Transformer insulation state on-line monitoring device

A monitoring device and insulation state technology, which is applied in the field of electric equipment insulation on-line monitoring device, can solve problems such as inability to completely eliminate accidents, long test time, power loss, etc., and achieve the effect of automatic management, simple software operation, and powerful data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

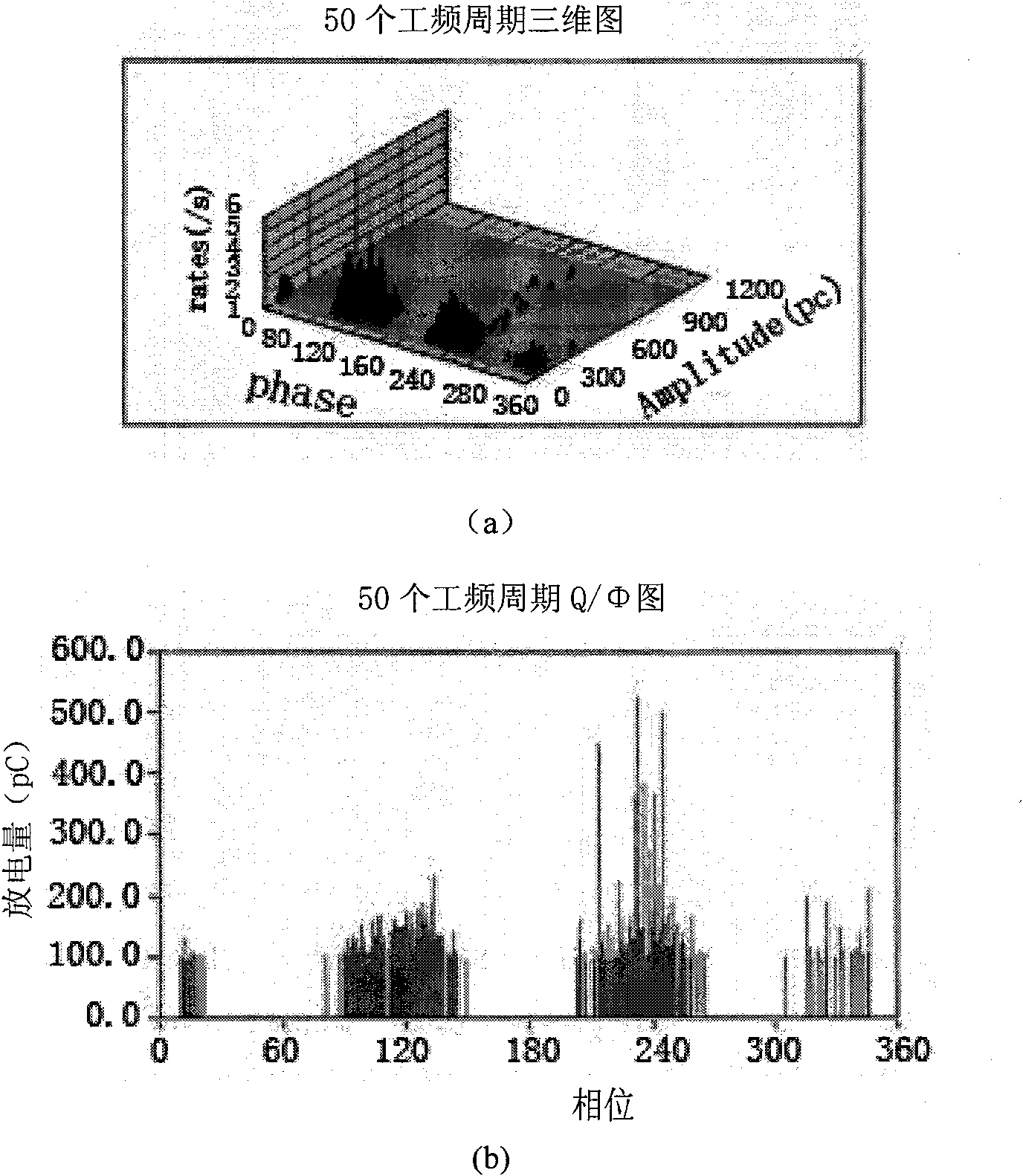

Image

Examples

Embodiment Construction

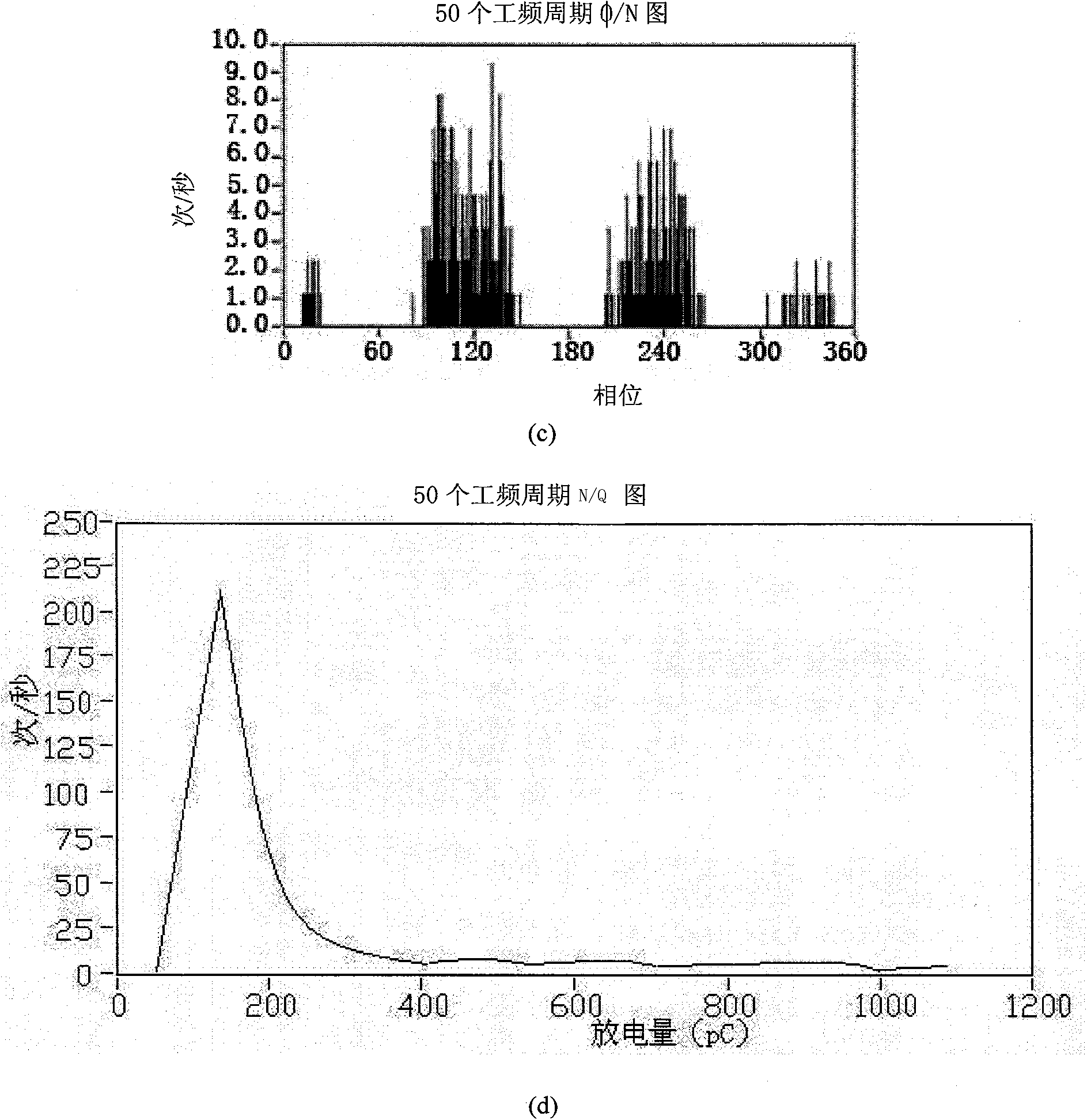

[0024] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] refer to figure 1 , a transformer insulation state on-line monitoring device, comprising an industrial computer 17, the PCI slot of the industrial computer 17 is provided with a data acquisition card 15 and a digital I / O card 16, and the digital I / O card 16 has three digital input and output ports , each port is composed of 8-bit digital quantity, the power signal control interface between the digital I / O card 16 and the power management unit 11, the signal channel control interface of the signal conditioning unit 13, the magnification control interface of the amplifier unit 14 and the dielectric loss iron The channel control interface of the core measurement unit 12 is connected through a data line, and the power output interface and control output interface of the signal conditioning unit 13 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com