Normally closed semiautomatic gas emergency cut-off magnetic valve

A semi-automatic technology for cutting off the electromagnetic, applied in the direction of valve details, safety valves, balance valves, etc., can solve problems affecting the life of the coil, high power consumption of the electromagnetic coil, leakage, etc., to improve production and assembly efficiency, ensure safe disassembly, and work The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

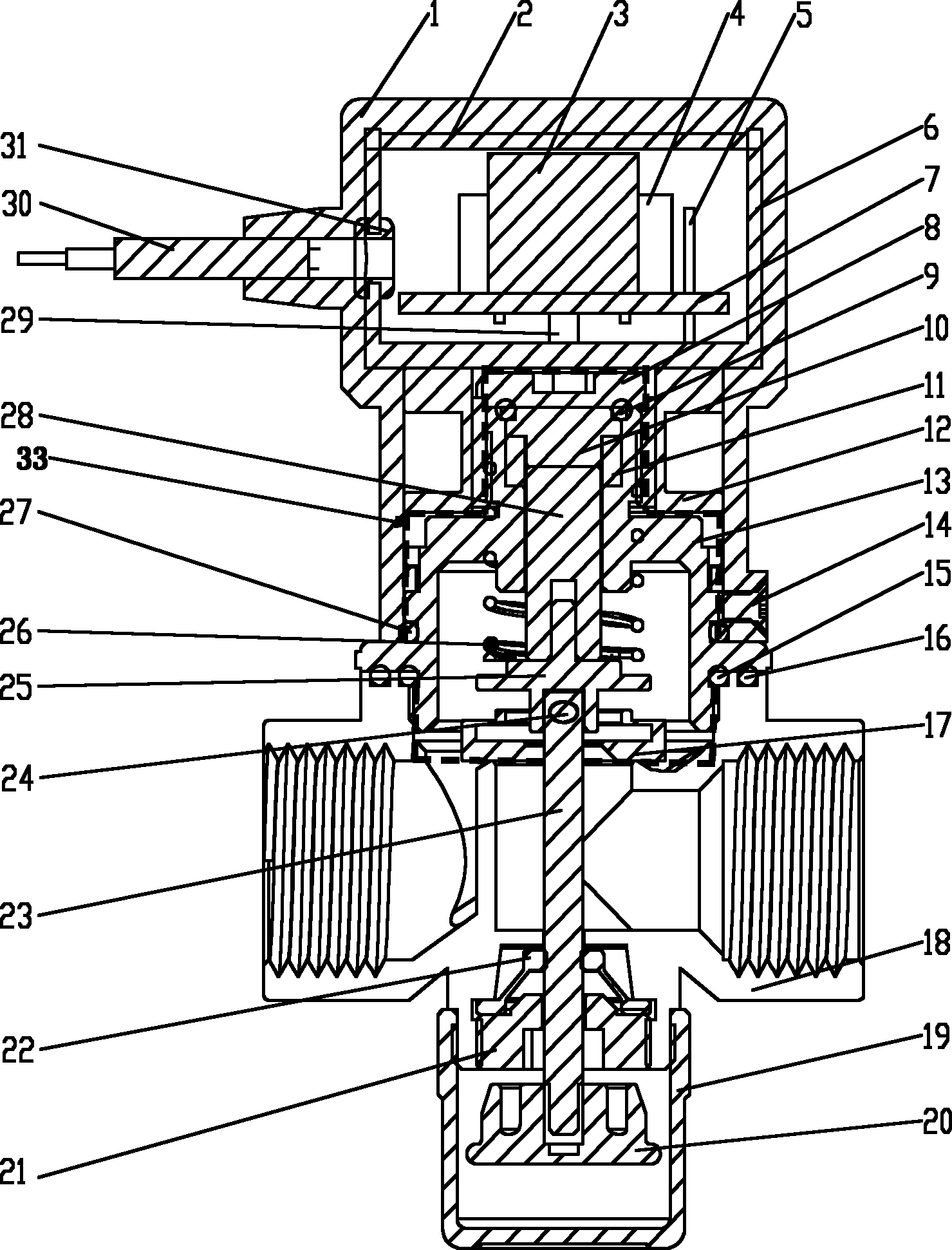

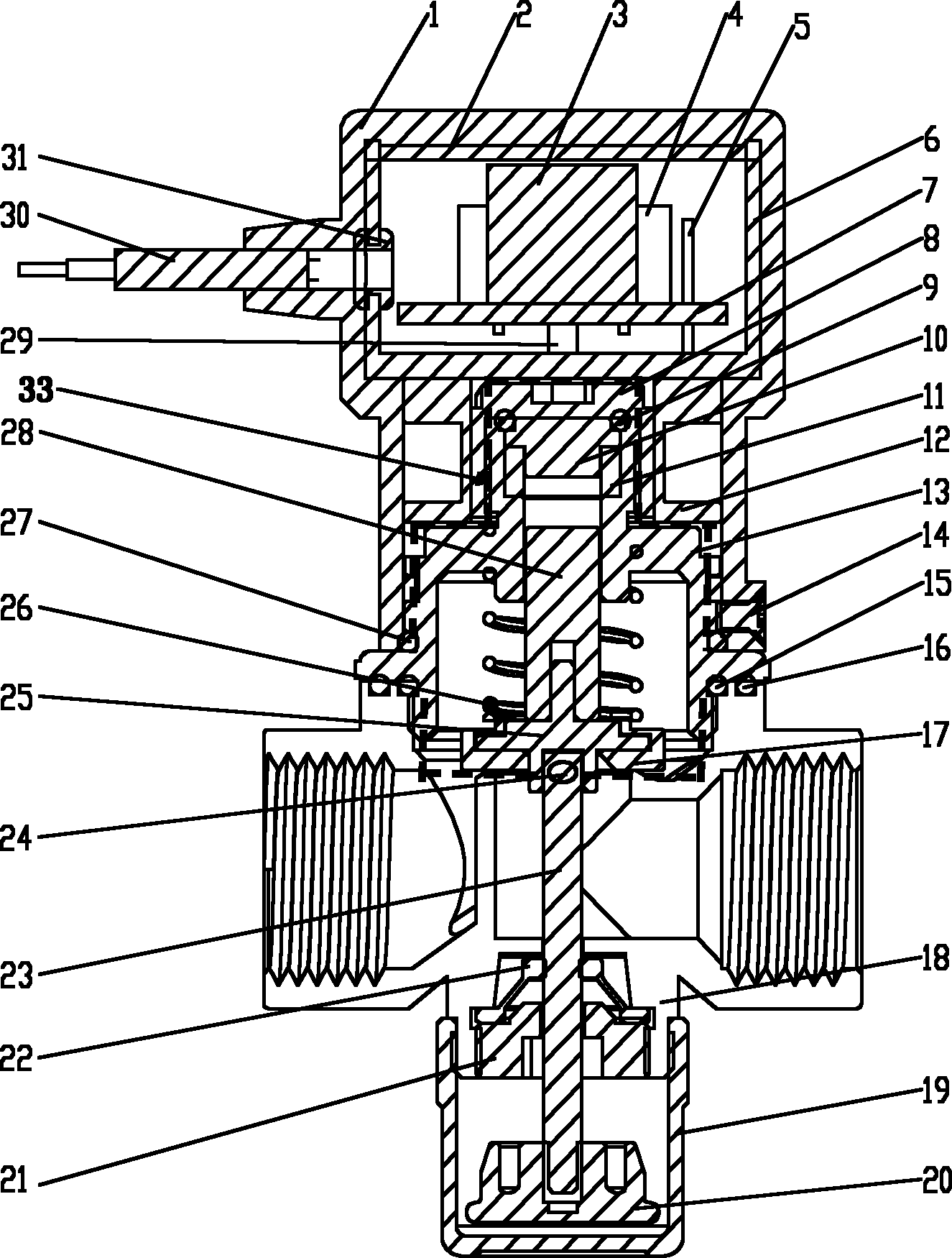

[0047] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0048] Such as figure 1 and figure 2 As shown, the present invention provides a normally closed semi-automatic gas emergency shut-off electromagnetic valve, which includes an electromagnetic coil assembly 1, an upper bonnet assembly 33 (in the dotted line frame of the figure), a valve body 18 and a valve opening handle assembly, the valve The body 18 contains the lower valve cover assembly; the electromagnetic coil assembly 1 and the valve cover assembly 33 are engaged with each other, and the two can be disassembled from each other, and are fixed with stop screws 14 after clamping; the upper valve cover assembly 33 and the valve body 18 The air inlet chamber of the air inlet chamber is sealed and fastened, such as O-ring or gasket thread fastening and crimping; the air outlet chamber of the valve body 18 is equipped with a valve opening handle assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com