Apparatus and method for monitoring and regulating cryogenic cooling

A kind of equipment and low-temperature technology, applied in lighting and heating equipment, household refrigeration equipment, metal processing equipment, etc., can solve problems such as measurement errors and inaccuracies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

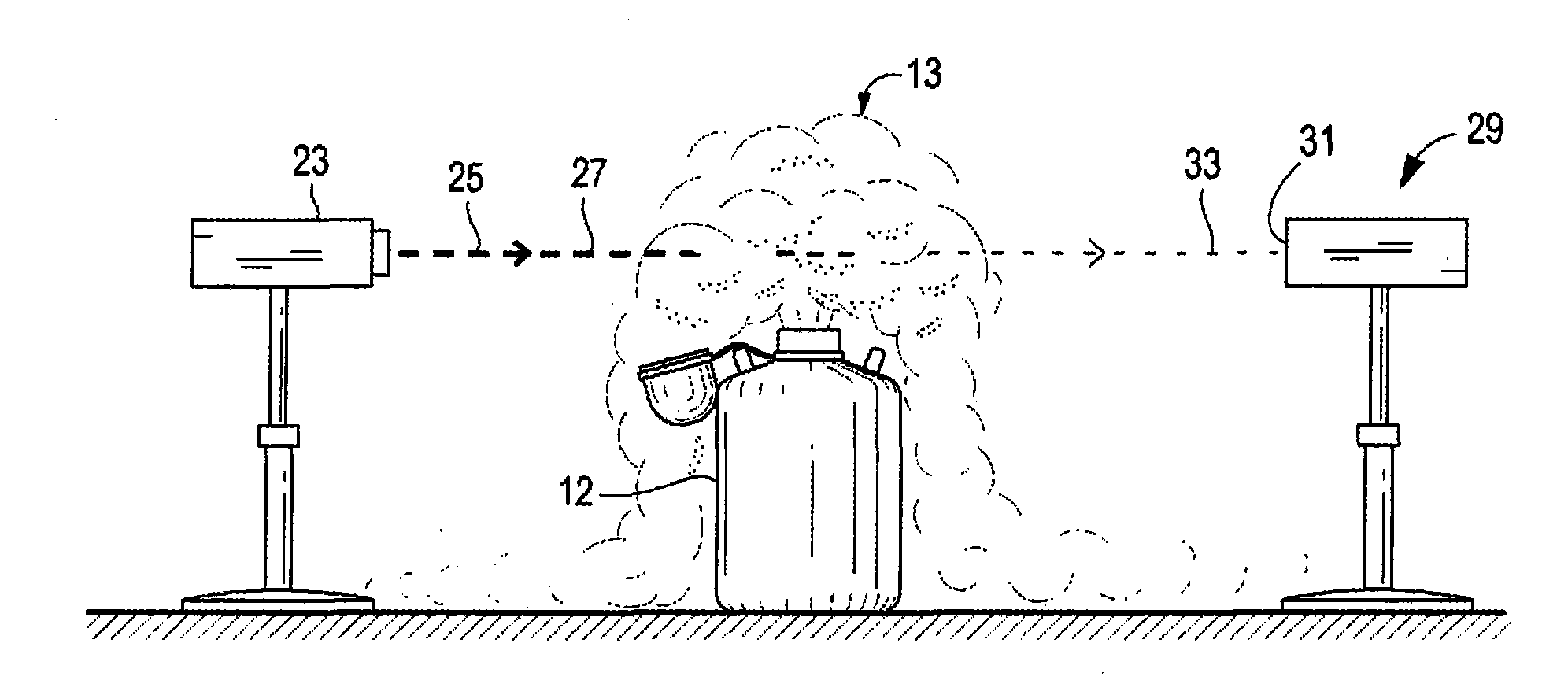

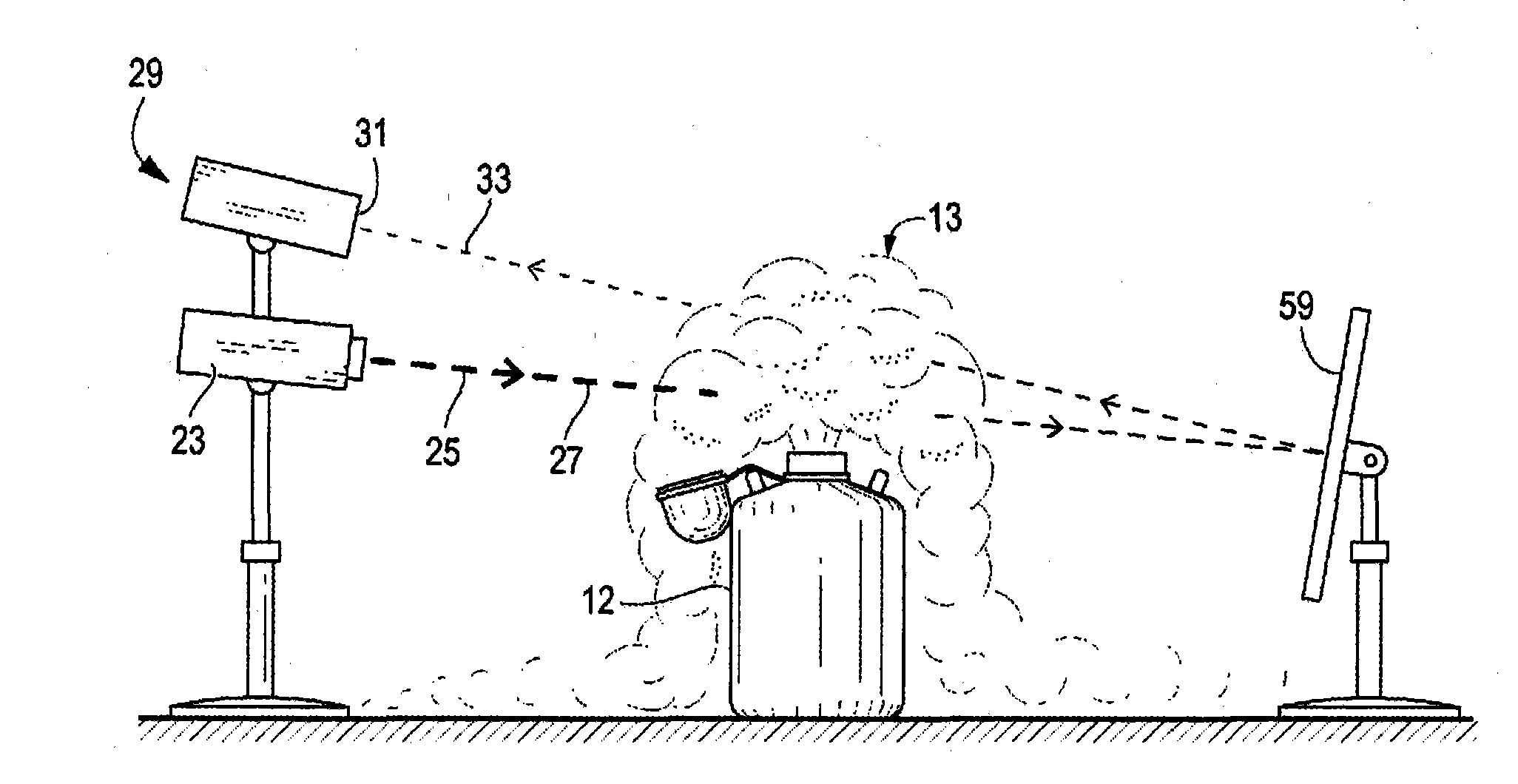

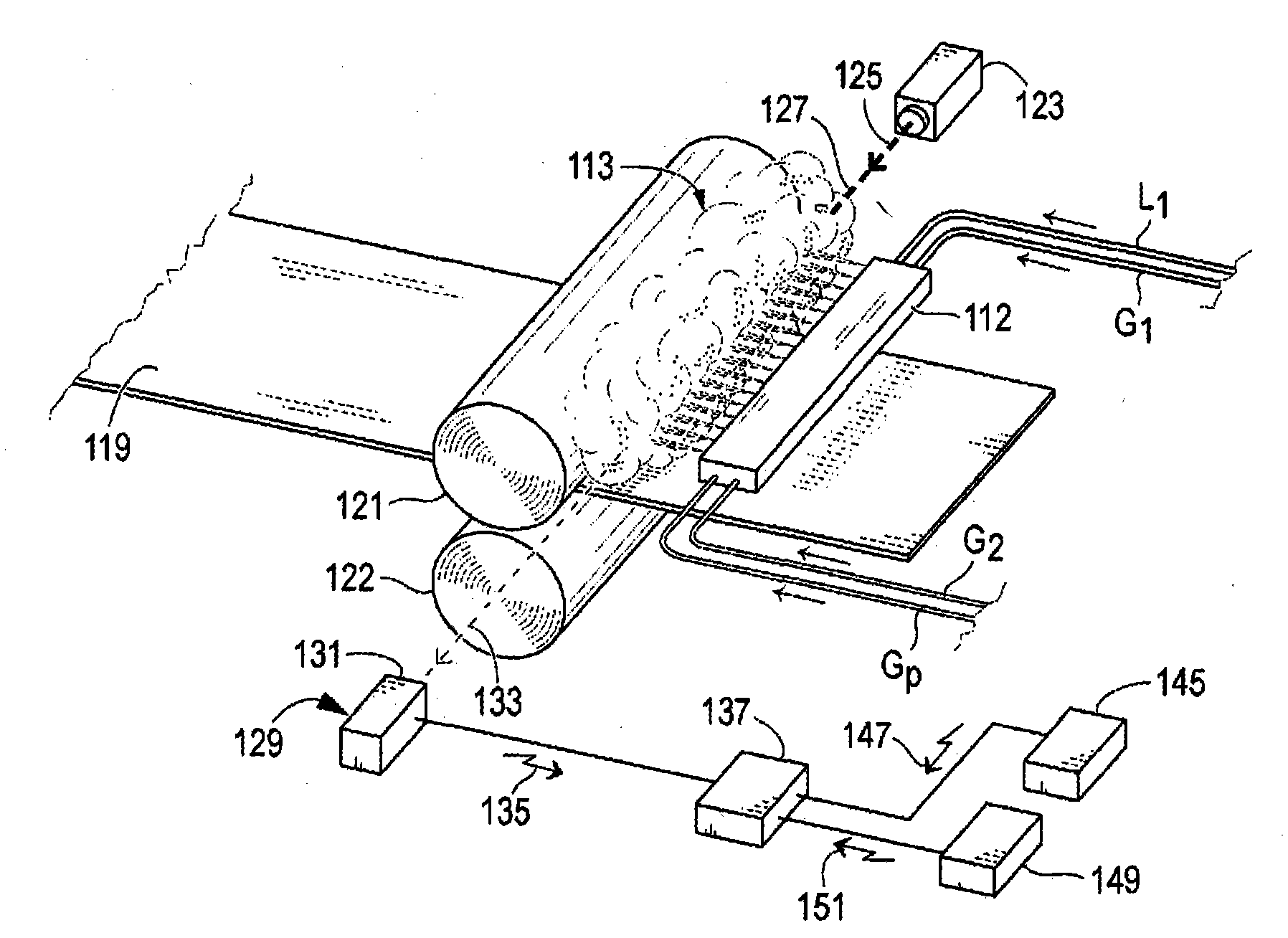

[0015] The present invention is an apparatus for use with a system having a cryogenically cooled member that generates a vapor cloud when in operation. Systems with cryogenically cooled components may include, but are not limited to, metal rolling and machining operations such as lathe turning, boring, milling, thermal spray coating applications, and food freezing applications.

[0016] "Cryogenic vapor" is a cryogenic injection of water contained in ambient air with, for example, liquid nitrogen (hereinafter "LIN"), gaseous nitrogen, argon, and carbon dioxide, or mixtures of two or more of these liquids and / or gases A suspension of microscopic water ice crystals that form on contact. Cryogenic vapors are usually white and opaque or translucent.

[0017] In experiments related to the development of the present invention, it has been observed that from the area where the cryogenic spray is directed onto the substrate (e.g., the workpiece and / or tool area and / or the part surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com