Bevel stacked triangular iron core structure

A triangular iron and triangle technology, applied in the direction of transformer/inductor core, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of large no-load current, low core efficiency and high machining accuracy, and achieve no-load current. and no-load loss reduction, cost saving, less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

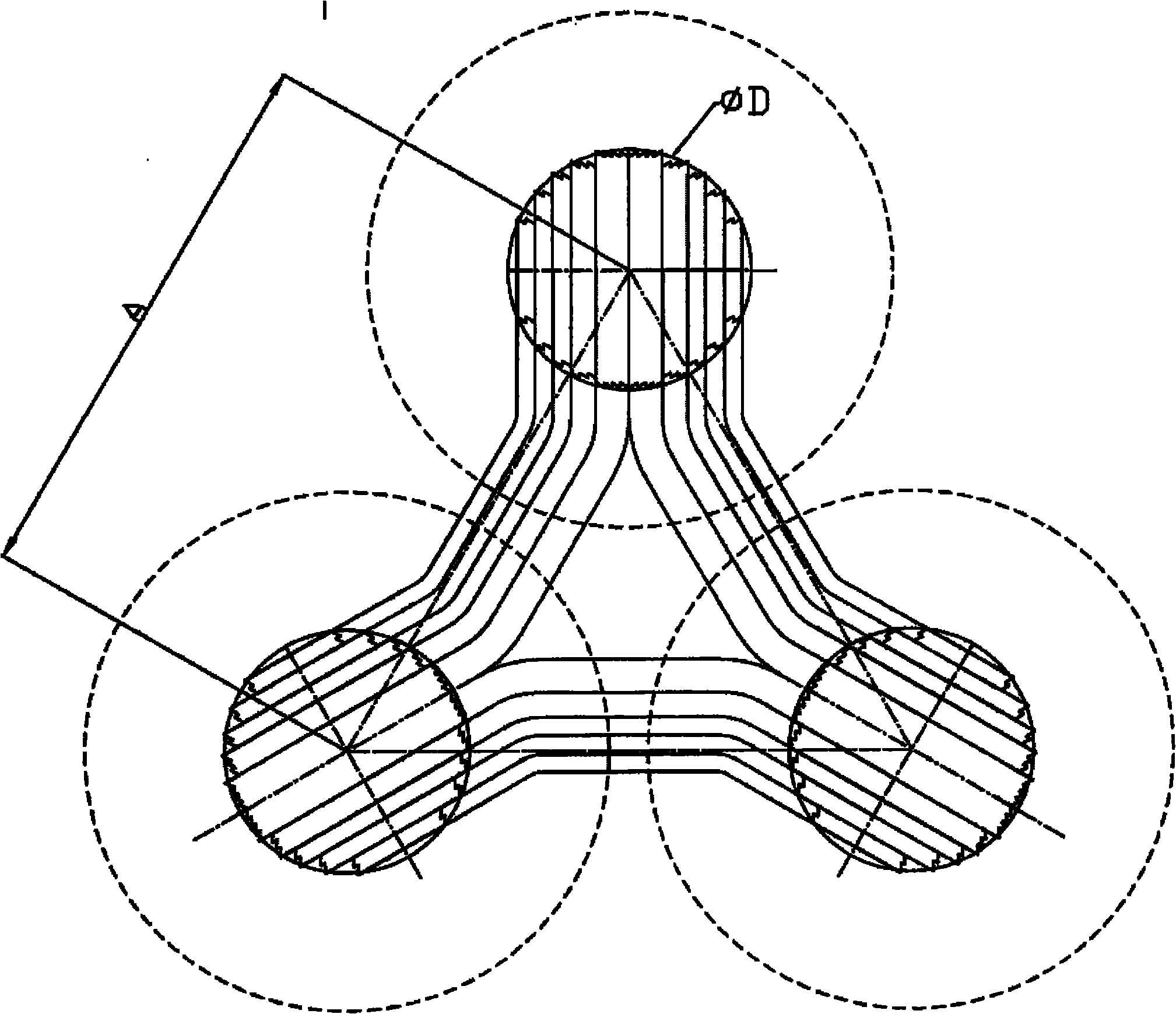

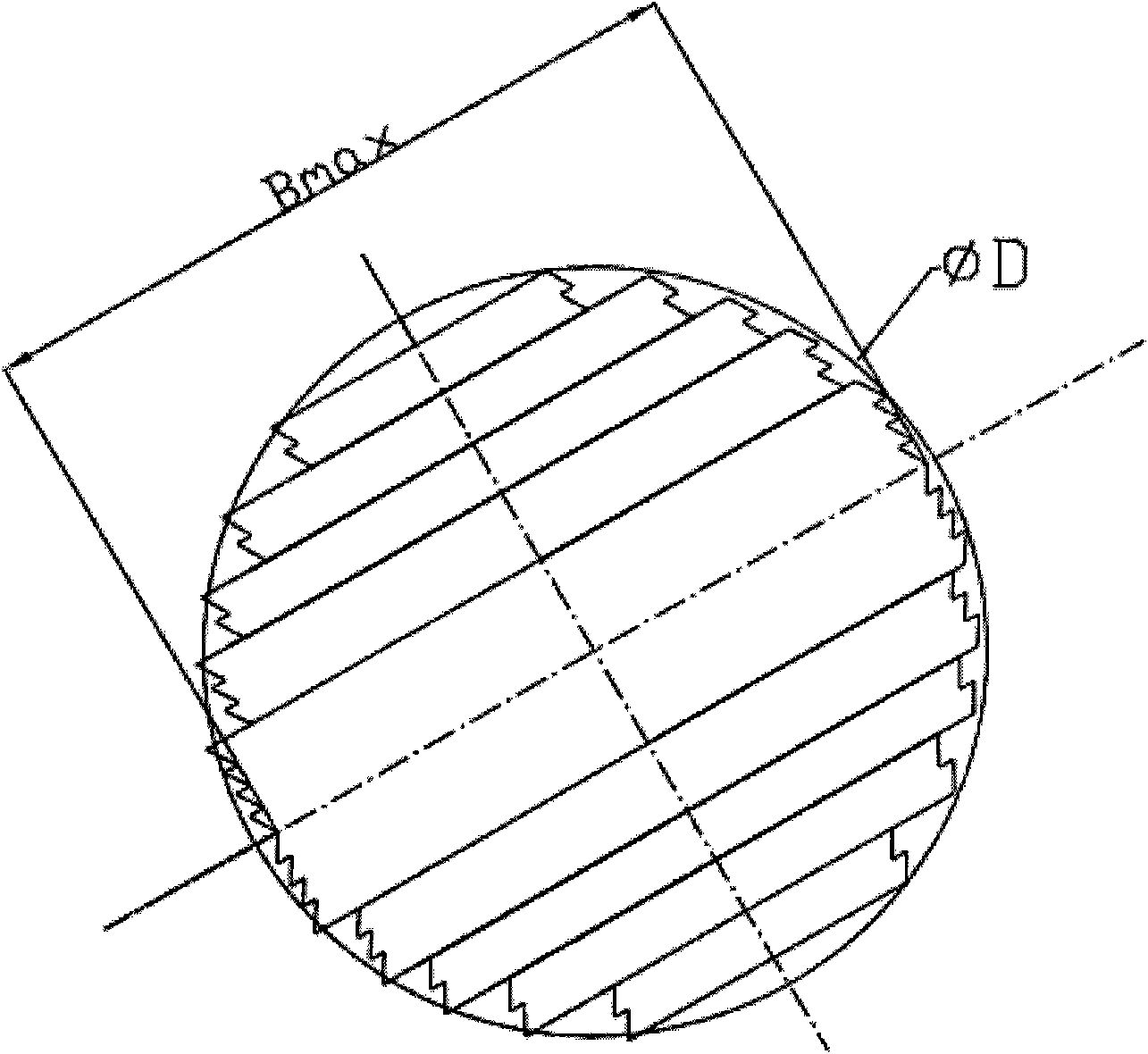

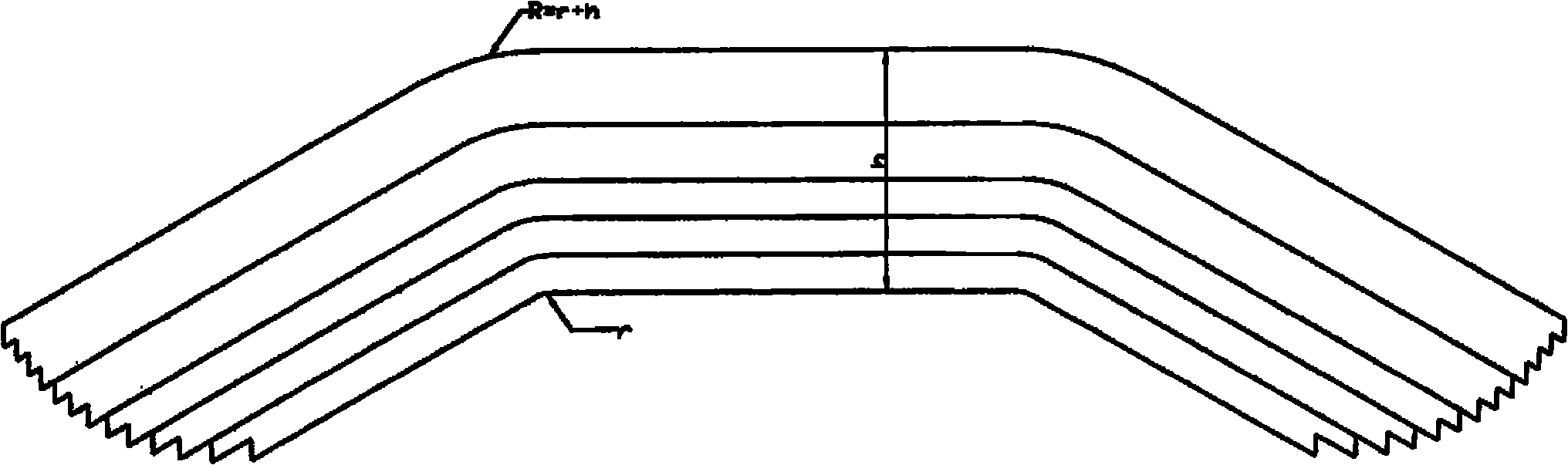

[0009] Firstly, according to the calculation method of planar three-phase transformer or reactor core, calculate the cross-sectional area (D) of the iron core column (D), the window height and the width of the multi-stage iron core to make the stacked triangular iron core structure transformer or reactor . The three-phase iron core is composed of three iron core columns with approximately circular cross-section shapes and six upper and lower yokes with approximately semicircular cross-sectional shapes and two ends folded into obtuse angles. The cross-sectional area of each yoke is equal to the cross-sectional area of the column half of. The slice length of each yoke piece is composed of the length of the arc and the length of the straight line. The length of the arc is calculated according to the radius of the mold arc (r) and the thickness of the laminations (h) at each level. The length of the straight line is calculated by the distance between phases (A) and Slice widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com