Pneumatic and manual dual-purpose sampling valve

A technology of sampling valve and spool, which is applied in the direction of sampling device, etc., can solve the problems of affecting the sealing performance of sampling valve, damage of sealing plug sealing material, and the sampling valve is not equipped with left and right spin limit devices, so as to improve the safety of use and reliability, reduce maintenance costs, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

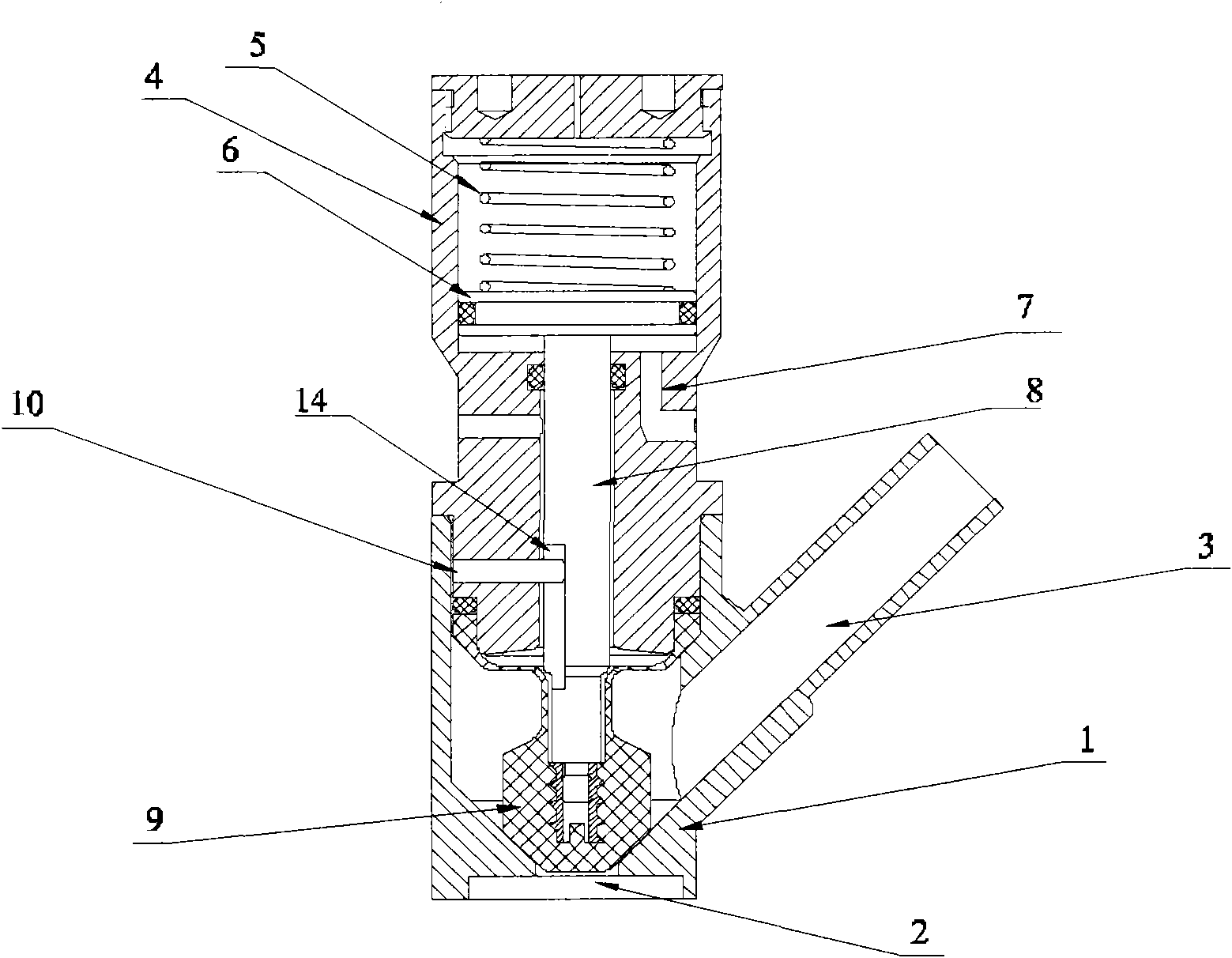

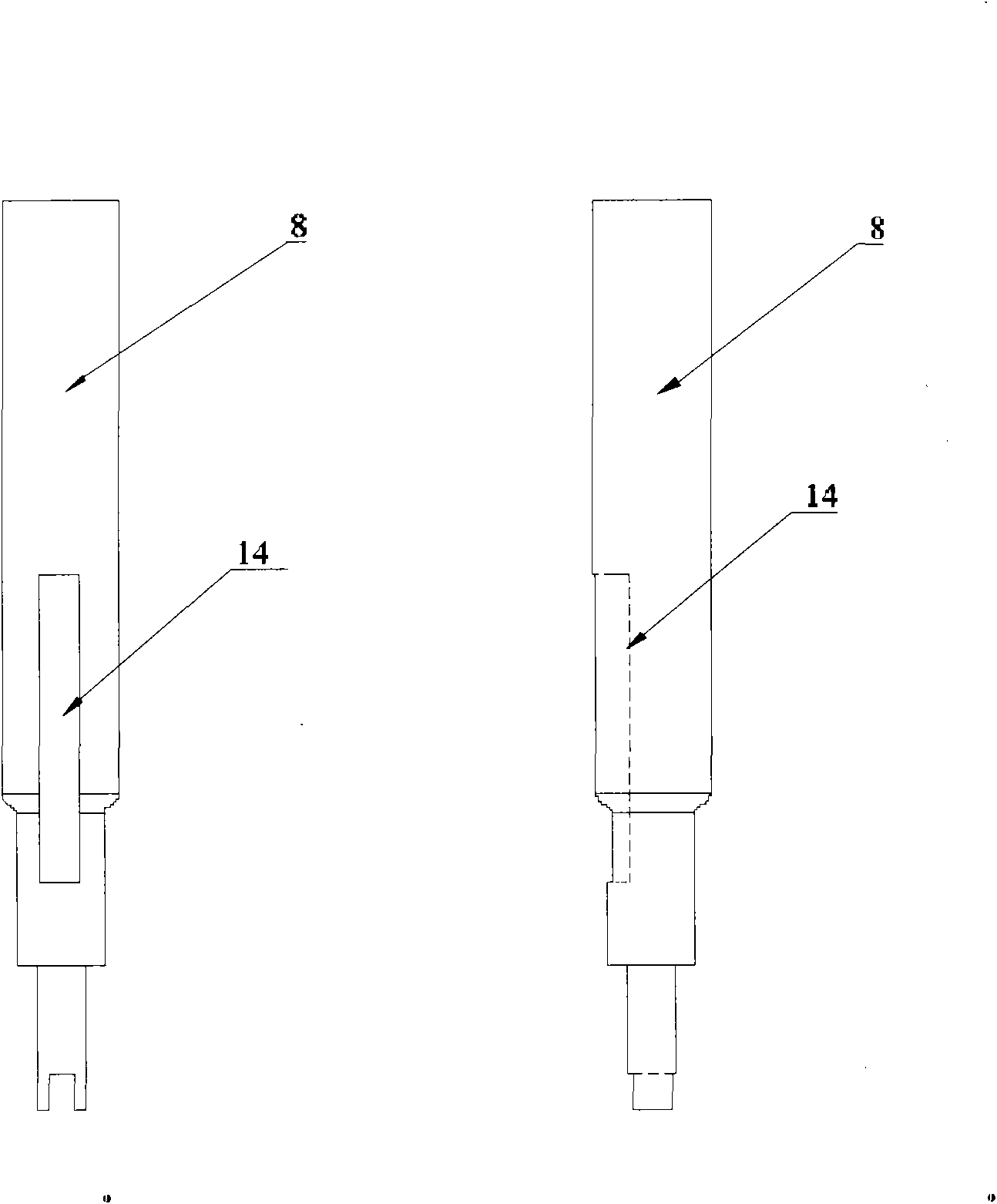

[0034] Such as figure 1 Shown is the sampling valve of the present invention, it can be seen from the figure that the sampling valve includes a cylinder 4, a piston control assembly located in the cylinder 4, the piston control assembly consists of a piston 6 and the The biasing member 5 used to reset the piston 6 is connected against the piston 6. In this embodiment, the biasing member 5 is a coil spring, and the number is one; the cylinder below the piston 6 4 is also provided with a power medium inlet and outlet 7, and the power medium inlet and outlet 7 is used to input or output power medium to provide a power source for the movement of the piston 6; in addition, the valve body 1 is located below the cylinder body 4, so that The valve body 1 is in sealing connection with the cylinder body 4, and an inlet port 2 and an outlet port 3 are arranged on the valve body. The sampling valve of the present invention also includes a valve core 8, which is an important part, and the...

Embodiment 2

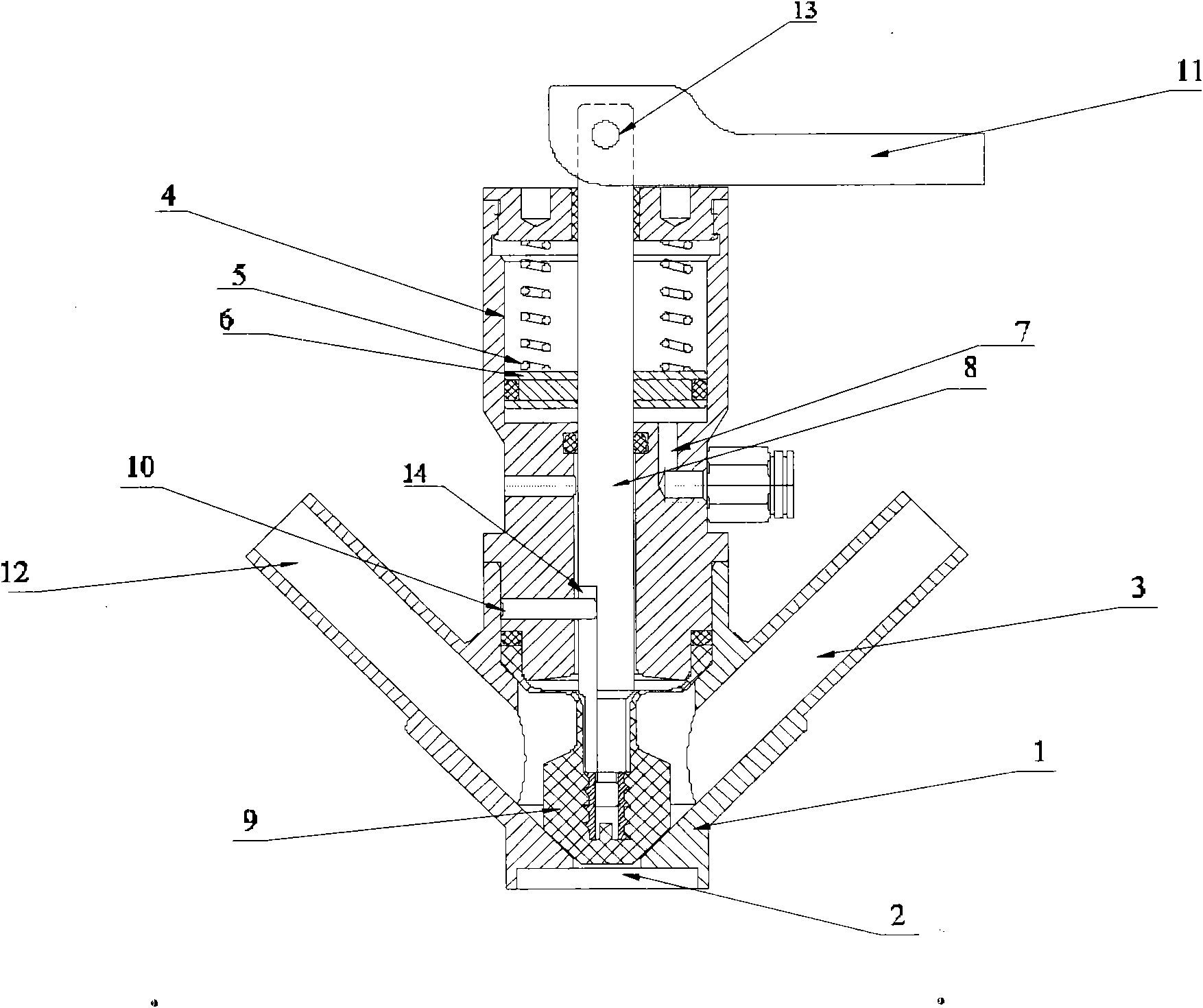

[0040] image 3 Another embodiment of the sampling valve of the present invention is given. In the sampling valve described in this embodiment, the upper end of the spool 8 passes through the piston 6 and extends out of the top end of the cylinder 4 to communicate with the handle 11. connection, the connection between the handle 11 and the valve core 8 is connected through a cam 13, and the handle 11 can be moved upward along the connection between the handle 11 and the valve core 8, so that the pneumatic setting can be used Parts enable manually controlled sampling.

[0041] In this embodiment, a coil spring is respectively arranged in the cylinder body 4 and at both ends of the valve core 8, see image 3 shown.

[0042] In this embodiment, two discharge ports are provided on the valve body, one discharge port 3 is used for sampling, and the other discharge port 12 can be used as a disinfection port.

[0043] When the sampling valve described in this embodiment is in use, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com