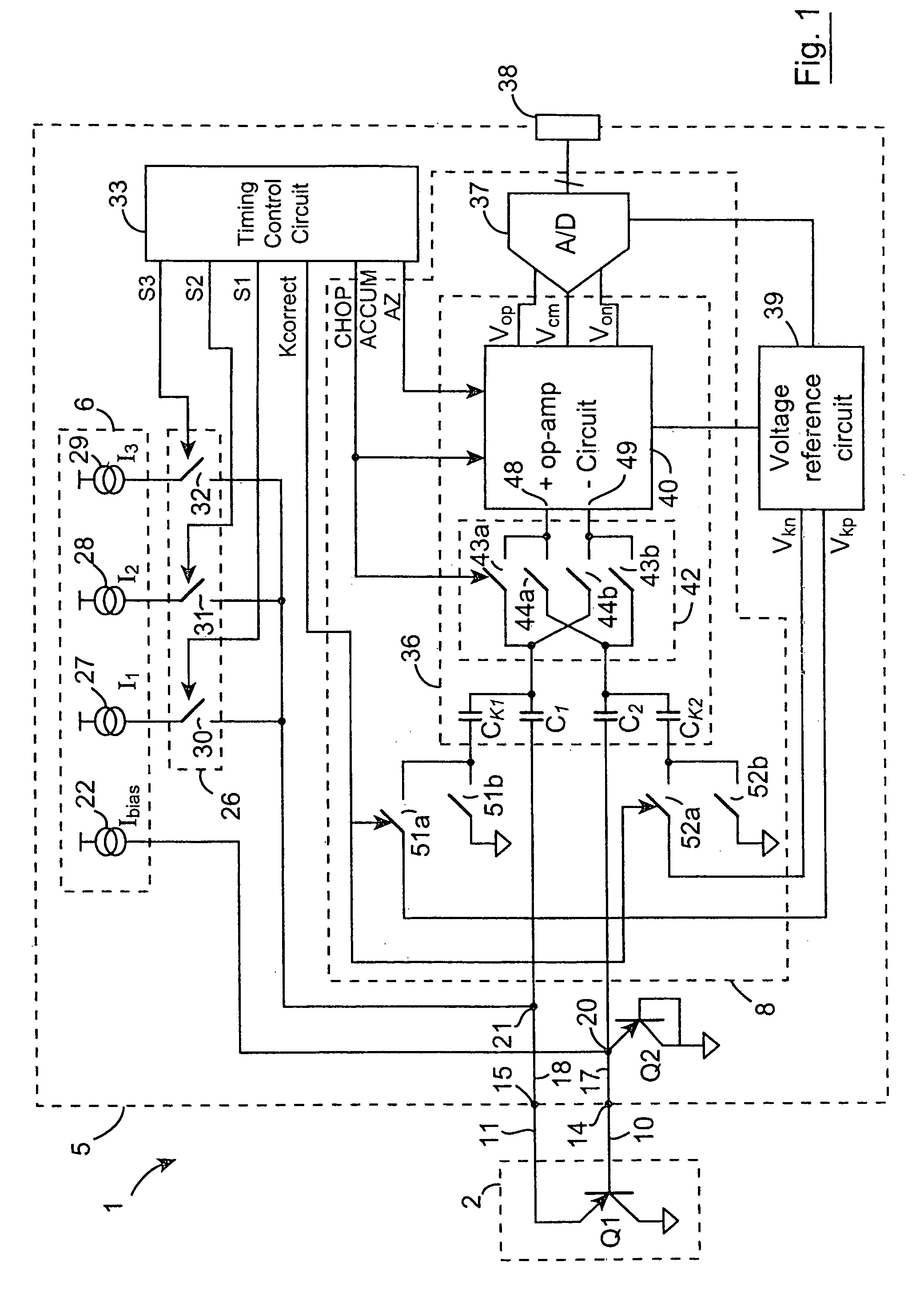

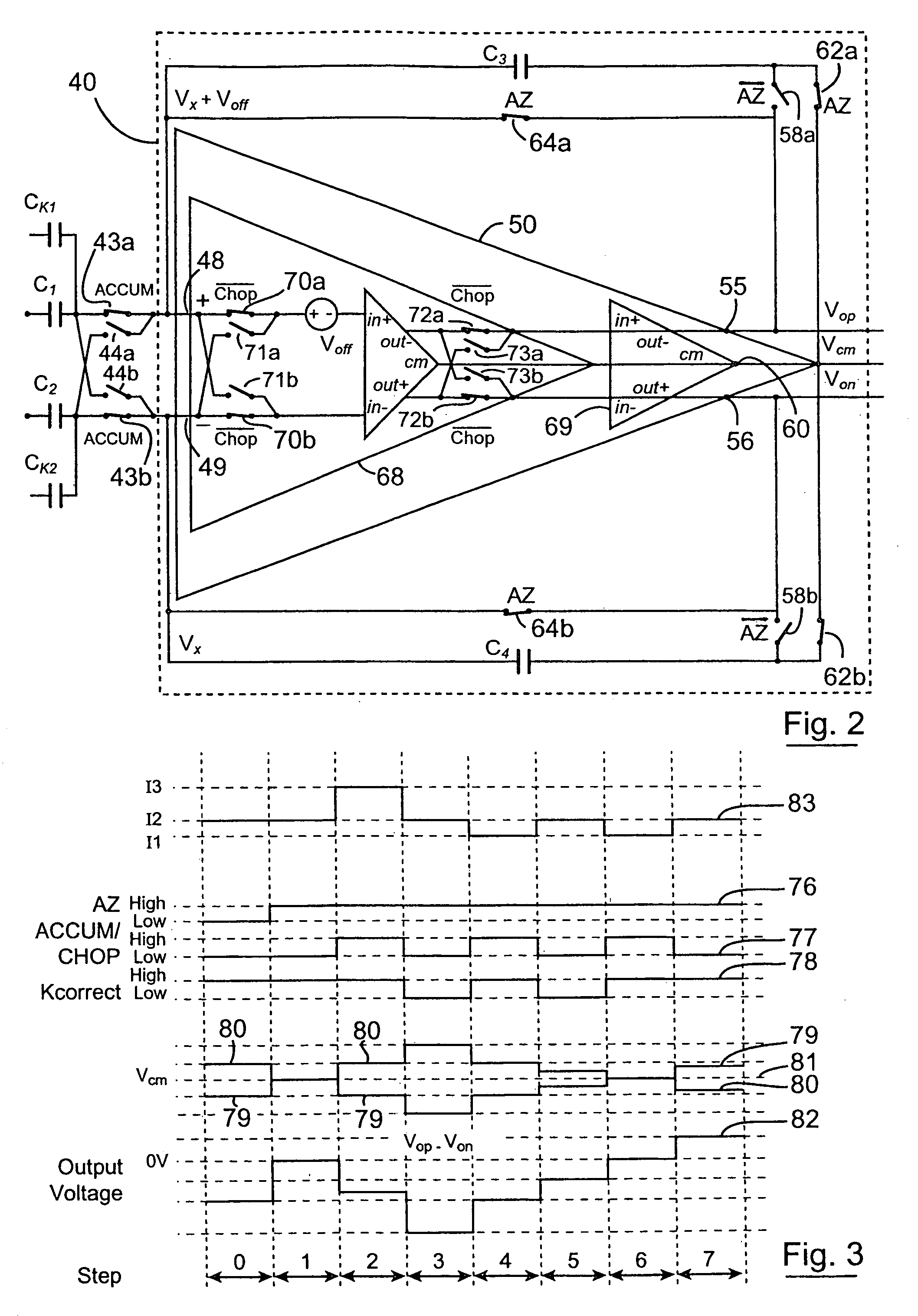

ActiveUS7010440B1Accurate representationEliminate the effects ofThermometer detailsThermometers using material expansion/contactionSwitched currentExcitation current

A switched current temperature sensing circuit (1) comprises a measuring transistor (Q1) which is located remotely of a measuring circuit (5) which applies three excitation currents (I1,I2,I3) of different values to the measuring transistor (Q1) in a predetermined current sequence along lines (10,11). Resulting base / emitter voltages from the measuring transistor (Q1) are applied to the measuring circuit (5) along the same two lines (10,11) as the excitation currents are applied to the measuring transistor (Q1). Voltage differences ΔVbe of successive base / emitter voltages resulting from the excitation currents are integrated in an integrating circuit (36) of the measuring circuit (5) to provide an output voltage indicative of the temperature of the measuring transistor (Q1). By virtue of the fact that the measuring transistor (Q1) is excited by excitation currents of three different values, the effect of current path series resistance in the lines (10,11) on the output voltage indicative of temperature is eliminated. The predetermined current sequence in which the excitation currents are applied to the measuring transistor (Q1) is selected to minimize the voltages in the integrating circuit (36) during integration of the voltage differences ΔVbe.

Owner:ANALOG DEVICES INC

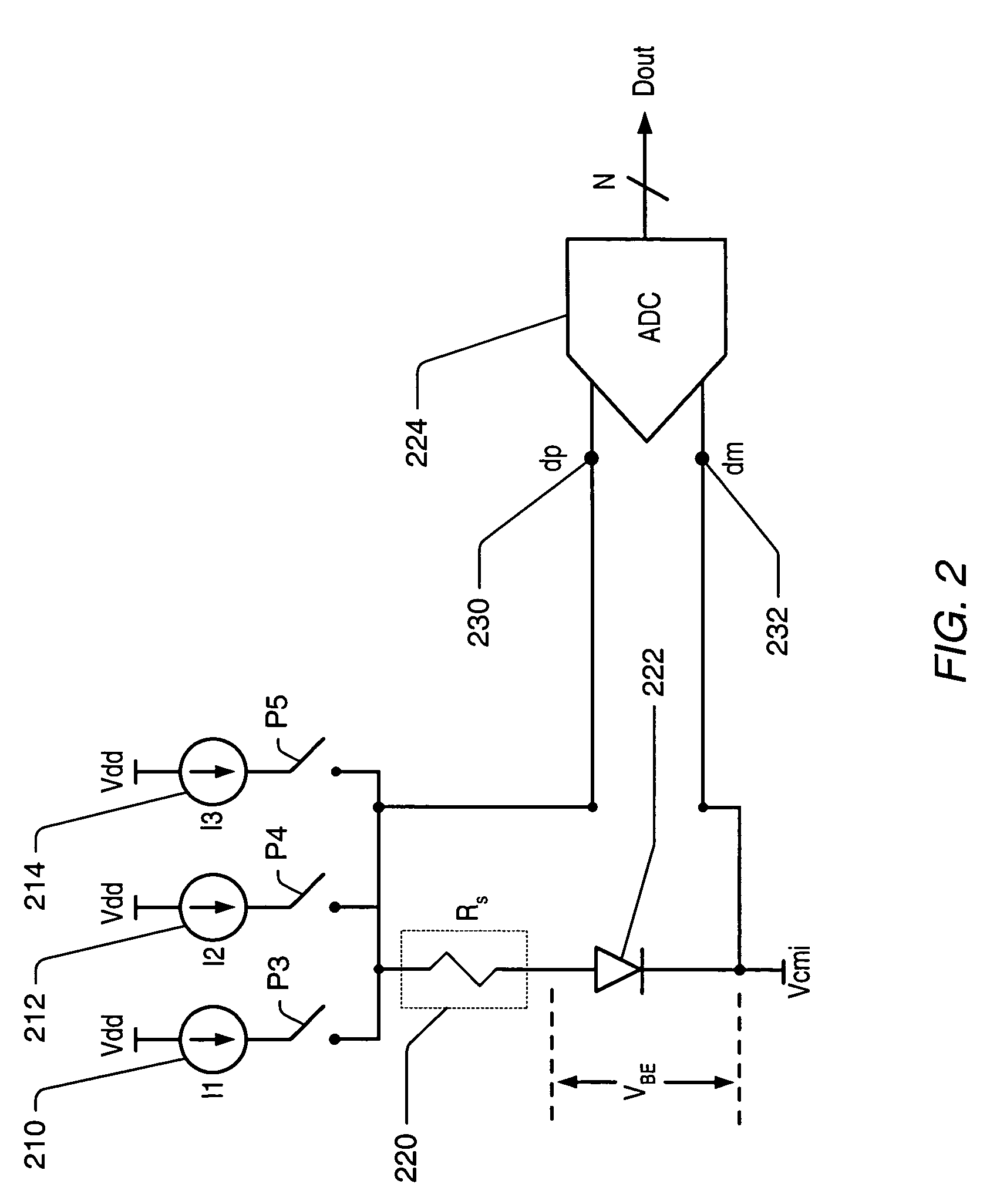

Integrated resistance cancellation in temperature measurement systems

ActiveUS7281846B2Eliminate needThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceIntegrator

A temperature measurement device may be implemented by coupling a PN-junction, which may be comprised in a diode, to an analog-to-digital converter (ADC) that comprises an integrator. Different currents may be successively applied to the diode, resulting in different VBE values across the diode. The ΔVBE values thus obtained may be successively integrated. Appropriate values for the different currents may be determined based on a set of mathematical equations, each equation relating the VBE value to the temperature of the diode, the current applied to the diode and parasitic series resistance associated with the diode. When the current sources with the appropriate values are sequentially applied to the diode and the resulting diode voltage differences are integrated by the integrator comprised in the ADC, the error in the temperature measurement caused by series resistance is canceled in the ADC, and an accurate temperature reading of the diode is obtained from the output of the ADC.

Owner:MICROCHIP TECH INC

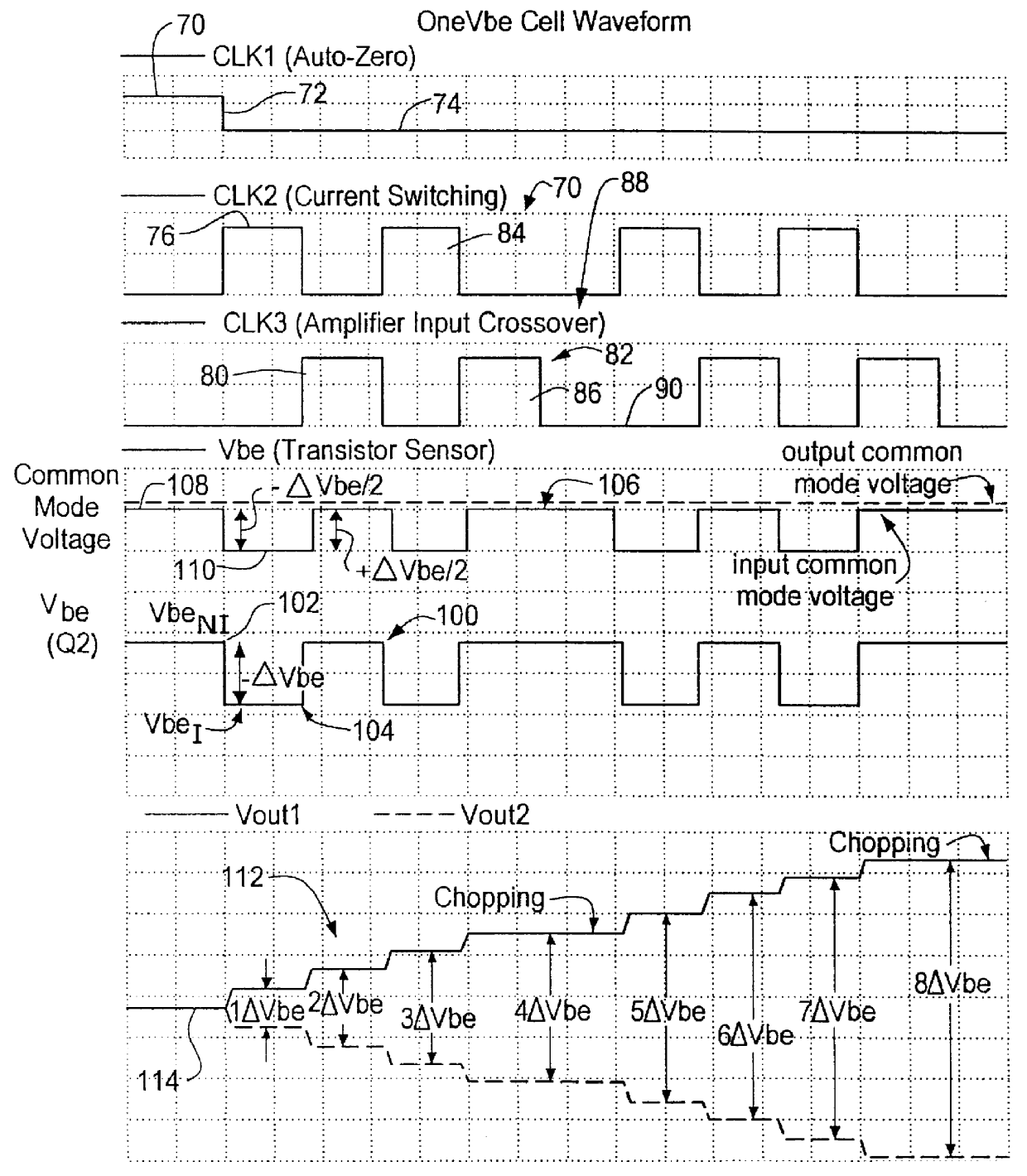

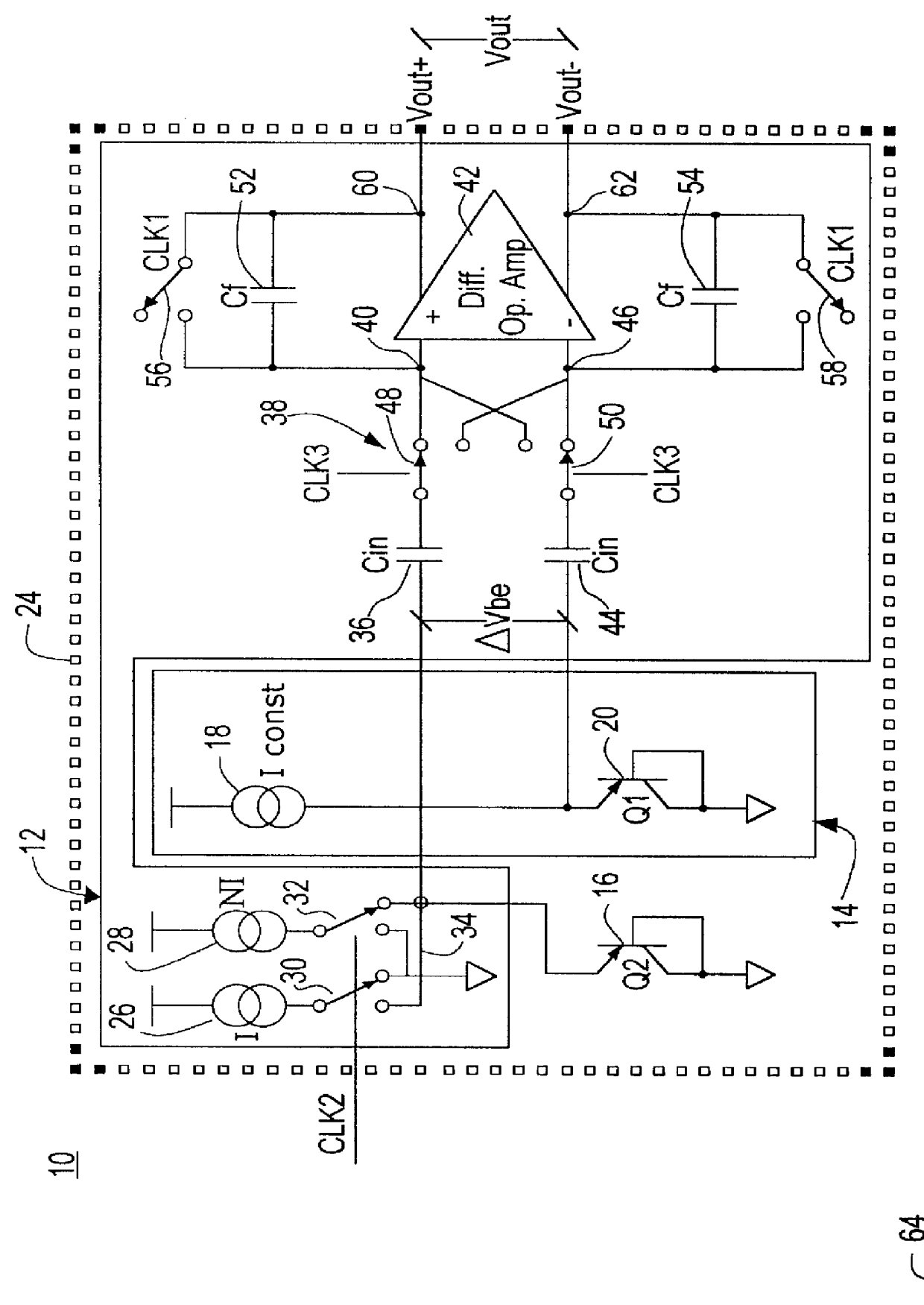

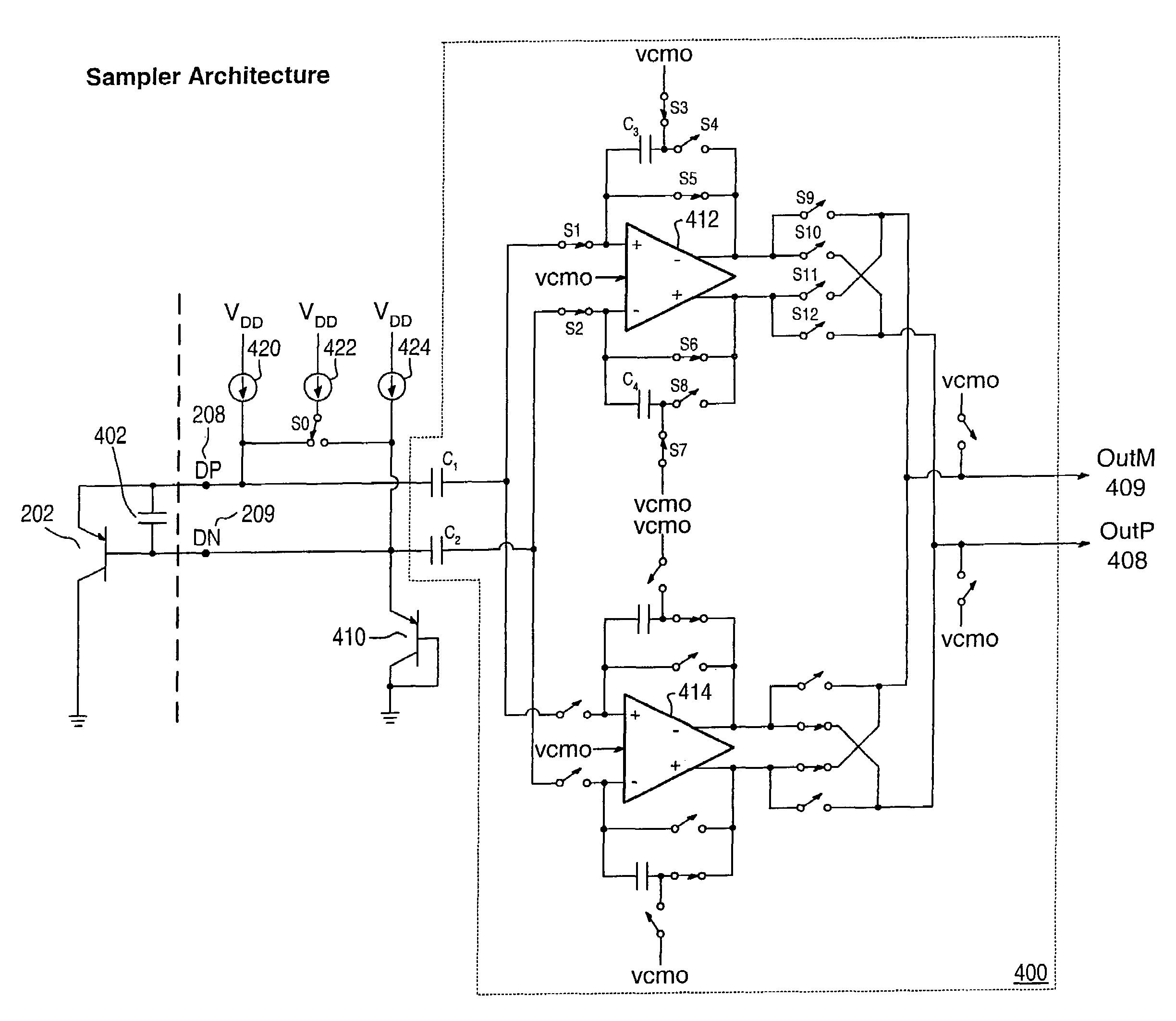

Decoupled switched current temperature circuit with compounded DELTA V be

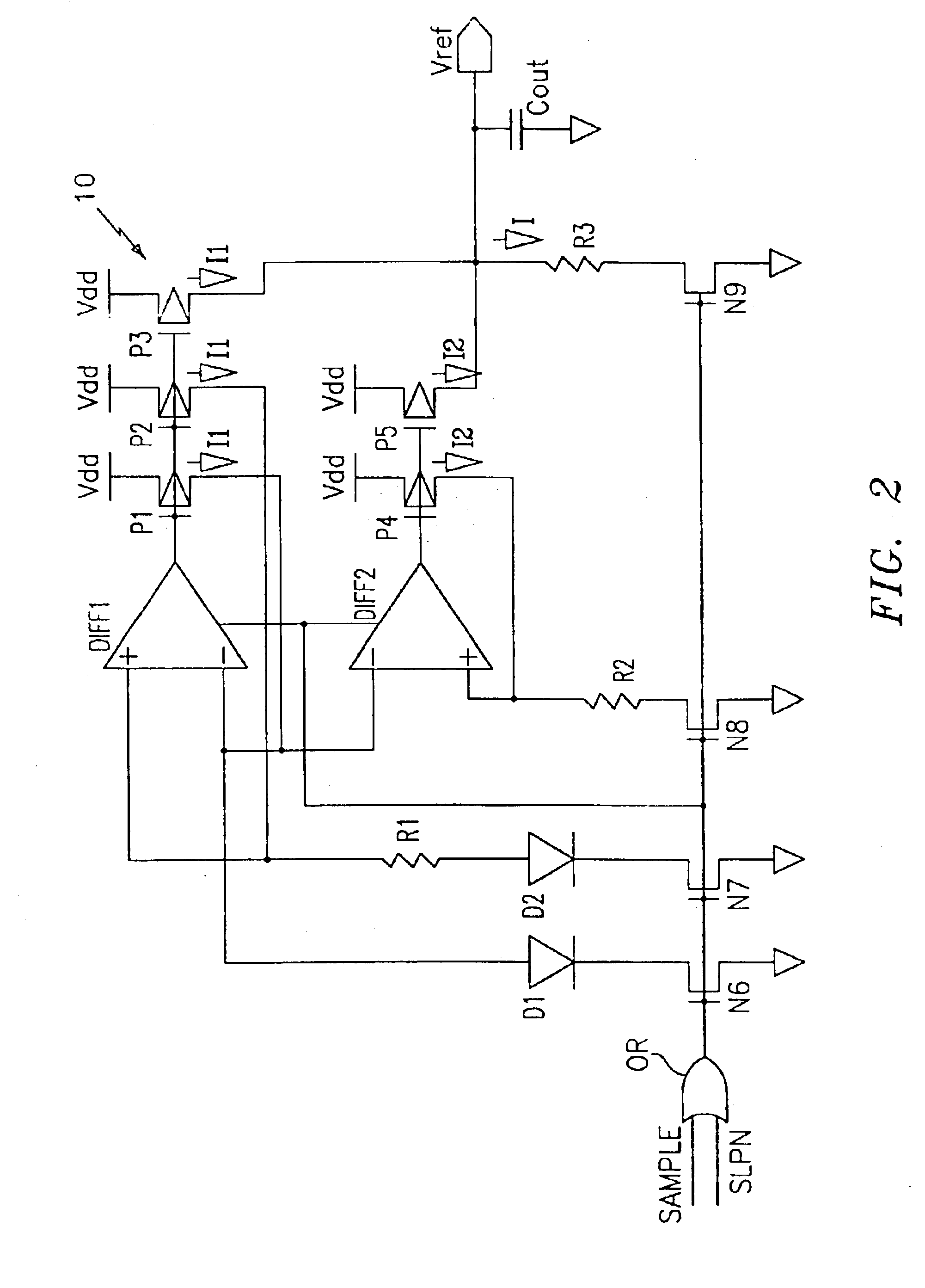

InactiveUS6097239AThermometers using electric/magnetic elementsElectronic switchingDelta-vAudio power amplifier

A decoupled switched current temperature circuit with compounded DELTA Vbe includes an amplifier having an inverting input with corresponding non-inverting output and a non-inverting input with a corresponding inverting output; a PN junction connected to the non-inverting input through a first input capacitor and a voltage reference circuit is connected to the inverting input through a second input capacitor; a current supply includes a low current source and a high current source; a switching device applies the high current source to the PN junction and applies the low current source to the PN junction for providing the DELTA Vbe of the PN junction to the first capacitor; a first feedback capacitor is interconnected between the inverting output and the non-inverting input and a second feedback capacitor is interconnected between the non-inverting output and inverting input of the amplifier to define the gain on each of the inputs to produce a differential voltage across the outputs representative of the temperature of the PN junction; first and second reset switching devices discharge the first and second feedback capacitors, respectively, and a multi-phase switched device alternately interchanges the connection of the first and second input capacitors with the amplifier inputs for compounding the single DELTA Vbe .

Owner:ANALOG DEVICES INC

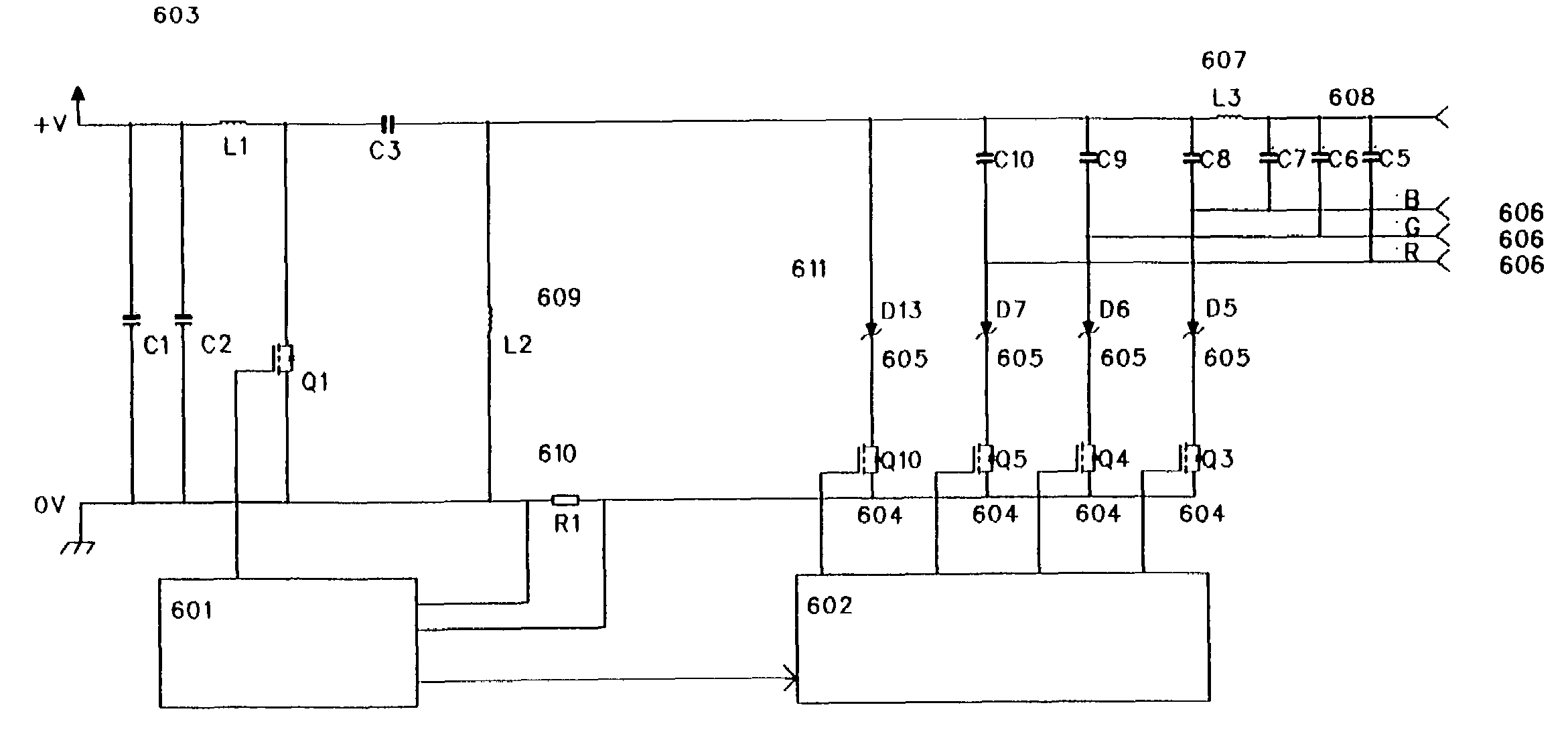

Controller circuit

InactiveUS7023147B2Life maximizationSimple, constant current sourceElectroluminescent light sourcesElectronic switchingConfined spaceEngineering

Owner:PENTAIR POOL PROD INC

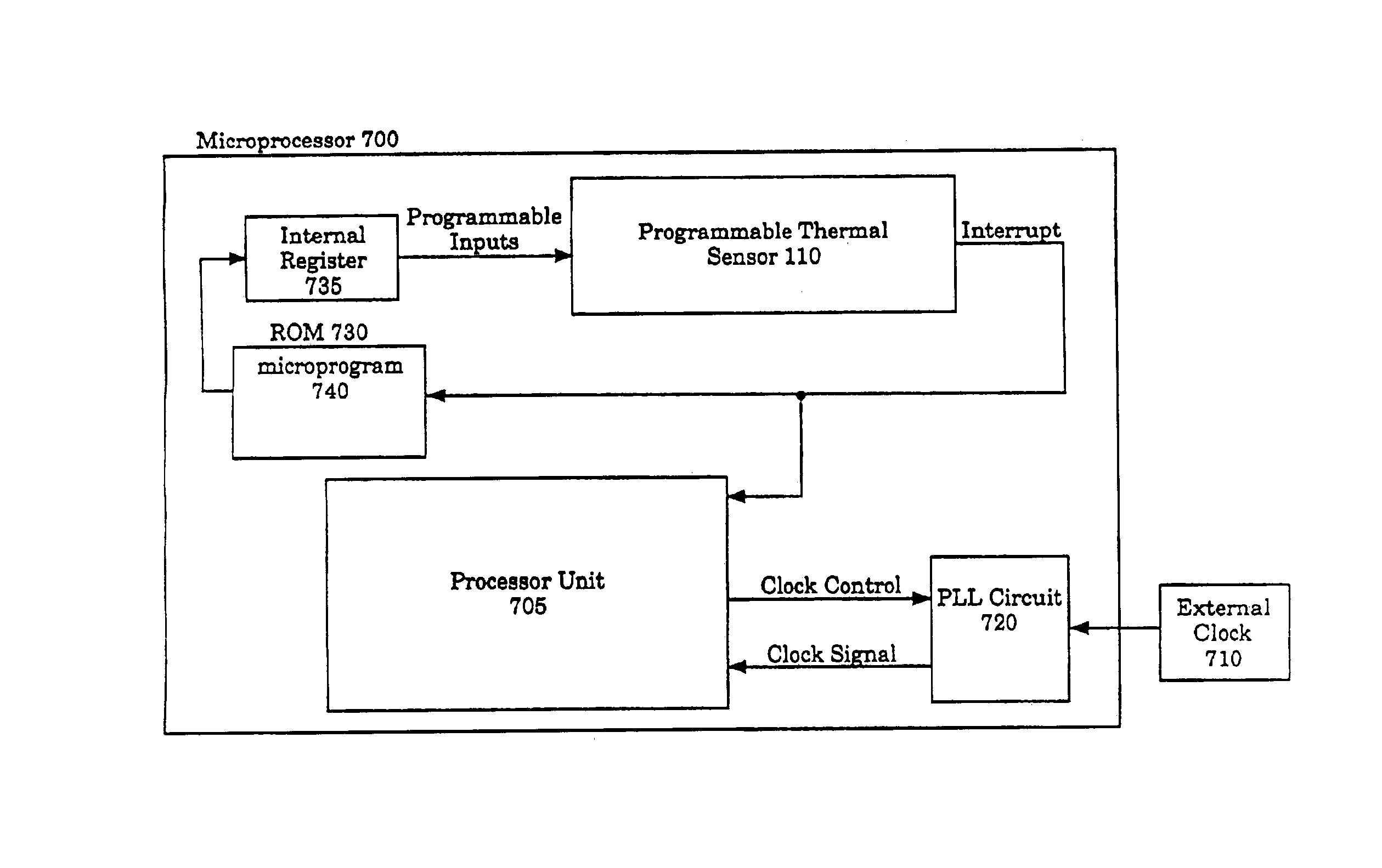

Temperature-based cooling device controller apparatus and method

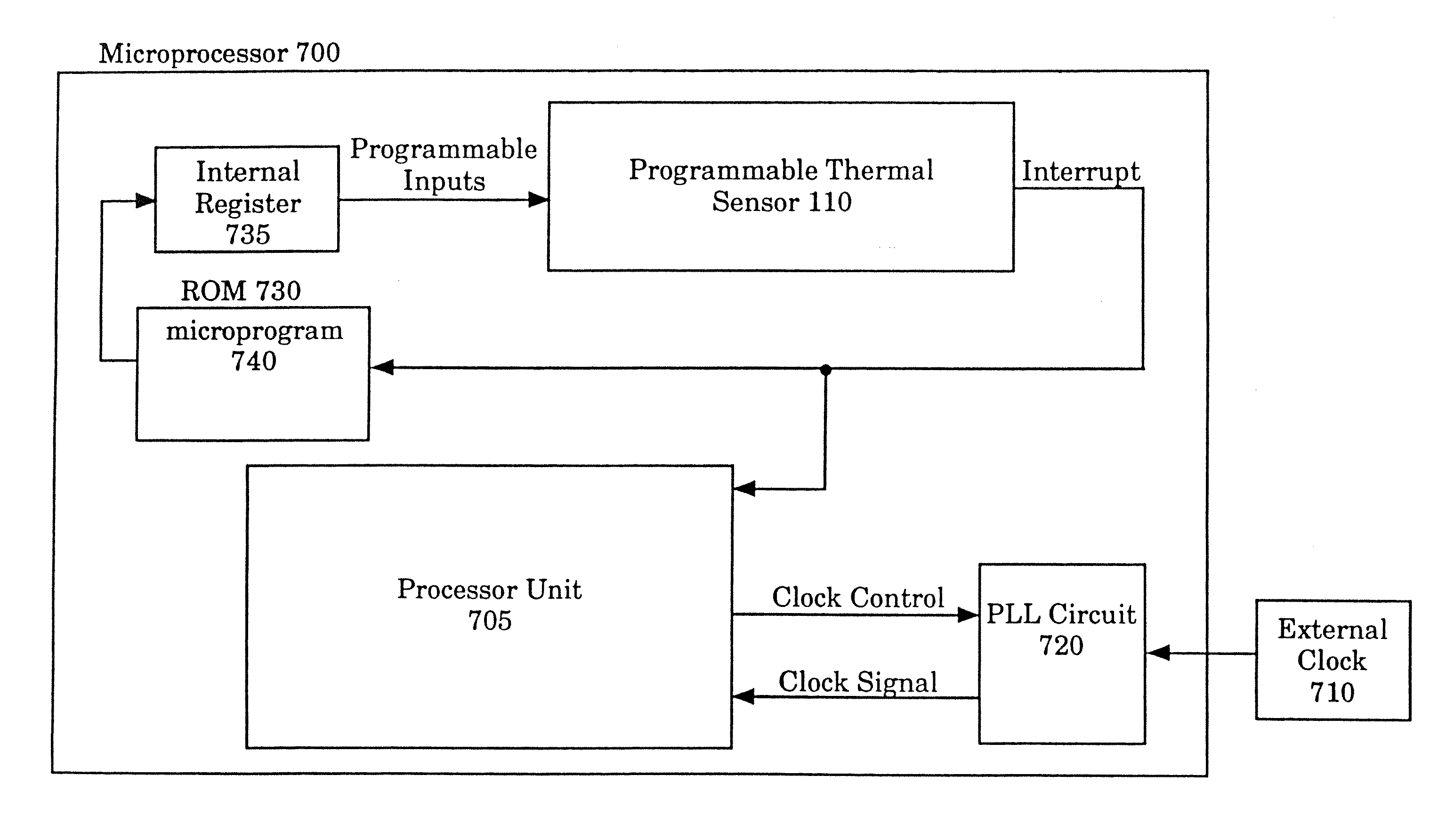

InactiveUS6975047B2Reduce clock frequencySystem clock frequency is increasedEnergy efficient ICTDigital data processing detailsProcessor registerThreshold temperature

A temperature-based cooling device controller is implemented in an integrated circuit such as a microprocessor. The temperature-based cooling device controller includes a register to store a threshold temperature value, a thermal sensor, and clock adjustment logic to activate a cooling device in response to the thermal sensor indicating that the threshold temperature value has been exceeded. In a microprocessor implementation, the microprocessor contains a plurality of thermal sensors each placed in one of a plurality of different locations across the integrated circuit and an averaging mechanism to calculate an average temperature from the plurality of thermal sensors. Threshold adjustment logic increases the threshold temperature value to a new threshold temperature value in response to the thermal sensor indicating that the threshold temperature value has been exceeded. Threshold adjustment logic further lowers the new threshold temperature to detect decreases in temperature.

Owner:INTEL CORP

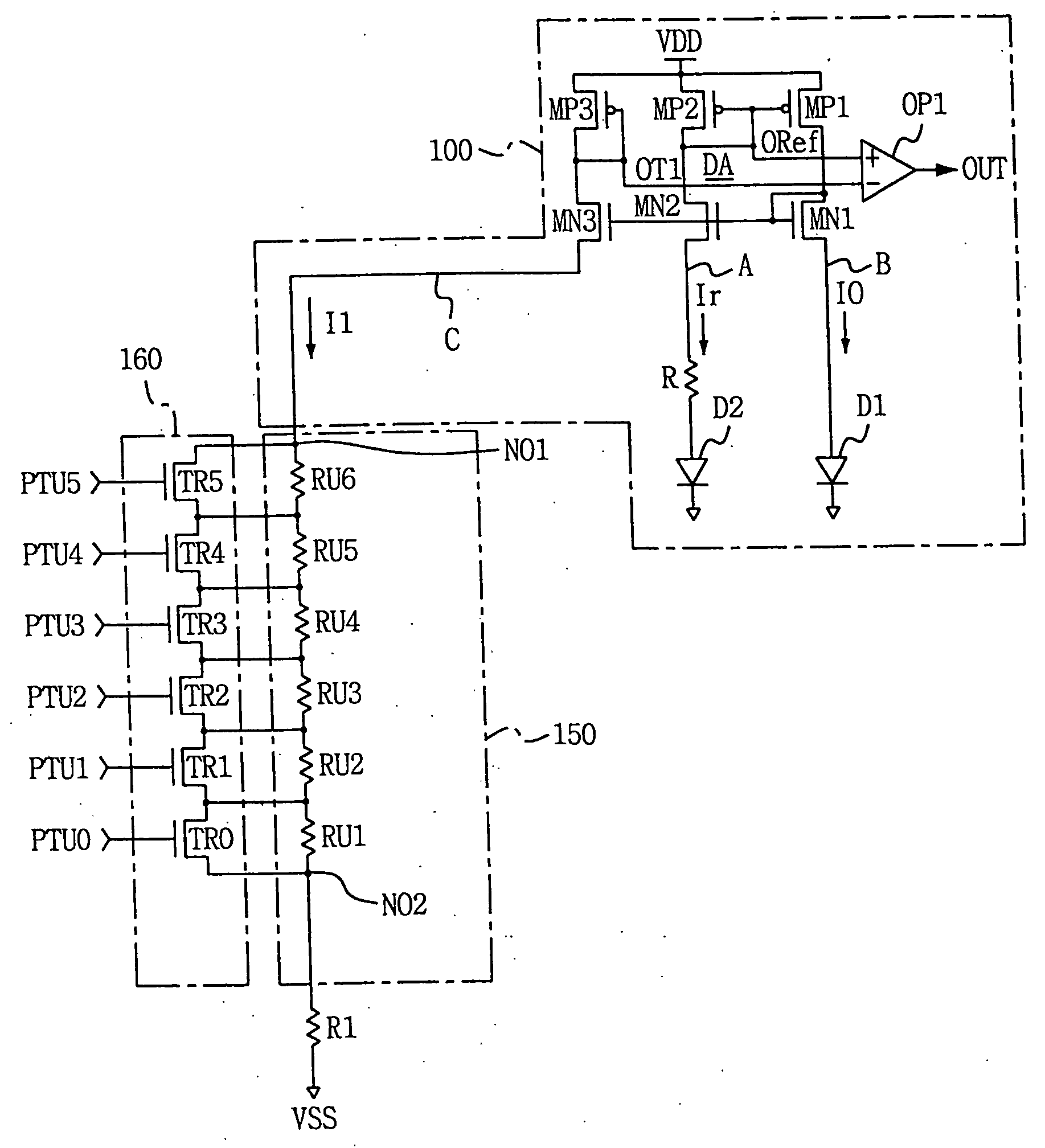

Temperature sensing circuit for use in semiconductor integrated circuit

InactiveUS20050074051A1Reduce consumptionReduce needThermometer detailsTesting/calibration apparatusEngineeringSemiconductor

A temperature sensing circuit has numerous trip points in conformity with a temperature change without adding decrease resistance branches, so as to obtain a fine control based on the temperature change. Accordingly, when employed in a semiconductor memory device, the temperature sensing circuit substantially reduces the consumption of refresh electrical power in a stand-by state without decreasing the reliability of the semiconductor memory device.

Owner:SAMSUNG ELECTRONICS CO LTD

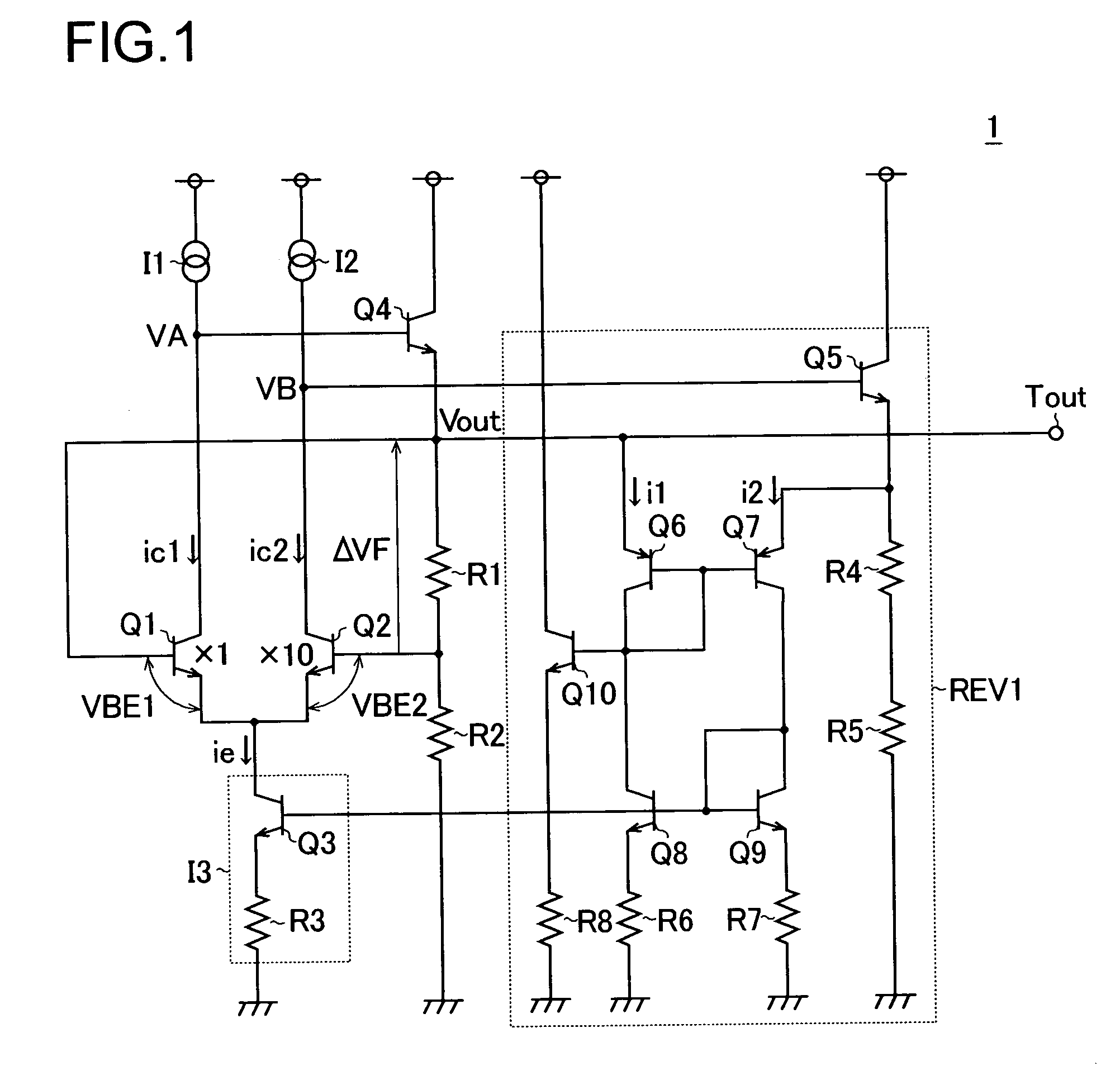

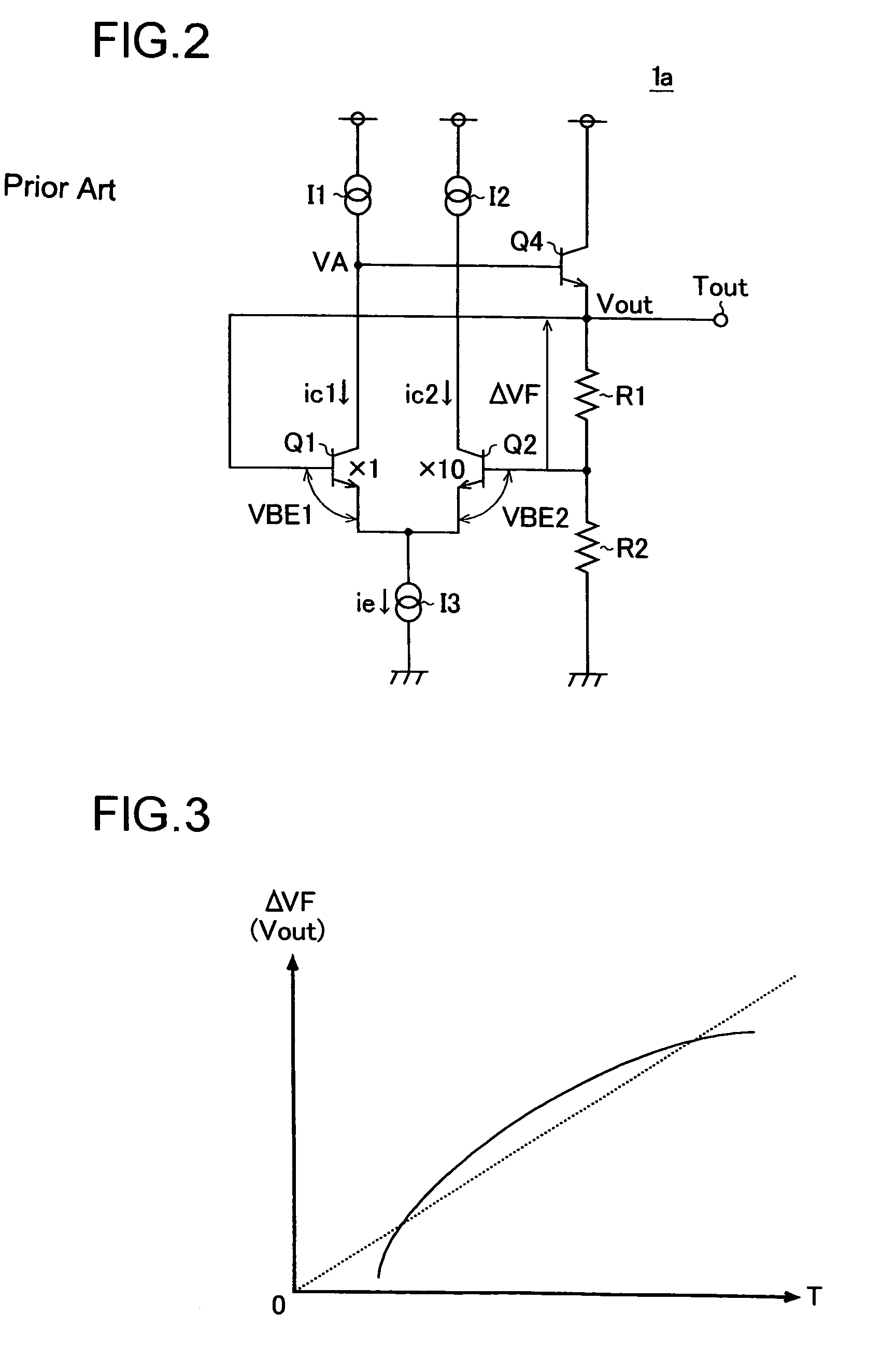

Semiconductor device, temperature sensor, and electronic apparatus comprising it

InactiveUS7176701B2Improve accuracyImprove linearityElectronic circuit testingResistance/reactance/impedenceEngineeringFeedback circuits

A temperature sensor including two transistors having different emitter current densities and performing temperature detection based on the fact that the difference in voltage between base and emitter changes with temperature. The temperature sensor is provided with a feedback circuit for controlling respective collector voltages and emitter currents such that the collector voltages of both transistors vary according to similar temperature characteristics.

Owner:ROHM CO LTD

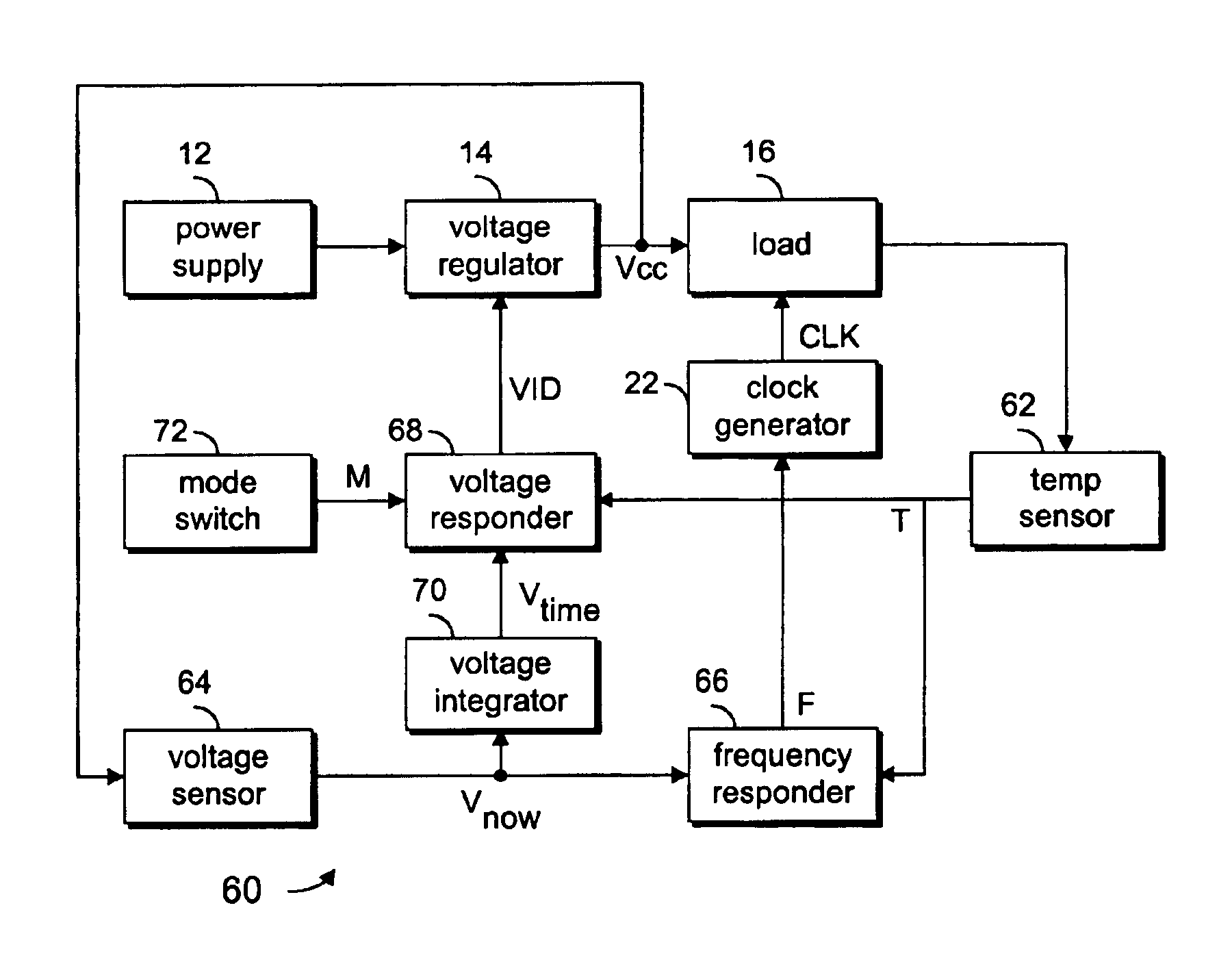

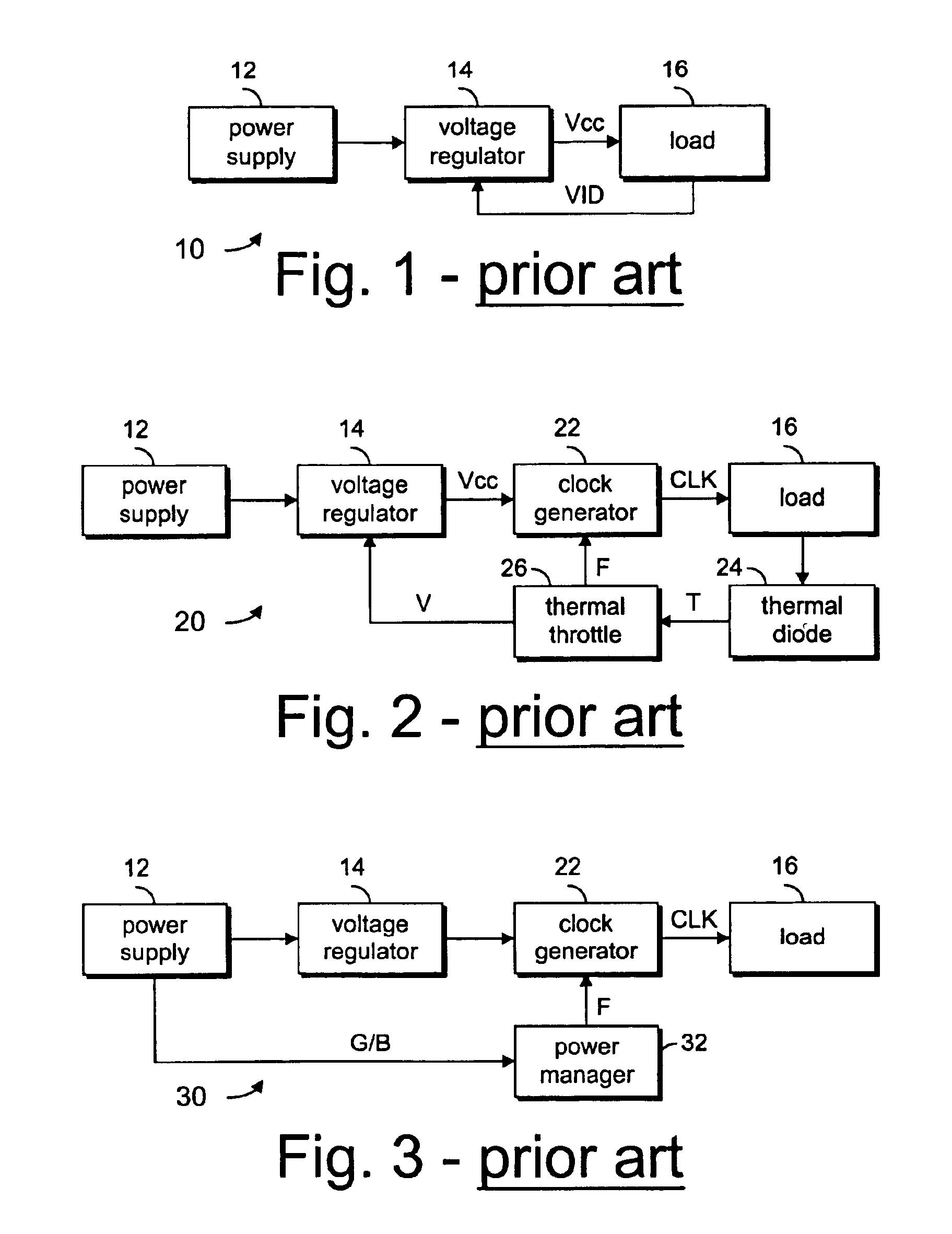

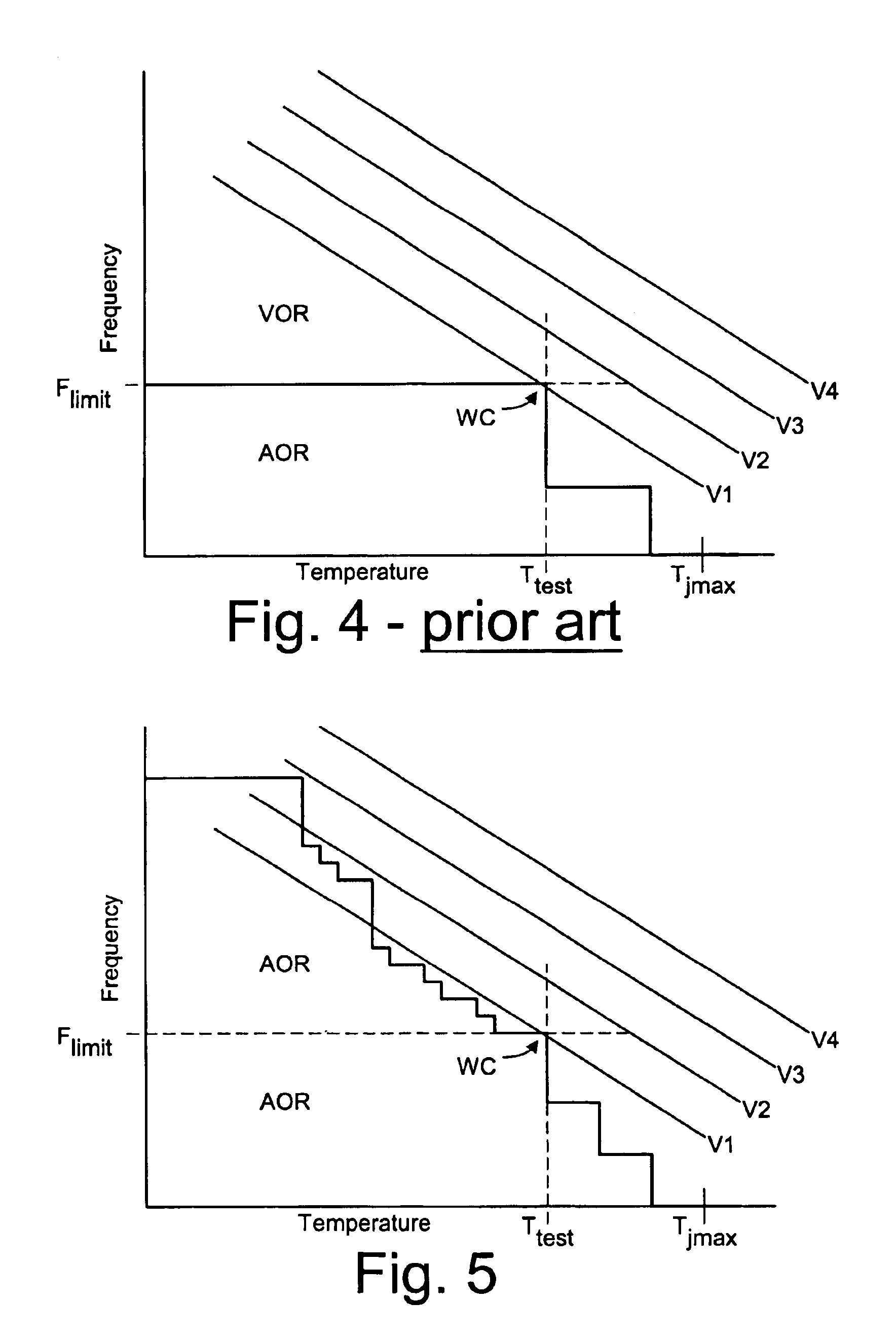

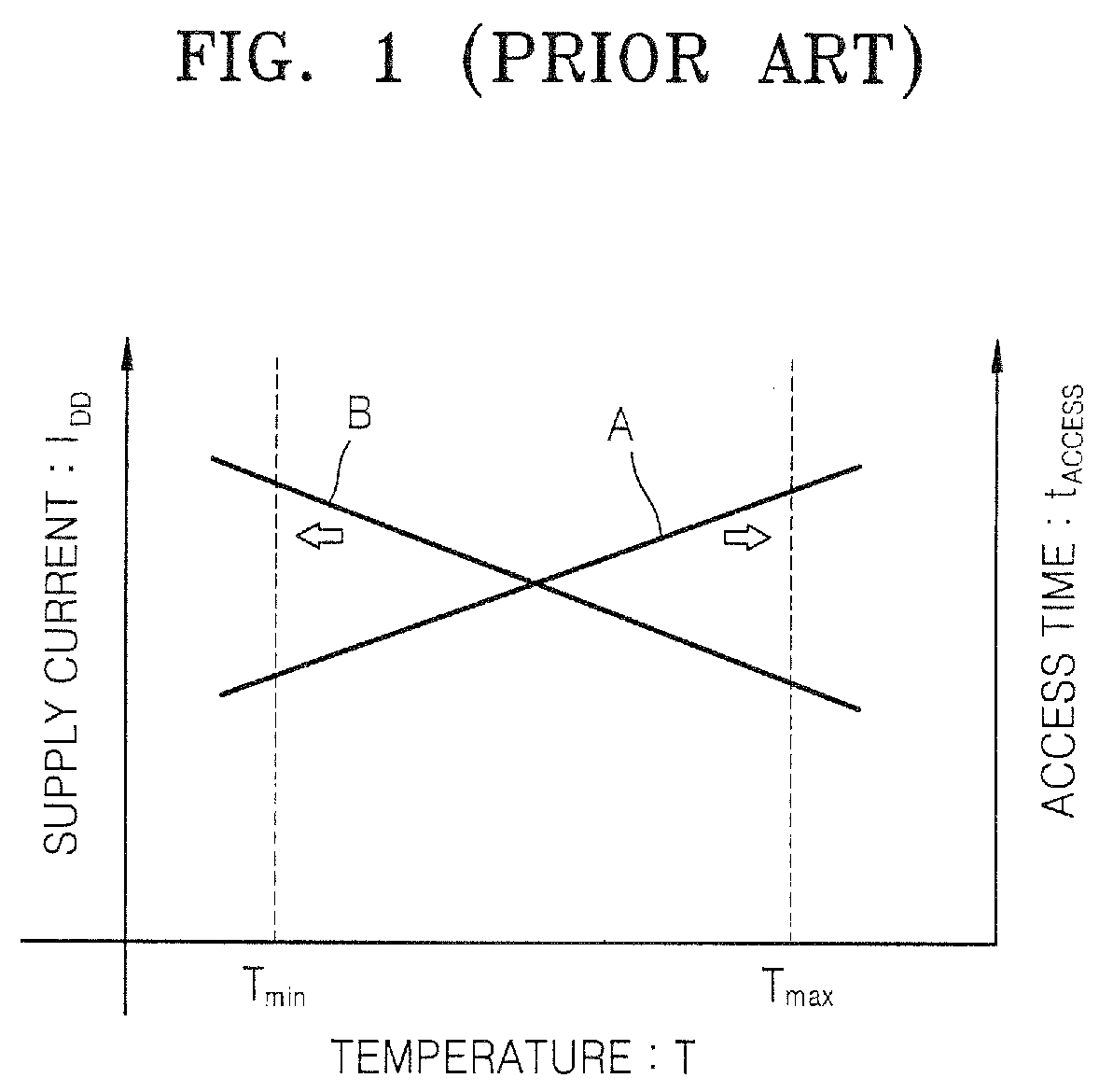

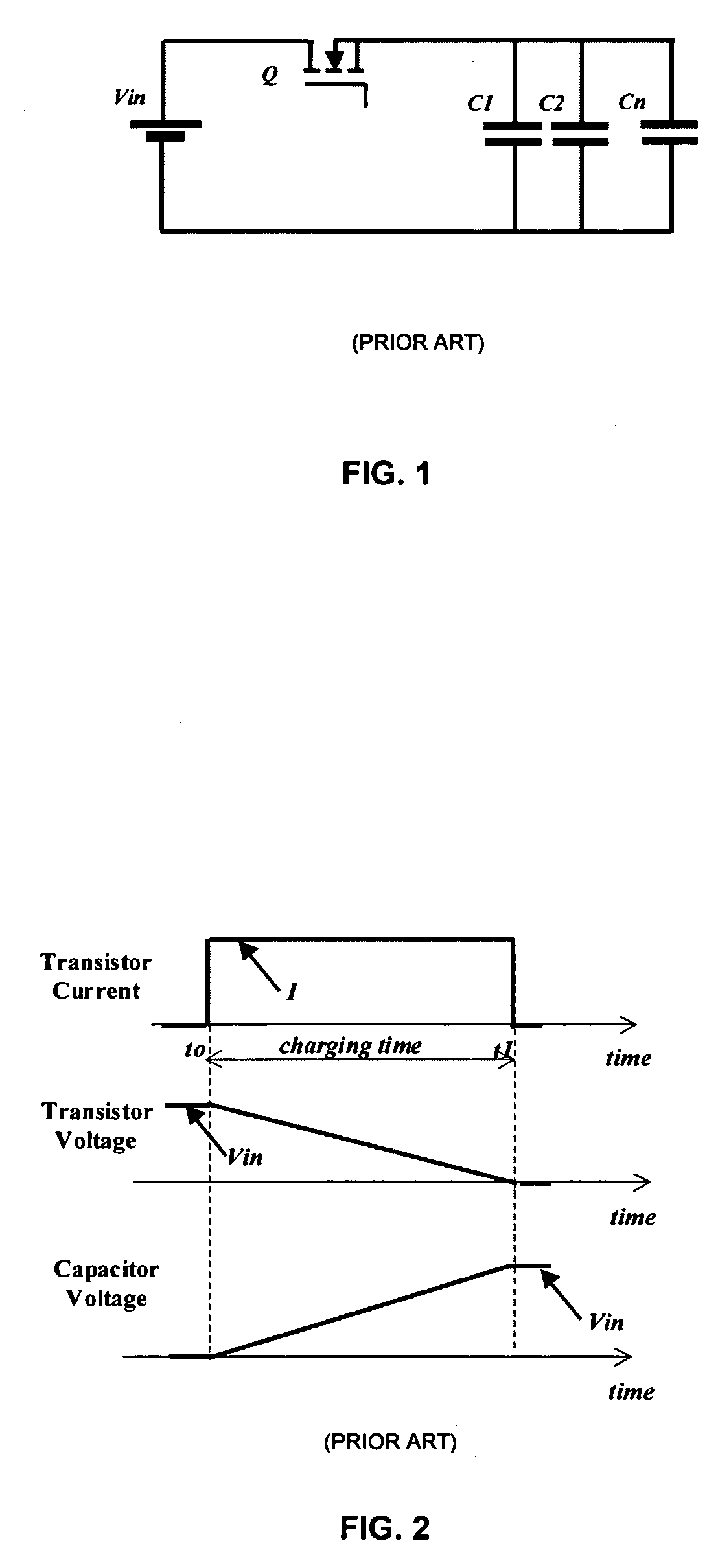

Altering operating frequency and voltage set point of a circuit in response to the operating temperature and instantaneous operating voltage of the circuit

InactiveUS6885233B2Electronic switchingPulse generation by opto-electronic devicesLoad circuitClock rate

Setting the clock frequency provided to a load circuit as function of the operating temperature and supply voltage of the load circuit, and setting the supply voltage as a function of the operating temperature of the load circuit. The load circuit can be safely operated above the frequency which would be the limit if the load circuit were operating at the maximum test temperature. At the given operating temperature, the supply voltage can be raised to permit even higher frequency operation, or lowered to reduce power.

Owner:SONY CORP OF AMERICA

Photoelectric conversion device and manufacturing method thereof

InactiveUS20060261253A1Total current dropNarrow downTelevision system detailsPhotometry using reference valueAudio power amplifierPhotoelectric conversion

It is an object to provide a photoelectric conversion device which detects light ranging from weak light to strong light. The present invention relates to a photoelectric conversion device having a photodiode having a photoelectric conversion layer, an amplifier circuit including a thin film transistor and a bias switching means, where a bias which is connected to the photodiode and the amplifier circuit is switched by the bias switching means when intensity of incident light exceeds predetermined intensity, and accordingly, light which is less than the predetermined intensity is detected by the photodiode and light which is more than the predetermined intensity is detected by the thin film transistor of the amplifier circuit. By the present invention, light ranging from weak light to strong light can be detected.

Owner:SEMICON ENERGY LAB CO LTD

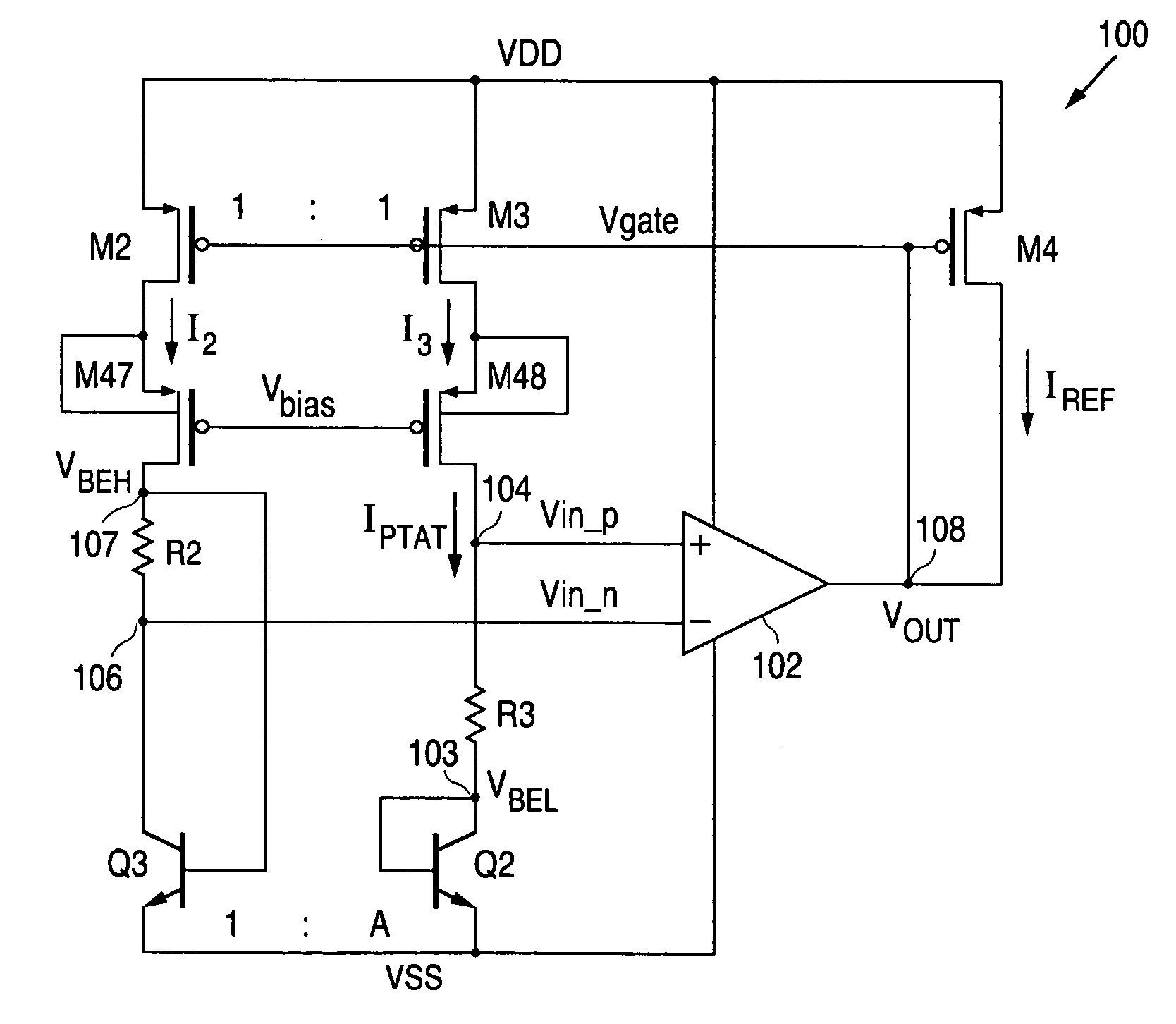

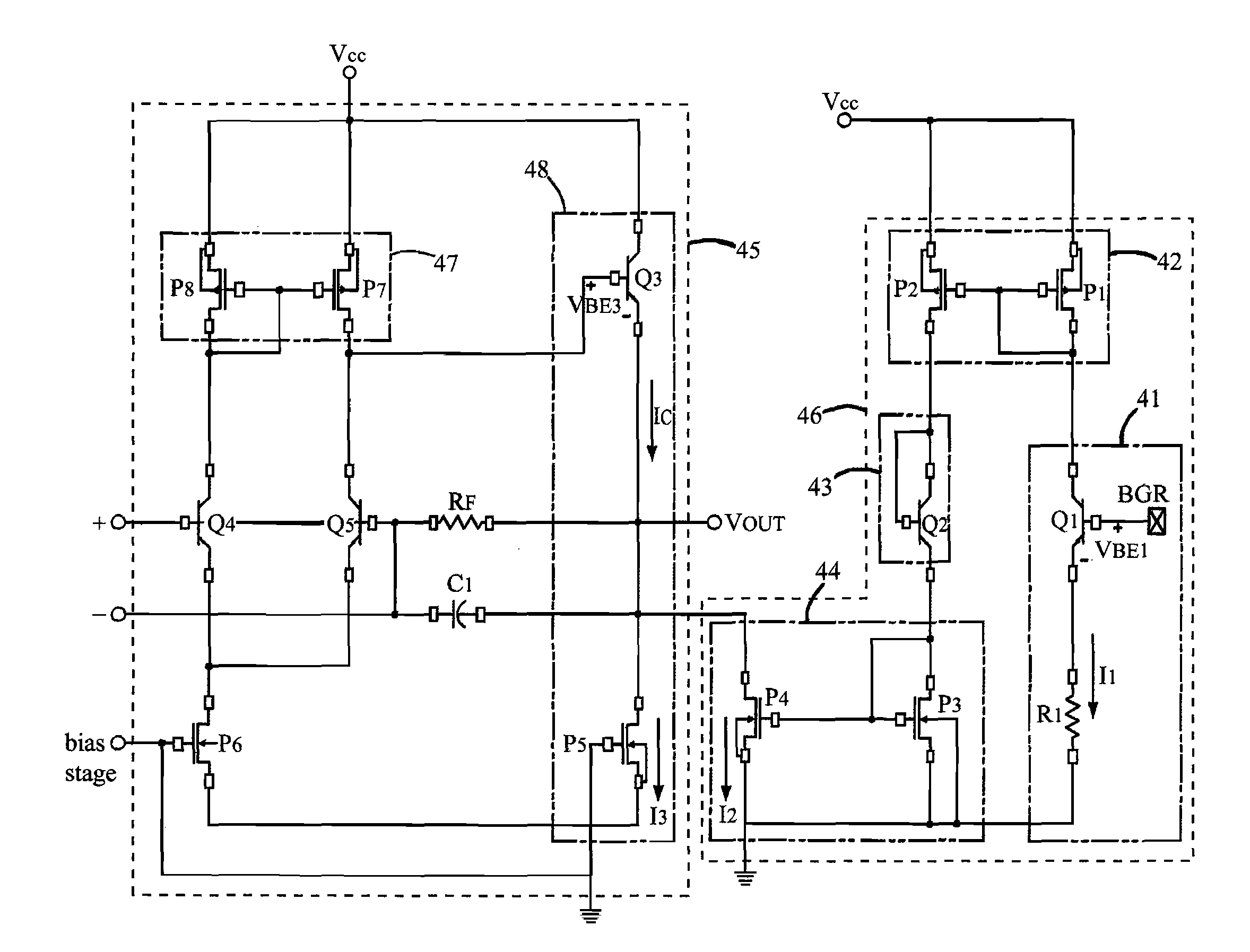

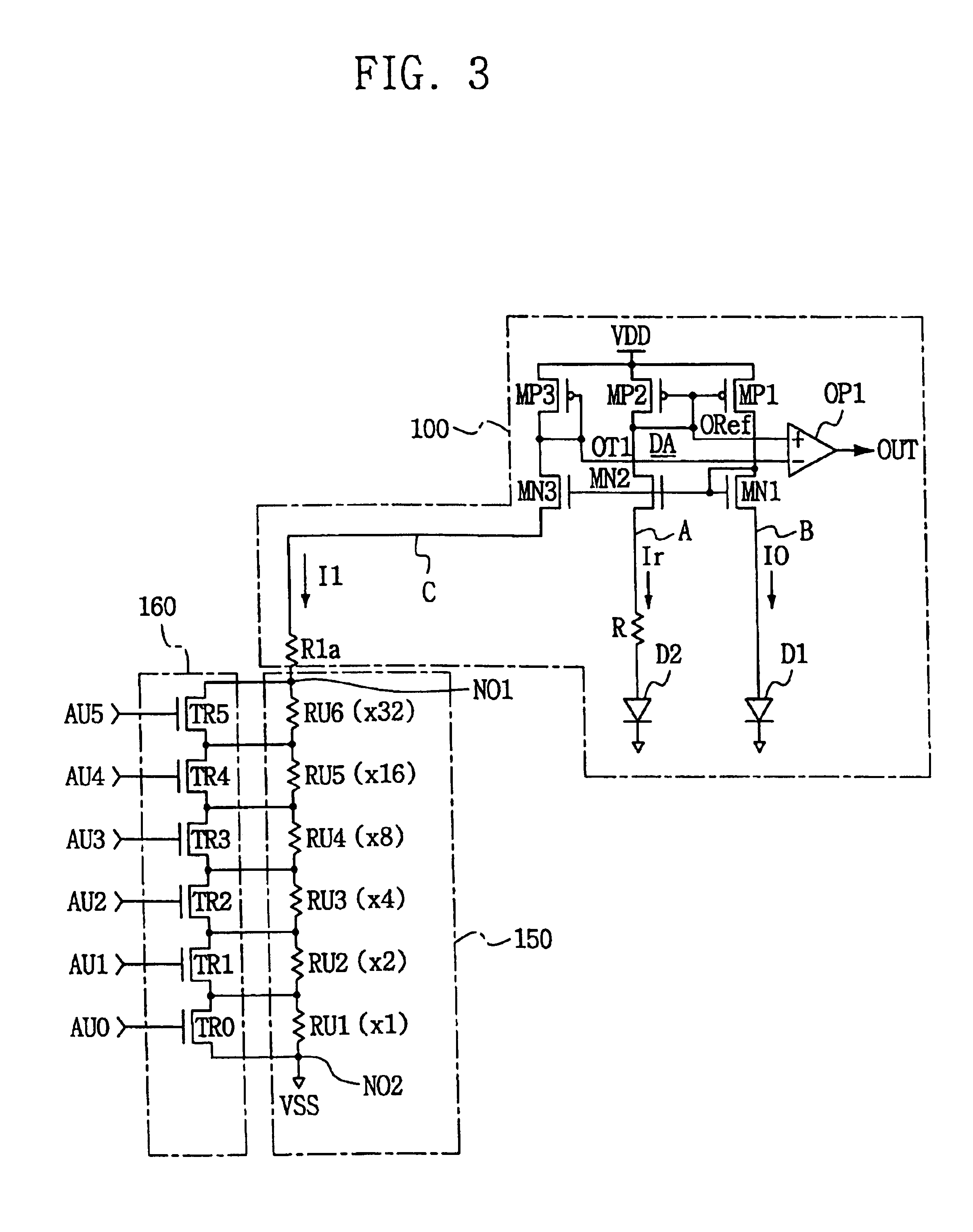

Low supply voltage band-gap reference circuit and negative temperature coefficient current generation unit thereof and method for supplying band-gap reference current

InactiveUS20080018319A1Reduce circuit areaLow costElectronic switchingPulse generation by opto-electronic devicesHigh resistanceLow voltage

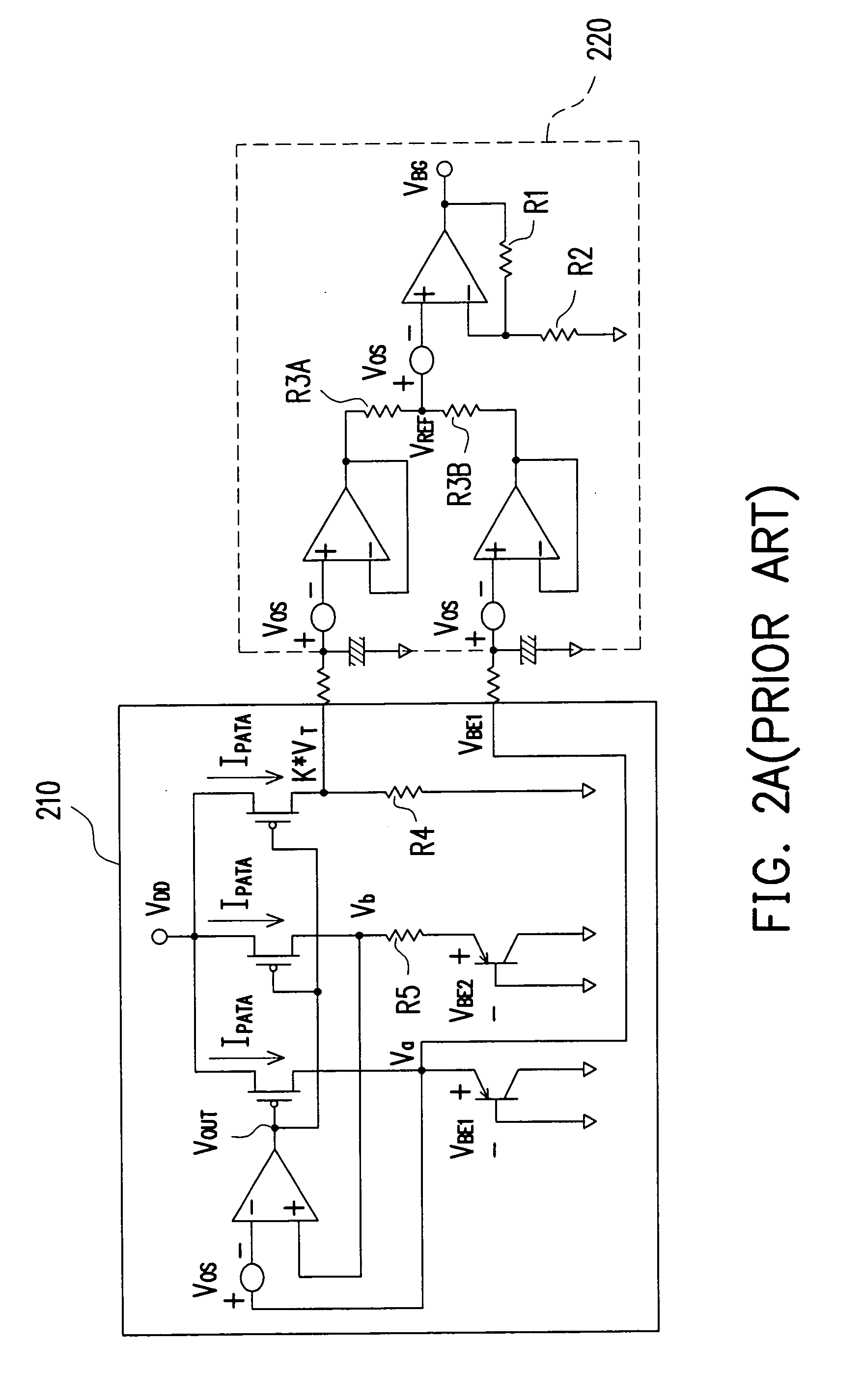

A low supply voltage band-gap reference circuit is provided, which includes a positive temperature coefficient current generation unit and a negative temperature coefficient current generation unit, and it is implemented by way of current summing. Through the current-mode temperature compensation technique, the present invention is able to reduce the voltage headroom and the number of operational amplifiers required by the conventional voltage-summing method, as well as the influence to the output voltage due to the offset voltage, thereby providing a stable and low voltage band-gap reference voltage level. In addition, by reducing the number of operational amplifiers and resistors of high resistance, the circuit area is reduced, and chip cost is saved.

Owner:FARADAY TECH CORP

Method and apparatus for low voltage temperature sensing

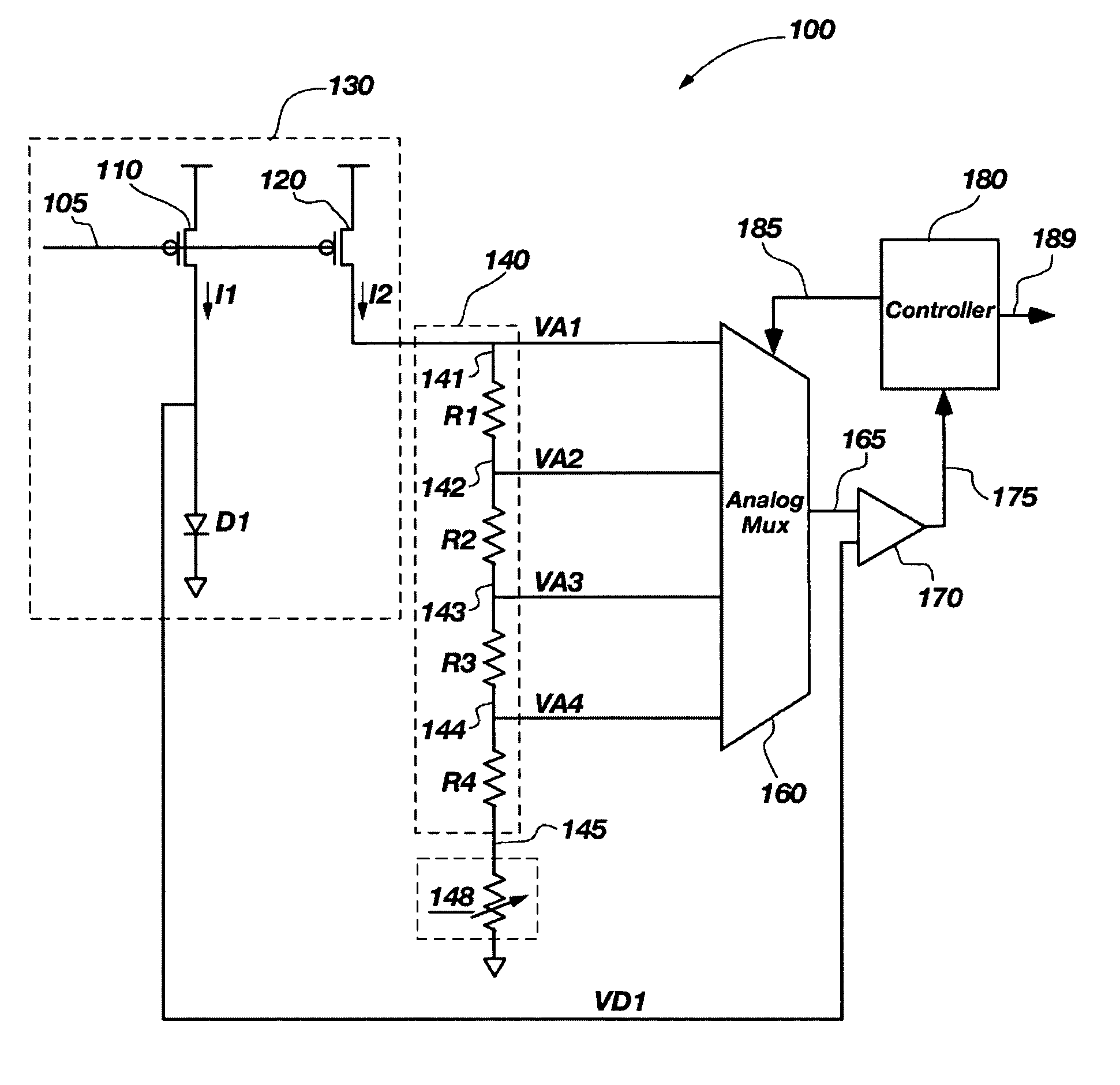

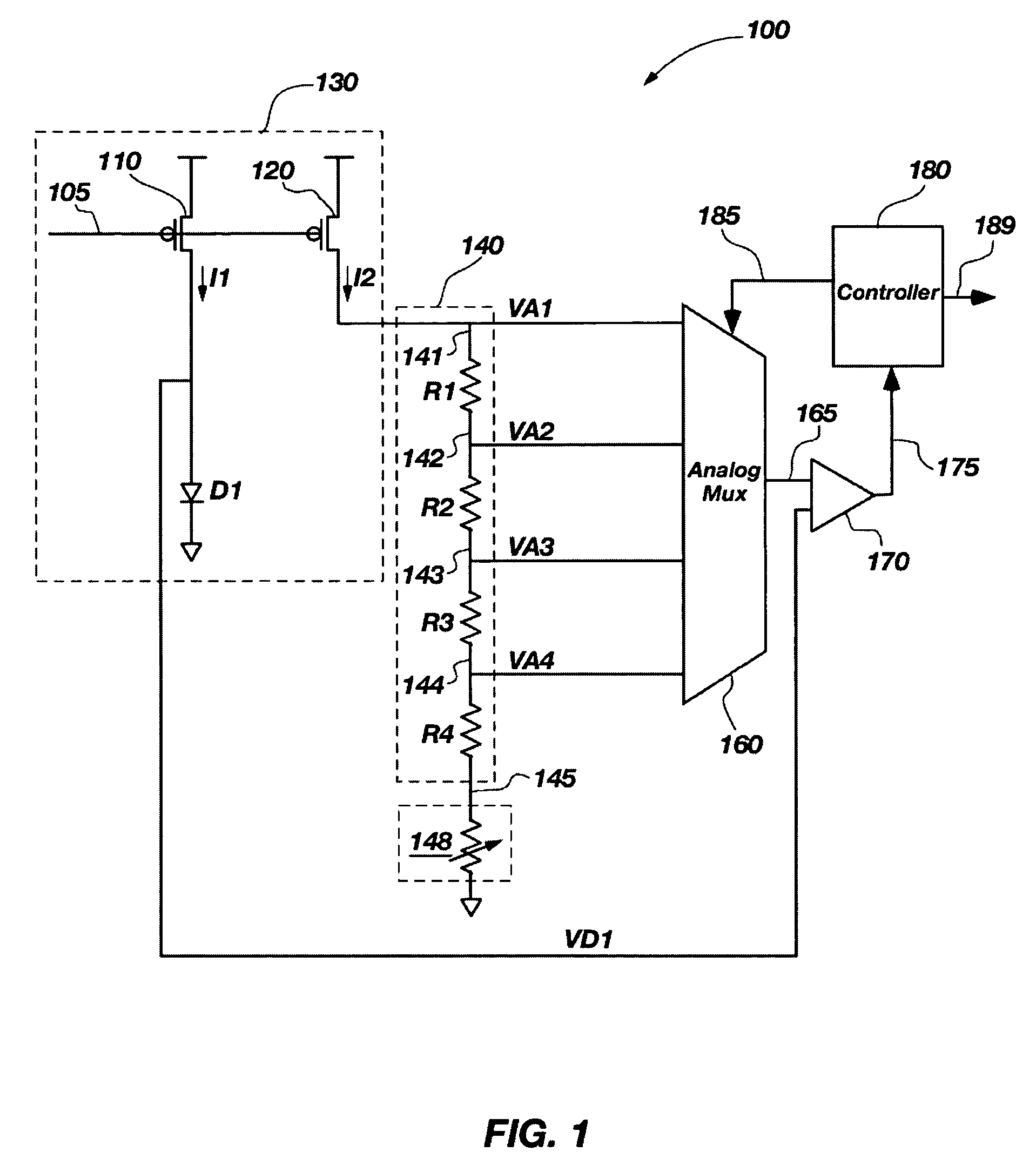

ActiveUS7084695B2Thermometer with A/D convertersThermometers using electric/magnetic elementsLow voltageReference current

Owner:MICRON TECH INC

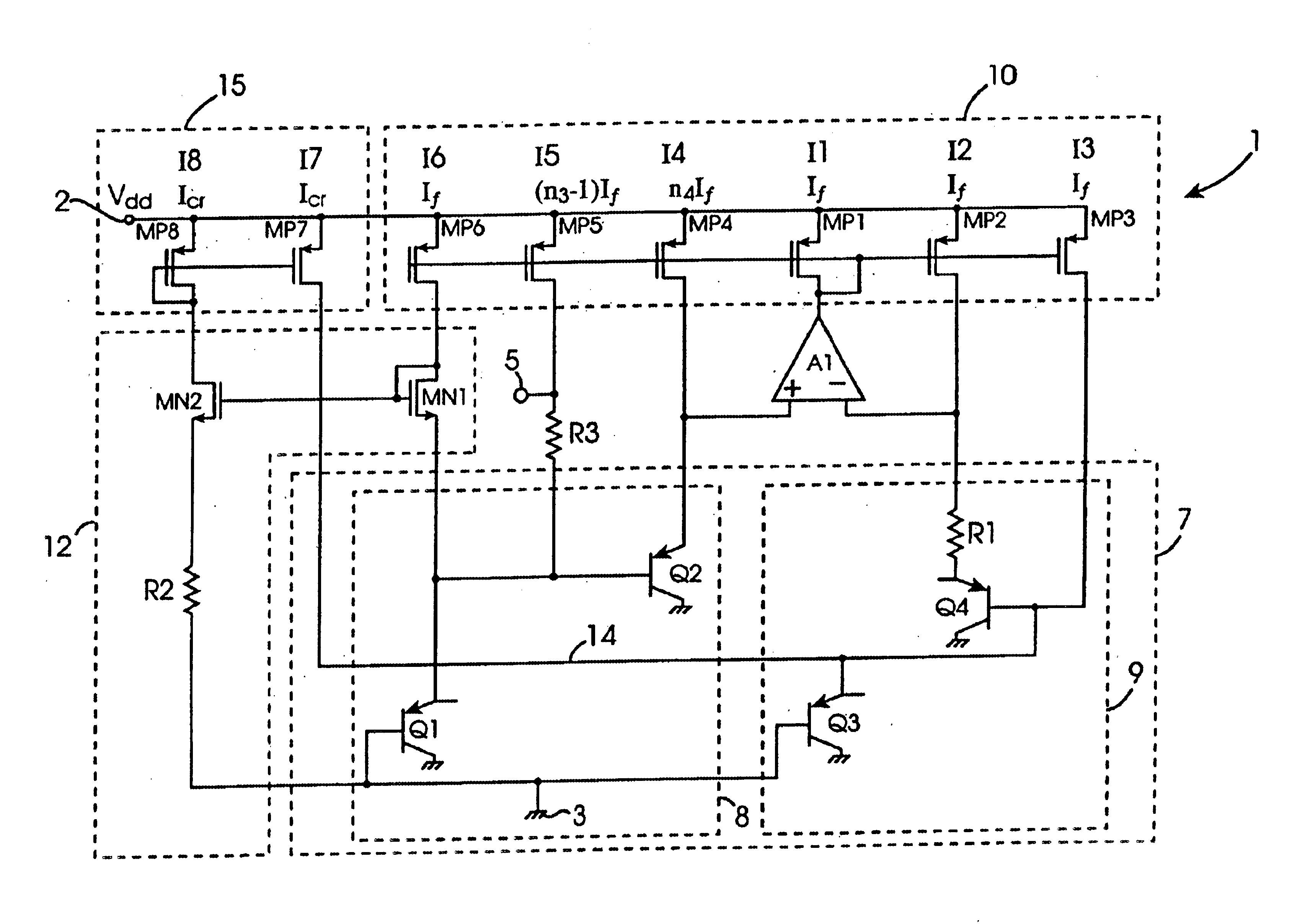

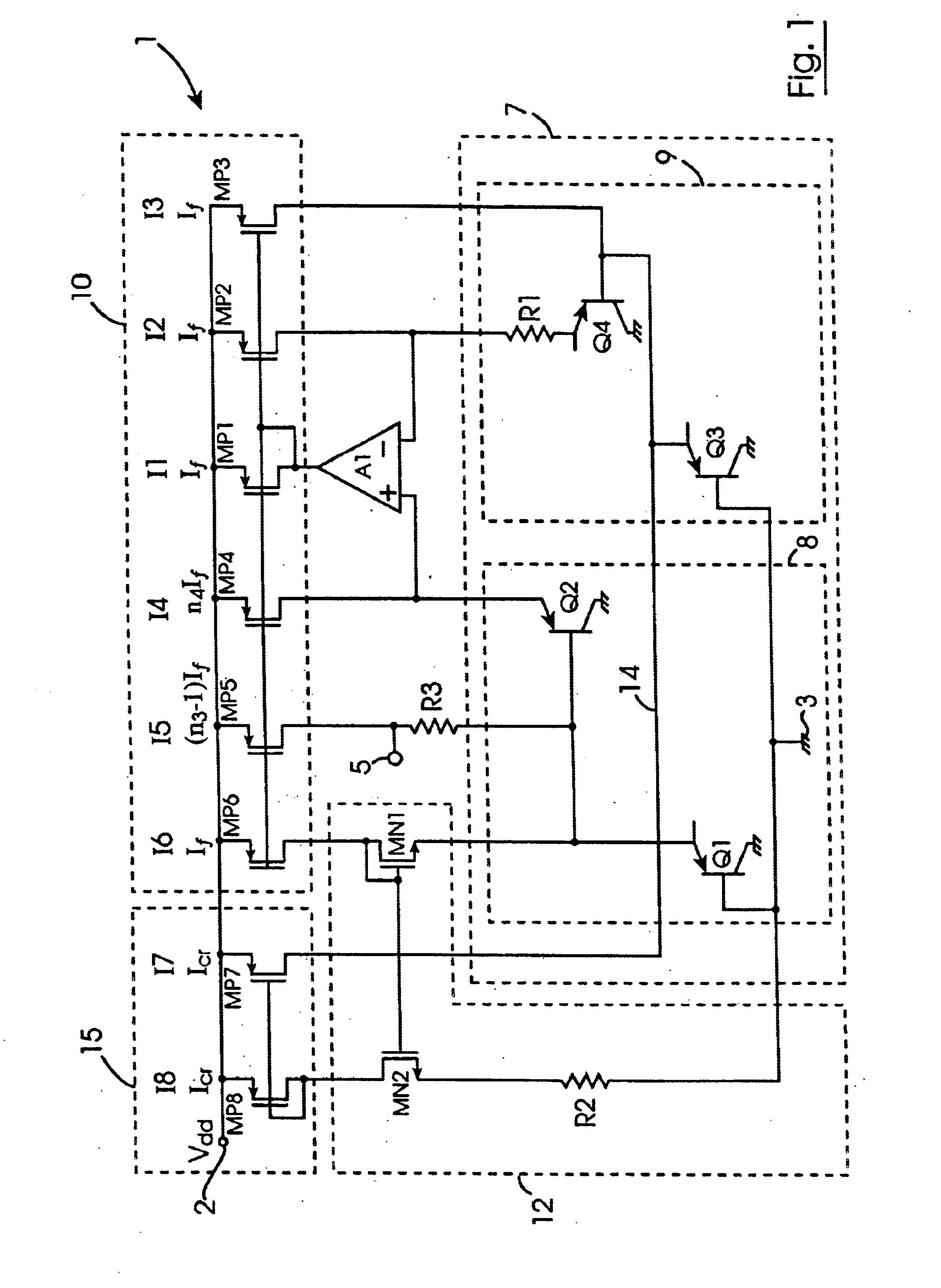

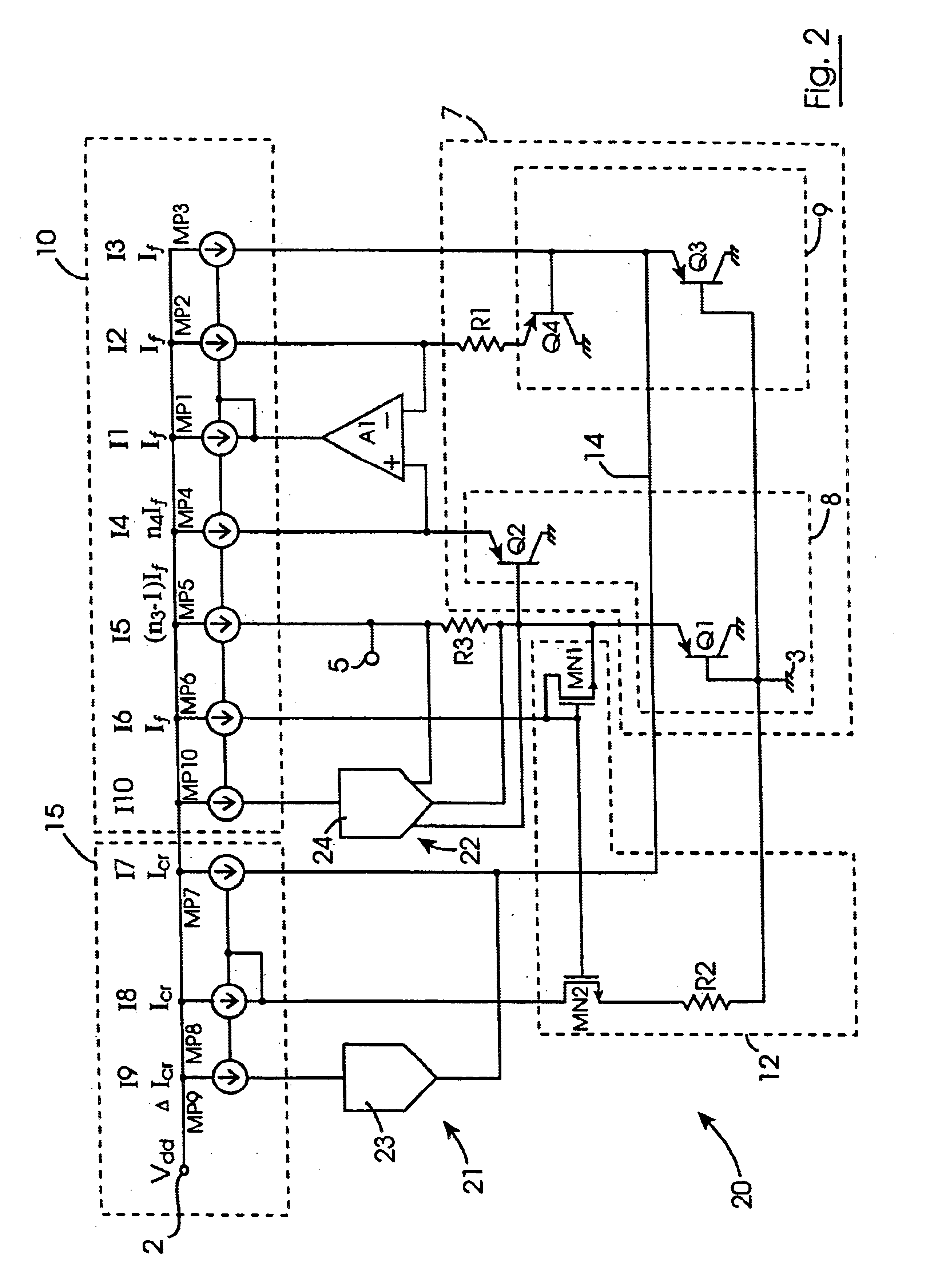

Bandgap voltage reference circuit and method for producing a temperature curvature corrected voltage reference

InactiveUS6828847B1Easy to implementLower requirementElectronic switchingPulse generation by opto-electronic devicesAudio power amplifierEngineering

A bandgap voltage reference circuit (1) comprises a bandgap cell (7) comprising first and second transistor stacks (8,9) of first transistors (Q1,Q2) and second transistors (Q3,Q4), respectively, arranged for developing a correcting PTAT voltage (DeltaVbe) across a primary resistor (R1) proportional to the difference in the base-emitter voltages of the first and second transistor stacks (8,9). A first current mirror circuit (10) provides PTAT currents (12 to 15) to the emitters of the first and second transistors (Q1 to Q4), and an operational amplifier (A1) maintains the voltage on the emitter of the first transistor (Q2) of the first transistor stack (8) at the same level as the resistor (R1) and sinks a PTAT current from the first current mirror circuit (10) from which the other PTAT currents are mirrored. The correcting PTAT voltage (DeltaVbe) developed across the primary resistor (R1) is scaled onto a secondary resistor (R3) and summed with the uncorrected base-emitter CTAT voltage of the first transistor (Q1) of the first transistor stack (8) for providing the voltage reference between an output terminal (5) and ground (3). A CTAT correcting current (Icr) is summed with the PTAT current (13) and applied to the emitter of the second transistor (Q3) of the second transistor stack (9) so that the correcting PTAT voltage (DeltaVbe) developed across the primary resistor (R1) has a TlnT curvature complementary to the TlnT temperature curvature of the uncorrected base-emitter CTAT voltage of the first transistor (Q1). Thus the reference voltage developed between the output terminal (5) and the ground (3) is temperature stable and TlnT temperature curvature corrected. The CTAT correcting current is derived from the base-emitter CTAT voltage of the first transistor (Q1) in a CTAT current generating circuit (12) through a second current mirror circuit (15).

Owner:ANALOG DEVICES INC

Temperature stable voltage reference circuit using a metal-silicon Schottky diode for low voltage circuit applications

ActiveUS7009444B1Electronic switchingPulse generation by opto-electronic devicesLow voltage circuitsMostly True

Silicon-based voltage reference circuits that generate a temperature independent voltage reference that is less than even the silicon bandgap potential. The voltage reference circuit includes a diode-connected metal-silicon Schottky diode that is biased with a current. In this configuration, the anode terminal of the Schottky diode is a CTAT voltage source in this configuration. The anode terminal has a voltage at zero degrees Kelvin at the barrier height of the Schottky diode, which may differ depending on the metal chosen, but in most cases is less than the bandgap potential of silicon. The voltage reference circuit also includes a PTAT voltage source. The PTAT voltage may be generated in a variety of ways. An amplifier amplifies the PTAT voltage, and a summer adds the CTAT voltage to the amplified PTAT voltage to generate the temperature stable voltage reference.

Owner:SEMICON COMPONENTS IND LLC

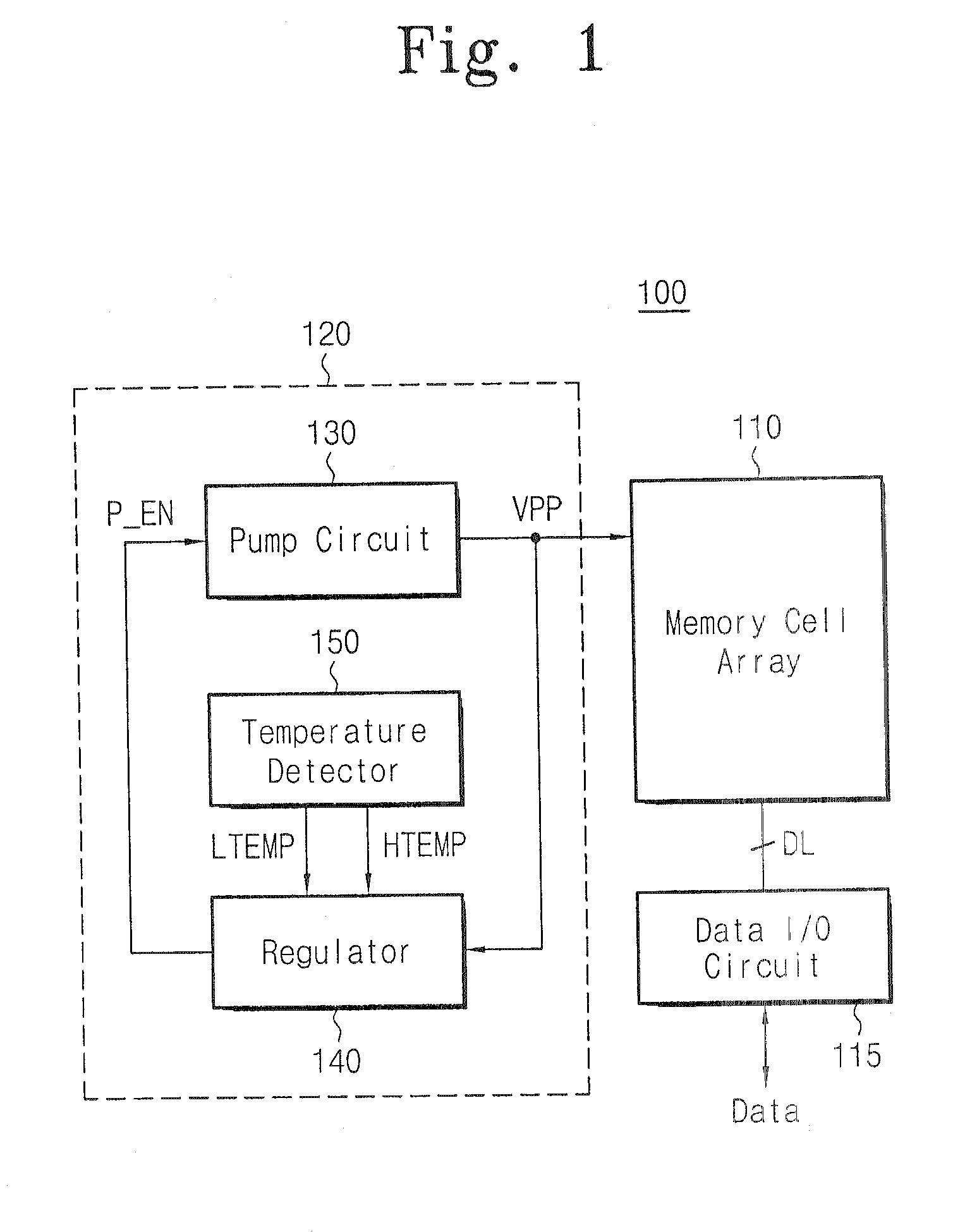

Semiconductor memory device controlling output voltage level of high voltage generator according to temperature variation

InactiveUS20080018377A1Data processing applicationsTicket-issuing apparatusAutomatic controlEngineering

A semiconductor memory device controlling an output voltage level of a high voltage generator according to a variation of temperature has a high voltage generator that provides a high voltage higher than a power source voltage through an output terminal, generates a temperature detection signal obtained by sensing a variation of a diode current according to a temperature variation, and adjusts a voltage level of the output terminal in response to the temperature detection signal. The device is able to automatically control an output voltage or current of the high voltage generator. Accordingly, it is possible to control fluctuation of output voltage level or current level due to a voltage variation, thereby lessening degradation of program or erasure characteristics of memory cells that is caused from the fluctuation of the output voltage or current.

Owner:SAMSUNG ELECTRONICS CO LTD

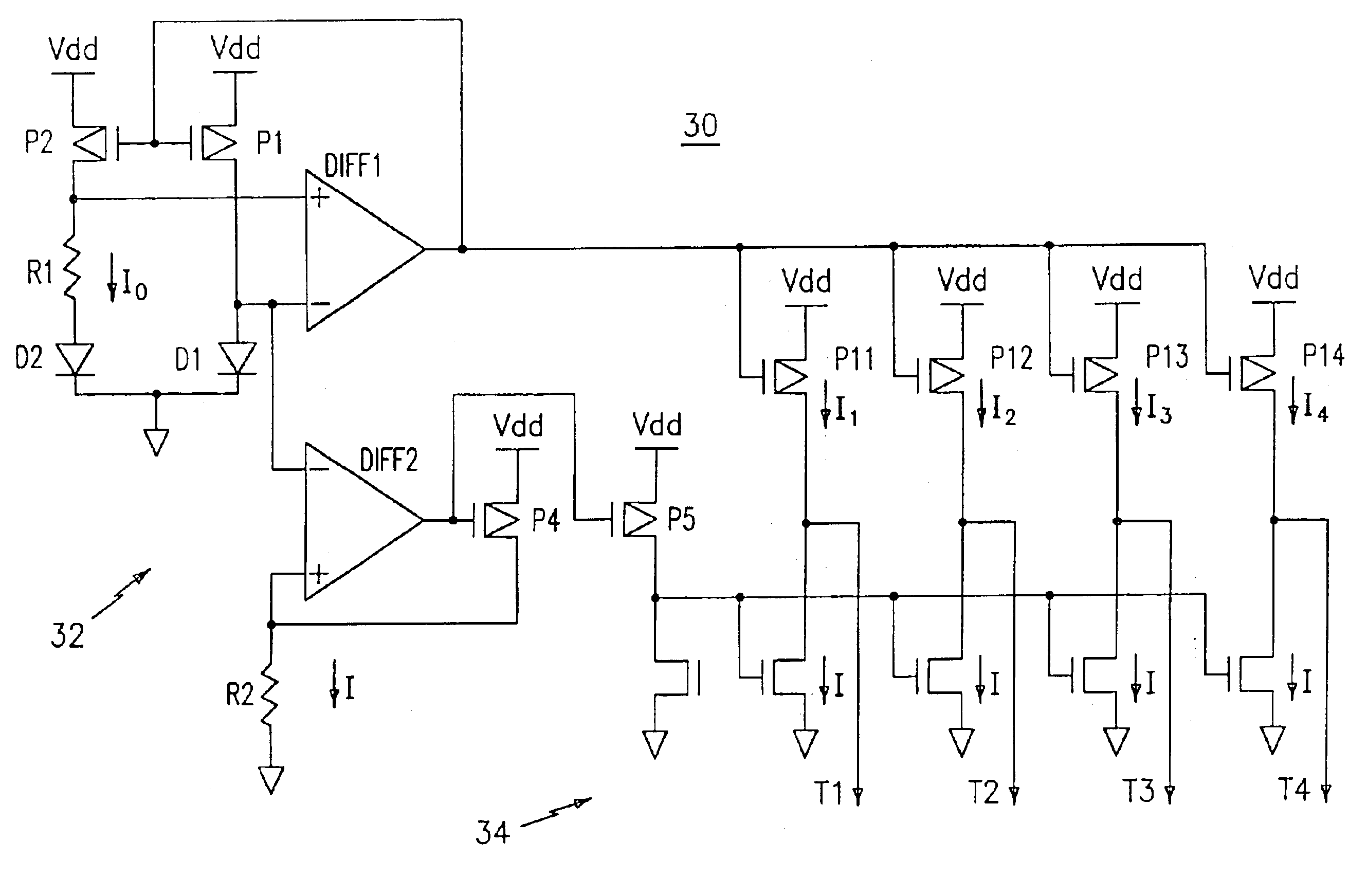

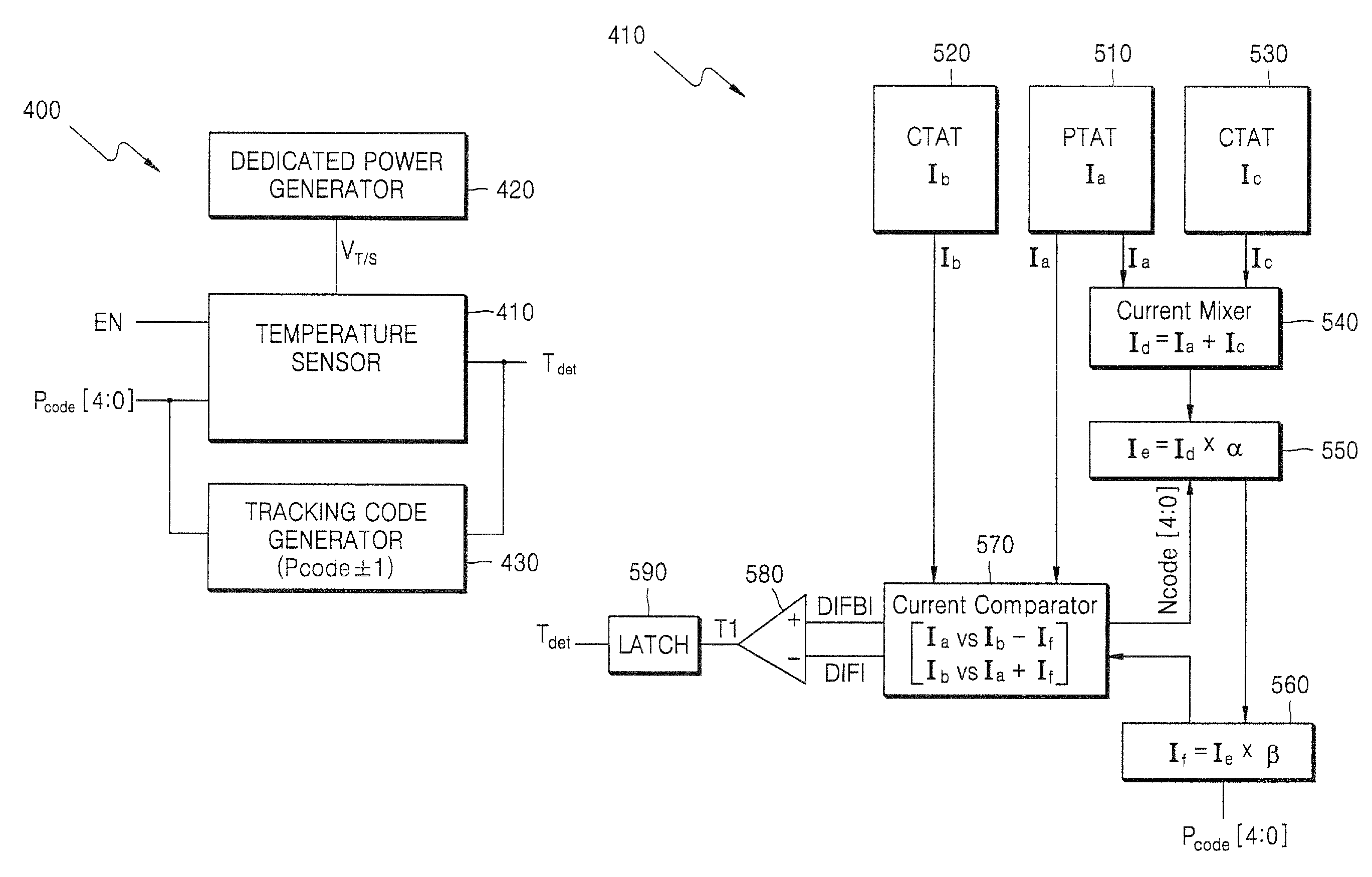

On chip temperature detector, temperature detection method and refresh control method using the same

ActiveUS7532056B2Thermometers using electric/magnetic elementsPower supply linesEngineeringCurrent generator

A temperature sensor includes a proportional to absolute temperature (PTAT) current generator configured to generate a first current proportional to temperature, a first complementary to absolute temperature (CTAT) current generator configured to generate a second current inversely proportional to temperature, a second CTAT current generator configured to generate a third current inversely proportional to temperature, and a temperature sensing unit configured to convert the first current, the second current, and the third current into a signal related to the temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

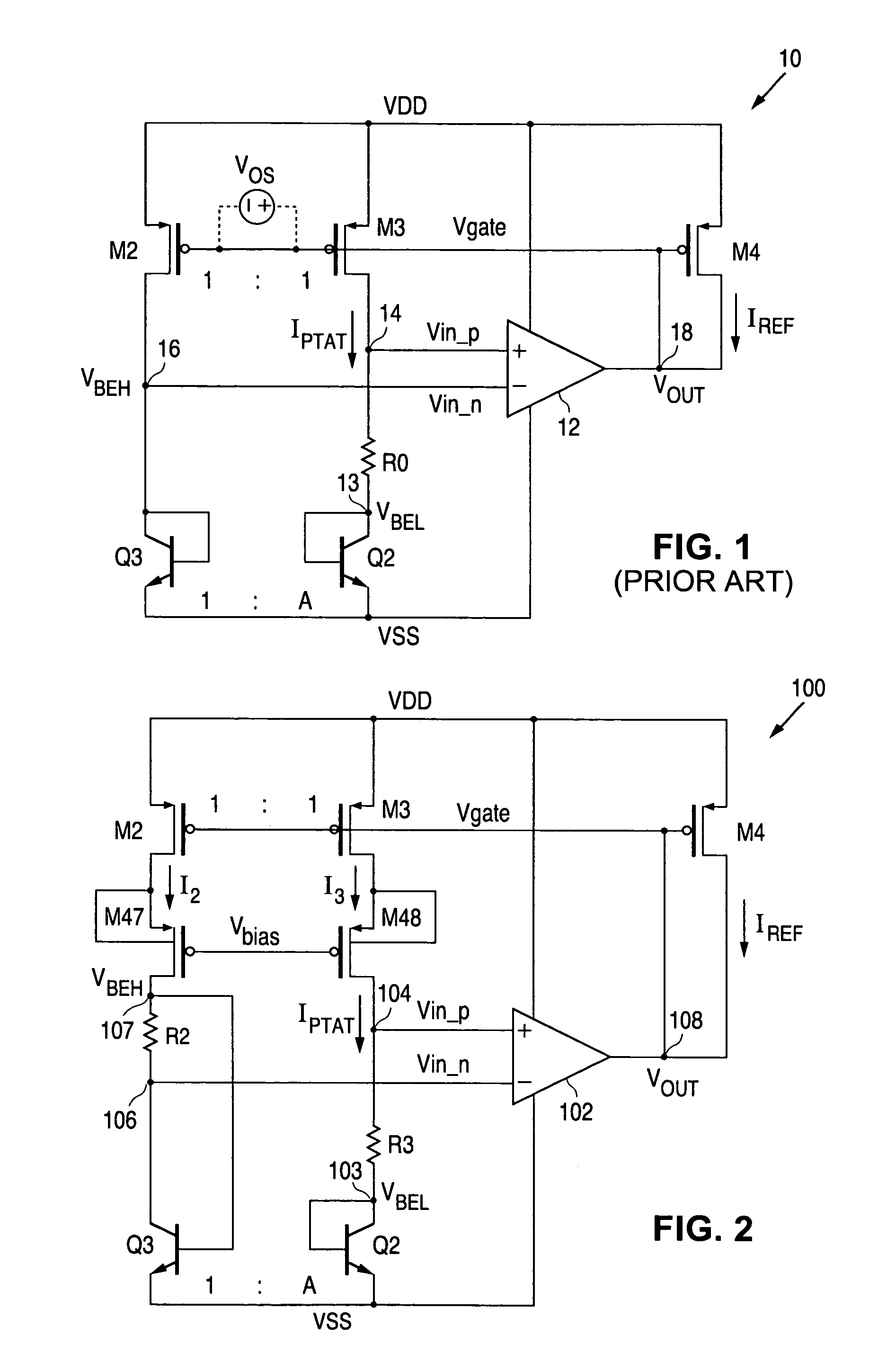

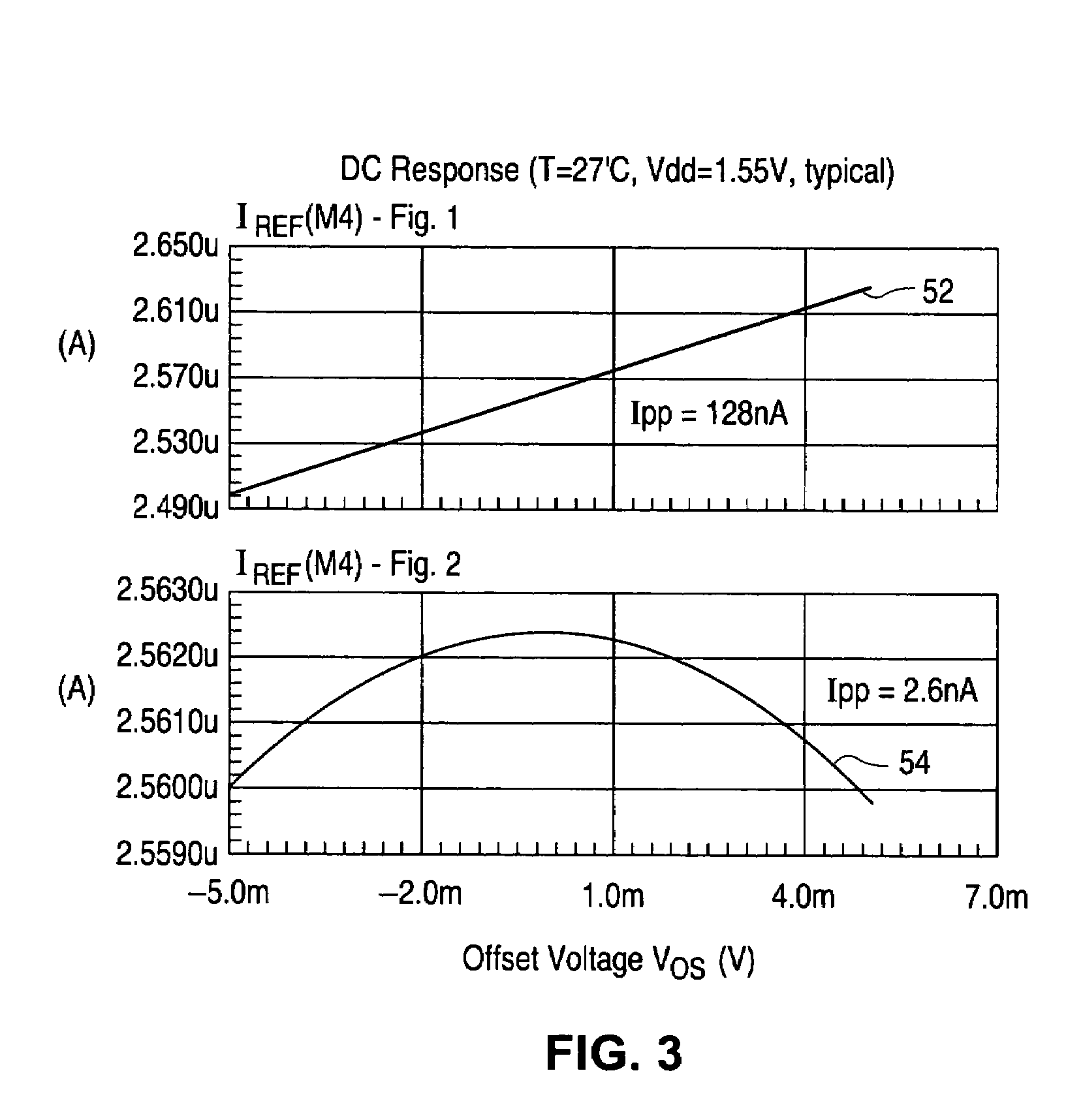

Self-regulating process-error trimmable PTAT current source

ActiveUS7236048B1Electronic switchingPulse generation by opto-electronic devicesElectrical resistance and conductanceProcess error

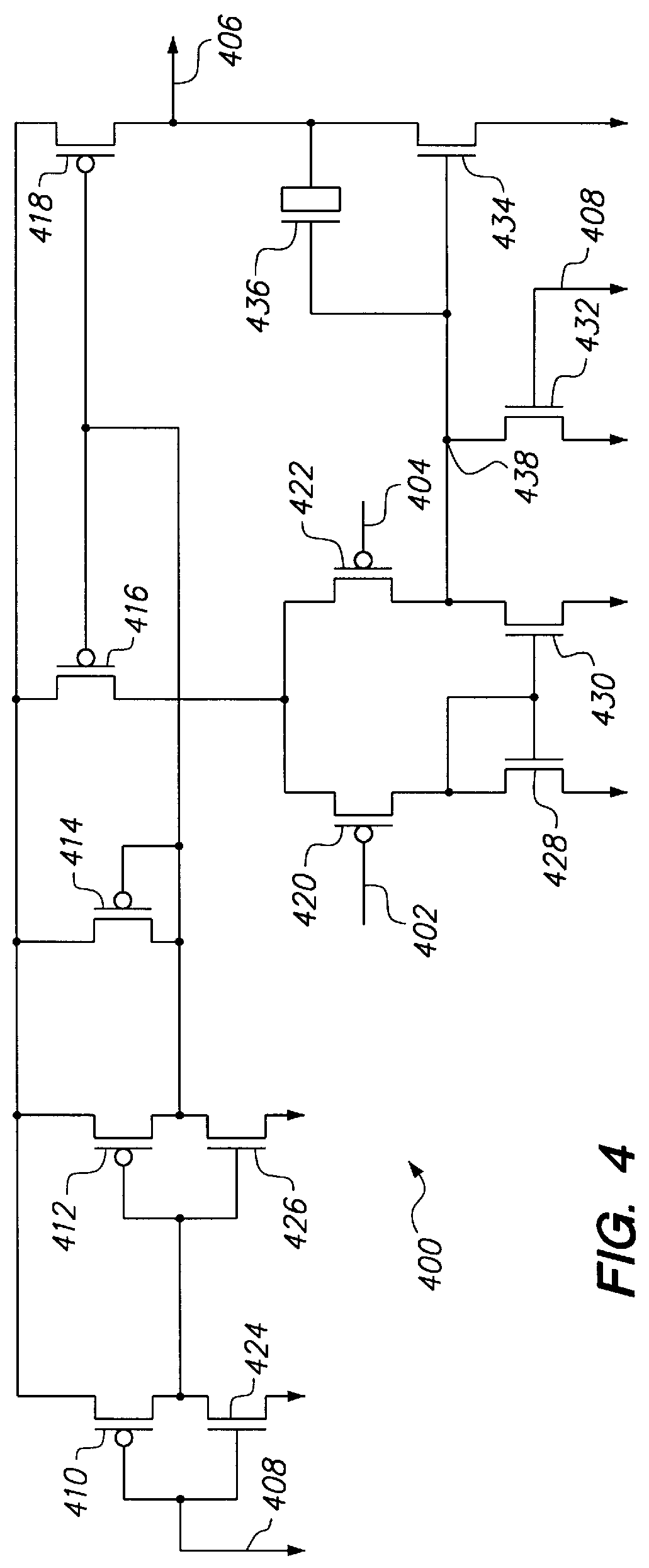

A current source for generating a PTAT current using two bipolar transistors with an 1:A emitter area ratio implements a split resistor architecture to cancel mismatch errors in the current mirror of the current source. In one embodiment, a first resistor is coupled to the unit area bipolar transistor and a second resistor is coupled to the A-ratio-area bipolar transistor. The first resistor has a resistance value indicative of the emitter resistance re of the bipolar transistors while the second resistor has a resistance value satisfying the equation re*(lnA−1). In another embodiment, an emitter area trim scheme is applied in a PTAT current source to cancel, in one trim operation, both bipolar transistor area mismatch error and sheet resistance variations. The emitter area trim scheme operates to modify the emitter area of the A-ratio-area bipolar transistor to select the best effective emitter area that provides the most accurate PTAT current.

Owner:NAT SEMICON CORP

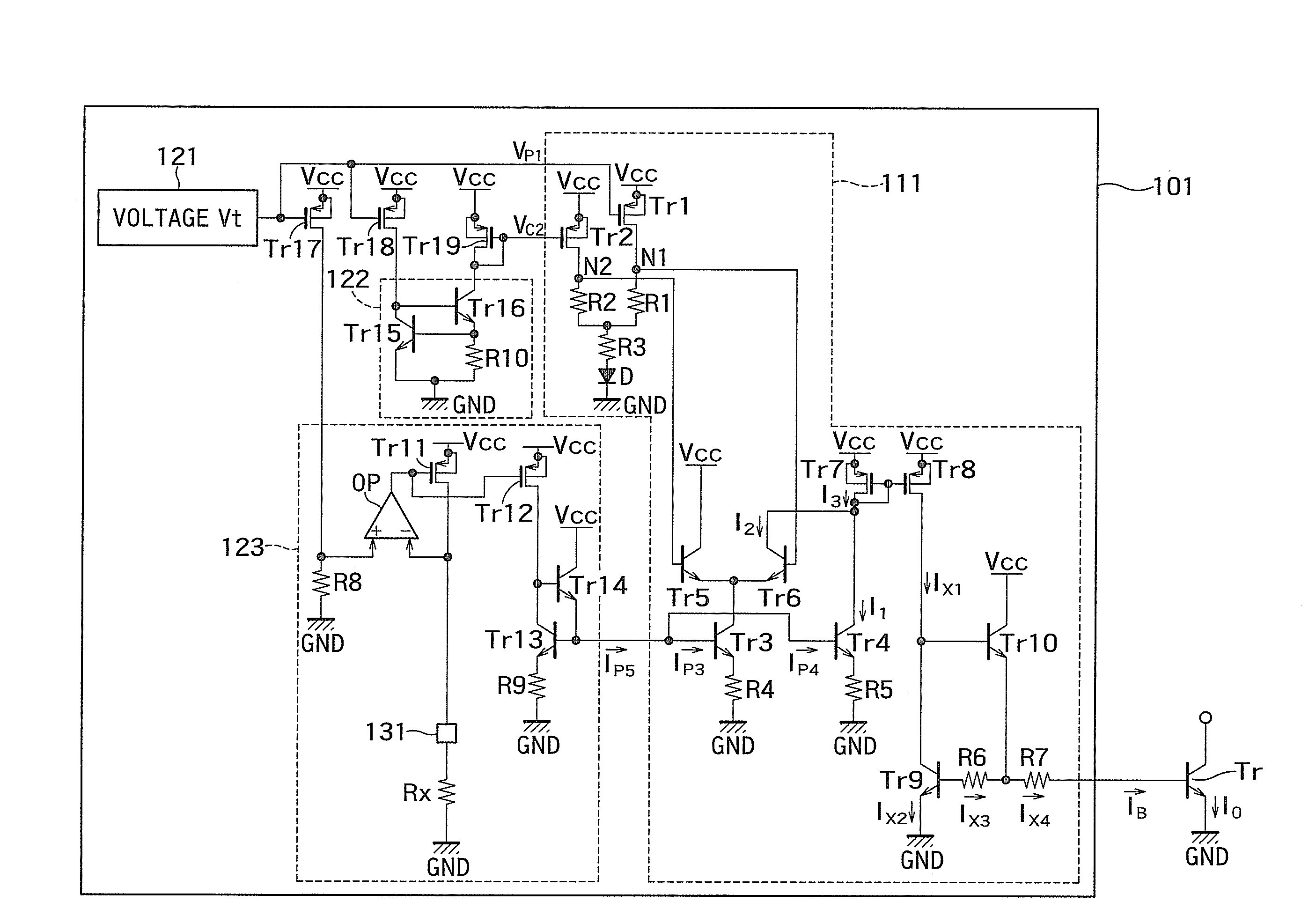

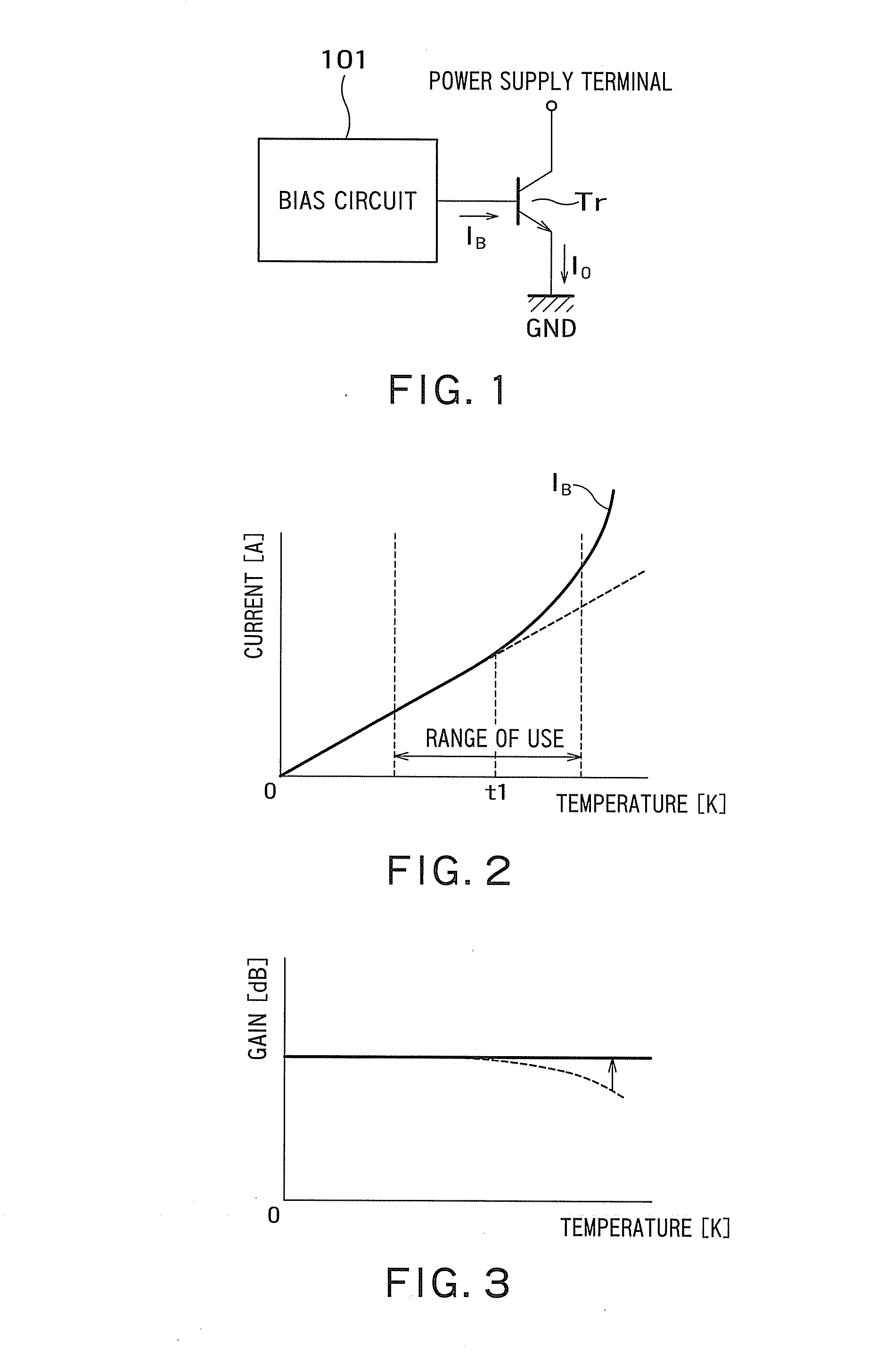

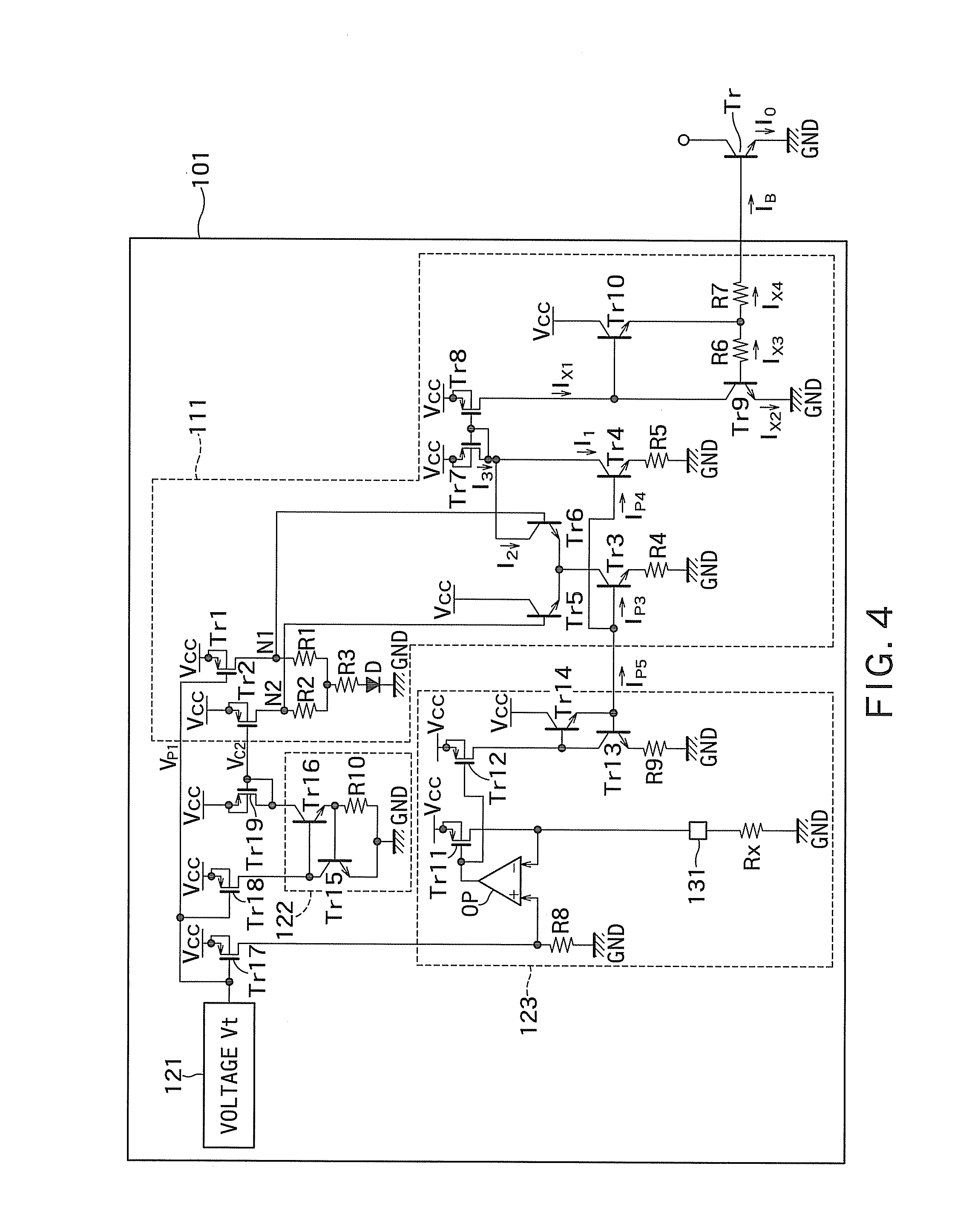

Temperature compensation circuit

A temperature compensation circuit according to an embodiment of the present invention includes a bias circuit configured to output a bias current having a current value increasing in proportion to an absolute temperature in a low-temperature region in which a temperature is lower than a predetermined temperature, and having a greater current value than the current value proportional to the absolute temperature in a high-temperature region in which the temperature is equal to or greater than the predetermined temperature, and a transistor having a control terminal supplied with the bias current. The bias circuit includes a first current generating circuit configured to generate a first current increasing in proportion to the absolute temperature, a second current generating circuit configured to generate a second current that does not flow in the low-temperature region and flows in the high-temperature region, and a control circuit configured to control the second current and having a connection terminal capable of being connected with an external resistor for adjusting a magnitude of the second current, and is configured to generate a third current by adding the first current to the second current, and output the bias current depending on or equal to the third current.

Owner:KK TOSHIBA

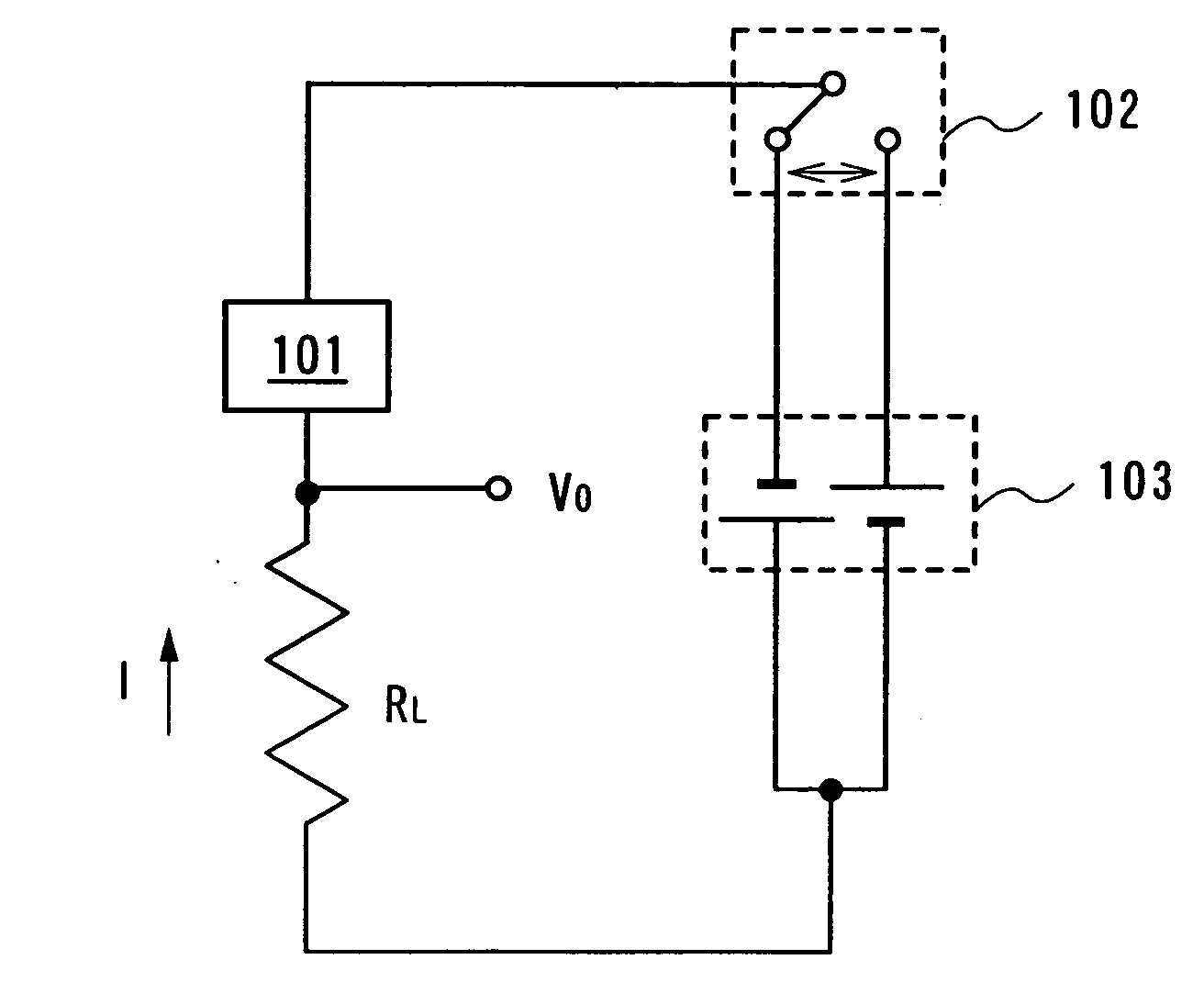

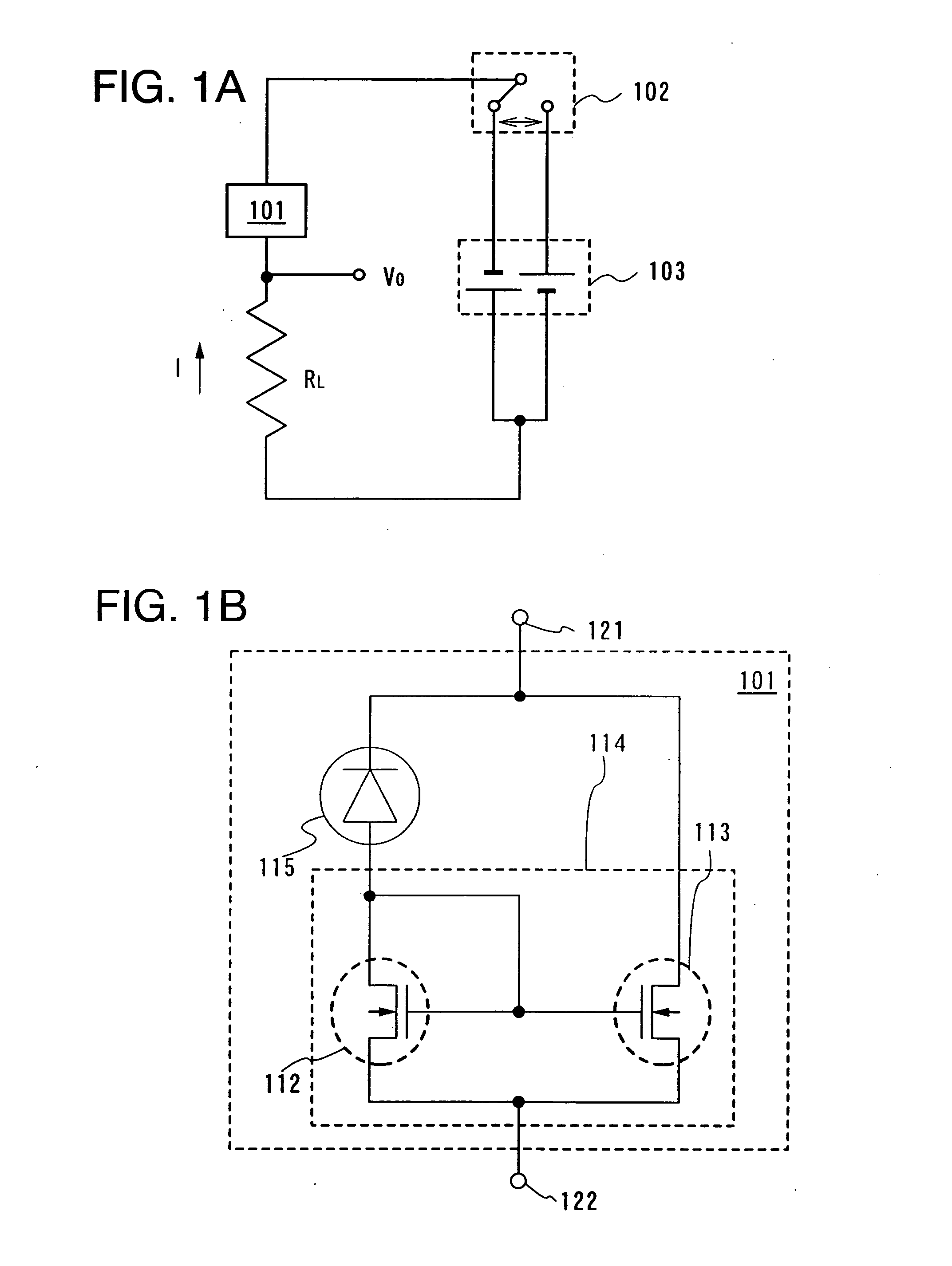

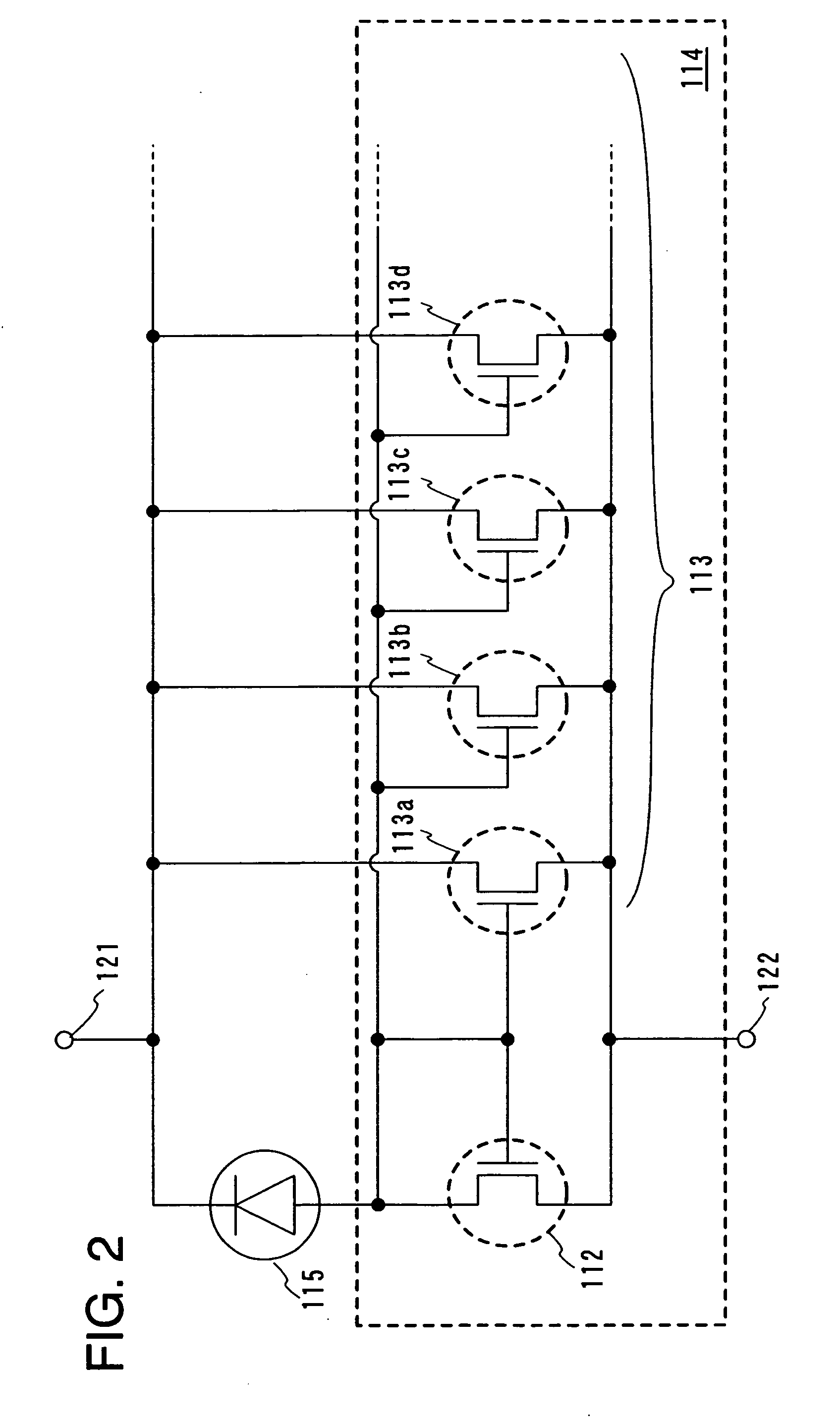

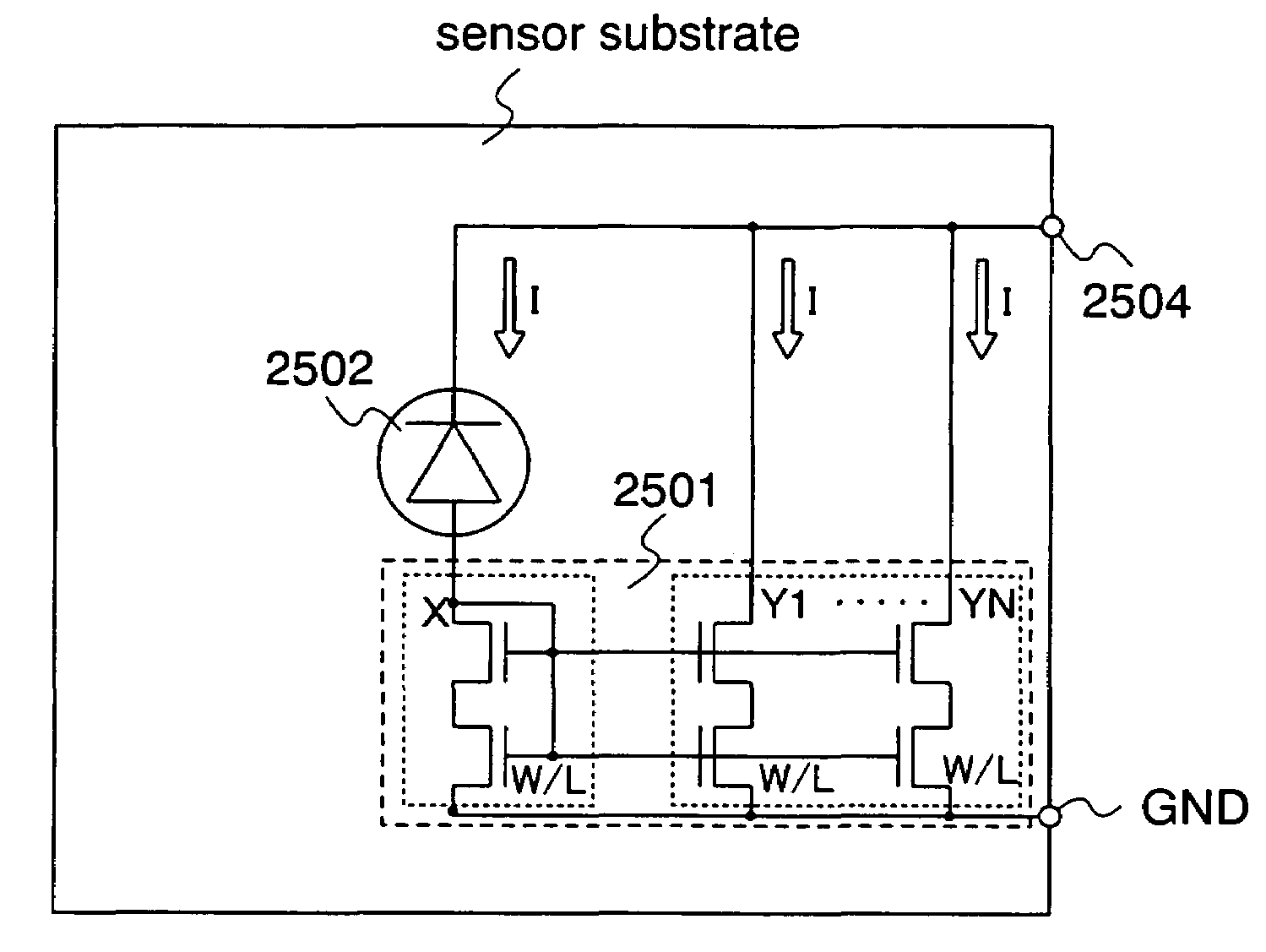

Optical sensor device and electronic apparatus

InactiveUS7253391B2Low costLarge installation spaceSolid-state devicesMaterial analysis by optical meansAudio power amplifierAmorphous silicon

In an optical sensor device employing an amorphous silicon photodiode, an external amplifier IC and the like are required due to low current capacity of the sensor element in order to improve the load driving capacity. It leads to increase in cost and mounting space of the optical sensor device. In addition, noise may easily superimpose since the photodiode and the amplifier IC are connected to each other over a printed circuit board. According to the invention, an amorphous silicon photodiode and an amplifier configured by a thin film transistor are formed integrally over a substrate so that the load driving capacity is improved while reducing cost and mounting space. Superimposing noise can be also reduced.

Owner:SEMICON ENERGY LAB CO LTD

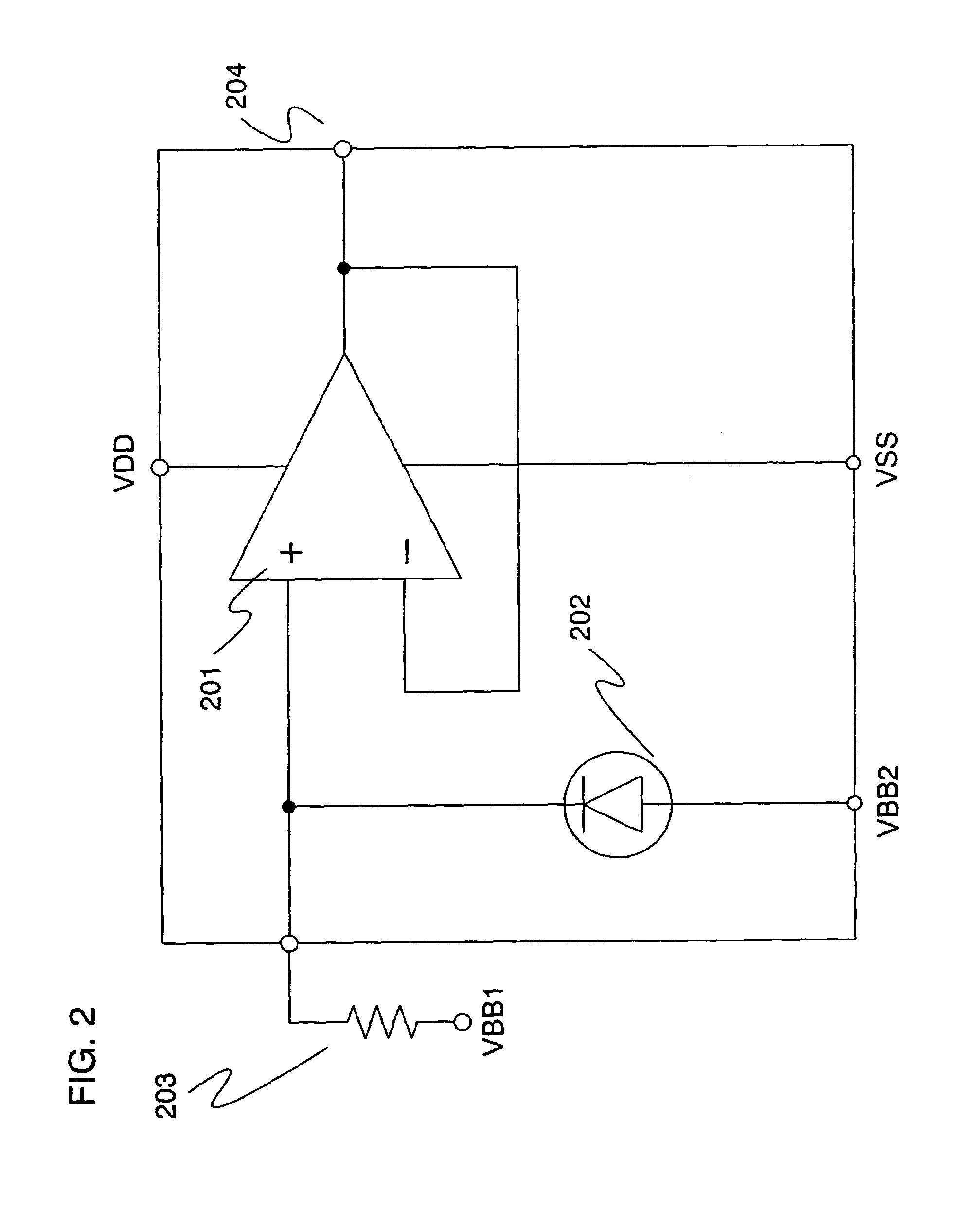

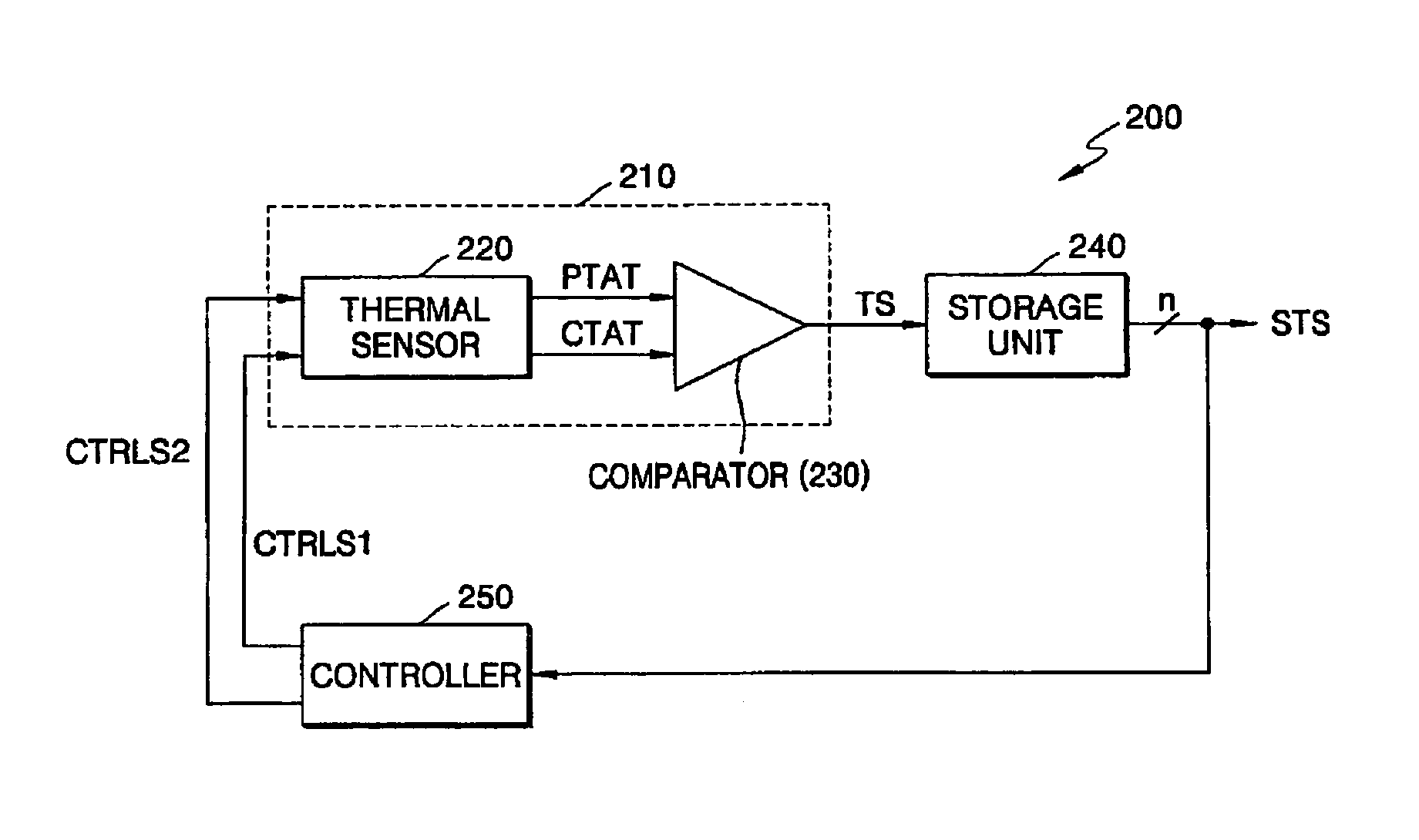

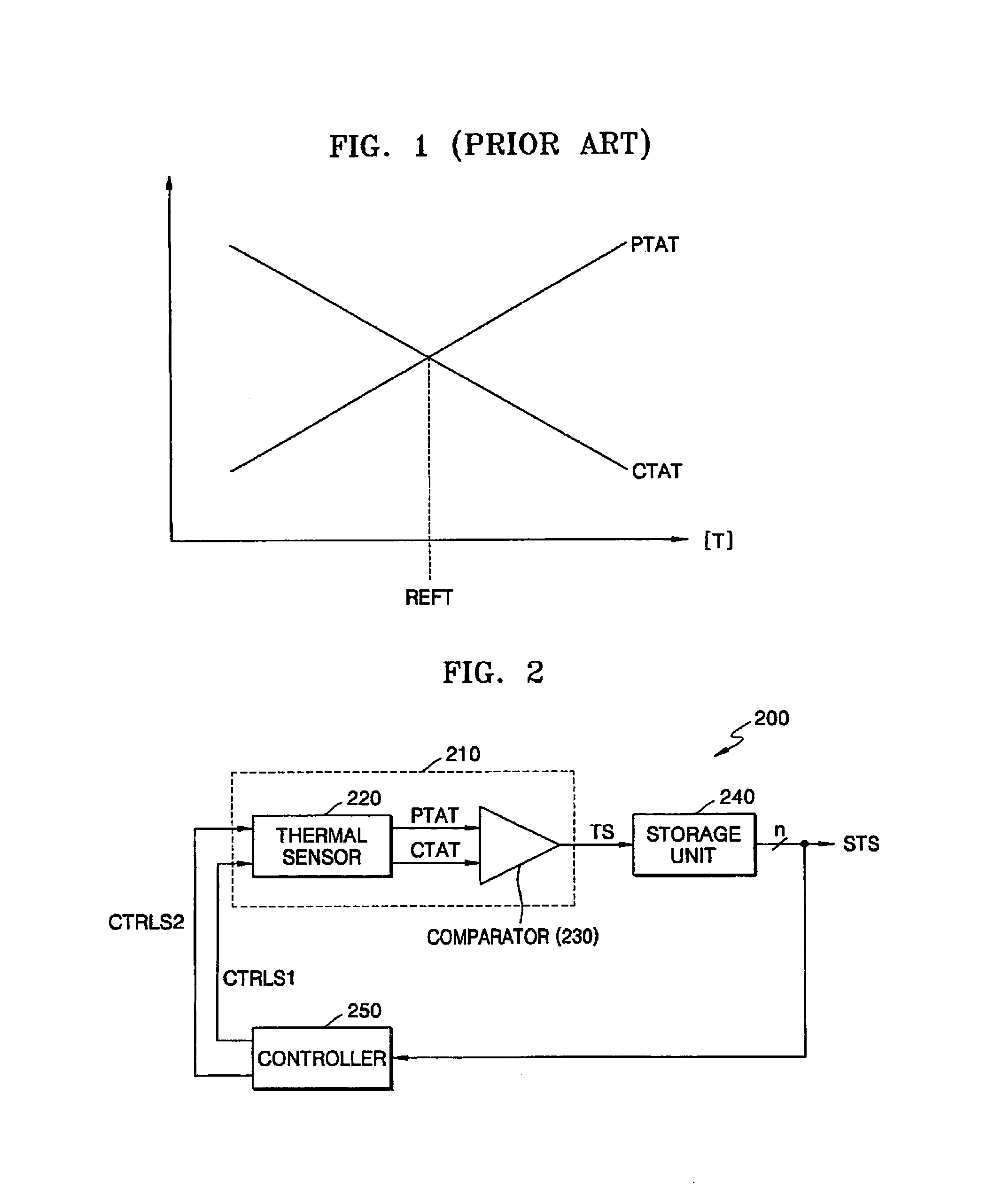

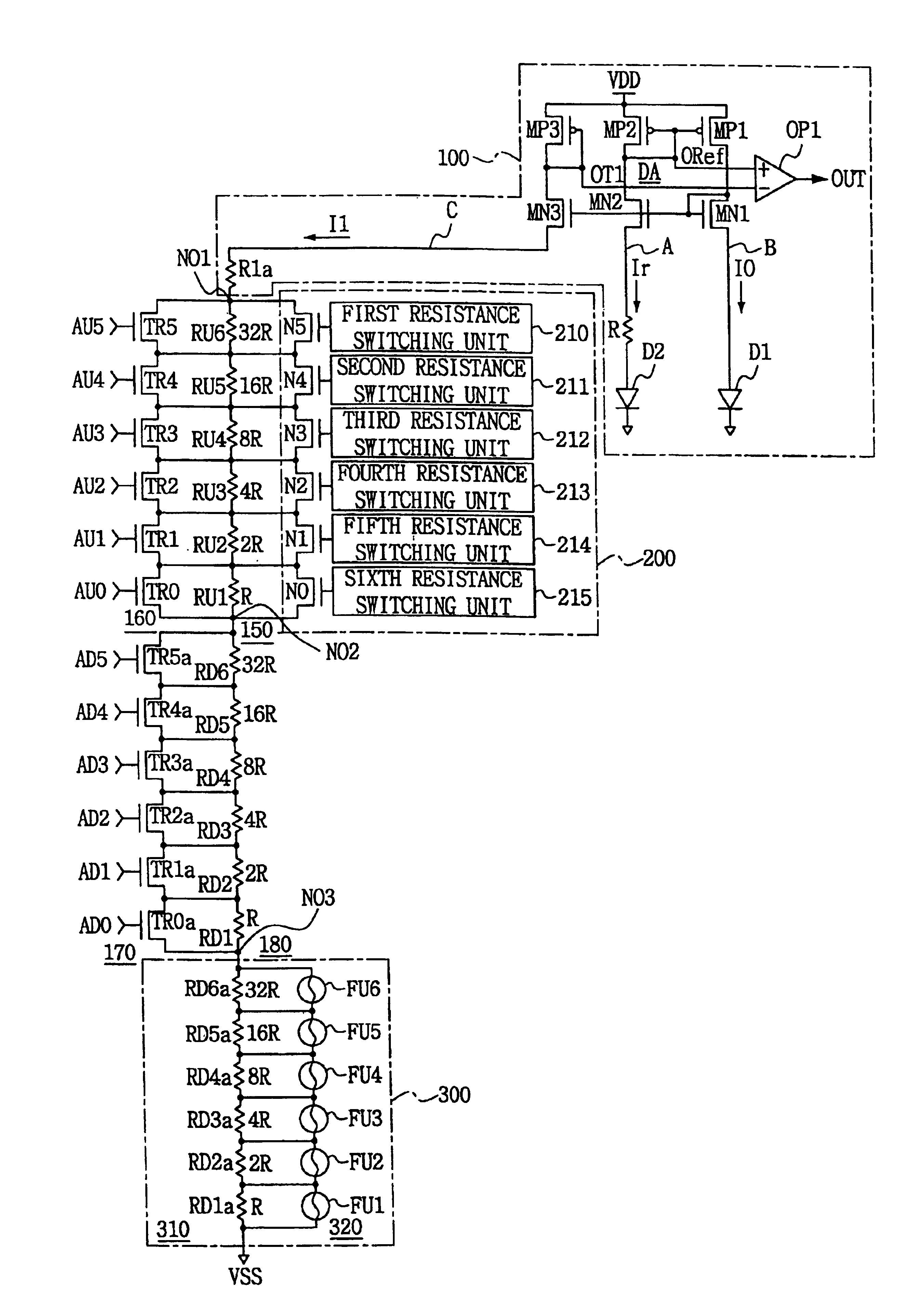

Temperature sensing circuit and method

ActiveUS7078955B2Semiconductor/solid-state device testing/measurementThermometers using electric/magnetic elementsControl signalSemiconductor

A temperature sensing circuit and method are provided. An example temperature sensing circuit includes a temperature sensing unit that outputs a temperature signal indicating whether the temperature in the semiconductor device is higher or lower than a reference temperature in response to a first current control signal or a second current control signal by using a first current level that is increased when the temperature rises and a second current level that is reduced when the temperature rises. The temperature sensing unit also includes a storage unit that stores and outputs the temperature signal, and a controller that changes the first current level or the second current level in response to the temperature signal output from the storage unit and generates the first current control signal or the second current control signal used to control the reference temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

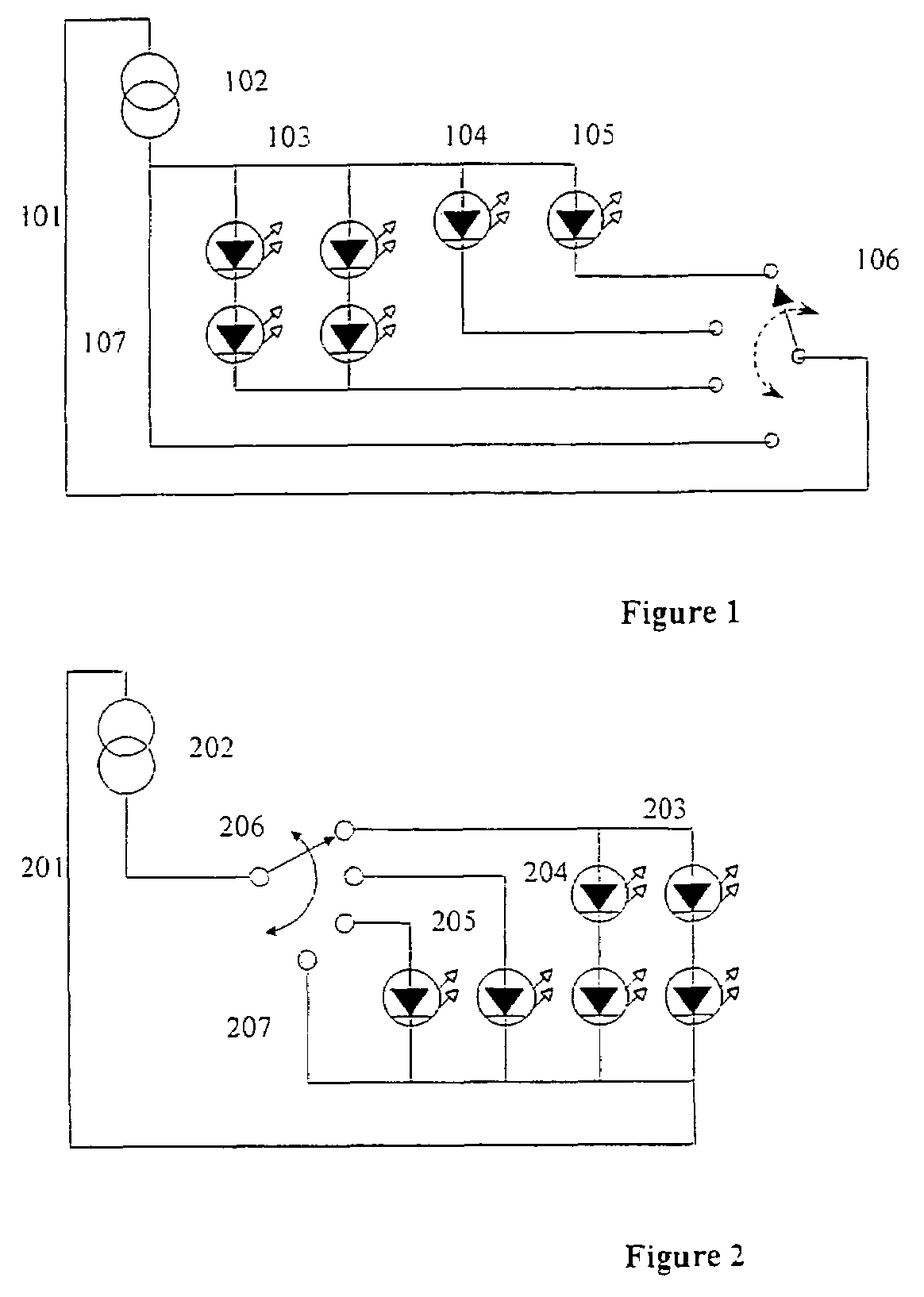

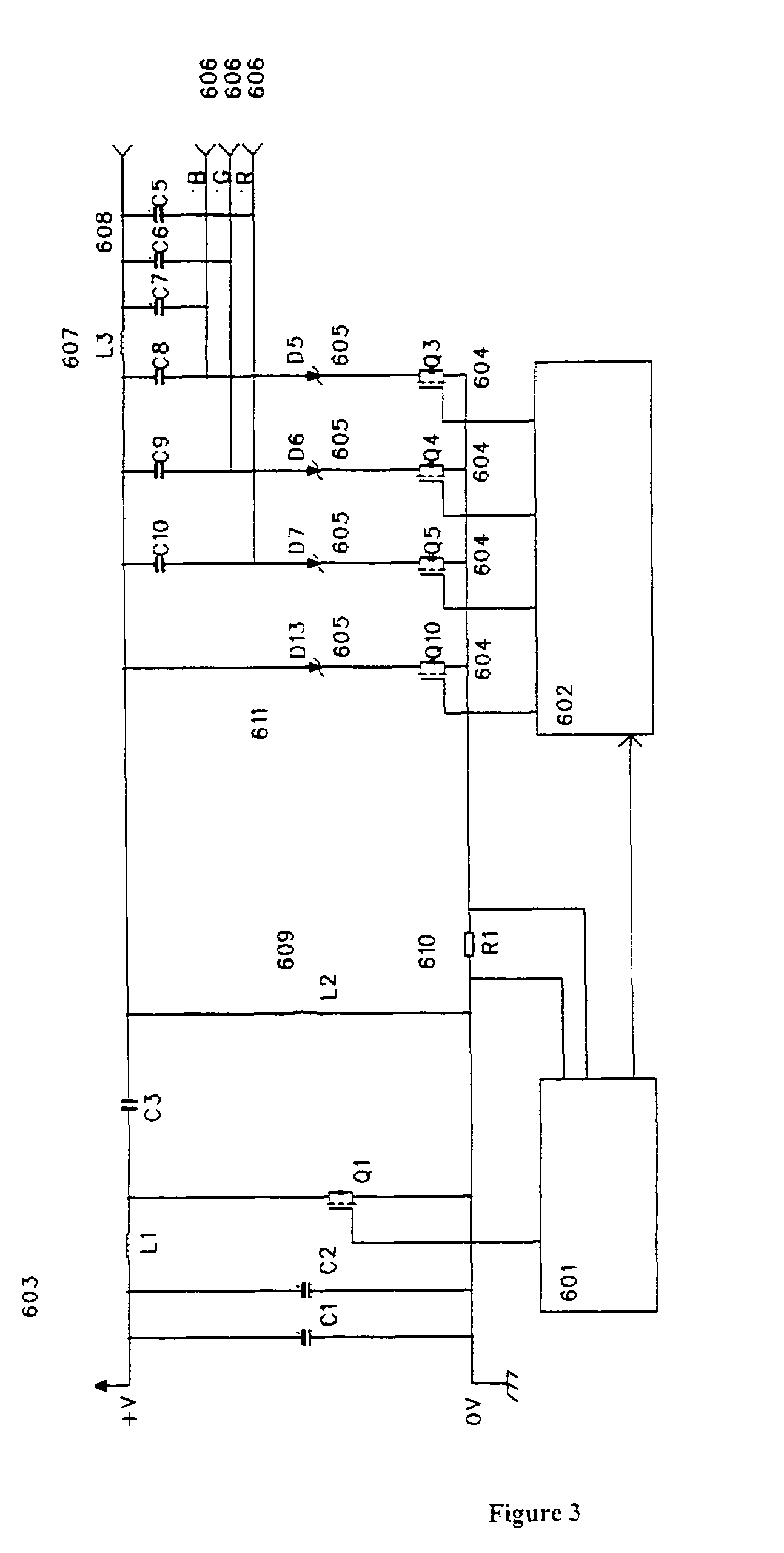

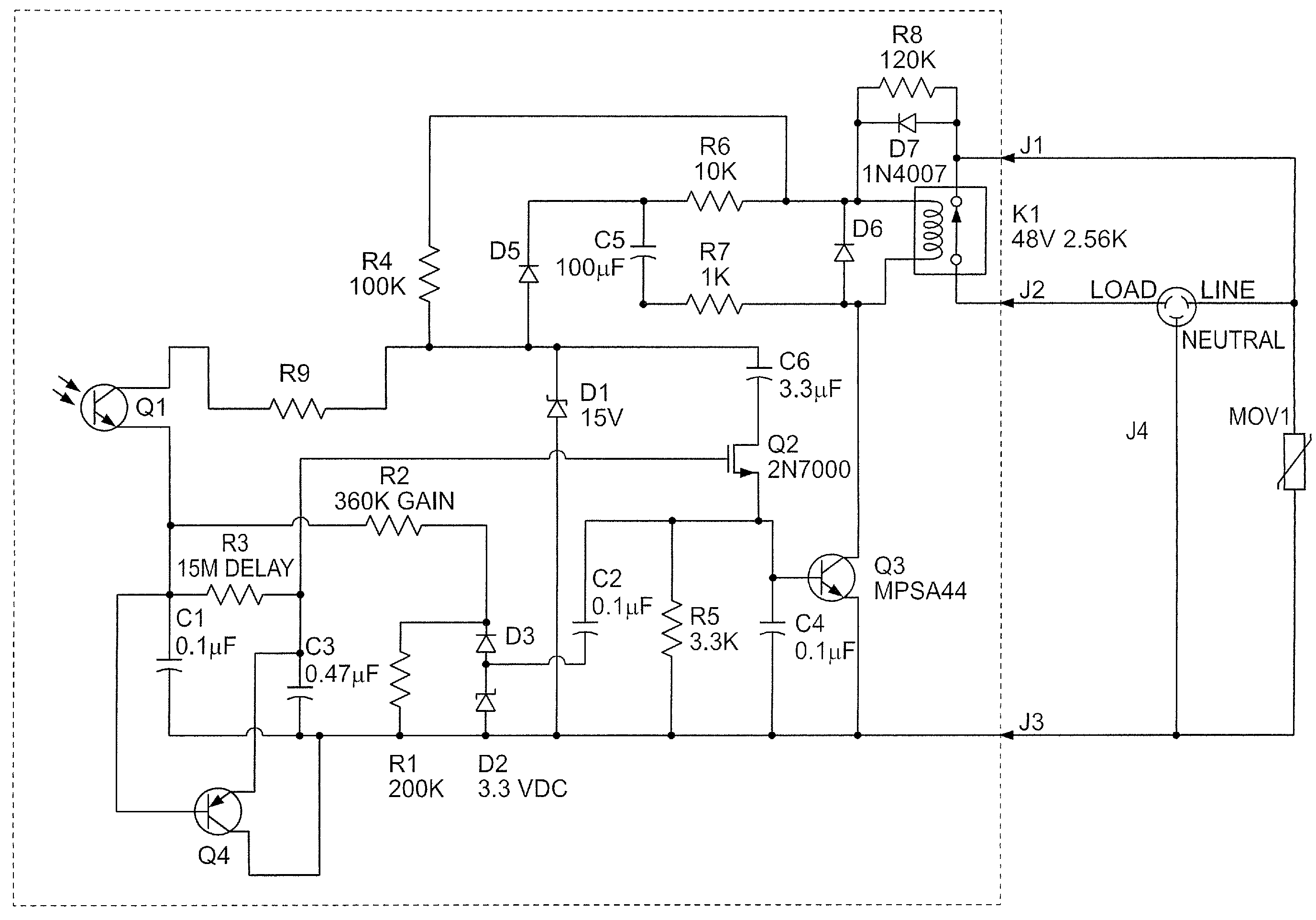

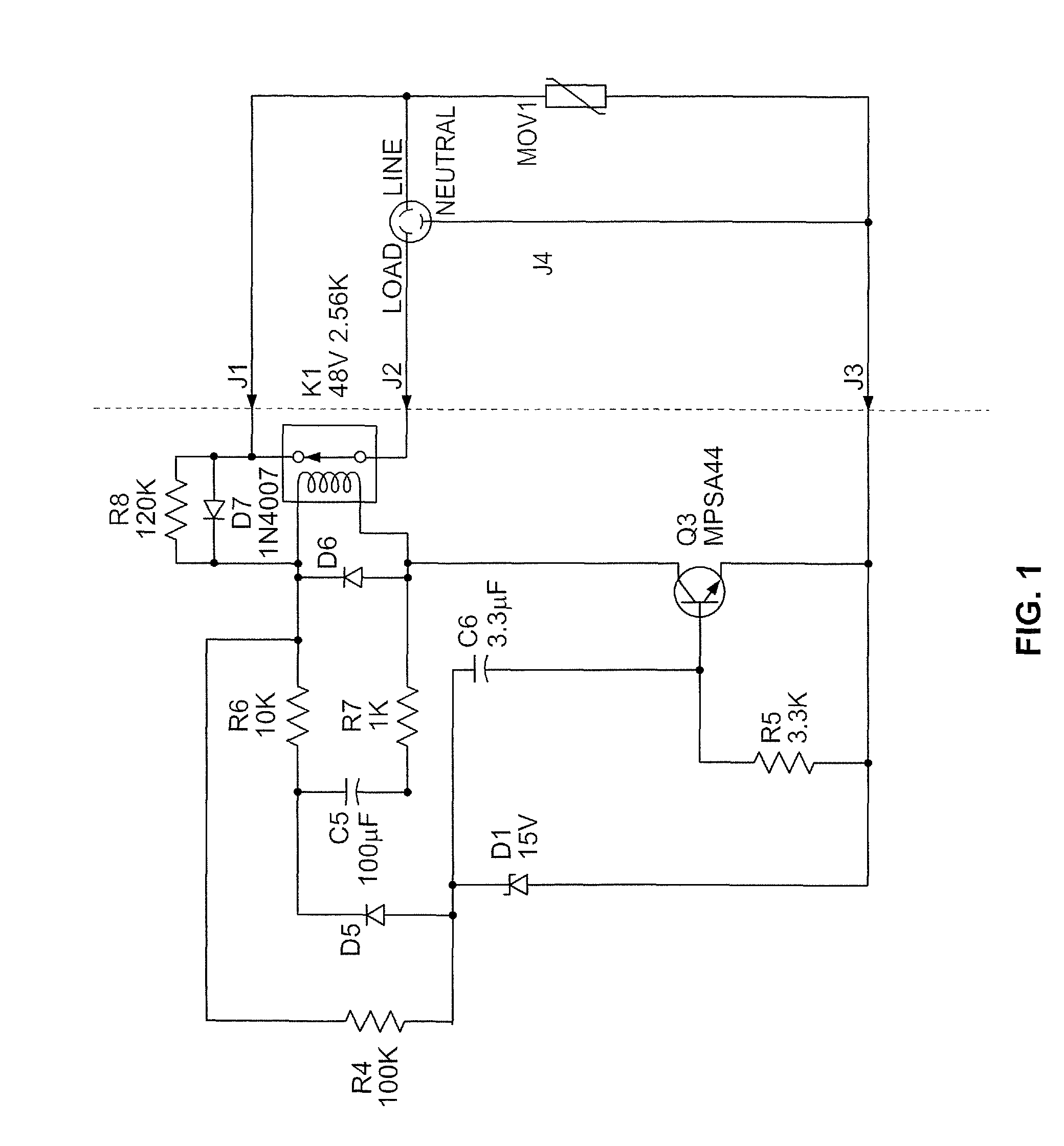

Photosensor circuits including a switch mode power converter

ActiveUS7804200B2Boards/switchyards circuit arrangementsElectronic switchingHysteresisLow-pass filter

Photosensor circuits include a relay coil configured to control application of an alternating current (AC) power source to a load. A pulse width modulator circuit is configured to generate a pulse width modulated signal having a pulse width that varies responsive to an average voltage across the relay coil. A drive transistor controls the average voltage across the relay coil responsive to the pulse width modulated signal. A photo control circuit controls application of the pulse width modulated signal to the drive transistor responsive to a detected light level. A half-wave rectifier provide a power signal to the pulse width modulator circuit and the photo control circuit during one of the halves of the line cycle of the AC power source. The photo control circuit includes a phototransistor. A low pass filter circuit filters the output current of the phototransistor to provide a light level signal voltage. A select transistor couples the pulse width modulated signal to the drive transistor during one of the halves of the line cycle of the AC power source responsive to the light level signal voltage having a selected level. A capacitor coupled between the second terminal of the phototransistor and the neutral bus modulates an amount of positive feedback through the first terminal of the phototransistor proportional to a current flowing through the relay coil to provide hysteresis to control of the relay coil by the photosensor circuit.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

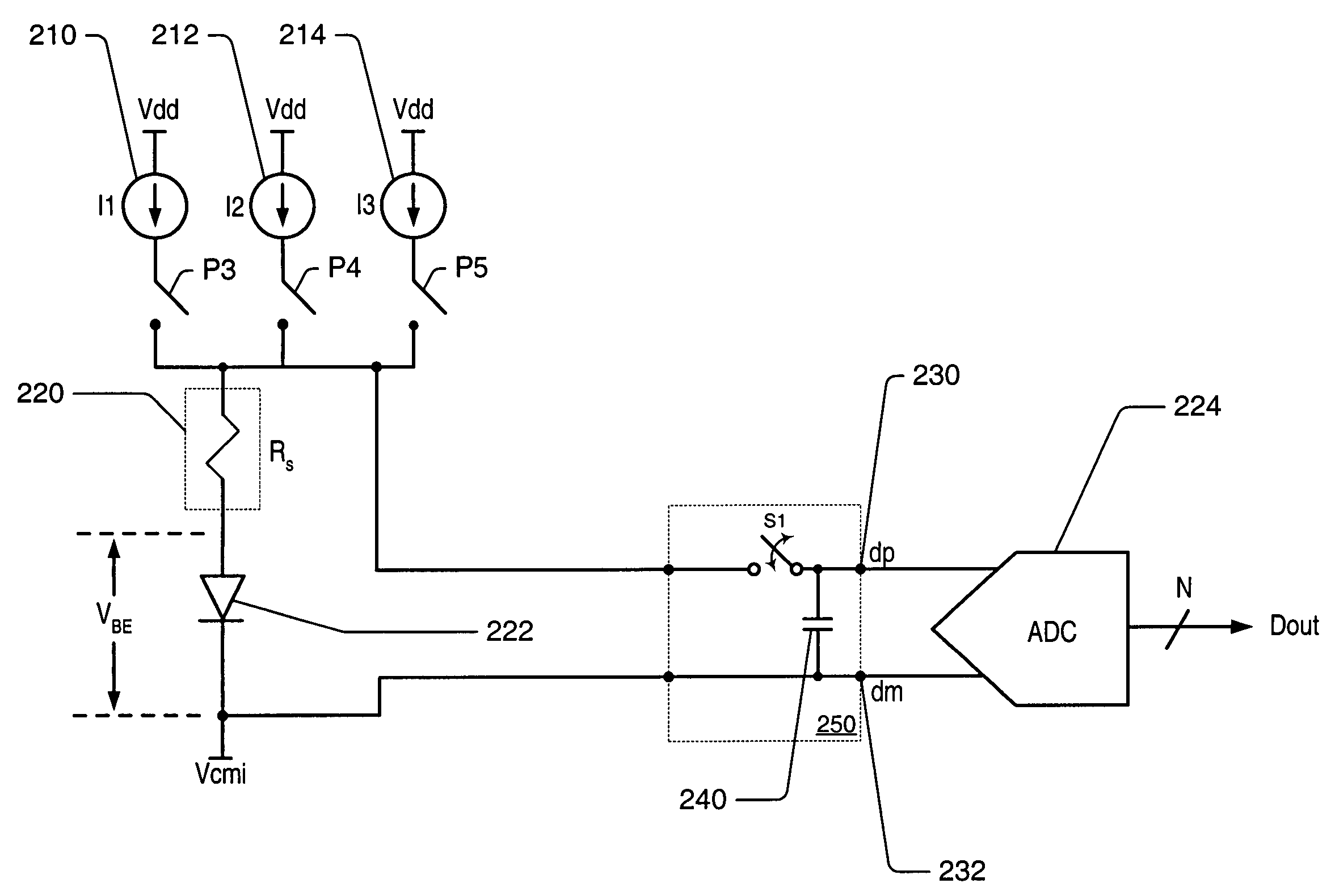

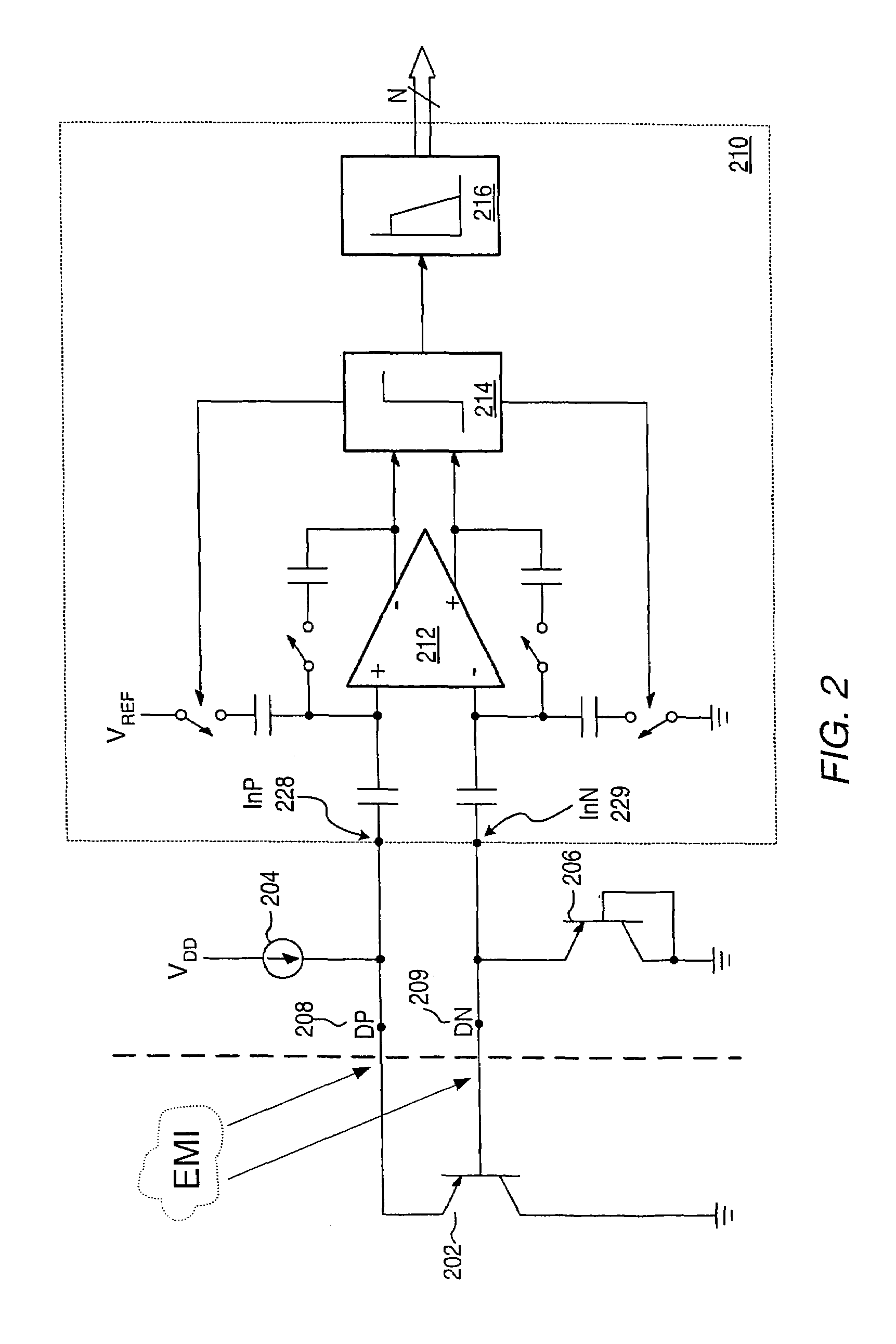

Proportional settling time adjustment for diode voltage and temperature measurements dependent on forced level current

ActiveUS7429129B2Increase conversion rateMinimizing temperature measurementThermometer detailsThermometers using material expansion/contactionAc componentsShunt capacitors

A temperature sensor circuit and system providing accurate digital temperature readings using a local or remote temperature diode. In one set of embodiments a change in diode junction voltage (ΔVBE) proportional to the temperature of the diode is captured and provided to an analog to digital converter (ADC), which may perform required signal conditioning functions on ΔVBE, and provide a digital output corresponding to the temperature of the diode. DC components of errors in the measured temperature that may result from EMI noise modulating the junction voltage (VBE) may be minimized through the use of a front-end sample-and-hold circuit coupled between the diode and the ADC, in combination with a shunt capacitor coupled across the diode junction. The sample-and-hold-circuit may sample VBE at a frequency that provides sufficient settling time for each VBE sample, and provide corresponding stable ΔVBE samples to the ADC at the ADC operating frequency. The ADC may therefore be operated at its preferred sampling frequency rate without incurring reading errors while still averaging out AC components of additional errors induced by sources other than EMI.

Owner:MICROCHIP TECH INC

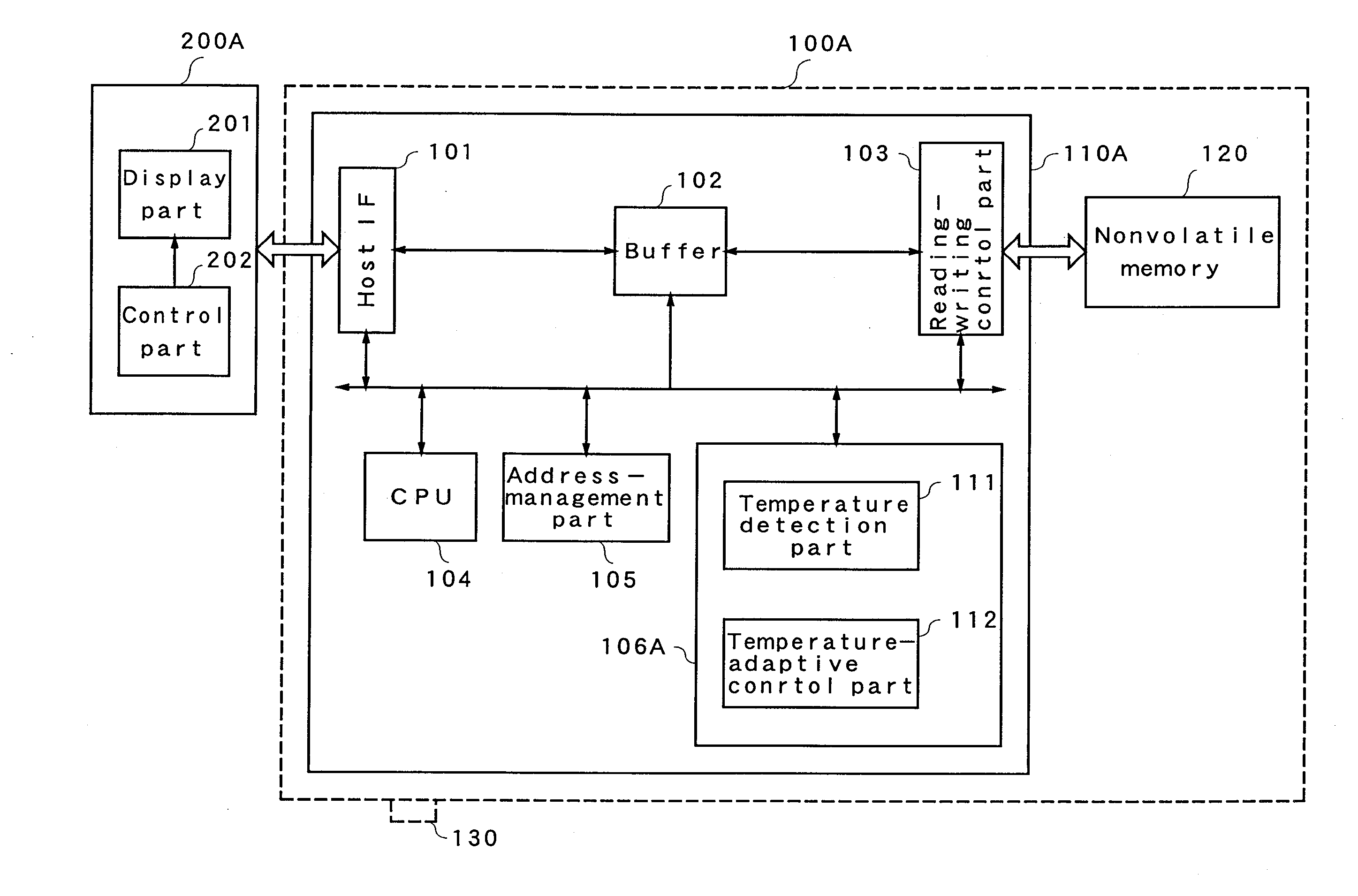

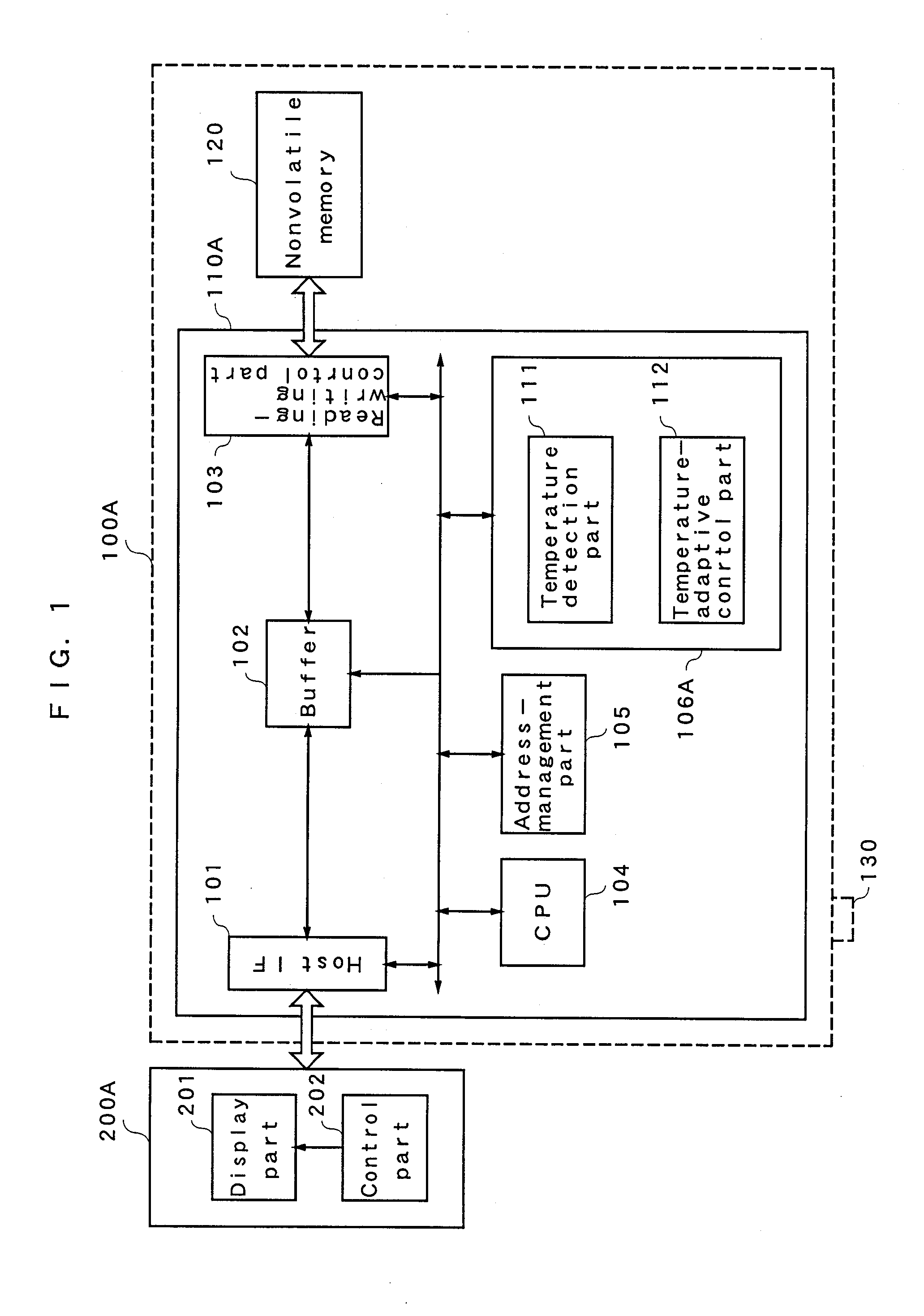

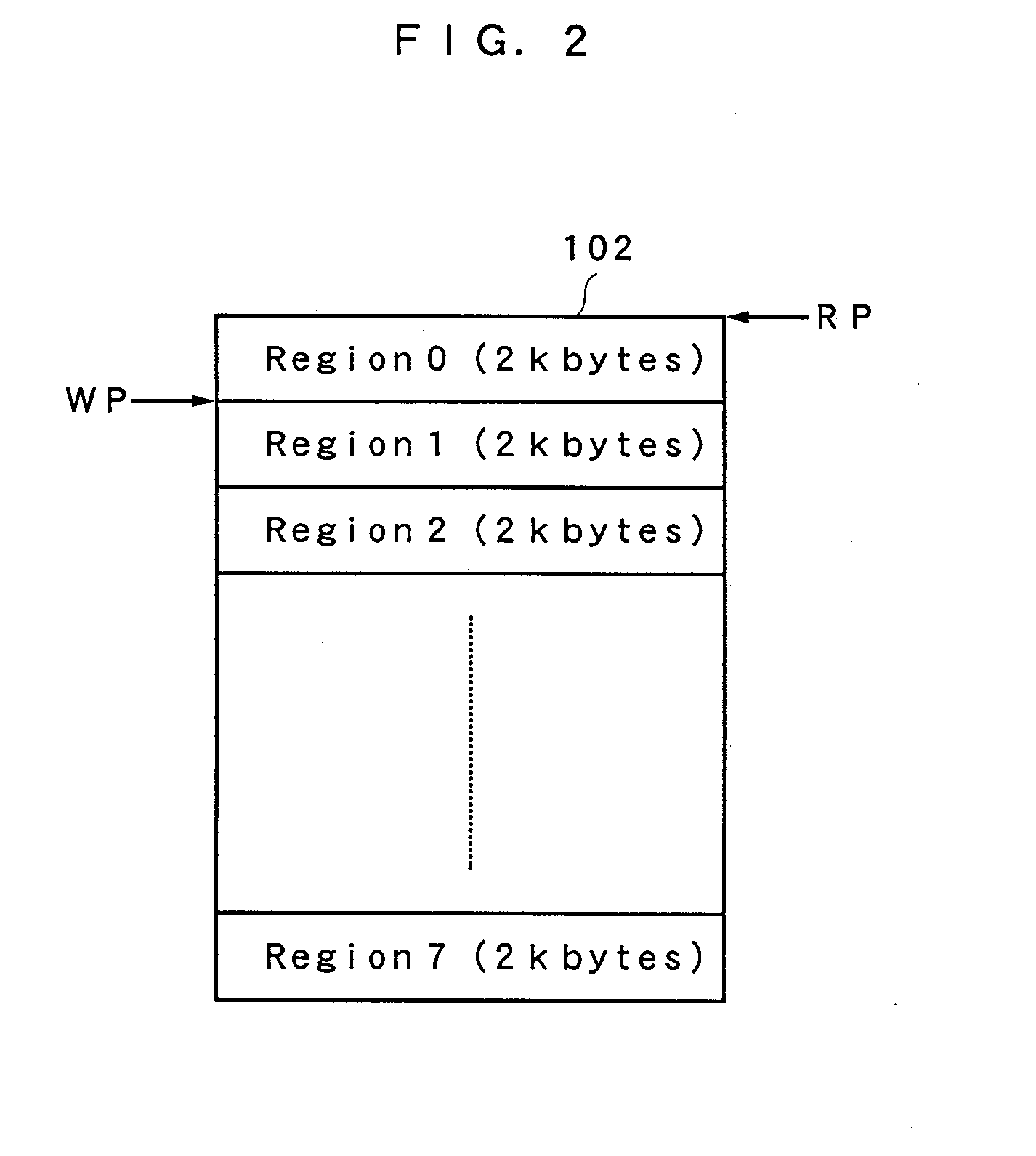

Nonvolatile memory device, nonvolatile memory system, and access device

ActiveUS20100023678A1Increase temperatureIncrease speedDigital data processing detailsRead-only memoriesEmbedded systemSemiconductor

When an access device accesses a nonvolatile memory device, the nonvolatile memory device or the access device detects or calculates a temperature T of the nonvolatile memory device. A temperature-adaptive control part of the nonvolatile memory device controls an access rate to a nonvolatile memory on the basis of the temperature T. Accordingly, the control part controls the rate so that the temperature T of the nonvolatile memory devices cannot exceed a limit temperature Trisk. In this manner, a nonvolatile memory system can eliminate a risk of a burn when ejecting the semiconductor memory device and can read and write data at a high speed.

Owner:SK HYNIX INC

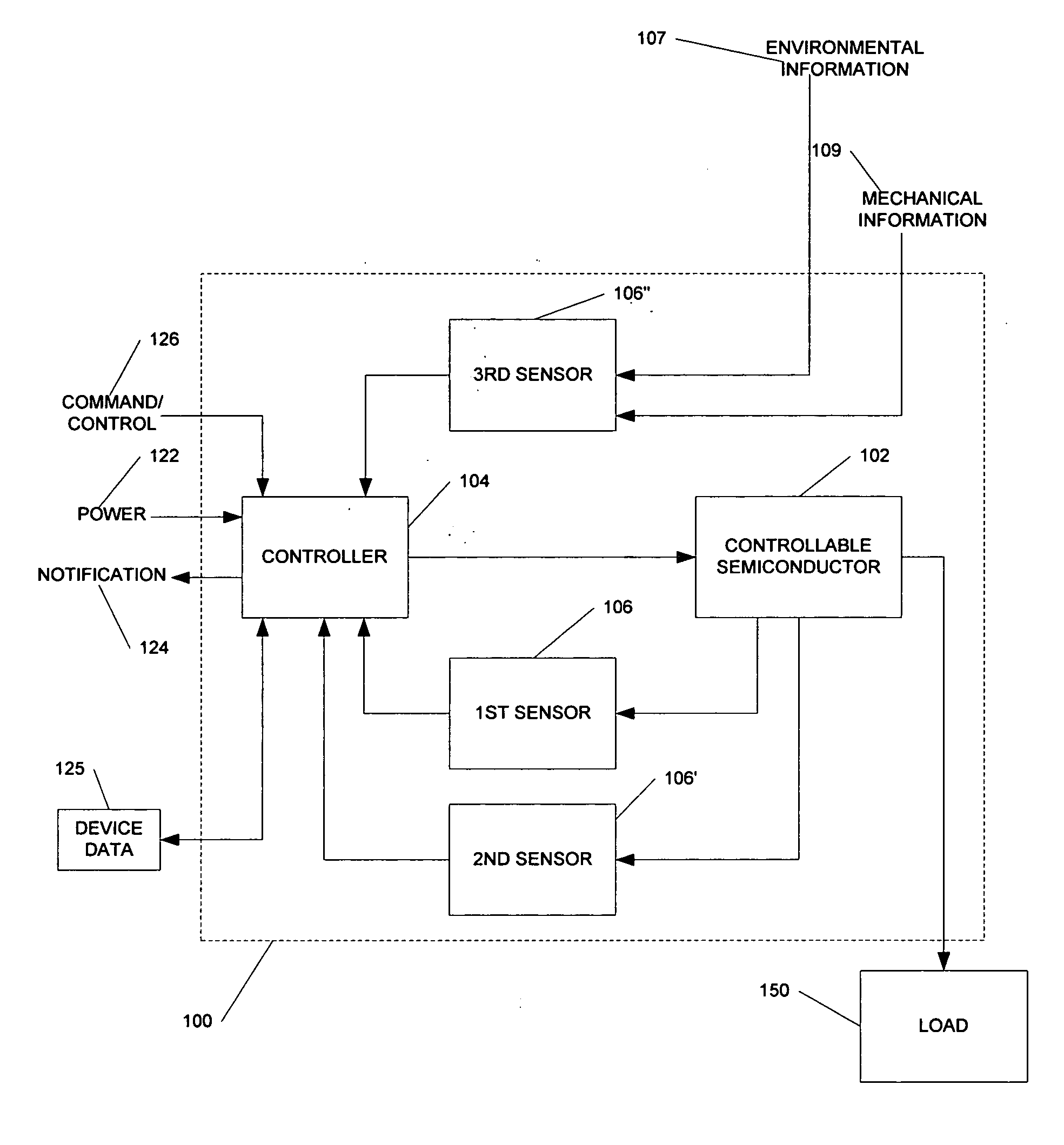

Integrated smart power switch

A device including a controllable semiconductor, sensor, and controller is provided. The controllable semiconductor is associated with a first operating parameter and a second operating parameter, wherein at least the first operating parameter is controllable. The sensor is in communication with the controllable semiconductor device and acquires data relating to the second operating parameter of the controllable semiconductor device. The controller is in communication with the controllable semiconductor device and the sensor, and the controller is configured to access device data associated with the controllable semiconductor, control the first operating parameter of the controllable semiconductor, and receive data from the first sensor relating to the second operating parameter. The controller determines a first predicted value dependent on the device data, compares the data relating to the second operating parameter with the first predicted value, and, if a first condition is detected based on this comparison, dynamically modifies the first operating parameter.

Owner:RAYTHEON CO

Optical sensor device and electronic apparatus

InactiveUS20050082463A1Low costReduction in mounting spaceSolid-state devicesMaterial analysis by optical meansAudio power amplifierAmorphous silicon

In an optical sensor device employing an amorphous silicon photodiode, an external amplifier IC and the like are required due to low current capacity of the sensor element in order to improve the load driving capacity. It leads to increase in cost and mounting space of the optical sensor device. In addition, noise may easily superimpose since the photodiode and the amplifier IC are connected to each other over a printed circuit board. According to the invention, an amorphous silicon photodiode and an amplifier configured by a thin film transistor are formed integrally over a substrate so that the load driving capacity is improved while reducing cost and mounting space. Superimposing noise can be also reduced.

Owner:SEMICON ENERGY LAB CO LTD

Circuit and method for compensating for offset voltage

InactiveUS7227389B2Variation in characteristicMultiple input and output pulse circuitsPulse automatic controlPhotovoltaic detectorsPhotodetector

A circuit for compensating for an offset voltage in a PhotoDetector Integrated Circuit (PDIC). The circuit includes a temperature detection unit, a current transfer unit and a current adjustment unit. The temperature detection unit generates a current that varies with variation in surrounding temperature. The current transfer unit transfers the generated current. The current adjustment unit adjusts the current transferred from the current transfer unit at a predetermined ratio and outputs the adjusted current.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

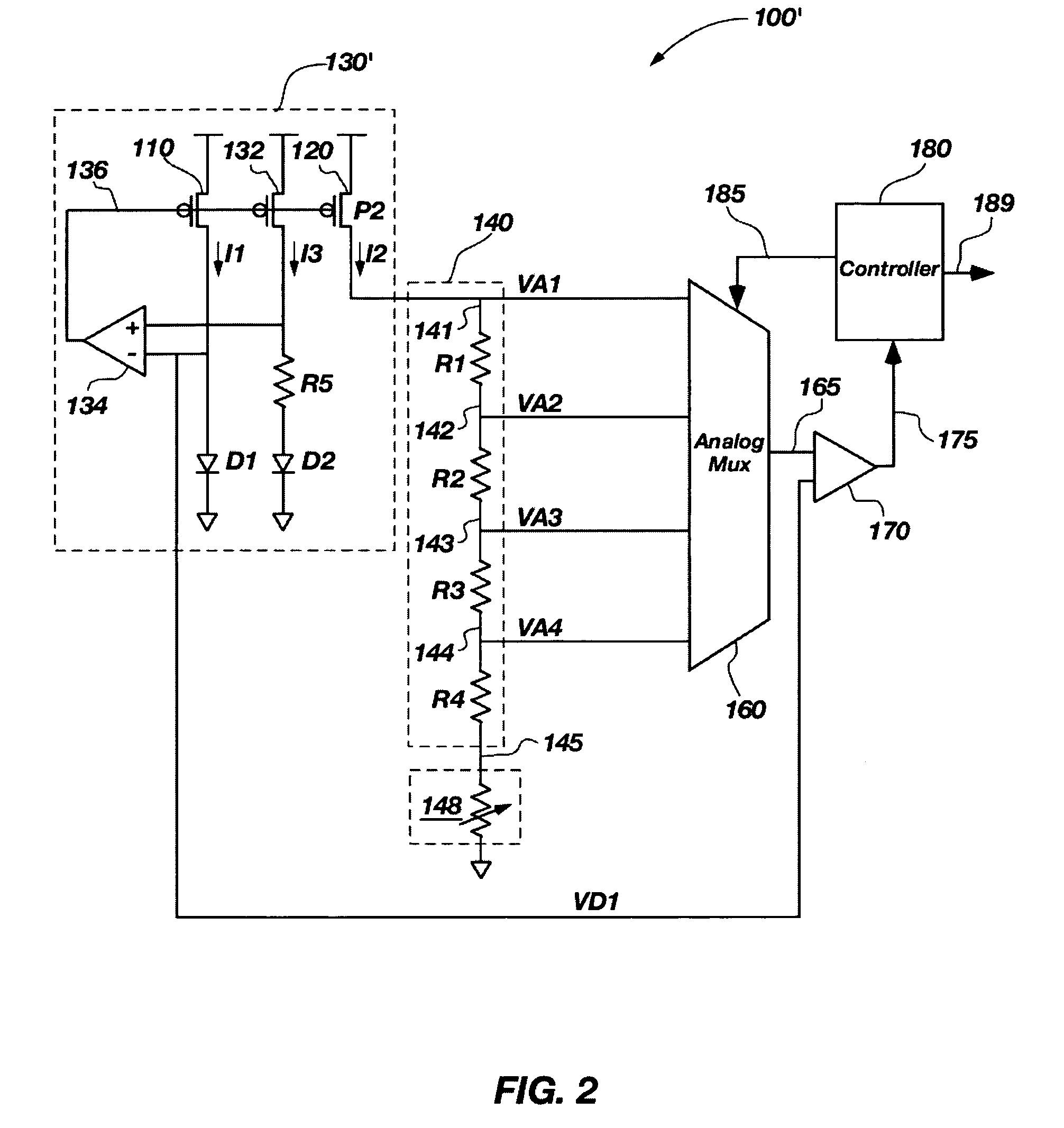

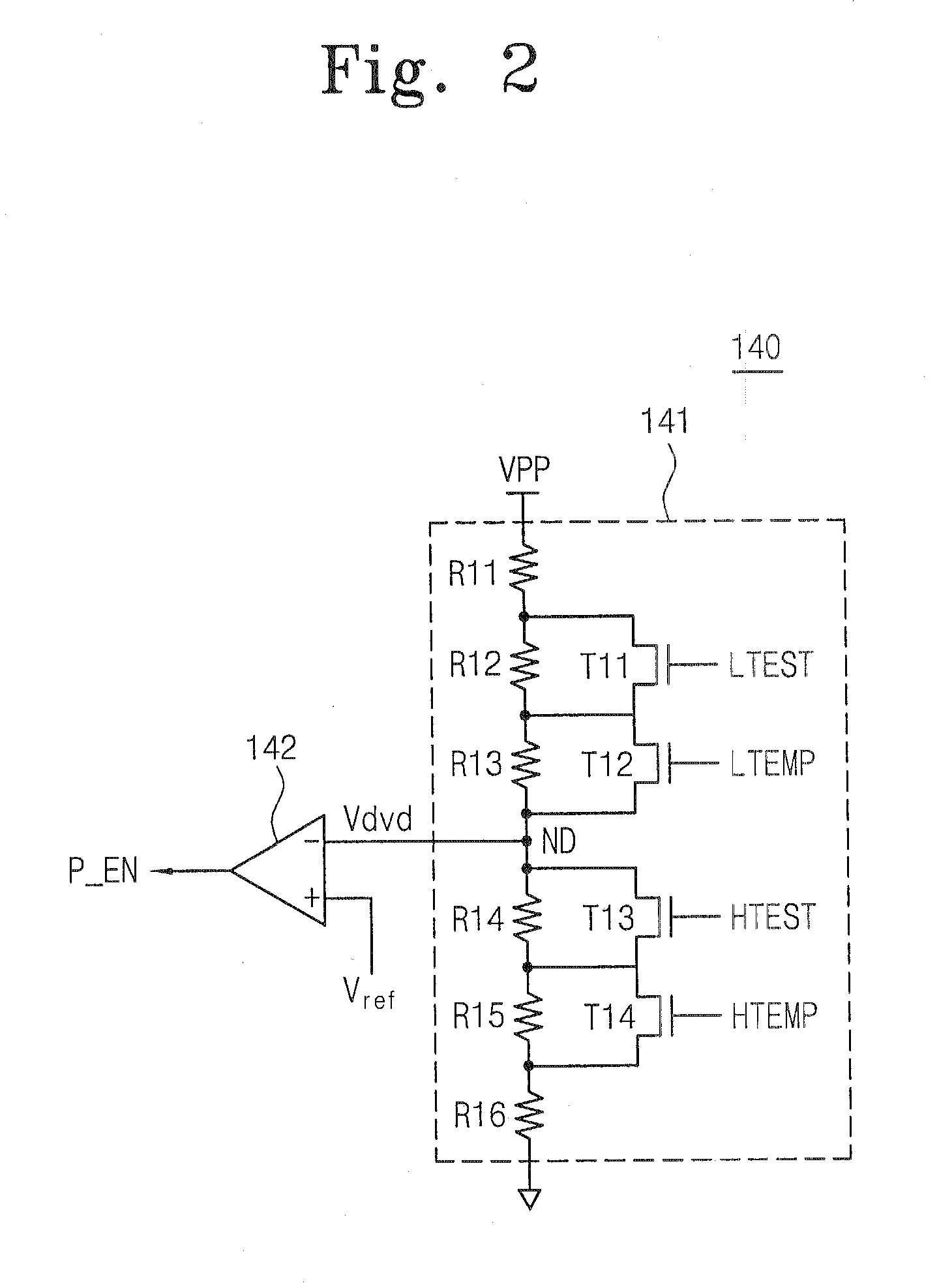

Temperature sensor and method for detecting trip temperature of a temperature sensor

InactiveUS6937087B2Multiple input and output pulse circuitsInstant pulse delivery arrangementsComparators circuitsTest sequence

A comparator circuit of a temperature sensor includes an output node and a variable current node. The output node is a first voltage at a given temperature when a current at the variable current node is less than a threshold current, and a different second voltage at the given temperature when the current at the variable current node is more than the threshold current. A variable resistance circuit includes at least n resistors of different resistive values connected in series between the variable current node of the comparator and a supply voltage, where n is an integer of 4 or more. A switching circuit is provided to selectively bypasses individual ones of the n resistors during a test sequence to determine a trip temperature of the sensor.

Owner:SAMSUNG ELECTRONICS CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com