Large-size direct type LED backlight source and preparation method

An LED backlight source, direct type technology, applied in the field of high-power LED backlight source structure and its preparation, achieves the effects of low energy consumption, reduced manufacturing and use costs, and prolonged heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

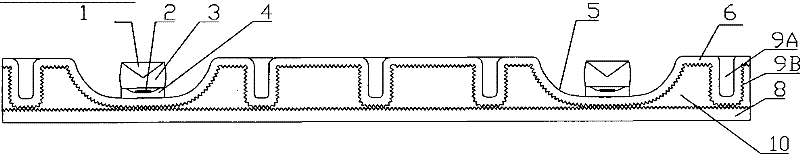

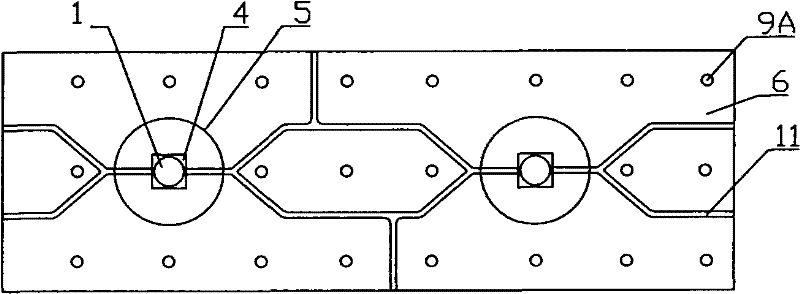

[0039] Such as figure 1 As shown, a large-size direct-lit LED backlight includes a metal substrate 6, a vapor chamber, and edge-emitting LEDs. A plurality of reflective bowls 5 are stamped on the metal substrate 6, and the reflective bowls 5 are evenly distributed on the metal substrate 6, which is a bowl-shaped free-form surface structure; support columns 9A formed by punching the metal substrate 6 are arranged between the reflective bowls 5, and the support columns 9A is an inwardly concave columnar structure.

[0040] Such as figure 2 As shown, a layer of Al is plated on the surface of the metal substrate 6 by the method of micro-arc oxidation. 2 o 3 Micro-arc oxidation film, used as a high thermal conductivity insulating dielectric layer, Al 2 o 3 The surface of the micro-arc oxidation film is covered with wiring circuits 11 connected to LED chips 2 .

[0041] The lower wall shell is a frame structure, which is stamped and formed by an aluminum rectangular plate, a...

Embodiment 2

[0053] Such as Figure 7 As shown, a large-size direct-lit LED backlight includes a metal substrate 6, a vapor chamber, and edge-emitting LEDs. A plurality of reflective bowls 5 are stamped on the metal substrate 6, and the reflective bowls 5 are evenly distributed on the metal substrate 6, which is a bowl-shaped free-form surface structure.

[0054] The metal substrate 6 is a copper substrate, its surface is covered with an insulating medium layer, and the surface of the insulating medium layer is covered with a wiring circuit 11 connected to the LED chip 2 . The insulating medium layer generally adopts high thermal conductivity epoxy glass brazing cloth or epoxy resin, and its thickness is 0.08mm-0.1mm.

[0055] The lower surface of the metal substrate 6 is provided with micro-protrusions 9B with a spacing of 0.1-0.2 mm and a height of 0.1-0.2 mm; the lower wall shell 8 is a frame structure, which is punched and formed by a copper rectangular plate, and is arranged on the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com