tib-containing for 3d printing 2 /tic aluminum-zinc-magnesium-copper alloy powder and preparation method thereof

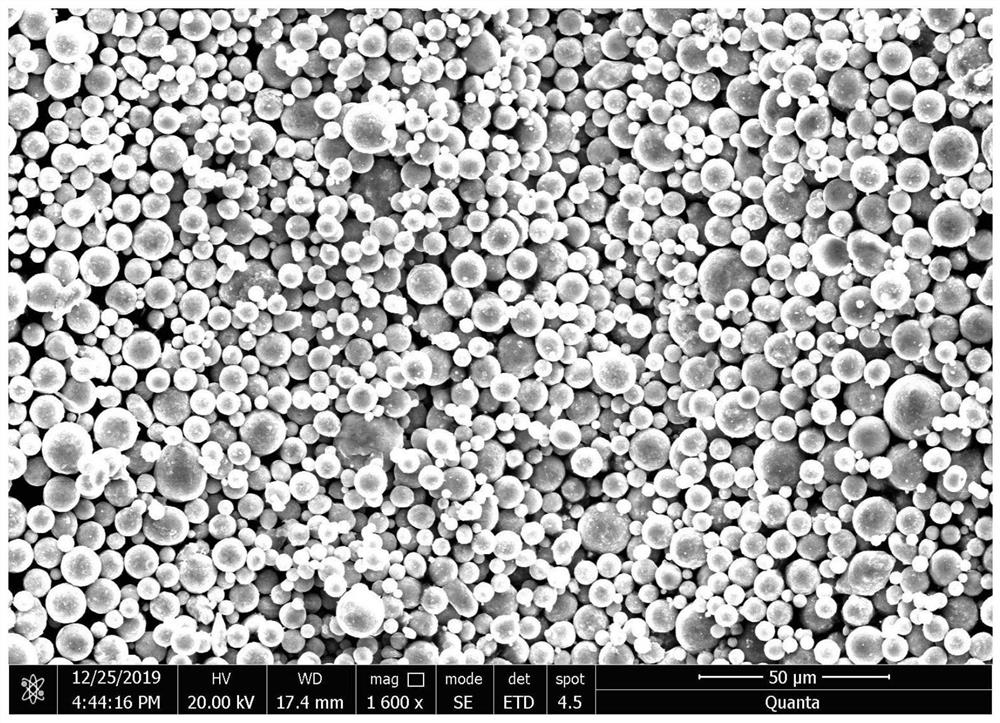

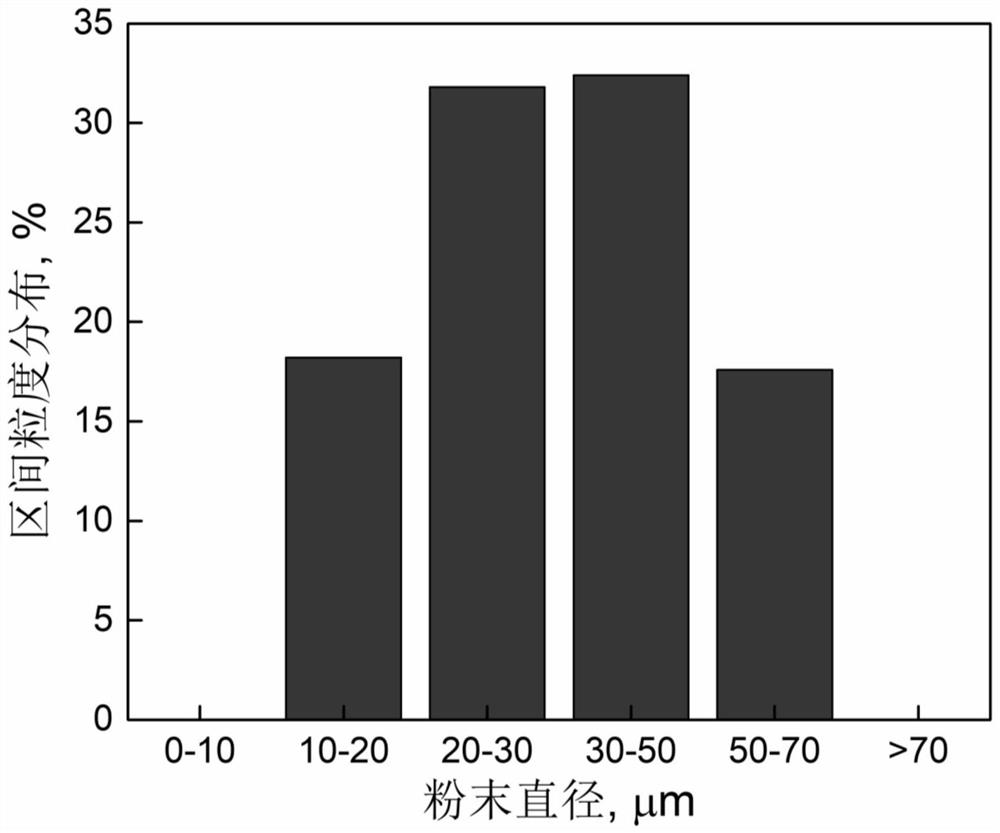

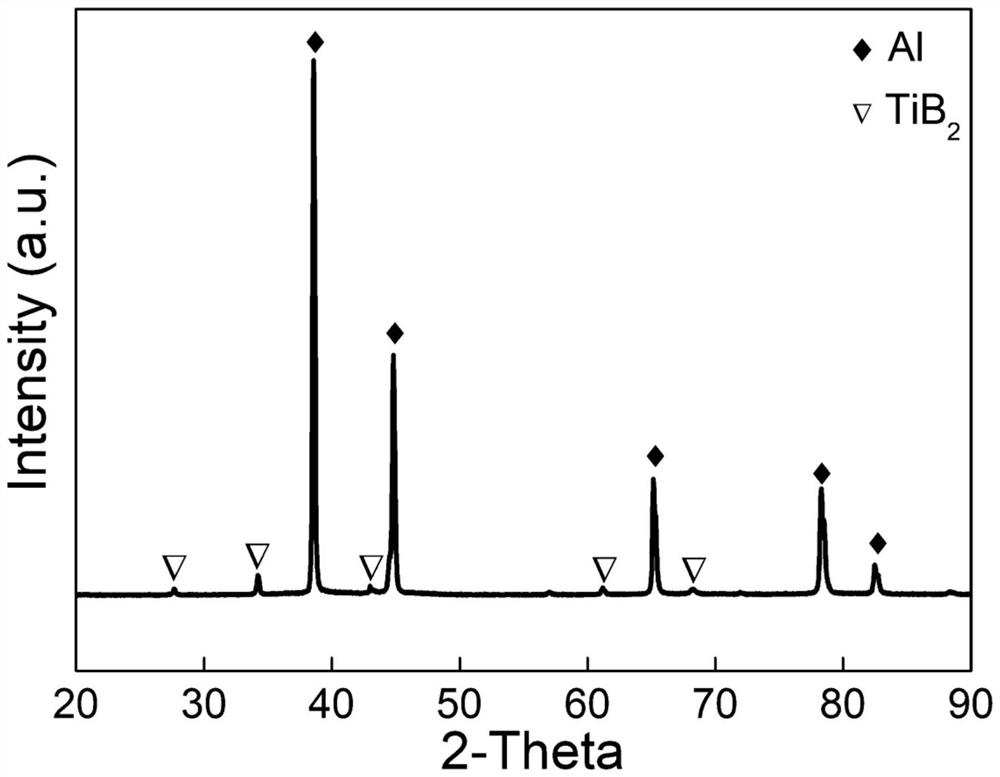

A technology of alloy powder and 3D printing, applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve problems such as thermal cracking and coarse grains, and achieve good wear resistance, fine grain size, and particle size distribution concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this example, in terms of weight percentage, the TiB-containing material used for 3D printing 2 The formula ratio of aluminum-zinc-magnesium-copper alloy powder of / TiC is as follows: TiB 2 : 8%; Zn: 9.15%; Mg: 2.5%; Cu: 1.16%; Zr: 0.11%; Sc: 0.17%; the balance is aluminum.

[0046] The TiB-containing material for 3D printing of the present embodiment 2 The preparation method of the aluminum-zinc-magnesium-copper alloy powder of TiC comprises the following steps:

[0047] (1) Put pure aluminum into the intermediate frequency induction melting furnace for heating and melting, adjust the melt temperature to 760°C, and add pure Zn, pure Cu, Al-Mg master alloy, and Al-Zr master alloy to the aluminum melt according to the preparation components. and Al-Sc master alloy, stirring and holding for ~30min to obtain an aluminum-zinc-magnesium-copper alloy melt with uniform composition; wherein, in the Al-Mg master alloy, the mass percentage of Mg is 5%, and the balance is Al;...

Embodiment 2

[0060] In this example, in terms of weight percentage, the TiB-containing material used for 3D printing 2 The formula ratio of aluminum-zinc-magnesium-copper alloy powder of TiC is as follows: TiB 2: 15%; TiC: 0.5%; Zn: 10%; Mg: 2.5%; Cu: 2.5%; Zr: 0.15%; Sc: 0.25%; the balance is aluminum.

[0061] The TiB-containing material for 3D printing of the present embodiment 2 The preparation method of the aluminum-zinc-magnesium-copper alloy powder of TiC comprises the following steps:

[0062] (1) Put pure aluminum into the intermediate frequency induction melting furnace for heating and melting, adjust the melt temperature to 780°C, and add pure Zn, pure Cu, Al-Mg master alloy and Al-Zr master alloy to the aluminum melt according to the preparation components and Al-Sc master alloy, stirring and holding for 30min to obtain an aluminum-zinc-magnesium-copper alloy melt with uniform composition; among them, in the Al-Mg master alloy, the mass percentage of Mg is 1%, and the balance...

Embodiment 3

[0075] In this example, in terms of weight percentage, the TiB-containing material used for 3D printing 2 The formula ratio of aluminum-zinc-magnesium-copper alloy powder of TiC is as follows: TiB 2 : 6%; Zn: 5%; Mg: 1.5%; Cu: 1%; Zr: 0.08%; Sc: 0.1%; the balance is aluminum.

[0076] In this example, the TiB-containing material used for 3D printing 2 The preparation method of the aluminum-zinc-magnesium-copper alloy powder of TiC, the steps are as follows:

[0077] (1) Press for 3D printing containing TiB 2 / TiC Al-Zn-Mg-Cu alloy powder ratio Weigh the raw materials, put pure aluminum into the intermediate frequency induction melting furnace, heat and melt, adjust the melt temperature to 730 ℃, add pure Zn, Pure Cu, Al-Mg master alloy, Al-Zr master alloy and Al-Sc master alloy, stir and hold for 30±10min to obtain a uniform Al-Zn-Mg-Cu alloy melt; among them, in the Al-Mg master alloy, Mg The mass percentage of Zr is 5%, and the balance is Al; in the Al-Zr master alloy, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com