Open magnetic circuit stacked coil component and process for producing the open magnetic circuit stacked coil component

A technology of stacking coils and open magnetic circuits, applied in coil manufacturing, inductance/transformer/magnet manufacturing, chemical instruments and methods, etc. , the temperature characteristics of the inductance value are flat, the temperature characteristics are flat, and the initial inductance is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

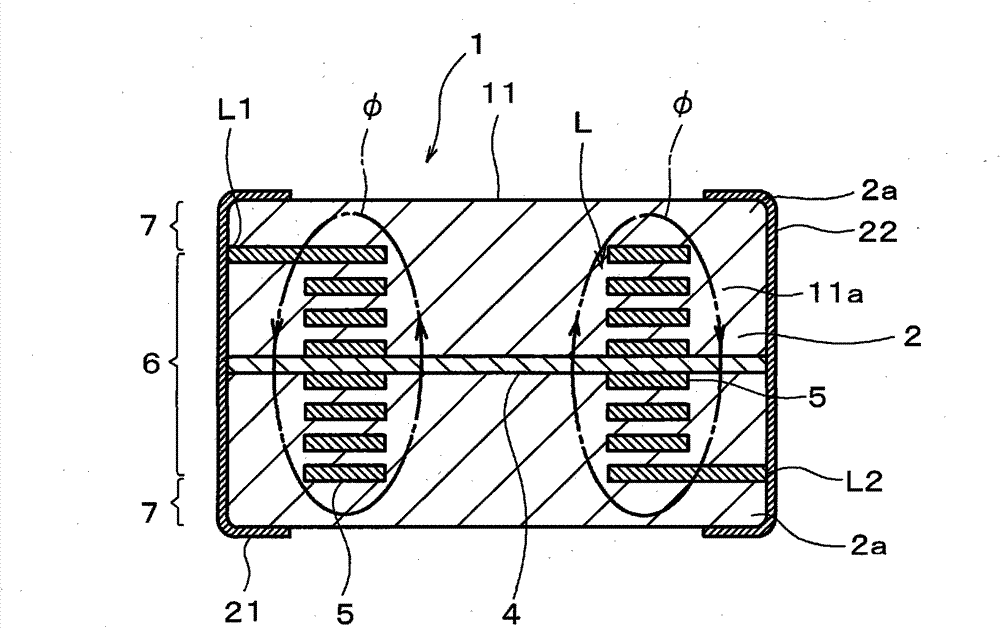

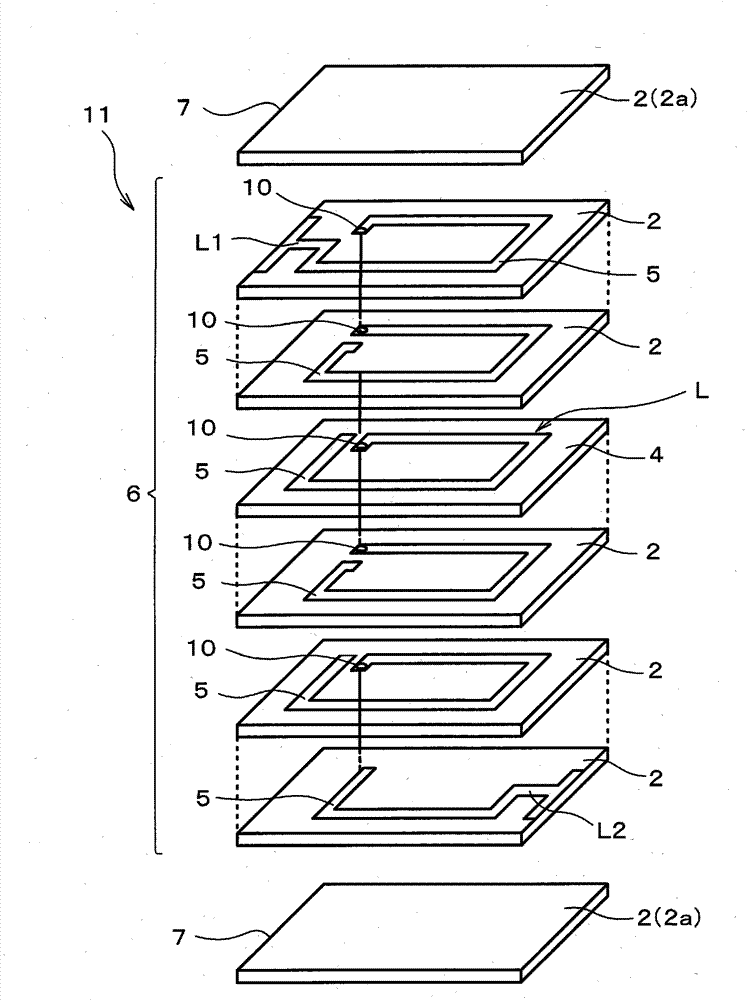

[0062] figure 1 is a cross-sectional view showing the structure of an open magnetic path type laminated coil component (a laminated inductor in the first embodiment) according to an embodiment (Embodiment 1) of the present invention, figure 2 is its stereogram, image 3 It is an exploded perspective view for explaining its internal structure and manufacturing method.

[0063] like Figure 1~3 As shown, the open magnetic circuit type laminated coil component 1 of this embodiment 1 is an open magnetic circuit type laminated inductor, and has a laminated body 11. The laminated body 11 is formed by laminating a plurality of coil conductors 5 and made of Ni-Zn- A plurality of magnetic layers 2 made of Cu-based ferrite material (refer to image 3 ) formed.

[0064] The laminated body 11 includes: a built-in coil laminated portion 6 in which a helical coil L is electrically connected to a plurality of coils arranged between a plurality of magnetic layers 2 through an interlayer ...

Embodiment 2

[0105] (Production of Magnetic Ceramic Green Sheets)

[0106] For 100 parts by weight of the magnetic material raw material (Ni-Zn-Cu-based ferrite material) having the same composition as in the case of Example 1 above, Co was mixed in the ratio shown in Table 2. 3 o 4 powder, and produced magnetic ceramic green sheets by the same method as in the case of Example 1 above. It should be noted that, in Table 2, the samples whose serial numbers are marked with * are outside the protection scope of the present application.

[0107] [Table 2]

[0108]

[0109] Thereafter, as in the case of Example 1, after via holes were formed at predetermined positions, predetermined conductor patterns for coils and via conductors for interlayer connection were formed on the surface of the magnetic ceramic green sheet.

[0110] It should be noted that, as the magnetic ceramic green sheet for the package portion, as in the case of the above-mentioned Example 1, the above-mentioned magnetic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com