A method for near-net-shaping al2o3 ceramic structural parts by laser

A technology of near-net laser forming and structural parts, which is applied in the direction of ceramic molding machines and manufacturing tools, which can solve the problems of easy generation of pores, cracks, poor surface quality and dimensional accuracy of formed parts, etc., and achieve grain refinement and surface improvement. Quality and dimensional accuracy, crack suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

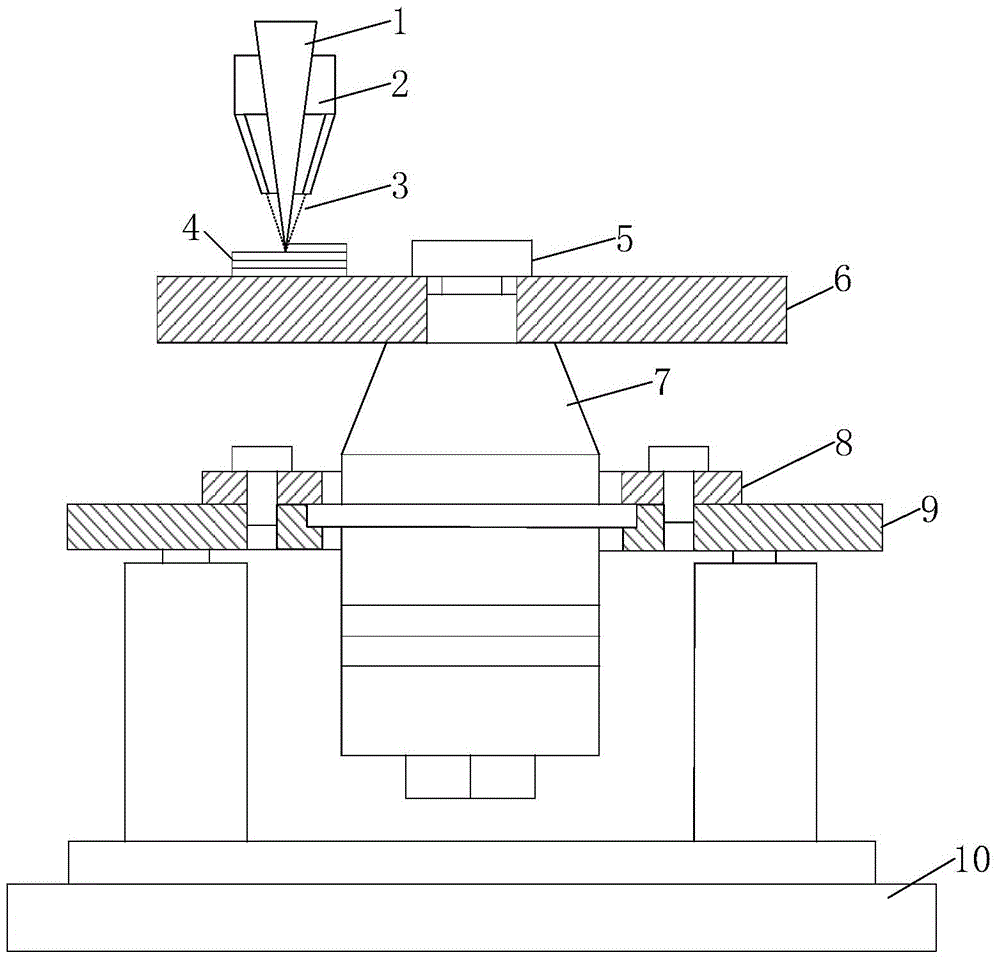

[0024] Such as figure 1 As shown, the laser near net shape Al 2 o 3 The method of ceramic thin-walled parts uses Nd:YAG solid-state continuous laser for near-net laser forming, and selects the titanium alloy circular substrate as Al 2 o 3 Forming substrate for ceramic thin-walled parts, high-purity Al 2 o 3 The ceramic powder is used as the molding material, and argon is used as the powder feeding and shielding gas. The specific implementation steps are as follows:

[0025] A, the ultrasonic transducer 7 is positioned on the support 9, and the annular flange on the ultrasonic transducer 7 is pressed by the pressure plate 8, and the ultrasonic transducer 7 is positioned and clamped, and the overall size is selected as Titanium alloy (Ti-6Al-4V) substrate 6 as Al 2 o 3 The forming substrate of the cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com