Super-high pressure mercury lamp for projector with high light utilization rate

A projector, ultra-high voltage technology, applied in the direction of optics, instruments, gas discharge lamp parts, etc., can solve the problem that the cathode spot is not located on the parabolic reflector or elliptical reflector, the light utilization rate is low, and the liquid crystal panel of the projector is limited. issues such as the process of miniaturization, to achieve the effects of increasing light utilization, meeting miniaturization, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

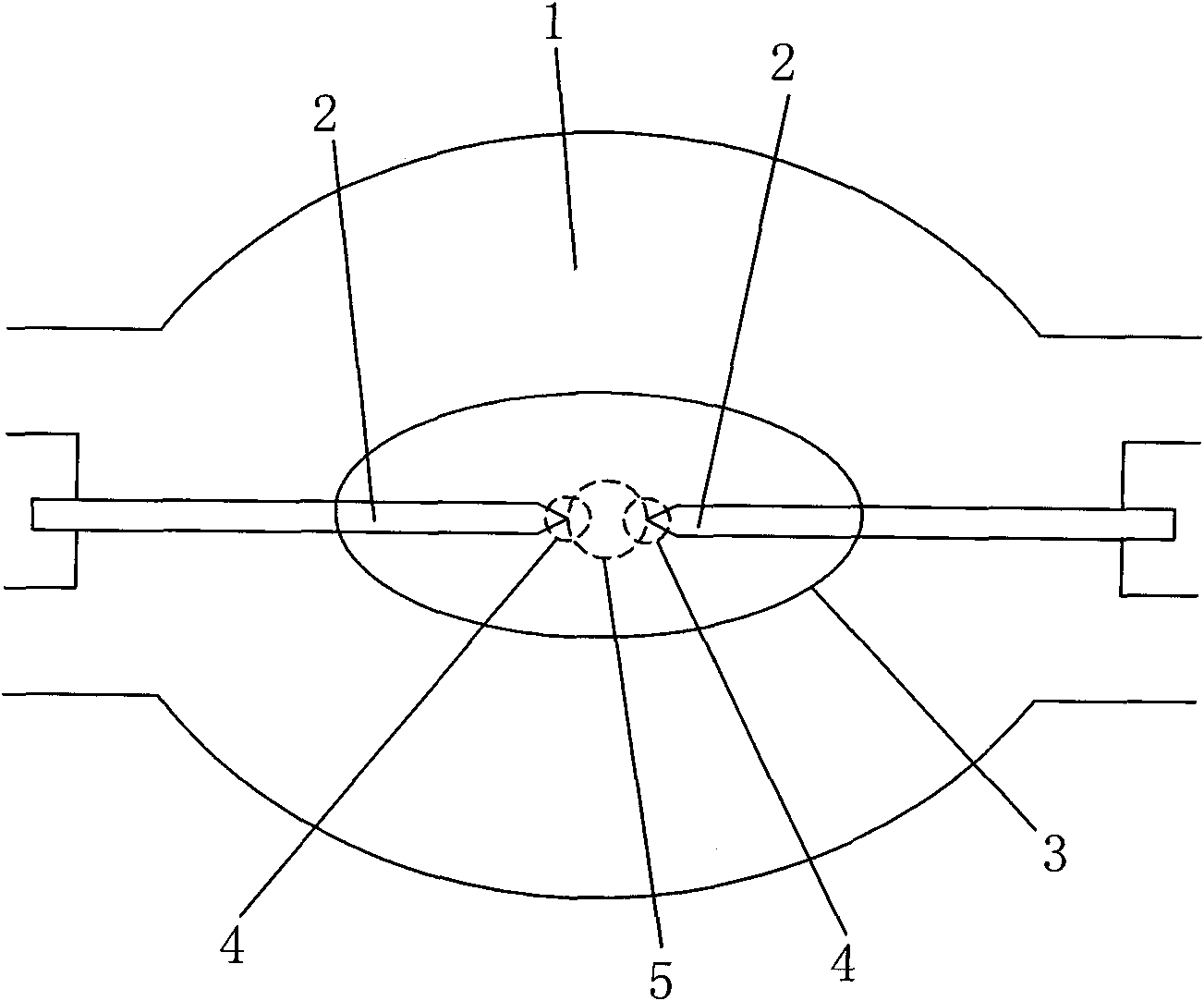

[0011] figure 1 It is shown that an ultra-high pressure mercury lamp for projectors with high light utilization efficiency in this example includes an arc tube 1 and two electrodes 2 arranged in a discharge space 3 of the arc tube 1 and placed opposite to each other. The distance between the two electrodes 2 is the distance at which the arc center 5 and the cathode spot 4 intersect or overlap when the discharge emits light.

[0012] figure 1 It is also shown that the ultra-high pressure mercury lamp of this example is an AC ultra-high pressure mercury lamp, the two electrodes 2 of the AC ultra-high pressure mercury lamp are the same, and there are two cathode spots 4, that is, the extreme tips of the two electrodes 2 take turns to withstand the ultra-high pressure. The bombardment of high-voltage electrons forms respective high-brightness spots near the ends of the two electrodes 2 .

[0013] The distance between the two electrodes of the existing AC ultra-high pressure merc...

Embodiment 2

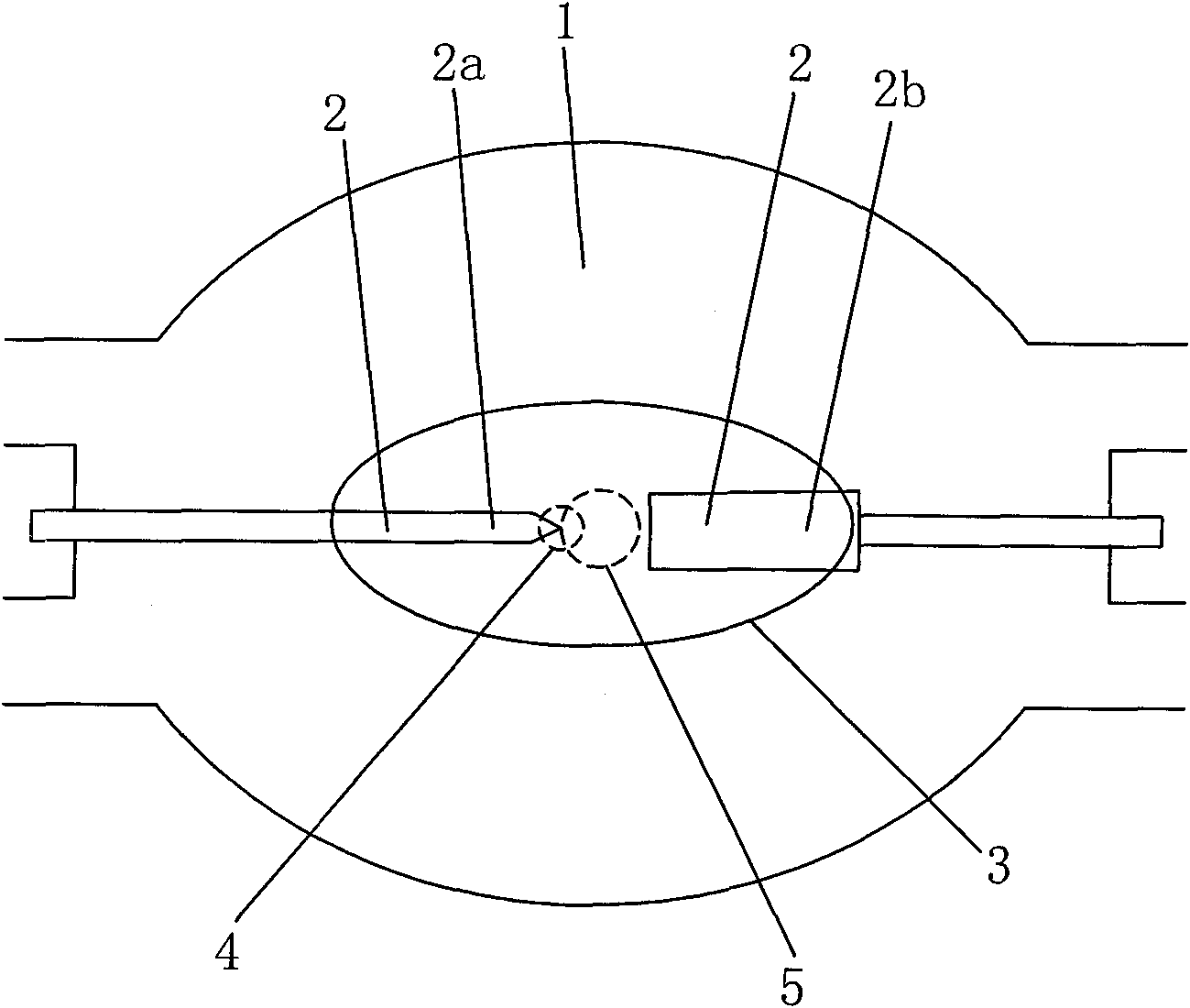

[0015] figure 2 It is shown that a specific embodiment of the present invention is: an ultra-high pressure mercury lamp for projectors with high light utilization rate, comprising an arc tube 1 and two electrodes 2 arranged oppositely in a discharge space 3 of the arc tube 1 . The distance between the two electrodes 2 is the distance at which the arc center 5 and the cathode spot 4 intersect or overlap when the discharge emits light.

[0016] figure 2 It is also shown that the ultra-high pressure mercury lamp in this example is a DC ultra-high pressure mercury lamp, and one of the two electrodes 2 is a cathode 2 a and the other is an anode 2 b. There is only one cathode spot 4 , which is bombarded by ultra-high voltage electrons at the very tip of the cathode 2 a in the electrode 2 , and a high-brightness spot is formed near the end of the cathode 2 a .

[0017] The distance between the two electrodes 2 (cathode 2a and anode 2b) of the existing DC ultra-high pressure merc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com