Fresh eucalyptus log barking machine

A debarking machine and wood technology, which is applied to wood processing utensils, bark, manufacturing tools, etc., can solve the problems of blockage of the central hole of the cutter head, low peeling efficiency, inconvenient maintenance, etc., and achieves small installed capacity, high peeling efficiency, and process less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

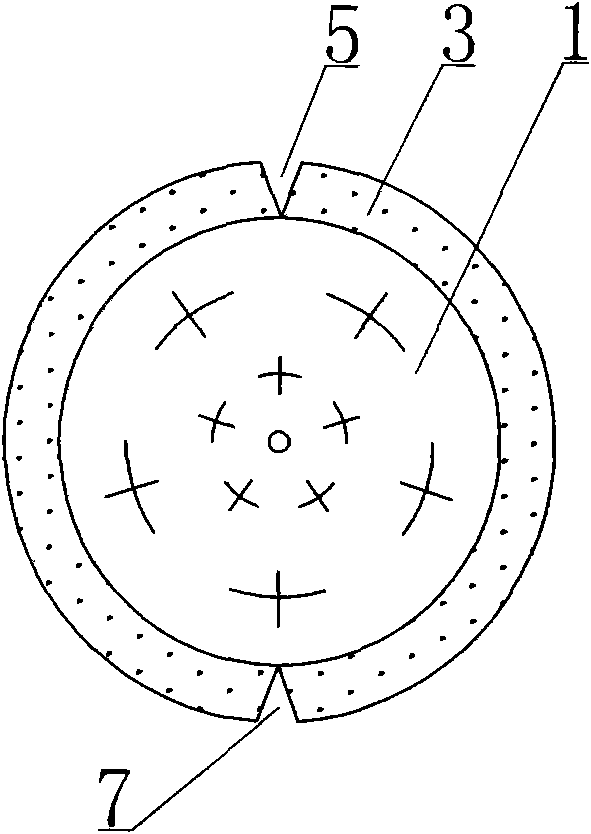

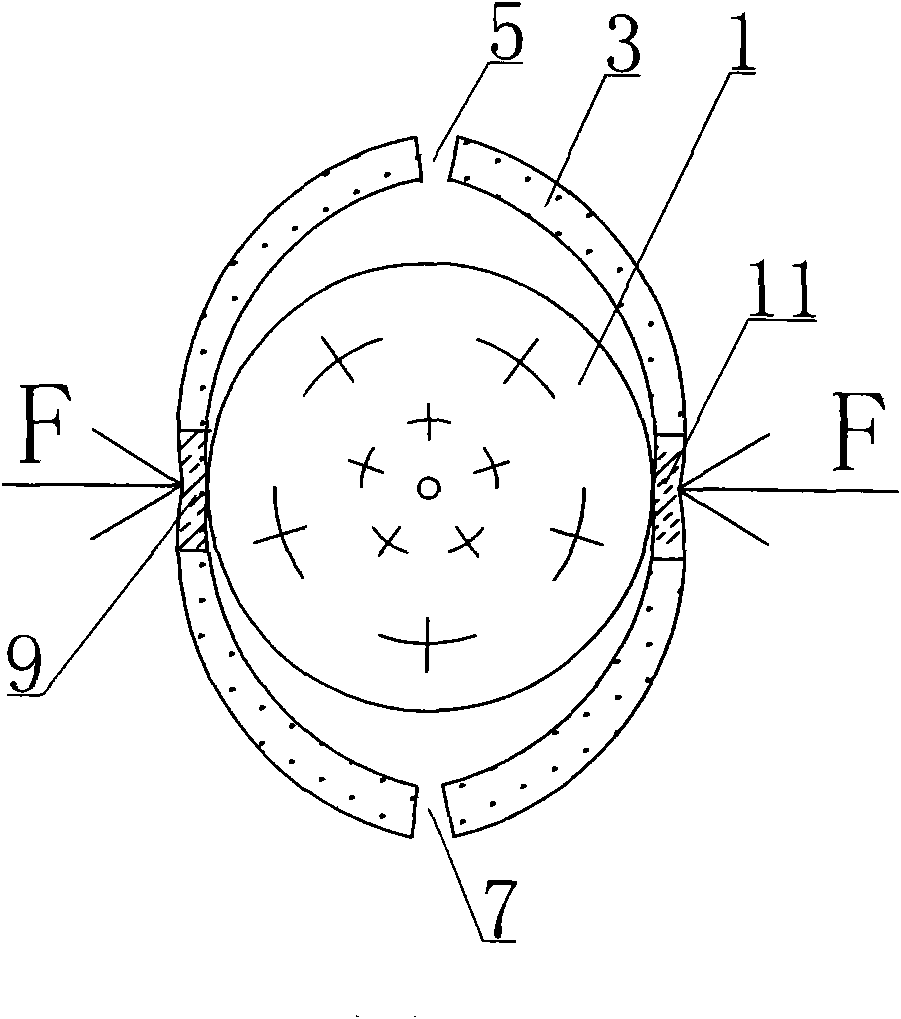

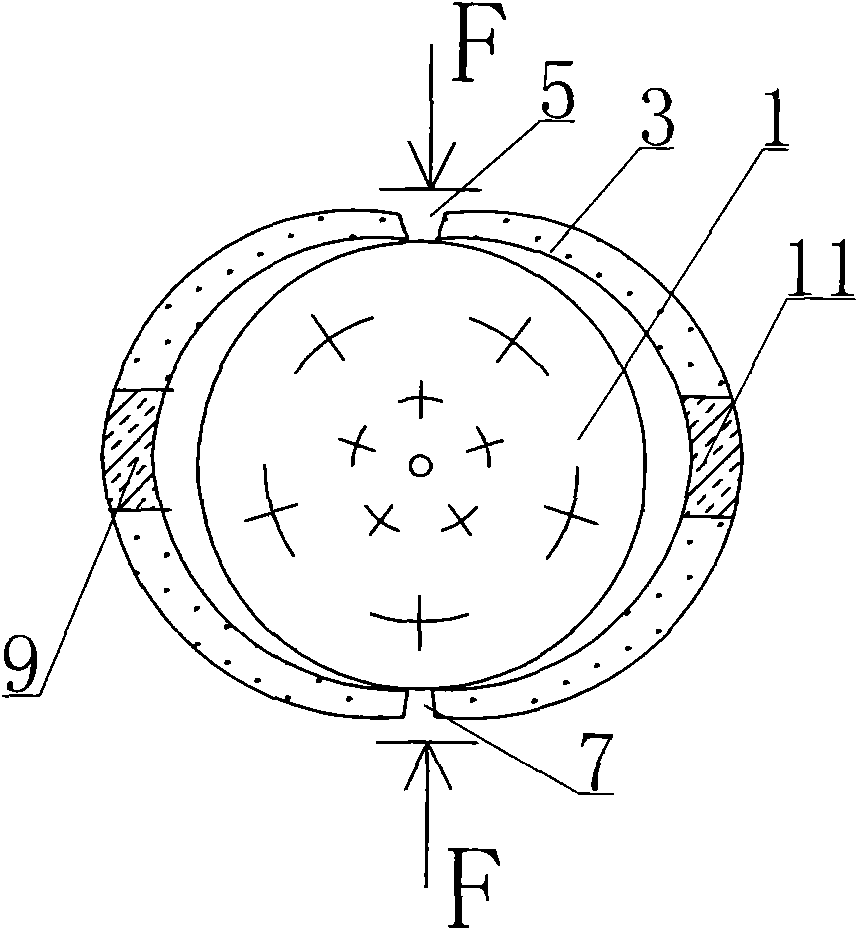

[0033] The present invention is further described below with reference to the accompanying drawings. The fresh eucalyptus segment wood peeling machine of the present invention, the peeling method of its bark is to go through the following three processes successively: first, utilize the hob of the upper input conveying wheel (15) and the hob of the lower input conveying wheel (13) to separate the fresh eucalyptus The bark of eucalyptus wood is split longitudinally up and down, dividing the bark into left and right halves. After being cut by a hob, the upper part of the bark (3) outside the wood (1) of the fresh eucalyptus segment has an upper edge (5), and the lower part has a lower edge (7). The bark is also cut into left and right halves.

[0034] Second, use the left stripe roller (17) and the right stripe roller (25) to exert force on the left half of the intermediate belt (9) and the right half of the intermediate belt (11) from the outside to the inside along the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com