Automatic transmission with planetary gear mechanism

A technology for automatic transmissions and planetary gears, applied in gear transmissions, elements with teeth, belts/chains/gears, etc., can solve the problem of difficult number of parts, simplify the structure and improve the reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

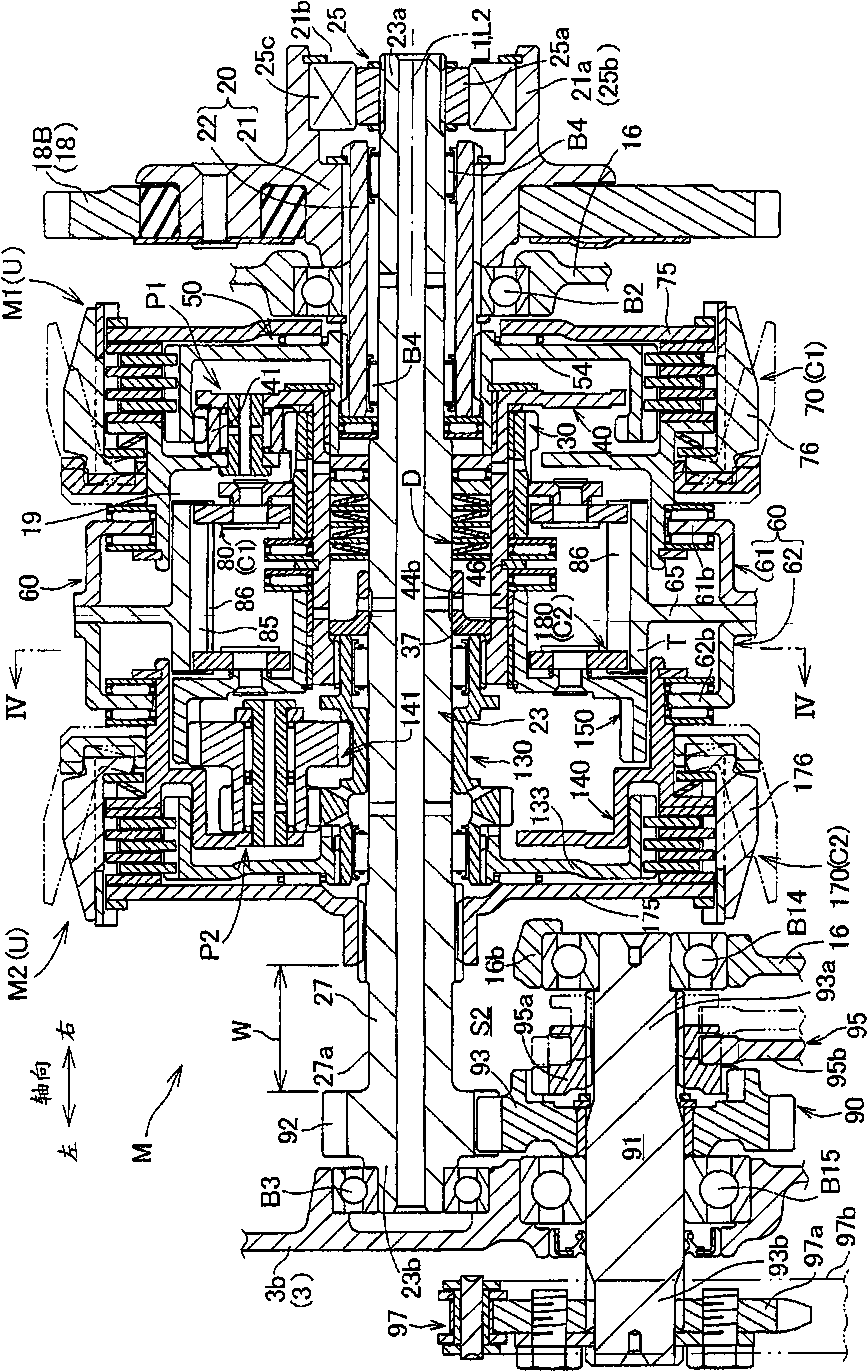

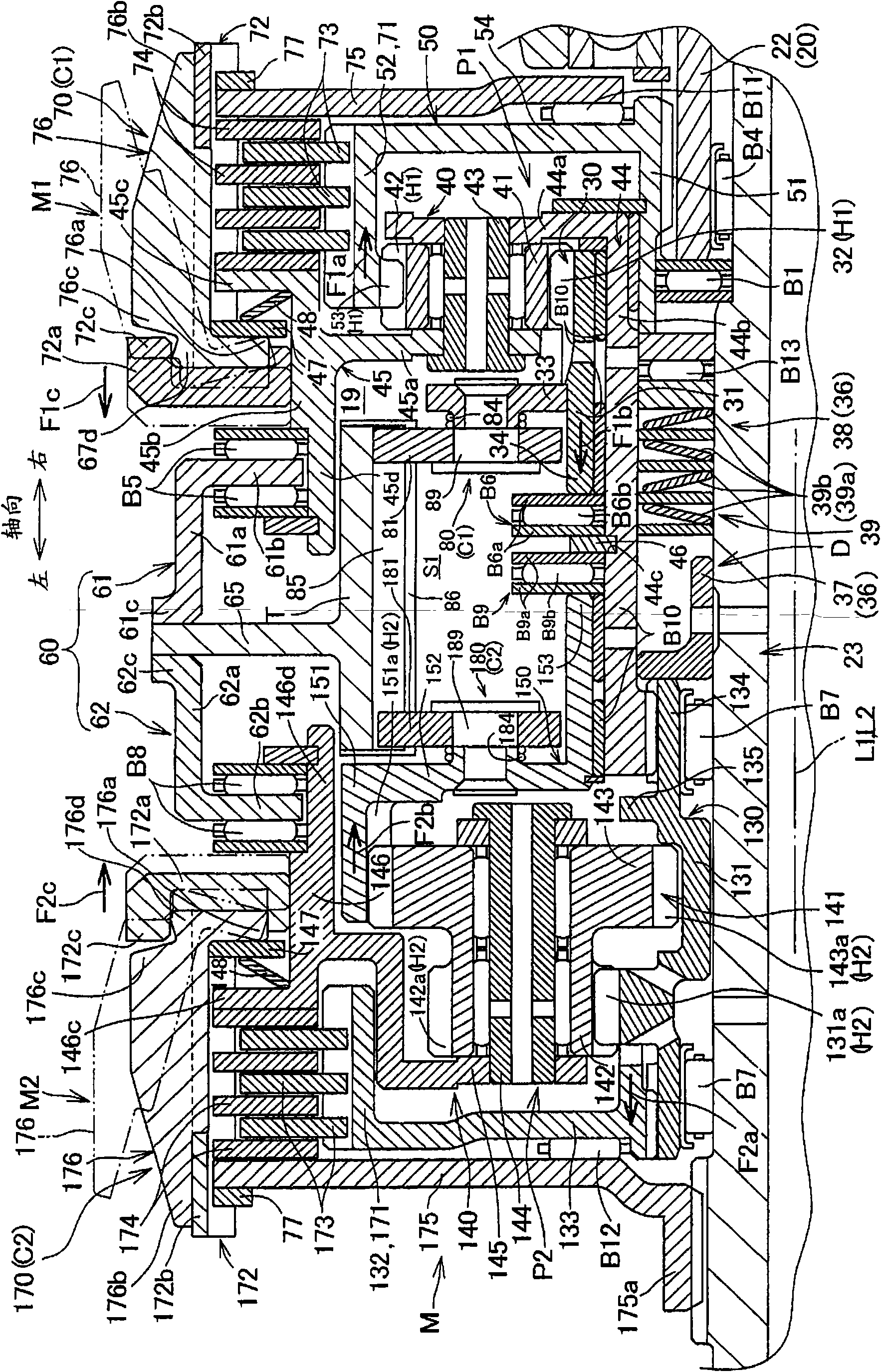

[0027] Below, refer to Figure 1 to Figure 6 Embodiments of the present invention will be described.

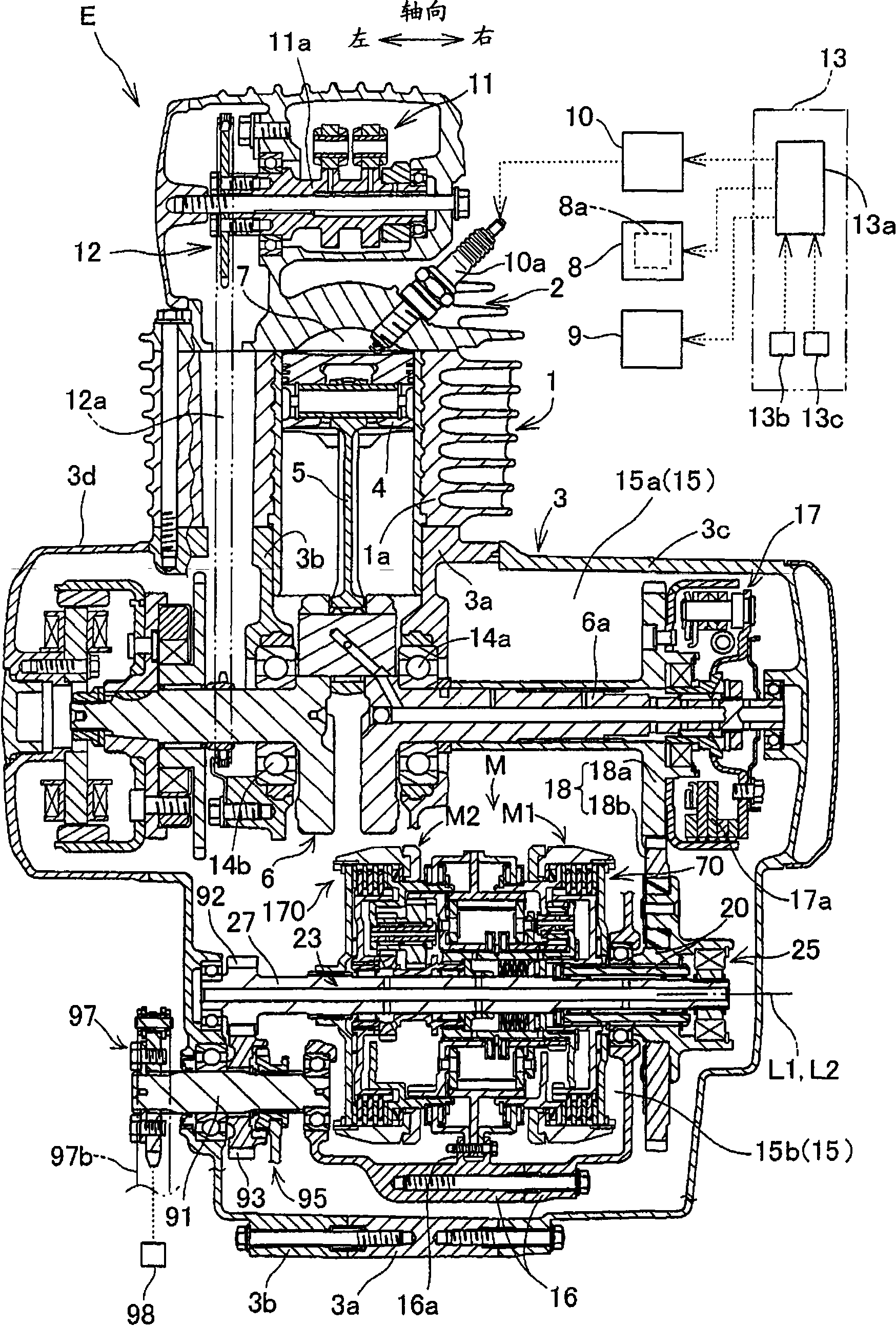

[0028] refer to figure 1 The automatic transmission M to which the present invention is applied is a vehicle automatic transmission, and the automatic transmission M together with the internal combustion engine E as a prime mover constitutes a power unit mounted on a motorcycle as a vehicle.

[0029] In addition, in the embodiment, the left-right direction and the front-rear direction correspond to the left-right direction and the front-rear direction of the motorcycle on which the power unit is mounted, respectively, and the vertical direction is the vertical direction.

[0030] In addition, within the scope of the specification or claims, the axial direction is a direction parallel to the rotation centerline of the input shaft or output shaft of the transmission, and the radial direction and circumferential direction are respectively the radial and circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com