Heteromorphic high-rate polymer lithium ion battery

A technology for lithium-ion batteries and lithium-ion battery packs, applied in secondary batteries, battery pack parts, non-aqueous electrolyte storage batteries, etc. Limitation, uniformity decline and other issues, to achieve the effect of heat dissipation, increase the sealing temperature, and improve battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

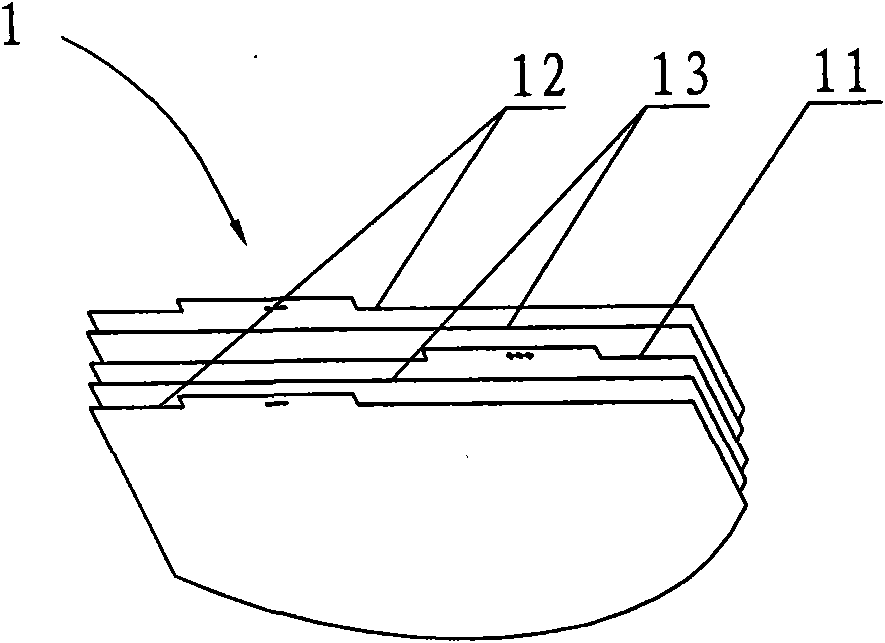

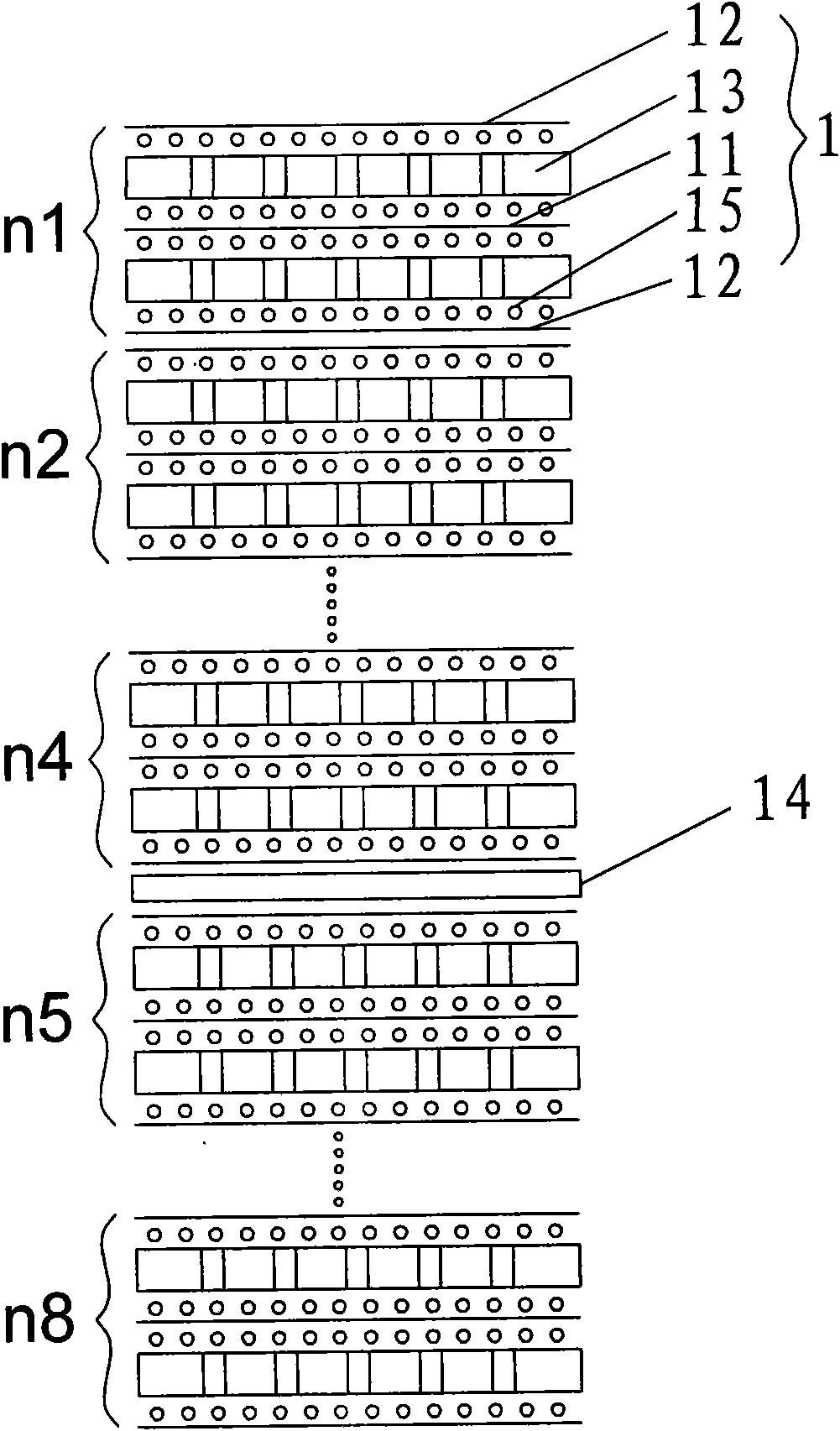

[0041] The battery sheet 1 in the present invention includes a positive electrode film 211 and two negative electrode films 12, the positive electrode film 11 is located in the middle, and a negative electrode film 12 is stacked on each side, as figure 2 , image 3 shown. The positive and negative membranes are separated by a porous ceramic diaphragm 13, and under the condition of thermal polymerization and curing of the high-temperature electrolyte 15, a battery sheet 1 is formed, which is generally called a bare battery in the industry.

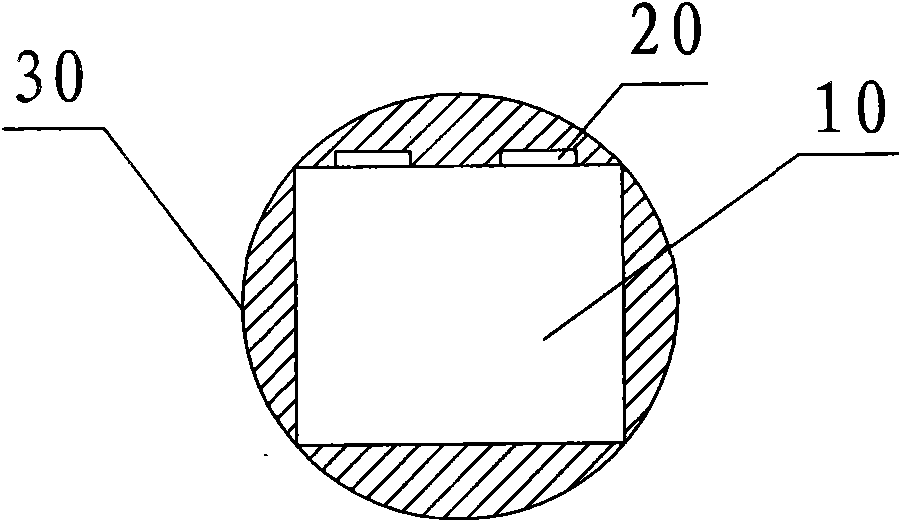

[0042] Take 8 pieces of battery sheet 1, overlap and stack them together, and heat seal the aluminum-plastic film synthesized by multi-layer composite materials to form battery 2, such as image 3 , Figure 4 shown. In this embodiment, one-half of the total number of battery sheets 1 , that is, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com