Starch separation method and device

A separation method and technology of separation equipment, which is applied in the direction of swirl devices and devices whose axial direction can be reversed, and can solve the problems of large water consumption, low extraction rate of potato starch, and low starch yield in starch production lines, etc. , to achieve the effect of improving quality and yield and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

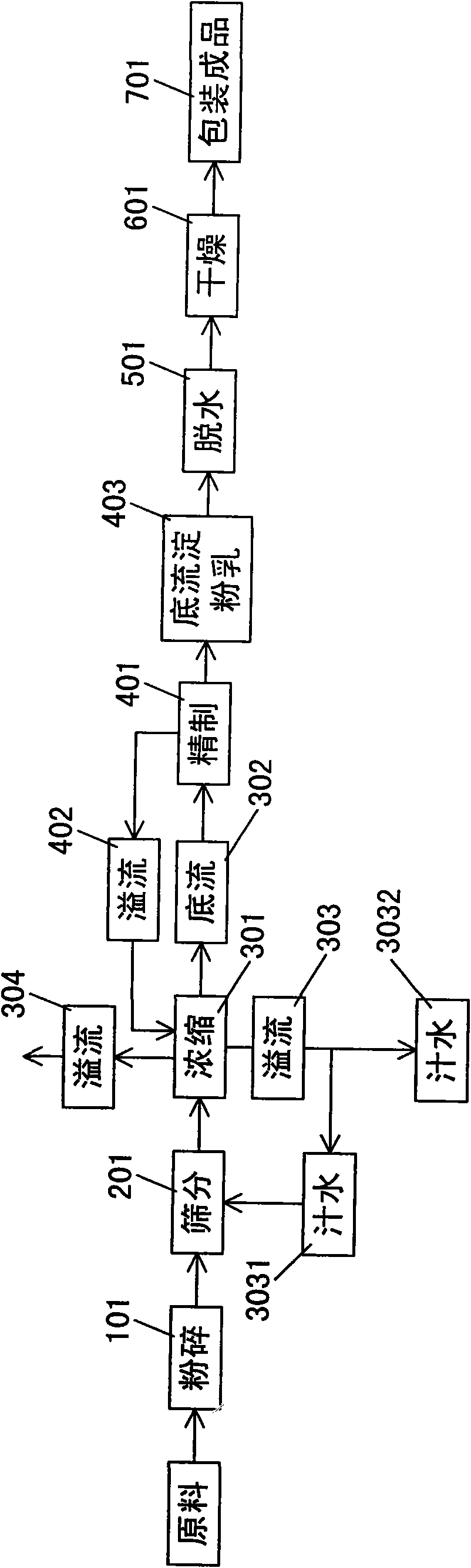

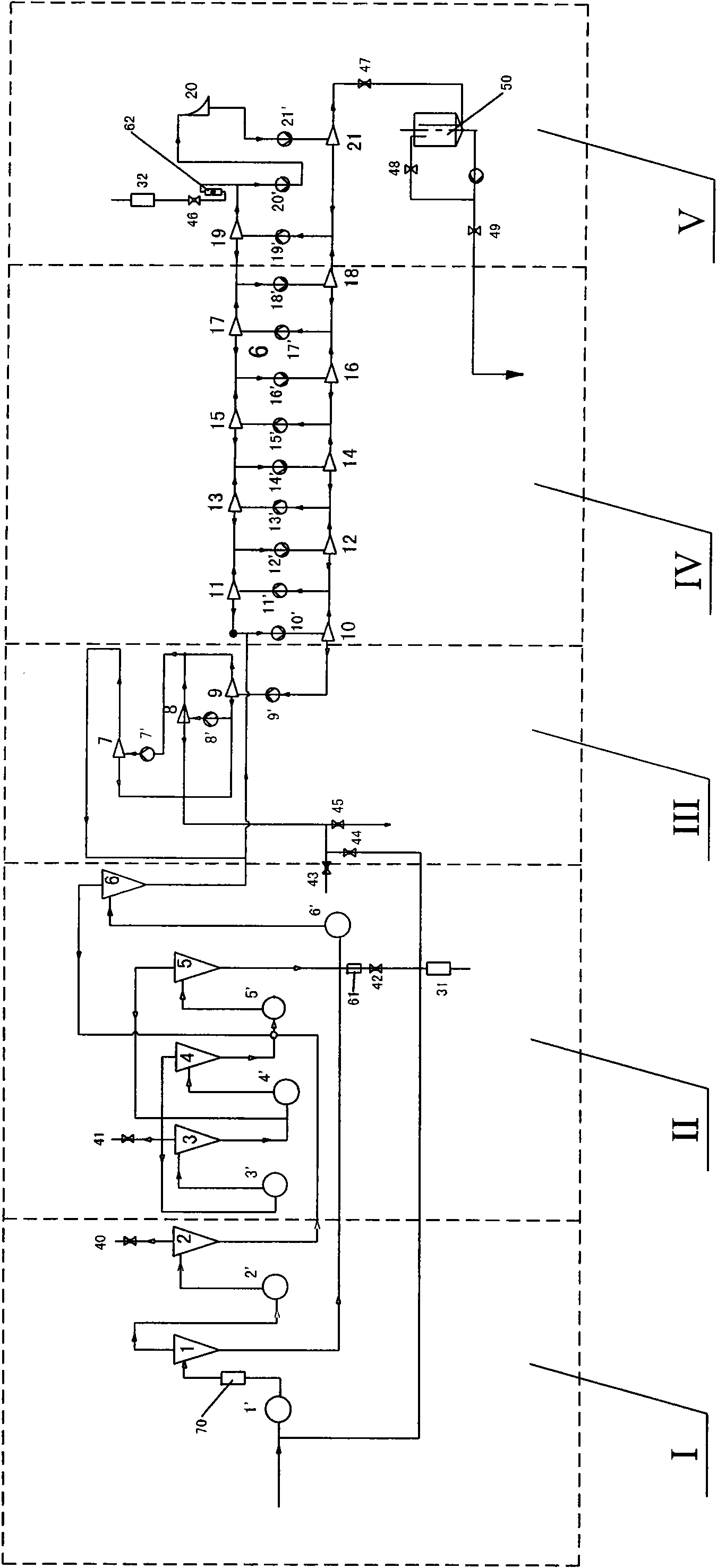

[0041] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0042] see figure 1 and image 3 , figure 1 It is a schematic diagram of the process flow of the present invention, image 3 It is the working flow diagram of the concentration unit and the refining unit of the present invention. The starch separation method of the present invention comprises the steps of pulverizing 101 raw materials, sieving 201, concentrating 301, refining 401, dehydrating 501, drying 601 and packaging finished products 701. After the raw materials are pulverized 101, sieved 201, they are transported into the concentrated 301 step In this step, the overflow 304 separated by the cyclone is directly discharged from the cyclone system, the underflow 302 enters the subsequent refining step 401 for further separation, and the underflow starch milk 403 finally obtained by the separation of the refining step is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com