Rotating floating body boat

A technology of floating body boats and floating bodies, which is applied in the field of shipbuilding, can solve the problems that cannot be widely used, requires large power, and is not economical, and achieves the effects of eliminating wave-making resistance, saving energy, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

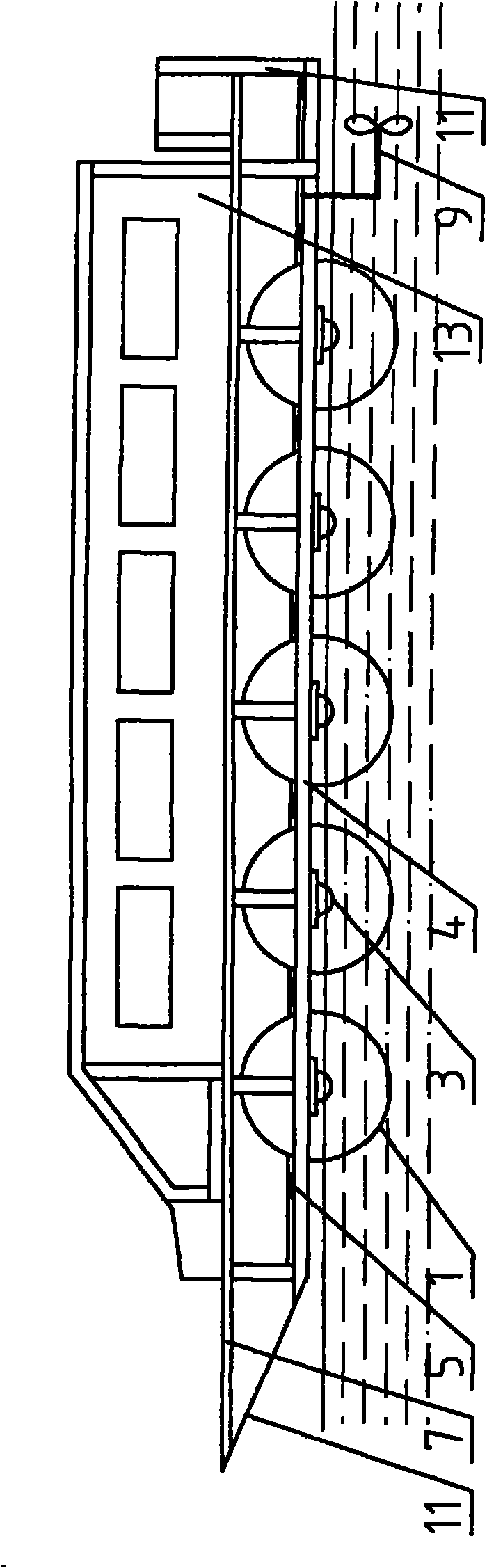

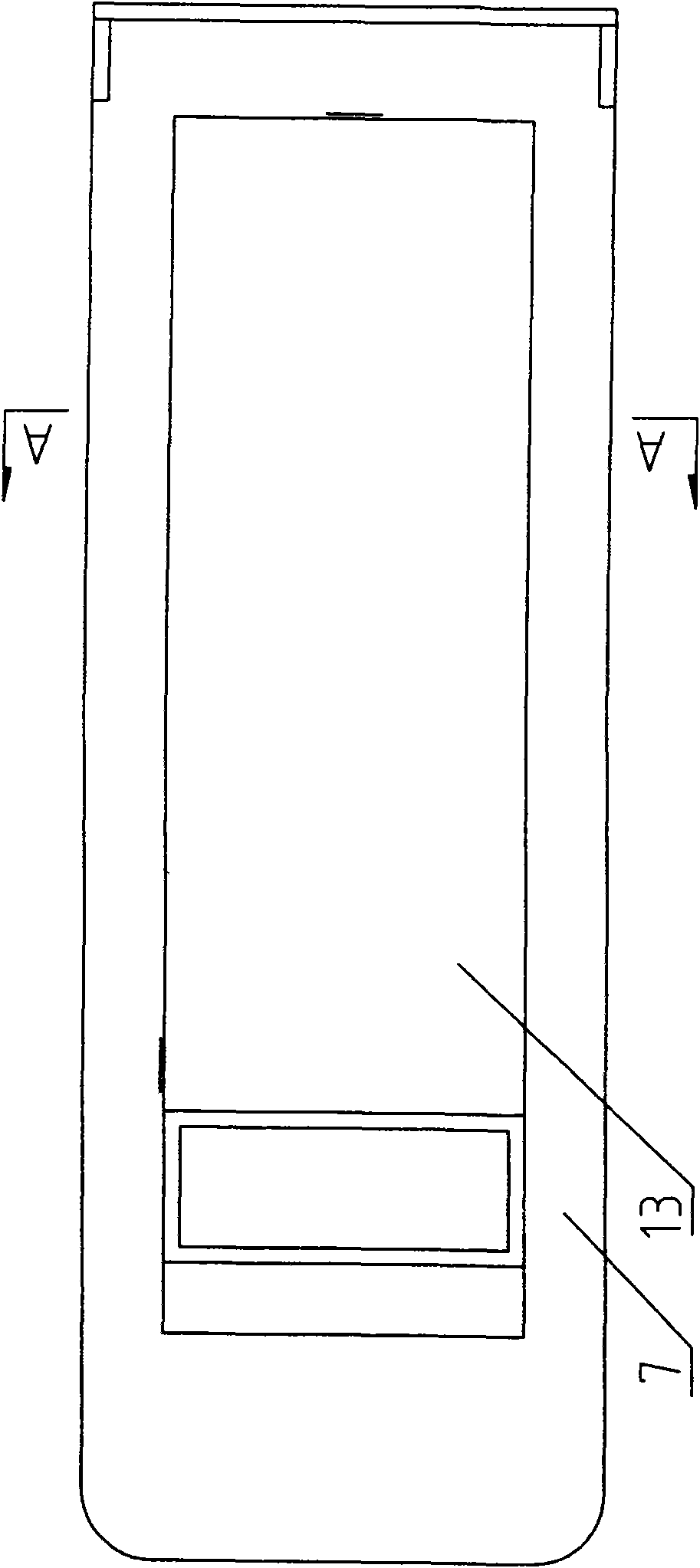

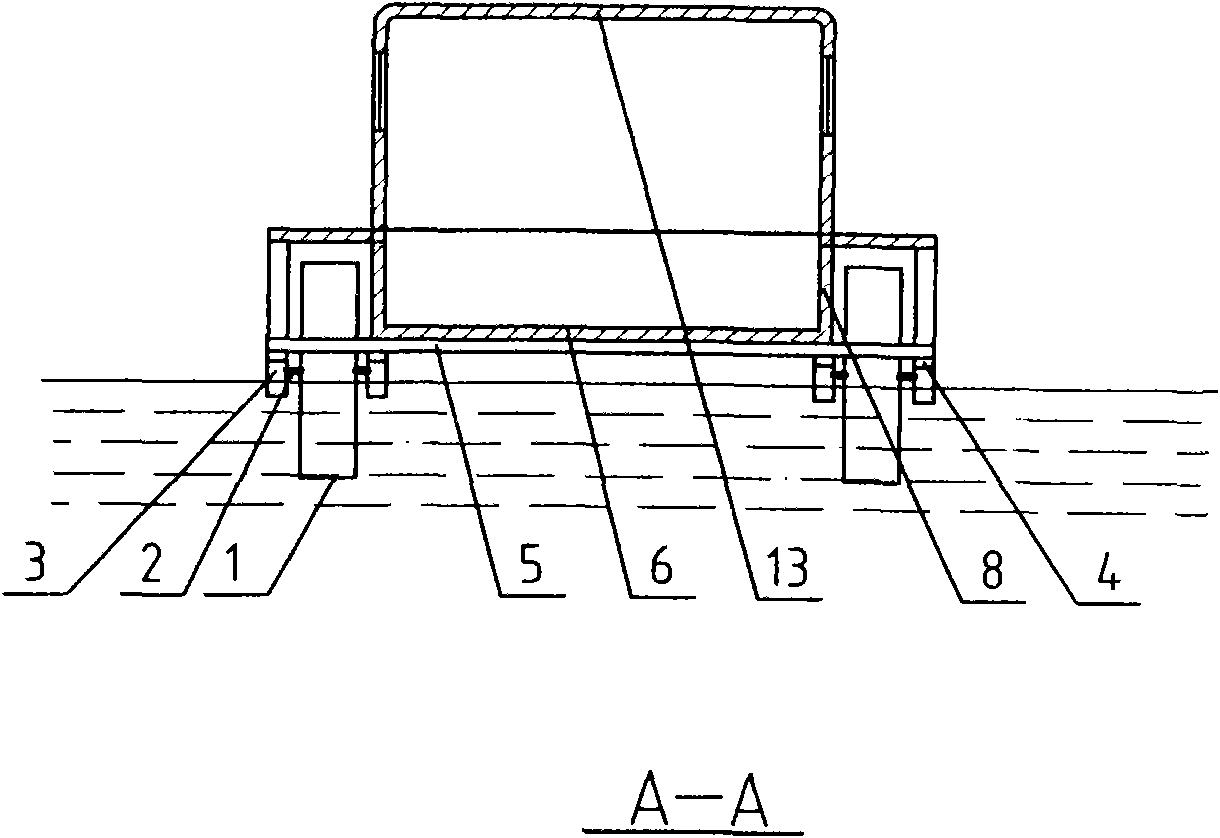

[0039] With reference now to the appendix of the first embodiment of the present invention Picture 1-1 , 1-2 , 1-3, to be elaborated, the rotating buoyant body (1) with buoyancy, its shell can be made of watertight hollow cylinder by plastics, wood or aluminum etc. (such as closed-cell foamed plastics), even if some rotating buoyant (1) shells are damaged, water ingress is also seldom, and the boat can still move forward, and the boat is highly safe; the rotating buoyant (1) can also be made into a solid one. For the cylindrical body, if rigid polyurethane structural foam is used, a high-density and tough outer skin and a low-density foam core can be obtained to form an integral foam plastic cylinder at the same time. A cylinder with high-density outer skin structural foam has good strength and hardness. , the low-density foam core keeps it light in weight, making the rotating floating body (1) simple to manufacture, corrosion-resistant, and low in cost. The arrangement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com