Anti-wear bearing retainer

A technology for bearing cages and cages, which is applied to the rigid brackets of bearing components, bearing elements, shafts and bearings, etc., can solve the problems of high manufacturing cost of copper cages and reduced lubricating performance of lubricating media, and achieve good internal toughness, High surface strength and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

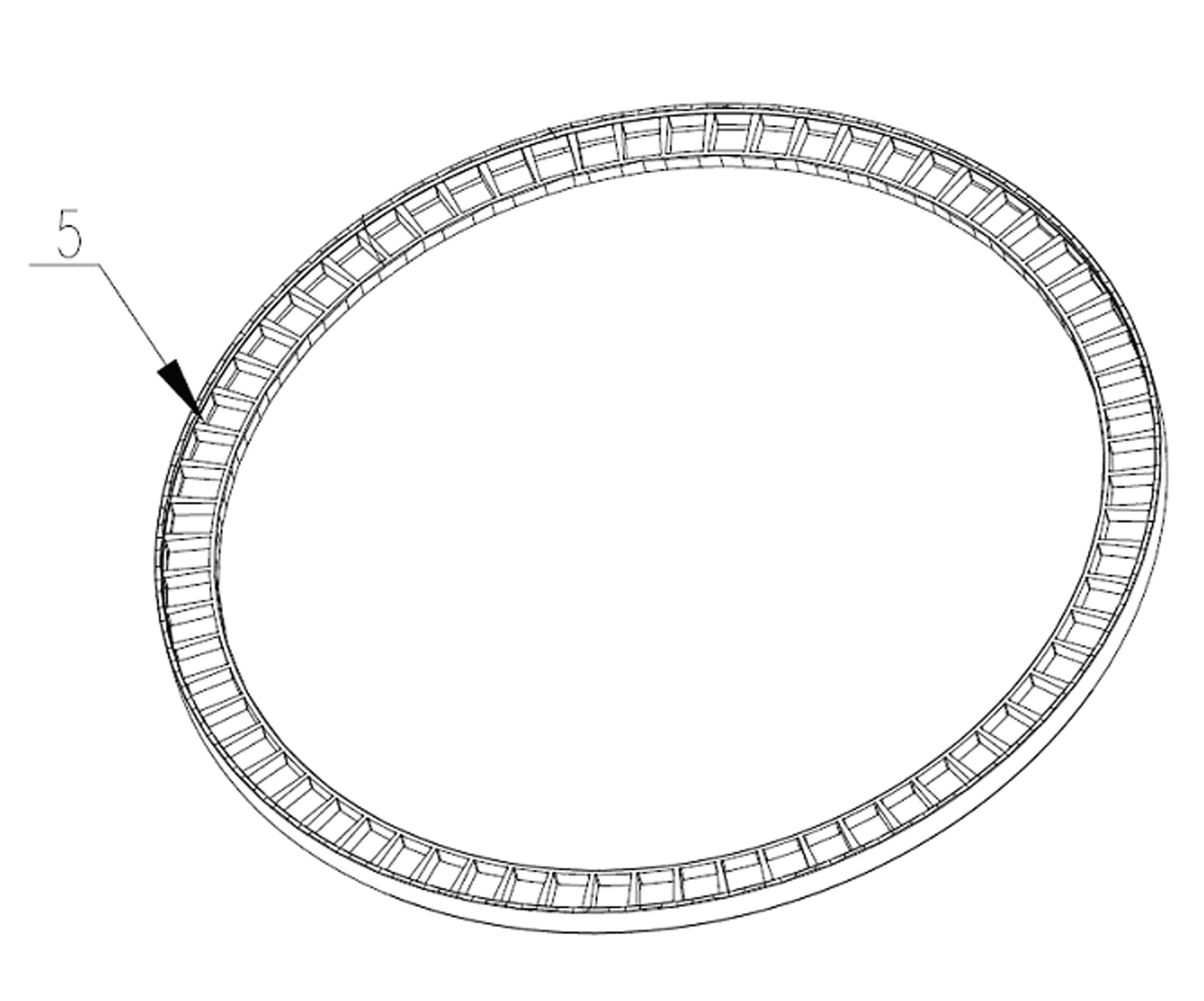

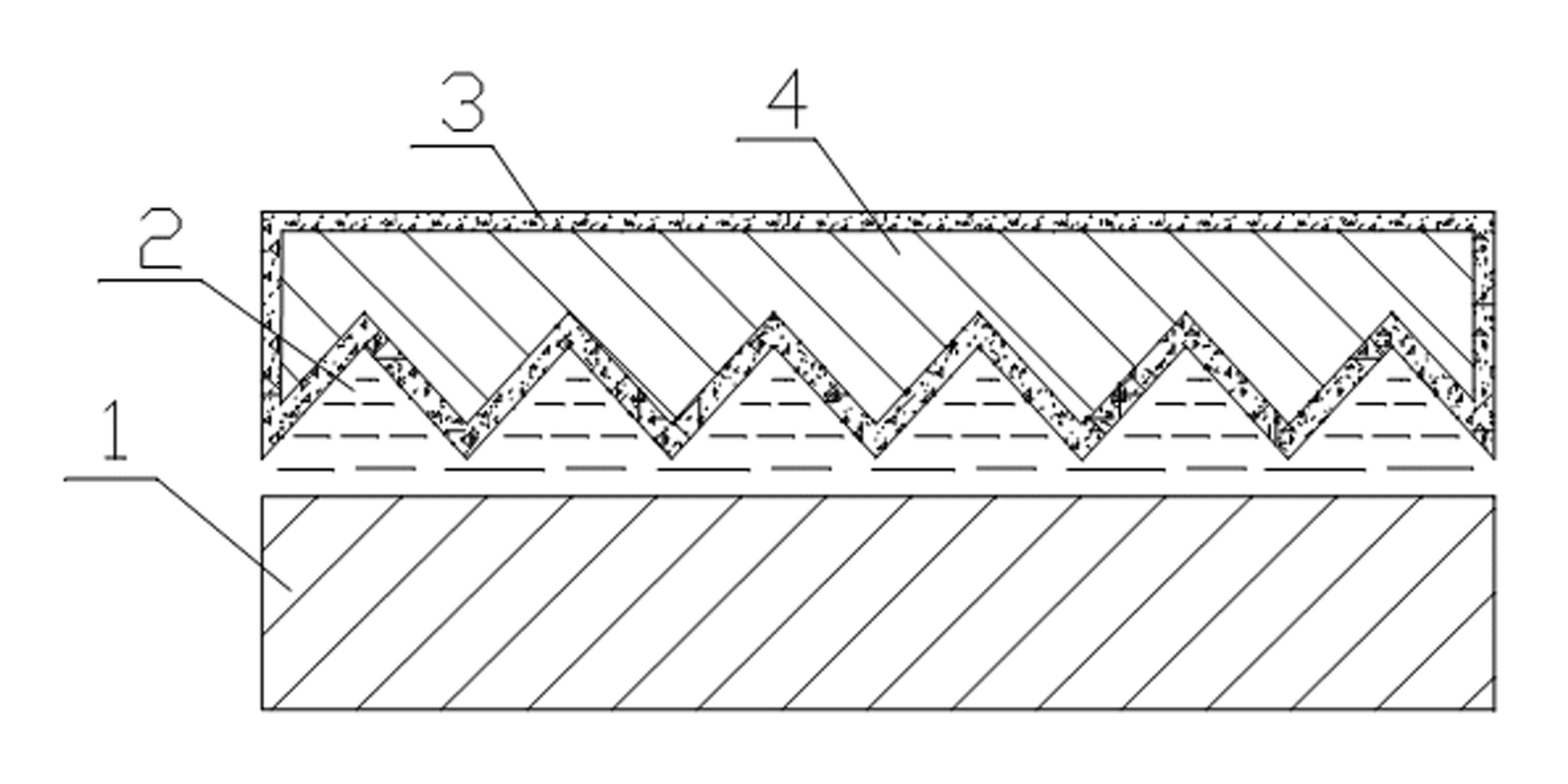

[0011] Referring to the drawings, this embodiment includes a cage body 5, the cage body 5 includes an alloy steel substrate 4, the alloy steel substrate 4 is provided with a groove 2, and the surface of the alloy steel substrate 4 and the surface of the groove 2 are sprayed with a layer Ceramic coating3.

[0012] The thickness of the ceramic coating 3 is 120 μm.

[0013] When the bearing 1 is in operation, due to the function of the groove 2, it is beneficial to avoid surface-to-surface contact between the cage 5 and the bearing 1. With the injection of the lubricating medium, it is conducive to the contact between the cage 5 and the bearing 1. Forming an oil film, and because the friction coefficient of the ceramic coating 3 is small, it is beneficial to reduce the friction between the cage 5 and the lubricating medium, does not affect the lubricating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap