Device for producing sulfuric acid and cement by decomposing and calcining gypsum

A sulfuric acid and cement technology, applied in sulfur compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of large resistance, high production cost and low preheating efficiency of cyclone preheaters, and reduce investment costs and operating costs. The effect of reducing plant height and equipment investment and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

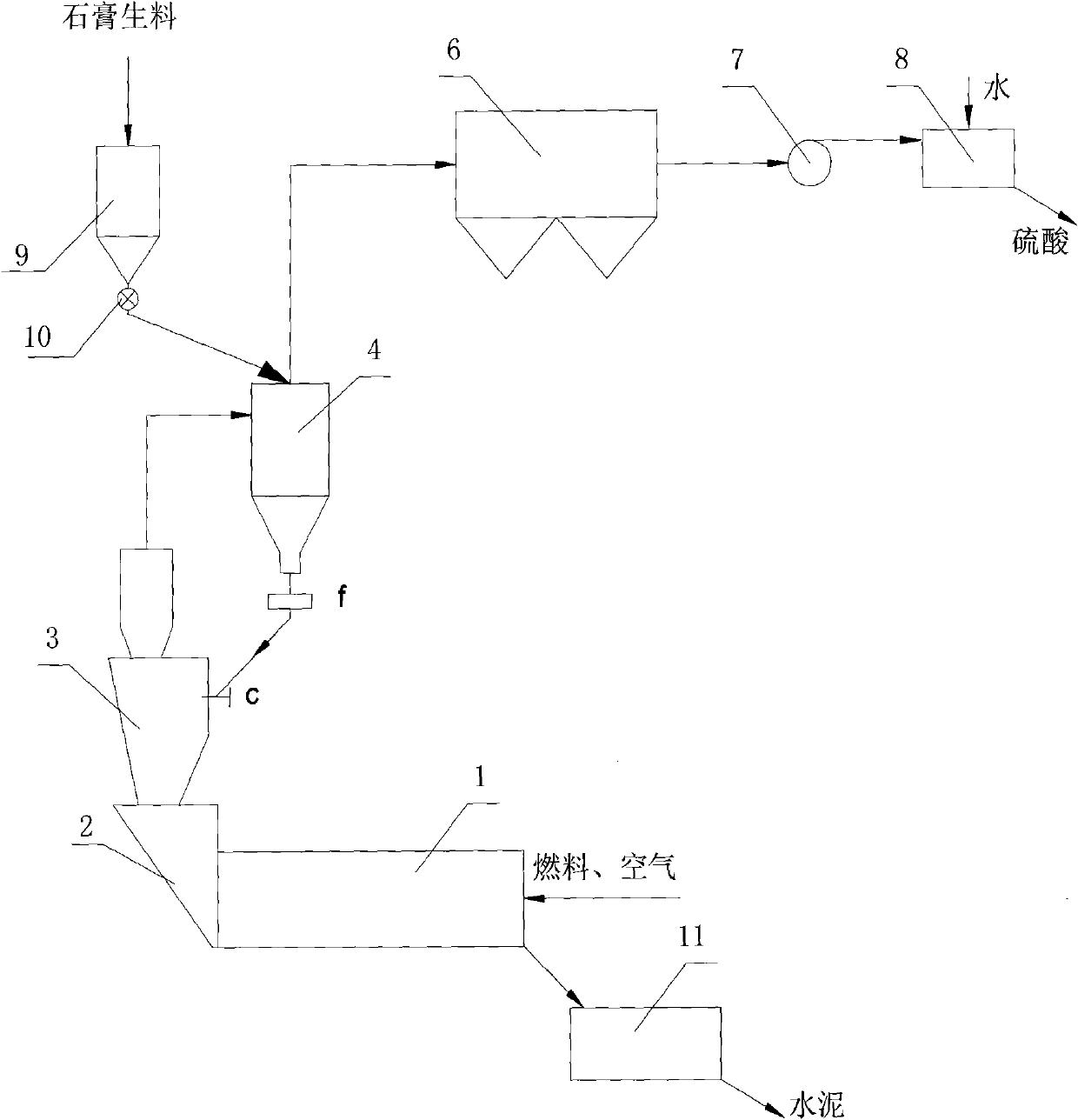

[0024] Example 1. As figure 1 Device shown:

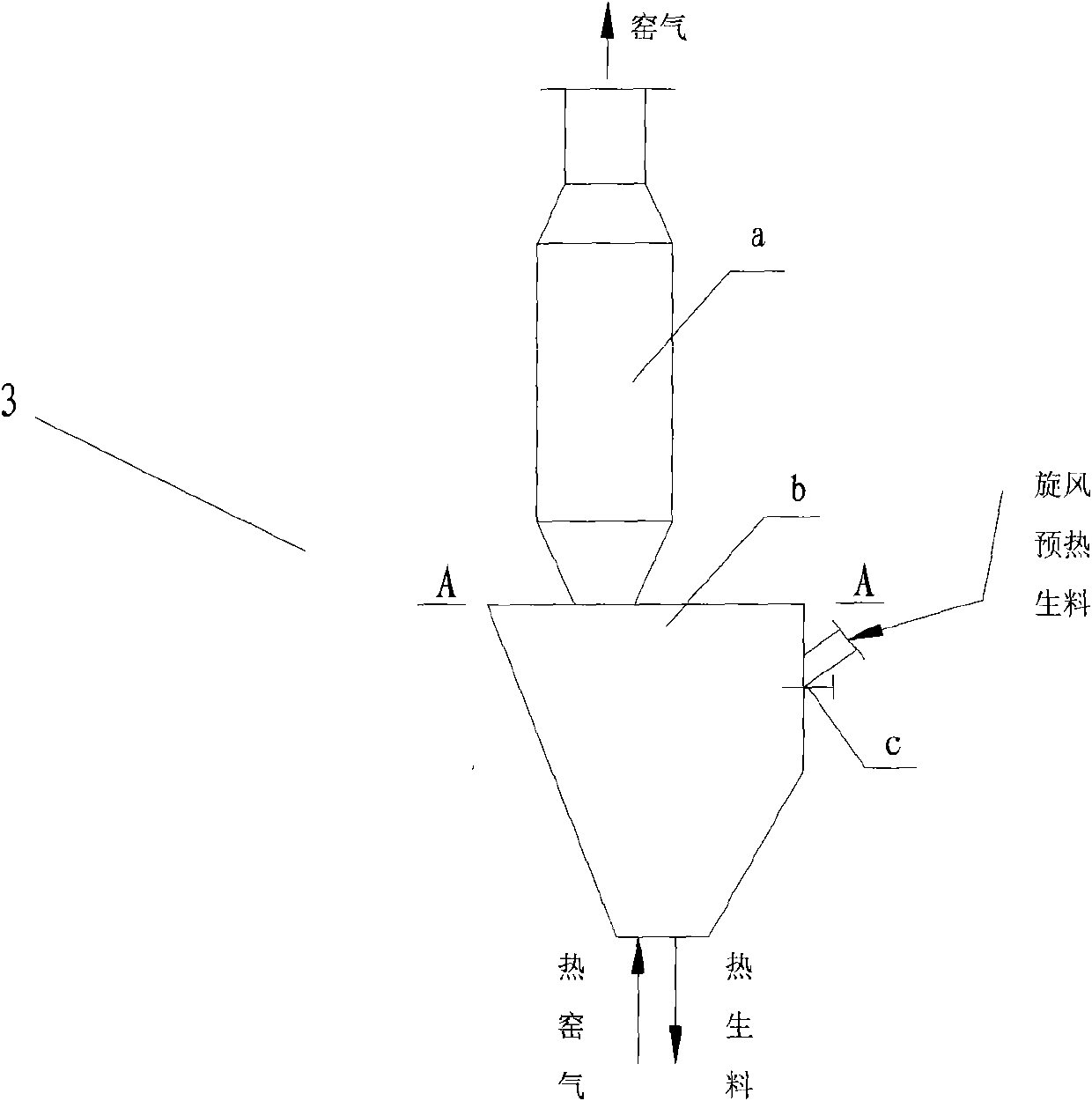

[0025]Wherein the calcining kiln 1 is a rotary type: the head is equipped with a multi-tube cooler, or not, and the length-to-diameter ratio is L / D=15-19. It is dynamically and sealed connected with the opening of the lower end of the smoke chamber 2; the lower end of the compound preheater 3 is welded to the upper end of the smoke chamber 2, and the material spreading valve c is welded to the lower opening of the first cyclone preheater 4 through the pipeline; the pipeline is provided with an air lock valve; The upper end of the first cyclone preheater 4 is provided with a material inlet, and the function of the air lock valve at the lower part of the cyclone preheater is to only allow the material separated by the cyclone preheater to move downward, and prevent the lower gas from passing through the air lock valve to the upper part. The upper opening of the first cyclone preheater 4 is welded to the dust collector 6 through the ...

Embodiment 2

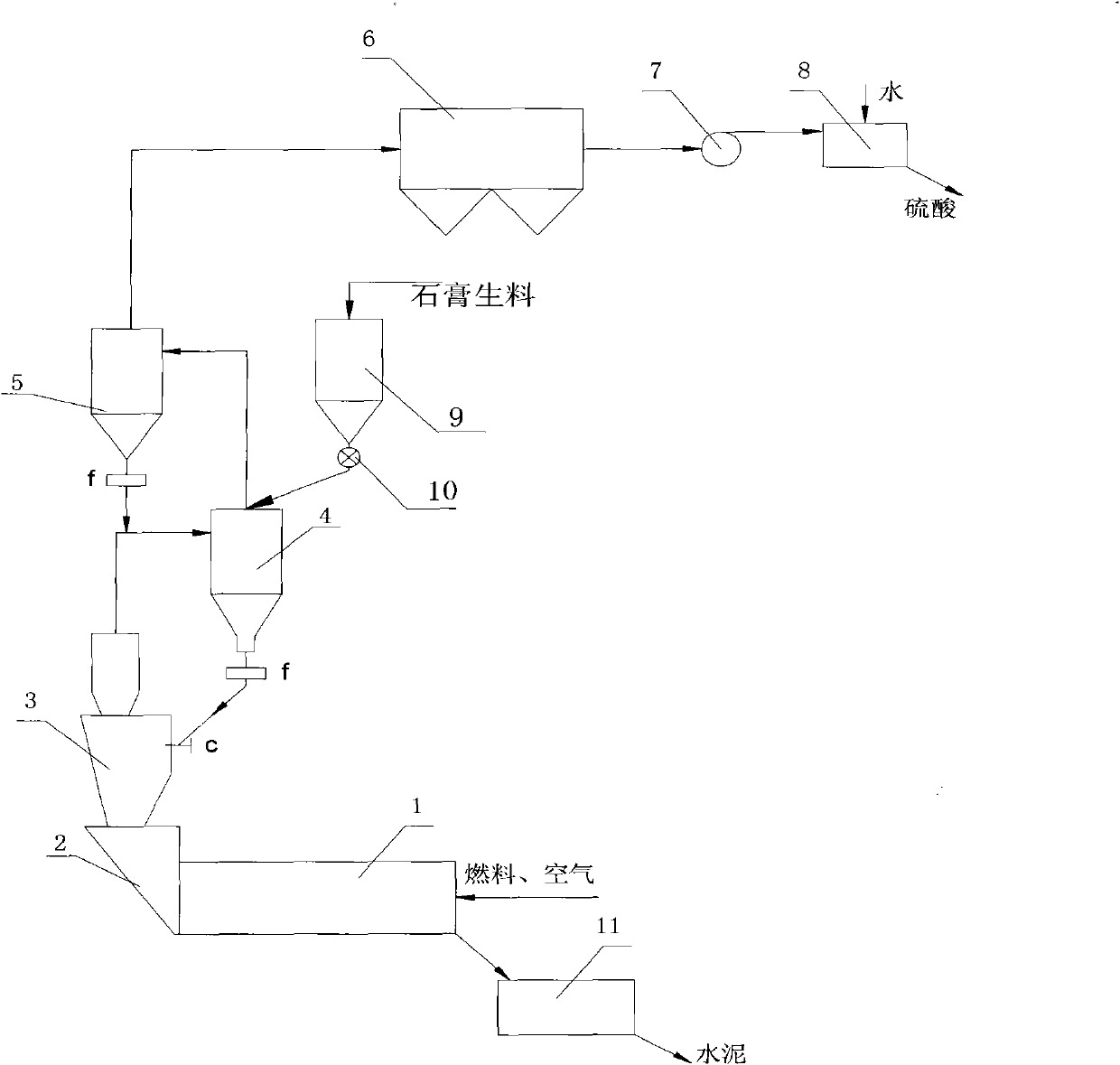

[0028] Example 2. If figure 2 device shown

[0029] Such as figure 2 Shown: The difference between this embodiment and Embodiment 1 is only that: the second cyclone preheater 5 with the same structure as the first cyclone preheater 4 is added, wherein the upper end opening of the second cyclone preheater 5 passes through the pipeline and dust removal 6 welds, the lower end opening is welded with the composite preheater 3 upper end opening through the pipeline, the pipeline is provided with an air lock valve f, and the second cyclone preheater 5 side opening is welded with the first cyclone preheater 4 upper end opening through the pipeline.

[0030] Such as figure 2 Structural manufacture of the device shown: roll and weld the outer shells of partial cone chamber b and spray chamber a with ordinary steel plates. One side of the partial cone chamber b is conical, the upper part of the other side is cylindrical and the lower part is conical, with an opening at the upper an...

Embodiment 3

[0031] Embodiment 3. adopt the device described in embodiment 1

[0032] Use desulfurized gypsum as raw material: store the gypsum raw meal with a moisture content of 0-15% in the storage hopper 9, meter it into the inlet of the first cyclone preheater 4 through the screw feeder 10, and spray it out of the composite preheater 3 The hot flue gas from the evacuation chamber enters the first cyclone preheater 4 together in a suspended state, and the temperature of the preheated and separated material reaches 230-360°C, and then enters the compound preheater 3 through the lower part of the first cyclone preheater 4 and enters the material spreading valve Enter the composite preheater 3, and exchange heat with the 800-1000°C hot flue gas from the calciner 1, and suspend heat exchange. The residence time is 2-5 seconds, reaching 600-800°C, and there is 0-20% raw meal break down. The preheated raw meal enters the calciner 1 through the smoke chamber 2 and continues to be decomposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com