CMOS/MEMS compatible spectroscopic gas sensor

A gas sensor and spectrum technology, applied in the field of a gas sensor, can solve the problems of weak anti-interference ability, easy poisoning of the sensor, high false alarm rate, and achieve fast response, good repeatability and consistency, and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the analysis of benzene vapor in ambient gas as a specific example and with reference to the accompanying drawings.

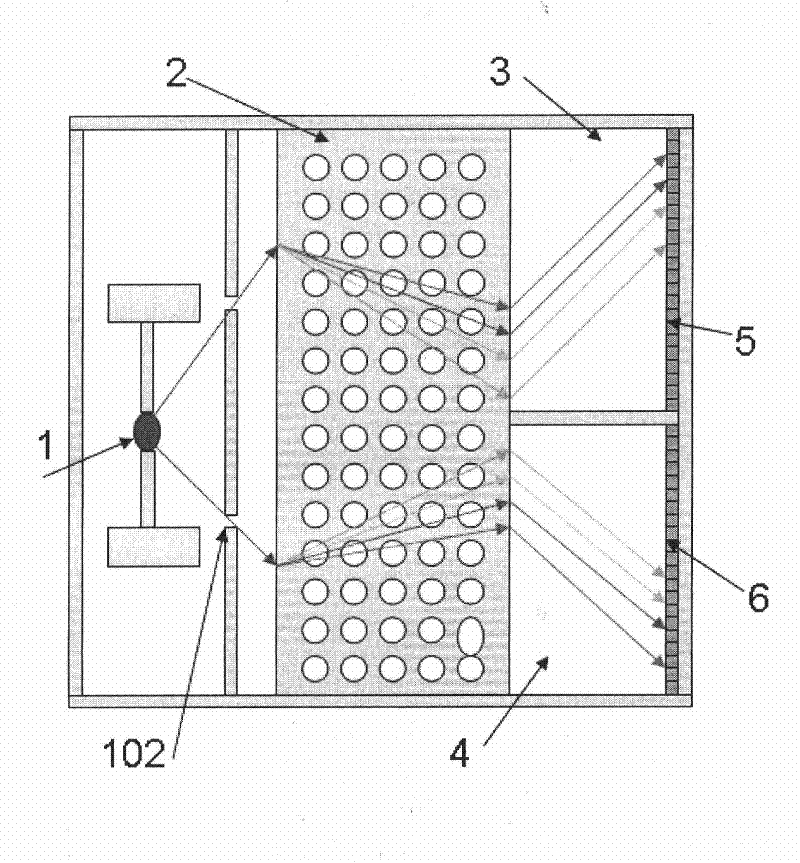

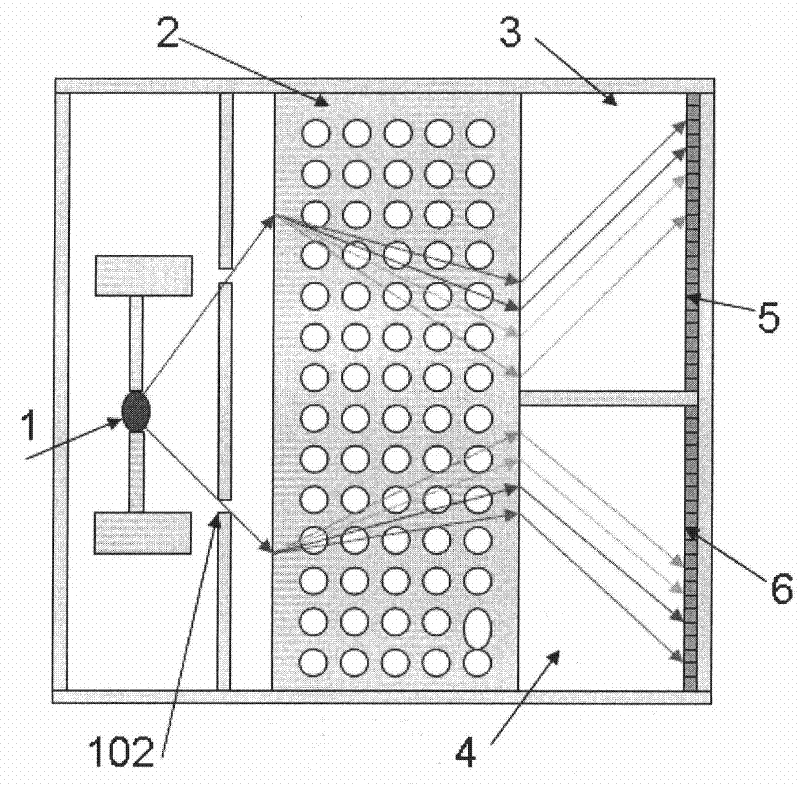

[0027] Such as figure 1 as shown, figure 1 The structural diagram of the CMOS / MEMS compatible spectral gas sensor provided by the present invention, the sensor is mainly composed of an infrared red source 1, a photonic crystal dispersion prism 2, a measuring gas chamber 3, a reference gas chamber 4, and a measuring gas chamber infrared photoelectric detection array 5 and the infrared photoelectric detection array 6 of the reference gas chamber.

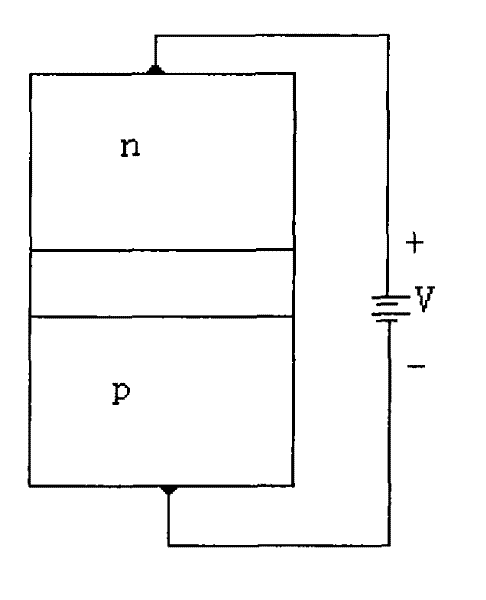

[0028] Infrared light source 1 is a diode integrated on a (110) silicon substrate. The diode has a stable infrared radiation output at 0-5 μm. The infrared light emitted by the luminescent tube passes through a pair of 5 μm deep and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com